Professional Documents

Culture Documents

Dupont Dryfilm Photoresist

Uploaded by

saandeep arduinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dupont Dryfilm Photoresist

Uploaded by

saandeep arduinoCopyright:

Available Formats

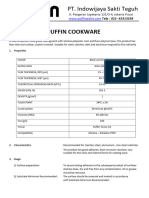

DuPont™ Riston® 200 Series

DATA SHEET & PROCESSING INFORMATION

Product Description

(Physical Parameters)

• Negative working, aqueous processable dry film photoresist

• Suitable for pattern plate applications on scrubbed and

unscrubbed electroless copper and most Direct Plate surfaces.

• Suitable for print and etch application with acid or alkaline

etching.

• Suitable for some gold plating applications.

• Suitable for some photochemical machining (chemical milling)

application.

• Suitable for tent-and-etch applications.

Available Thickness: 38 microns (1.5 mil)

50 microns (2.0 mil)

Unexposed Color in Yellow Light: Green

Exposed Color in Yellow Light: Dark Green

Exposed Color in White Light: Blue

Print-Out (Phototropic) Image: Strong

Contrast to Copper: Strong

Odor: Low

DS95-17 Rev. 6.0 (07/07) 1

PART 1: Copper Surfaces and Surface Preparation Jet Pumice:

3F or 4F grade, unfused, 15-20 % v/v, fines removal and

Electroless Copper Surfaces replenishment per vendor recommendations; high pressure 10

Post-Electroless Rinsing/ Drying bar (147 PSI) final rinse (pH 6-8); hot air dry.

Jet or Brush Aluminum Oxide (Al2O3):

• Drag-out rinse: 1 minute; stagnant, to remove

most of the copper solution.

• Counterflow rinse: 2 tanks, 2 minutes each, air Follow vendor recommendations.

sparged.

• Heated (stagnant) rinse: 3 minutes; 50-65°C (120-150°F) Compressed Pad Brushing:

for removal of residual electro-

500 grit; 7-9 mm (1/4- 3/8") brush foot print; high pressure (8-

less.

• Neutralization/ Passivation:5 minutes, 5 vol% sulfuric 10 bar) final rinse (pH 6-8).

acid+ 5 wt% citric acid or Bristle Brushing:

commercial antitarnish.

500 grit; 7-9 mm (1/4-3/8") brush foot print; final rinse: 2-3 bar,

• Counterflow rinse: 2 tanks, 2 minutes each, air

sparged. pH 6-8.

• Deionized water rinse: 1 minute, pH 5-7. Note: Electroplated copper surfaces for tent-and-etch

• Drying: Blow dry (uniform, stain-free

applications are frequently “de-noduled” e.g. by compressed

copper); followed by 5-10

minutes oven drying at 60-65°C pad brushing prior to pumice scrubbing.

(140-150°F) if needed to

completely remove moisture

Control Tests:

from holes.

• Water Break Test: •30 seconds

• Ra: 0.10-0.3 μm

Unscrubbed Electroless Copper

No antitarnish applied Direct Plate (Metallization)

Riston® 200 can be laminated to unscrubbed electroless A variety of Direct Plate processes are in use as alternatives

copper with or without anitarnish. to the formaldehyde based electroless process. Dry film

Minimize prelamination hold time (<4 hours) to avoid oxidation adhesion and/or plating bath compatibility should be confirmed.

and recontamination, with no antitarnish. Some Direct Plate processes are preceded by a microetch to

Regeneration of surface after excessive (>4 hrs.) hold remove activator (catalyst) from copper surfaces. This

times: produces a smooth copper surface especially when more than

1. Hot soak panel for 3 minutes

0.8 μm (30 microinches) are removed.

2. Rinse thoroughly

3. Etch 0.13 μm (5 microinches) of copper

4. Rinse thoroughly Vendor Copper (Print & Etch)

5. Dip in 5-10% sulfuric acid / 5 vol% citric acid

Scrubbed Vendor Copper

Antitarnish Applied See: “Scrubbed Electroless Copper Surface” for scrubbing

The following antitarnishes have been used successfully per step.

manufacturers recommendations: To remove vendor applied antitarnish conversion coatings (e.g.

