Professional Documents

Culture Documents

Galvacon Gc243 Tds Eng

Uploaded by

SHAIK ASIMUDDINCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Galvacon Gc243 Tds Eng

Uploaded by

SHAIK ASIMUDDINCopyright:

Available Formats

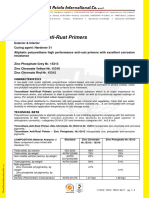

T E C H N I C A L D A T A S H E E T

Galvacon™ GC-243

Cold Galvanizing Compound for Iron and Steel

Description: Uses: Surface Preparation:

GalvaconTM is a ready to apply organic zinc GalvaconTM is widely used to repair or replace All surfaces must be dry, clean, sound and free

compound for cold galvanizing on iron and hot-dip galvanizing. As an extreme duty primer of contaminants. Remove all dirt, grease, chalk,

steel. Is an equivalent to hot-dip galvanizing for abraded or damaged areas on galvanized mildew, oil, rust, dust, and other soluble

containing 97% pure zinc metal for interior and steel. Excellent protection treatment for rust in contaminants from steel surfaces by solvent

exterior. Excellent for treatment of rust; will welded or abraded areas where the protective cleaning or other method.

stop rust expansion on iron and steel metals. galvanizing has been removed from the metal

surface. Also recommended for long-term SSPC-SP1 Solvent Cleaning

protection of structural steel, water and waste Use this method to remove off all visible oil,

facilities, power plants, steel decking and grease, soil, drawing and cutting compounds,

Meets Requirements for: bridges. and other soluble contaminants from steel

MPI: N/A

surfaces with solvent Lanco® Lacquer Thinner

Technical Data: LT-102, vapor cleaning, alkali, emulsifying

Green Performance1: N/A agent, or steam.

Product Type: Alkyd Resin

Green Performance 2: N/A

VOC Compliant (<400g/L): Yes

Finish: Flat (1º - 3º) SSPC-SP3 Power Tool Cleaning

*Geometry 60º

Use this method to remove all loose mill scale,

SCAQMD: N/A Solids (%): 88 ± 2% by weight loose rust, loose paint, and other loose

58 ± 2% by volume

AIM & OTC: N/A detrimental foreign matter by power wire

Weight/Gallon: 24 ± 0.05 lbs. brushing, power sanding, power grinding,

(10.89 ± 0.02 kg.)

power tool chipping, and power tool descaling.

Product Advantages: Colors: Gray

Drying Time: SSPC-SP6 / Commercial Blast Cleaning

• 97% pure zinc metal To touch: 25 - 30 min. Use this method to remove mil scale with

To topcoat: 20 - 24 hrs.

• Equivalent protection to hot-dip galvanizing Coverage: commercial blast cleaning method. Preparing

• Anti-corrosive protection for weldments metal surfaces for coating by the use of

Theorical: Up to 930 ft.2 per

• For direct use on prepared iron and steel gallon @ 1 mil abrasives propelled through nozzles or by

• High performance and lead free base coat centrifugal wheels. It requires the removal of all

Recommended: 400-450 ft.2 /gal.

• Resistant to oxidation 2 visible scale, rust and other surface

(37-41 m /gal.) @

• Impact and abrasion resistant 2.1 dry mils, 3.6 wet mils contaminants. Generally evenly dispersed very

• Fast-drying light shadows, streaks and discoloration

Performance: Sizes: 1 gallon caused by stains of rust, stains of mill scale and

1 quart

stain of previously applied paint may remain on

DOD-P-21035A Yes

Thinning: Lacquer Thinner LT-102 no more than 33% of the surface. Slight

Flash Point: 83 0F TOC residues of rust and paint may also be left in the

MIL-P-21035A Yes

craters or pits if the original surface is pitted.