• Enthone Enteck Cu56 chromate conversion coatings) and/or copper tarnish (oxides),

it is recommended to precede pumice or aluminum oxide

Scrubbed Electroless Copper Surfaces scrubbing with a spray acid cleaner or 10-15% sulfuric acid or

Brush Pumice: a microetch.

3F or 4F grade, fused, 15-20 % v/v, 9-12 mm (3/8-1/2") brush

foot print, fines removal and replenishment per vendor Chemically Cleaned Vendor Copper

recommendations; high pressure (10 bar) final rinse (pH 6-8); Alkaline Spray Cleaner for removal of organic contaminants

hot air dry. followed by a spray microetchant for conversion coating

(chromate) and/or copper oxide removal (about 2-2.5 μm; 80-

100 microinch etch). A 10% sulfuric acid spray may be used

between alkaline cleaner and microetchant to help with the

conversion coating removal. In this case only 1.5 μm (60

DS95-17 Rev. 6.0 (07/07) 2

microinch) microetch depth is required. To remove residual Note: use distilled water; hard water is acceptable but may

salts after microetching from the copper surface, an acid rinse cause scale build up and clog nozzles.

or efficient water spray rinsing have been employed Note: Reduced lamination roll pressure and/or temperature

successfully. In-line systems for prelamination cleaning may may be required in tenting applications to avoid tent breakage

not require an antitarnish treatment after chemical preclean to and resist flow into through-holes.

preserve the cleaned surface. Non-in-line systems with hold

times of several hours will require antitarnish. For antitarnish

Post-Lamination Hold Time

selection: see “Electroless Copper with Antitarnish”. • Panels may be exposed immediately after lamination;

however, allow enough time for panels to cool to room

Electrochemically Cleaned Vendor Copper temperature before lamination (about 15 minutes; use

accumulator in in-line systems).

Conveyorized systems combining reverse current • Minimize hold time for best tenting performance.

electrochemical cleaning and microetching are offered to • Maximum hold time (guidelines):

effectively remove chromate conversion coatings with minimal Wet Lamination: 24 hours

Dry Lamination: up to 3 days

copper removal. The alkaline electrochemical cleaner first Hold times should be determined empirically based on the

removes trace organics and chromates. After a rinse, a temperature and relative humidity of the storage area.

microetch removes about 0.8μm (30 microinches) of copper.

Following a second rinse an antitarnish may be applied. Note: Guideline- strip within 5 days after lamination.

Double-Treated Copper Surfaces Panel Handling/Racking/ Stacking

Normally no prelamination cleaning required; vapor degreasing

or chemical cleaning to remove organics is optional. Tacky Preferred: Vertical racking in slotted racks

roller cleaning recommended to remove particles. Less desirable: Stacking

To minimize adverse effects: stack on edge vertically after

PART 2: Lamination cooling; avoid dust and dirt trapping between panels; insert

unlaminated panel between stack support and first laminated

Lamination Conditions panel to protect laminated panel. Unlaminated support panel

DuPont HRL-24 & HRL-24/YieldMaster® Film Laminator should be at least as big as the laminated panels. Thin flexible

• Pre-Heat: Optional innerlayers usually cannot be racked. Preferred techniques:

• Roll Temperature: 105°C ±5°C(221 ±9°F)

• Roll Speed: 0.6-1.5 m/min (2-5 ft/min) hanging panels vertically or stacking on edge after cool down.

• Air Assist Pressure: 0-2.8 bar (0-40 psig) If innerlayers are stacked horizontally in trays, the stack height

should be limited especially for panels with thin photoresist

Note: for 1•4 bar use heavy-duty rolls)

and fine circuitry.