Viscosity: 98 - 102 Ku's

ASTM D 3960 Yes

TT-P-641 G Type I Yes

Percent Pigment SSPC-SP10 Brush-Off Blast Cleaning

by Weight: 80 ± 2%

Use this method to remove old coating

VOC: <320 g/L completely for best performance near white

bast cleaning. Blasted surfaces should be

coated within 8 hours after blasting or before

Notice: The technical data contained herein are rusting or other contamination of the surface

true and accurate to the best of our knowledge. occurs.

Published technical data and instructions are

subject to change without prior notice.

S.D.S.: Available upon request.

www.lancopaints.com continued on back

Page 2 Galvacon™ GC-243 Rev. 06 / 2016

Method of Application:

Clean all surfaces as recommended. Lanco® GalvaconTM GC-243 must be

thoroughly stirred, until pure zinc content is completely dispersed. Apply

Lanco® GalvaconTM GC-243 to clean and dry metal surfaces.

Brush: Use a good quality nylon or polyester brush.

Roller: Use a Lanco® All-Purpose 1/4” Nap Enamel Roller PA-565.

Conventional spray: Reduce Lanco® GalvaconTM GC-243 at a ratio of four

parts Lanco® GalvaconTM GC-243 to one part of Lanco® Lacquer Thinner

LT-102. For pressure feed, use DeVilbiss MBC gun with E-tip and needle

and 704 air cap or equivalent at 40-45psi atomizing pressure, 3/8” ID

material hose, double regulated pressure tank with oil and moisture

separator. Special packing may be necessary due to the abrasive nature of

the zinc dust in this product.

Airless Spray: No reduction required when spraying. Minimum of 28:1 ratio

pump, .013”-.015” tip, 1/4” ID Teflon material hose.

Dipping: Because of individual requirements, call the lab at Lanco® Mfg.

Corporation for instructions.

Note: During lunch, breaks or any period of work stoppage, material should

be removed from hoses. Release pressure from equipment and flush hoses

and equipment with Lanco® Lacquer Thinner LT-102.

Drying Time: Lanco® GalvaconTM GC-243 dries fast (set to touch in 25

minutes). Allow 24 hours before applying topcoat.

Disposal: Keep container closed when not in use. In case of spilling, absorb

with inert material and dispose of in accordance with applicable local, state

and federal regulations.

Precaution: Keep away from heat, sparks, and open flame. Vapor is heavier

than air. Prevent build-up of vapor — open windows and doors. Use only in

cross-ventilated areas. Extinguish all flames and pilot lights, and turn off

stoves, heaters, and/or electric motors, and eliminate all other sources of

ignition during use and until all vapor is gone. Keep container closed when

not in use.

Danger: Use only with adequate ventilation. Avoid prolonged or repeated

breathing of vapor. Do not take internally. Swallowing may cause injury,

illness or death. Avoid prolonged or repeated contact with skin. Do not allow

contact with eyes or product to in eyes. Do not eat, drink or smoke in work

areas.

• NORTH AMERICA • 600 Mid Florida Drive Airport Industrial Park of Orlando, Florida 32824 • Tel. (407) 240-4000 Fax (407) 240-4046

• CARIBBEAN & SOUTH AMERICA • Urb. Aponte #5, San Lorenzo, Puerto Rico USA 00754 • Tel. (787) 736-4221 Fax (787) 736-5313

• CENTRAL AMERICA • Zona Industrial Bes, lote #4, El Coyol de Alajuela, Costa Rica • Tel. (506) 2438-2257 Fax (506) 2438-2162

You might also like

- Galvacon Gc243 Tds EngDocument2 pagesGalvacon Gc243 Tds EngShaik Asim UddinNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- GalvaconDocument2 pagesGalvaconechavarriNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Zinc Dust Primer P296 V1.4Document3 pagesZinc Dust Primer P296 V1.4Yango JukopilaNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- TDS RovalDocument4 pagesTDS RovalSyahril Fira86No ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- NSF 61 PaintDocument2 pagesNSF 61 Paintraviraj londheNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Catalyzed Epoxy: Tile-Clad HSDocument2 pagesCatalyzed Epoxy: Tile-Clad HSAnn HewsonNo ratings yet