• Water flow Rate, each valve

(YieldMaster® models only) : 5 – 15 cc/min

PART 3: Tenting

Riston® 200 has been designed to provide excellent tenting in

Note: use distilled water; hard water is acceptable but may both plating and etching processes. Tents of 6.3 mm (250 mil)

cause scale build up and clog nozzles. or larger can be tented. For large holes best yields are

obtained with the Riston® 220. For best results minimize hold

time between lamination and exposure, use optimized

Lamination Conditions

DuPont ASL-24 & ASL-24/YieldMaster® Film Laminator developer conditions, reduce possible handling damage , and

• Seal Bar Temp.: 65 ±15°C (150 ±27°F) optimize board deburring. Tent failure rates below 1.0%

• Lam. Roll Pressure: 3.0-5.0 bar ( 43-72 psig)

• Lamination Temp.: 105 ± 10°C (220 ± 18°F) should be possible in most applications.

• Seal Time: 1-4 seconds

• Seal Bar Pressure: 3.5-4.5 bar (50-65 psig)

• Lamination Speed: 1.5-3 m/min (5-10 ft/min)

• Water Flow Rate, each valve (Yieldmaster® models only):

5-15 cc/min

DS95-17 Rev. 6.0 (07/07) 3

PART 4: Exposure Vacuum Frame Operation

• Contact Mode:

Preferred: Hard Contact

Resolution (Lines & Spaces; L/S)

• Check for small, immovable Newton’s Rings as an

indicator of good contact between the panel, phototool,

• In Optimized Production Environment and vacuum frame cover

(hard contact, high intensity exposure, good

development and rinse control): 75 micron (3 mil L/S) • Use air bleeder veins to channel air to vacuum port and

reduce vacuum drawdown time.

• In Lab Environment: 50 micron (2 mil L/S) • Bleeder Vein Thickness: same as panel

PART 5: Development

Phototool (5 mil) Line Reproduction with Riston® 200

Chemistries/Make-up

1:1 Reproduction ± 2 micron (0.080 mils) from nominal

215 RST 12 - 18 • Sodium carbonate, anhydrous, ( soda ash), Na2CO3

220 RST 12 - 20

Working solution: 0.85 wt%. Use 8.5 g/l (0.071 lb./gal)

• Sodium carbonate, monohydrate; Na2CO3•H2O

Note: DuPont PC-530 a medium collimated light exposure unit. Working solution: 1.00 wt%. Use 10 g/l (0.083 lb./gal)

Exposure Intensity • Potassium carbonate (potash; K2CO3)

• >5 mW/cm2 at the photoresist surface for For make up use either potassium carbonate powder, i.e.

200-250 μm (8-10 mil) L/S resolution; higher intensities

anhydrous (potash) K2CO3 or a liquid concentrate such as

are desirable for finer L/S.

DuPont D-4000 developer (40% concentrate):

Working solution: 1.0 wt%. Use 0.018 liter of D-4000 per

liter of sump, or use 10g/liter (0.083 lb/gal) of anhydrous

Exposure Energy vs “Steps Held” For Recommended potassium carbonate.

Exposure Range

Riston® 215 220

Equations to calculate required amounts for

mJ/cm2 35-90 45-100 desired wt% of working solutions:

RST 12-20 12-20

SST 8-10 8-10 • Na2CO3: kg Na2CO3 = wt% x sump vol

liters x 0.01 lb. Na2CO3

= wt% x sump vol gallons x 0.083

• D-4000: liters (or gallons) D-4000 = wt% x

• Steps held can vary by +/-1 RST depending sump vol liters (or gallons) x 0.018

• K2CO3: kg K2CO3 = wt% x sump vol

on the development breakpoint used

liters x 0.01 1lb. K2CO3

.• If panels are exposed when warm, there = wt % x sump vol gallons x 0.083

may be a slight increase in the steps held.

Note:

• RST = DuPont Riston® 25-Step Density Tablet;

• SST = Stouffer 21-Step Sensitivity Guide;

• “Step Held” = last step covered •50% with photoresist.

DS95-17 Rev. 6.0 (07/07) 4

Control Test Note: Total time in developer = Time to clean divided by

Titration of fresh developer solution (e.g. 25ml), before Breakpoint.

defoamer addition, with 0.1 N HCl to the Methyl Orange end • Time to Clean ( time in developer to wash off unexposed

point. resist):16-21 seconds for Riston® 215 depending on

wt% = N x ml HCl x FW / 20 x ml conditions.

Sample • Shorter times to clean are achieved at higher

(N= acid normality; FW = formula weight) temperatures, higher carbonate concentrations, and

FW of Na2CO3=106 higher pressures.

FW of Na2CO3•H2O= 124 • If developer conveyor speed is too fast for match with

FW of K2CO3 = 138 other in-line equipment: lower soda ash concentration

down as far as 0.5wt%. Consider lowering

Defoamers temperature. Do not lower spray pressure below

Riston® 200 will usually require some defoamer. The need for recommended levels.

defoamer and the amount required are dependent on water

quality, carbonate purity, photoresist loading, and equipment Resist Loading

design. If required, add 0.8 - 1.3 ml/liter (3-5 ml/gallon) of:

• Resist Loading:0-0.3 mil-m2/liter (0-12 mil-ft2/gal)

• Alpha Metals (Ardrox) PC 4772 or PC4772D

• Chemelex BB Note: this range gives a fairly constant time to clean; higher

loadings increase the time to clean.

For batch operation: add defoamer during initial make up; For

automatic replenishment systems: add defoamer directly to the

Rinsing & Drying Recommendations

sump in a high turbulence area at a predetermined rate. Do not

• Rinse water: hard water preferred (140-320 ppm

add defoamer to the supply tank or to the replenishment

CaCO3 equivalent), but 200 can be developed in soft

solution.

water. If hard water is not available, a first soft water

rinse may be followed by a dilute acid rinse, followed by

Development conditions

a water rinse.

• Spray Pressure: 1.4-2.4 bar (20-35 psig)

• Rinse temperature: 15-25°C (60-80°F)

• Spray Nozzles: high impact direct-fan nozzles

• Rinse spray pressure: 1.4-2.4 bar (20-35 psig). Use

preferred; a combination of cone

high impact , direct-fan nozzles.

and fan nozzles may be preferred if

• Effective Rinse Length: Minimum of 1/2 of length of

film tent breakage is experienced.

developer chamber; >1/2 preferred.

• Chemistry:

• Drying: blow dry thoroughly; Hot air preferred

Na2CO3: 0.7-1.0 wt%; 0.85 wt% preferred

Na2CO3•H2O: 0.8-1.1 wt%; 1.0 wt% preferred

Controls:

K2CO3: 0.8-1.1 wt%; 1.0 wt% preferred

• For batch processing: adjust conveyor speed to

• Temperature: 27-35°C (80-95°F); 30°C (85°F)

maintain desired breakpoint; dump developer solution

preferred

when pH of solution reaches 10.2.

Dwell Time

• Developer conveyor speed: see “Dwell Time”.

• Breakpoint: 50-70% % (60 % preferred)

• Feed & Bleed: to keep loading at about 0.2 mil-m2 l (8 mil-

• Time in Developer (Dwell Time), at 2.0 bar (30 psig)

ft2/gal), activate addition of fresh developer at pH 10.5;

spray pressure, 60% breakpoint, 30°C, fresh developer

stop addition when pH 10.7 is reached.

solution at recommended carbonate concentrations in a

Chemcut 2000 developer:

Riston® 215: 30-40 seconds

Riston® 220: 40-55 seconds

DS95-17 Rev. 6.0 (07/07) 5

• Rinse

Developer Solution pH Response to Resist - Two-stage, counterflow

Loading for Riston® 200 - Flow: sufficient to prevent color, foam, solids buildup

- Rinse temperature: 15-25°C (60-80°F); preferred range: 20-

pH Loading Loading 25°C (70-80°F)

(mil-m2/lt) (mil-ft2/gal) - Rinse time: • 1 minute

10.97 0 0

10.81 0.05 2 Microetch

10.67 0.10 4 • Etch Depth: 0.15-0.26 μm (5-10 μ”) of copper

10.48 0.20 8 - Sodium or ammonium persulfate & 1% H2SO4 at 20-25°C (68-

10.33 0.30 12 77°F)

Control Test:

• Check etch rate by weight loss with coupon.