- Carboguard 893 SG: Selection & Specification DataDocument5 pagesCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNo ratings yet

- Bipigard ST Cte BlackDocument3 pagesBipigard ST Cte BlackKhirod KroutNo ratings yet

- Carbothane 8832: Selection & Specification DataDocument4 pagesCarbothane 8832: Selection & Specification Dataluisbarrios104No ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Polane T, Polyurethane Enamel ADocument2 pagesPolane T, Polyurethane Enamel A김도균No ratings yet

- Painting HintDocument19 pagesPainting HintSenthil KumaranNo ratings yet

- Phenoline 187 Chemical Resistant Tank LiningDocument5 pagesPhenoline 187 Chemical Resistant Tank LiningQuy RomNo ratings yet

- Bipigard ST Cte Black PDFDocument2 pagesBipigard ST Cte Black PDFKhirod KroutNo ratings yet

- Grease NO. 0, 1, 2, 3 & MP: DescriptionDocument1 pageGrease NO. 0, 1, 2, 3 & MP: DescriptionKian GonzagaNo ratings yet

- Prime Coat Primer WP038 TDS ENGDocument2 pagesPrime Coat Primer WP038 TDS ENGVladimir DovalNo ratings yet

- Carbozinc 11 HS PDSDocument2 pagesCarbozinc 11 HS PDSvietrossNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- dupont-dryfilm-photoresistDocument8 pagesdupont-dryfilm-photoresistsaandeep arduinoNo ratings yet

- Ultra Cote 101 PrimerDocument3 pagesUltra Cote 101 PrimerGilbert Dela Serna IINo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Product Data: Carboguard 190 HDocument2 pagesProduct Data: Carboguard 190 HClarkFedele27100% (1)

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification DataDuongthithuydungNo ratings yet

- Carboguard 893 SG PDSDocument2 pagesCarboguard 893 SG PDSAhmed ElbahrawyNo ratings yet

- Phenoline 187 Finish PDSDocument5 pagesPhenoline 187 Finish PDSQuy RomNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSKhemaraj Path100% (1)

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Cutting Oil for Non-Ferrous Metals and Carbon SteelsDocument1 pageCutting Oil for Non-Ferrous Metals and Carbon SteelsahmetNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Royalthane 450HSDocument2 pagesRoyalthane 450HSSyed FaridNo ratings yet

- BECKOPOX EM 2120w - Allnex - Bilingual 27 FebDocument15 pagesBECKOPOX EM 2120w - Allnex - Bilingual 27 FebDhruv Sevak100% (1)

- Tinorethane Anti-Rust PrimersDocument4 pagesTinorethane Anti-Rust PrimersAbed samadsureyft7vewyrNo ratings yet

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- IONYX T2AMicrobial Data SheetDocument5 pagesIONYX T2AMicrobial Data SheetCristian Alejandro Cardenas VillegasNo ratings yet

- Technical Data Sheet for Epoxy CoatingDocument5 pagesTechnical Data Sheet for Epoxy CoatingQuy DomNo ratings yet

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27No ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDocument4 pagesQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayNo ratings yet

- Plasite 4100 PDS-3Document5 pagesPlasite 4100 PDS-3Linnie McleodNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- DEC Riston EM213 DataSheetDocument7 pagesDEC Riston EM213 DataSheetks_spyroNo ratings yet

- Bar-Rust 231LV Surface Tolerant EpoxyDocument4 pagesBar-Rust 231LV Surface Tolerant EpoxyAhmed IbrahimNo ratings yet

- Phenoline 187 FinishDocument5 pagesPhenoline 187 FinishDuongthithuydungNo ratings yet