Hold Time after Development before Prepare coupons in the same manner as production

0-5 days panels (e.g. antitarnish treatment of electroless copper,

Riston® 200 lamination, development, preplate clean;

Note: minimize white light exposure during post development use realistic hold times).

hold to prevent film embrittlement.

PART 7: Etching

Developer Maintenance • Riston® 200 series resists are compatible with most

Clean at least once a week to remove resist residue, calcium acid etchants, e.g. cupric chloride (free HCl normality <

carbonate (scale), defoamer, and dye from developed resist. 3.0 N), H2O2/H2SO4, and ferric chloride.

Dye buildup can be minimized by the use of anti-foam. • Riston® 200 series resist are compatible with alkaline

ammonical etchants (pH < 9.5).

PART 6: Plating

(acid copper sulfate; tin/lead, tin; nickel; gold) During alkaline etching, the replenisher flood rinse should be

(Follow plating vendors’ recommendations ) well vented (flow toward etch chamber) to minimize ammonia

vapors that may attack the resist.

Preplate Cleaning

• Preplate Cleaning Process Sequence

PART 8: Stripping

- Acid Cleaner : 40-55°C (105-130°F); 2-3 minutes

Aqueous Caustic (NaOH or KOH) Conveyorized

- Spray Rinse: 1-2 minutes

Stripping

- Microetch to remove 0.15-0.26 μm (5-10 μ")

Note:

copper (time: as required)

• Dwell Time = 2x Time to strip resist

- Spray Rinse: 1-2 minutes

• High caustic concentrations produce larger skin sizes

- Sulfuric acid (5-10 vol%) dip; 1-2 minutes

and higher loading capabilities.

- (Optional: spray rinse; 1-2 minutes)

• Recommended Acid Hot Soak Cleaners Stripper Dwell Times (seconds) at 55°C

(130°F), 1.7 kg/cm2 (25psig ), Over

Note test results, e.g.: Recommended Exposure Range

MacDermid Metex 9268: 10 vol%;38- 50°C (100-120°F); 3 - 5

215 220

min

Note: Other cleaners may perform equally well but have not 1.5 wt% NaOH 80 -110 sec 150 -190 sec

been tested. 3.0 wt% NaOH 60 - 80 100 -120

1.5 wt% KOH 110 -140 120 -170

3.0 wt% KOH 50 -70 90-110

DS95-17 Rev. 6.0 (07/07) 6

• KOH generally produces smaller skin sizes than NaOH. rinse chamber. The most effective filter systems collect the

stripper skins immediately after they were generated, before

Particle Size at 1.5% NaOH: 2-4 mm entering recirculation pumps, and they feature continuous

Particle Size at 3.0% NaOH: 3-10 mm removal of skins from the stripper solution.

Particle Size at 1.5% KOH: 1-3 mm

Particle Size at 3% KOH: 2-10 mm Equipment Cleaning

• Solubility of Stripped Particles: TBD • Cleaning of Equipment

• Rate of dissolution of Stripped Particles: TBD Drain and flush with water. Fill unit with 5 wt% KOH or NaOH,

heat to 55°C (130°F), and circulate (spray) for 30 minutes to

• Higher stripping temperature increases the stripping dissolve photoresist particles. Then drain the unit. Repeat

rate. procedure if required to remove heavy residues. Remaining

• Stripping rate can be increased with higher impact blue dye stains on equipment may be removed by circulating 5

sprays. Use higher pressures and/or high-impact spray vol.% HCl at 55°C (130°F) for 30 minutes (HCl can damage

nozzles. Avoid low impact deflector nozzles. stainless steel). Then drain the unit, fill with water, recirculate

• Time to strip increases with white light exposure. A 20% for 30 minutes, and drain. There are also proprietary cleaners

increase in strip time over 8 days exposure is not available which may offer better results.

unusual.

• Higher levels of exposure increase Time-to-Strip: Proprietary Strippers

Are used for higher strip speed, higher resist loading, to

minimize chemical attack on tin or tin/lead, or to reduce copper

Defoamers

oxidation, e.g. to facilitate AOI.

Additives for foam control may not be required depending on

equipment design and operation.

The following proprietary strippers have been used

successfully:

Alpha Metals (Adrox) PC4069

Riston® 200 % TTS Increase Atotech BC 925F

Riston® Step 10-18 Dexter RS 1609

3% KOH/NaOH 0 - 10% Atotech RR3

1.5% KOH/NaOH 15 - 40%

Other strippers may perform equally well but have not been

tested.

Controls/ Solution Maintenance:

Reworking Panels for Re-use

• Preferred: Continuous replenishment (feed & bleed)

Stripped panels may contain organic residues from photoresist

using board count.

or defoamers. After stripping, regenerate a fresh copper

Maintain resist loading at < 0.4 mil-m2/liter (<15 mil-

surface as follows, before mechanically cleaning the panels:

square feet/ gallon ), for caustic strippers

• Soak for three minutes in a hot soak cleaner at the

• Batch: up to 0.5 mil-m2/liter (20 mil-square feet/ gallon).

recommended temperature.

Maintain breakpoint at <50% by lowering conveyor

• Rinse thoroughly.

speed or by starting batch stripping with a lower

• Etch 0.13 μm (5 microinches) of copper if panels are

breakpoint and changing the solution once breakpoint

deeply oxidized.

moves above 50%. However, low breakpoints can lead

• Rinse thoroughly.

to attack of solder on plated work, or cause copper

• Dip in 5-10% sulfuric acid.

oxidation.

• Rinse thoroughly

• Filtration Systems

• Dry

Spray stripping equipment should contain a filtration system to

collect and remove resist skins to avoid nozzle clogging, to

extend stripper life, and to avoid resist skins from reaching the

DS95-17 Rev. 6.0 (07/07) 7

Storage

See recommendations in the General Processing Guide (DS98-

41)

Waste Disposal

For questions concerning disposal of photoresist waste refer

to the latest DuPont literature and Federal, State, and Local

Regulations.

Safe Handling

Consult the Material Safety Data Sheet (MSDS) for Riston® dry

film photoresist vapors. The vapor MSDS for this film was

prepared using the highest lamination roll temperature

recommended for use. If you choose to exceed this

temperature, be aware that the amount of vapor may increase

and that the identity of the materials vaporized may vary from

those in the MSDS. For more Safe Handling information, see

publication TB-9944 “Handling Procedure for DuPont

Photopolymer Films”.

For further information, please contact your local

representative.

DuPont Electronic Technologies

14 T. W. Alexander Drive

Research Triangle Park, NC 27709 USA

www.imaging-materials.dupont.com

This information corresponds to DuPont’s current knowledge on the subject. It is offered solely to provide possible suggestions for your own

experiments and is not intended to substitute for any testing you may need to conduct to determine the suitability of DuPont’s products for

your particular purposes. This information may be subject to revision as new knowledge and experience becomes available.

Since DuPont cannot anticipate all variations in actual end-use conditions, it makes no warranties and assumes no liability in connection with

any use of this information. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any

patent right

Caution : Do not use in medical applications involving permanent implantation in the human body. For other medical applications, see

“DuPont Medical Caution Statement”, H-51459.

DS95-17 Rev. 6.0 (07/07) 8

You might also like

- DEC Riston EM213 DataSheetDocument7 pagesDEC Riston EM213 DataSheetks_spyroNo ratings yet

- Galvacon Gc243 Tds EngDocument2 pagesGalvacon Gc243 Tds EngShaik Asim UddinNo ratings yet

- Galvacon Gc243 Tds EngDocument2 pagesGalvacon Gc243 Tds EngSHAIK ASIMUDDINNo ratings yet

- NSF 61 PaintDocument2 pagesNSF 61 Paintraviraj londheNo ratings yet

- BECKOPOX EM 2120w - Allnex - Bilingual 27 FebDocument15 pagesBECKOPOX EM 2120w - Allnex - Bilingual 27 FebDhruv Sevak100% (1)