- RZ 5215 1Document2 pagesRZ 5215 1amirhosseinNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- Aramco Painting Q ADocument31 pagesAramco Painting Q Aravi ajith88% (16)

- Best Practices For Preparing Concrete Surfaces Prior To Repairs and OverlaysDocument92 pagesBest Practices For Preparing Concrete Surfaces Prior To Repairs and Overlayschancer2100% (1)

- Vetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedDocument2 pagesVetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedSHAIK ASIMUDDINNo ratings yet

- Bitumastic 300 M PDSDocument4 pagesBitumastic 300 M PDSBilal GhazanfarNo ratings yet

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Pyrocrete column design detailsDocument2 pagesPyrocrete column design detailsSHAIK ASIMUDDINNo ratings yet

- Visio-Overall Drawing with Description 출판품질Document1 pageVisio-Overall Drawing with Description 출판품질SHAIK ASIMUDDINNo ratings yet

- Cementitious Floor Levelling CompoundDocument4 pagesCementitious Floor Levelling CompoundSHAIK ASIMUDDINNo ratings yet

- Semstone 145: Selection & Specification DataDocument4 pagesSemstone 145: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- TDS Renderoc LAXtra IndiaDocument2 pagesTDS Renderoc LAXtra IndiaSHAIK ASIMUDDINNo ratings yet

- January February March AprilDocument1 pageJanuary February March AprilMunirah AliNo ratings yet

- Nitoseal 125: Constructive SolutionsDocument2 pagesNitoseal 125: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- MOS For Minor Concrete Repair in APM2-Cooling Tower - MPCDocument37 pagesMOS For Minor Concrete Repair in APM2-Cooling Tower - MPCSHAIK ASIMUDDINNo ratings yet

- Vetoproof CM741 MDS PDFDocument2 pagesVetoproof CM741 MDS PDFSHAIK ASIMUDDINNo ratings yet

- Concure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust ProoferDocument4 pagesConcure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust Prooferraja qammarNo ratings yet

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocument4 pagesFosroc Nitobond EP - Epoxy bonding agent for concreteganmosesNo ratings yet

- Galvashield CCDocument3 pagesGalvashield CCtalatzahoorNo ratings yet

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- ASTM C 309 Curing CompoundDocument3 pagesASTM C 309 Curing CompoundAlbert Ghobrial0% (1)

- Nitocote HT120: Constructive SolutionsDocument3 pagesNitocote HT120: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Vetocure Doc Technical Map en 3457Document2 pagesVetocure Doc Technical Map en 3457SHAIK ASIMUDDINNo ratings yet

- TDS Nitoprime 31 Saudi ArabiaDocument2 pagesTDS Nitoprime 31 Saudi ArabiaSHAIK ASIMUDDINNo ratings yet

- TDS Fosroc Nitoseal PS200 Saudi ArabiaDocument4 pagesTDS Fosroc Nitoseal PS200 Saudi ArabiaSHAIK ASIMUDDINNo ratings yet

- High-strength heat resistant cement groutDocument4 pagesHigh-strength heat resistant cement groutSHAIK ASIMUDDINNo ratings yet

- Fosroc Reebol: Constructive SolutionsDocument2 pagesFosroc Reebol: Constructive SolutionsVincent JavateNo ratings yet

- Tds Thioflex 600 Saudi ArabiaDocument5 pagesTds Thioflex 600 Saudi ArabiaSHAIK ASIMUDDINNo ratings yet

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocument4 pagesFosroc Nitobond EP - Epoxy bonding agent for concreteganmosesNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Conbextra HT: Constructive SolutionsDocument3 pagesConbextra HT: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- High-strength heat resistant cement groutDocument4 pagesHigh-strength heat resistant cement groutSHAIK ASIMUDDINNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- How to Write Construction Programmes & SchedulesFrom EverandHow to Write Construction Programmes & SchedulesRating: 4 out of 5 stars4/5 (9)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)