- Nerocoat Pure Polyester Powders 6200 PDSDocument2 pagesNerocoat Pure Polyester Powders 6200 PDSarvind kumar yadavNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Optimum Anode-to-Cathode Speed: Copper XHB 5305Document2 pagesOptimum Anode-to-Cathode Speed: Copper XHB 5305Roger Mendoza CaceresNo ratings yet

- 00.2.TDS - RS 500 PDocument4 pages00.2.TDS - RS 500 PMuhammad TantowiNo ratings yet

- Drilling Mud ChemicalsDocument15 pagesDrilling Mud ChemicalsSantosh JayasavalNo ratings yet

- Ultra Cote 101 PrimerDocument3 pagesUltra Cote 101 PrimerGilbert Dela Serna IINo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- TDS PUFFIN COOKWARE STOVING DoneDocument3 pagesTDS PUFFIN COOKWARE STOVING DoneYoga RahadianNo ratings yet

- TDS RovalDocument4 pagesTDS RovalSyahril Fira86No ratings yet

- BergerDocument2 pagesBergerBhanu Pratap ChoudhuryNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Bipigard ST Cte BlackDocument3 pagesBipigard ST Cte BlackKhirod KroutNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- Eutalloy 11496Document2 pagesEutalloy 11496jorge_20120% (1)

- Powder Type FDocument3 pagesPowder Type Fferdlh9No ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Hi Pon 20 10 Epoxy Zinc Phosphate 63 Ver 4.0 PDFDocument5 pagesHi Pon 20 10 Epoxy Zinc Phosphate 63 Ver 4.0 PDFPushpendraNo ratings yet

- Ul Ul Ul Ultracote Tracote Tracote TracoteDocument3 pagesUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleNo ratings yet

- Ultracote 635 HBDocument3 pagesUltracote 635 HBCherbee Ferrer100% (1)

- High Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationDocument4 pagesHigh Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationChandresh M SachdevNo ratings yet

- Method Statement For Steel Substrate - Unique Eng - 03.10.2023Document2 pagesMethod Statement For Steel Substrate - Unique Eng - 03.10.2023janakaNo ratings yet

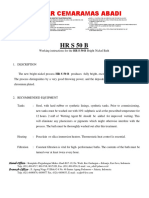

- HR S 50 B (Bright Nickel Bath)Document8 pagesHR S 50 B (Bright Nickel Bath)Sinar Cemaramas AbadiNo ratings yet

- 924-Basic Cold Rolling-Pickling-RollingDocument77 pages924-Basic Cold Rolling-Pickling-RollingHerdisNo ratings yet

- Optimum Anode-to-Cathode Speed: Copper Acid, High-Speed 5260Document2 pagesOptimum Anode-to-Cathode Speed: Copper Acid, High-Speed 5260Roger Mendoza CaceresNo ratings yet

- Croda NF-TDocument3 pagesCroda NF-Tnirai101259No ratings yet

- Heat Resisting Chimney Black SPL PMG 2019100114 Na Na 38 30Document2 pagesHeat Resisting Chimney Black SPL PMG 2019100114 Na Na 38 30giyo.bgpNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- Chrome PlatingDocument11 pagesChrome PlatingMahesh Babu100% (1)

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationAhmed ElbahrawyNo ratings yet

- Pt. Sinar Cemaramas Abadi: Soak Cleaner HR 12Document1 pagePt. Sinar Cemaramas Abadi: Soak Cleaner HR 12Sinar Cemaramas AbadiNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DataQuy RomNo ratings yet

- Scotch-Weld: Epoxy AdhesiveDocument6 pagesScotch-Weld: Epoxy AdhesiveJun Bryan Ramirez AbangNo ratings yet

- Nerocoat Epoxy Powders 6000 PDSDocument2 pagesNerocoat Epoxy Powders 6000 PDSarvind kumar yadavNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DatajoehodohNo ratings yet

- Painting HintDocument19 pagesPainting HintSenthil KumaranNo ratings yet

- Carbozinc 11 HS PDSDocument2 pagesCarbozinc 11 HS PDSvietrossNo ratings yet

- Metallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingDocument5 pagesMetallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingGee AbrahamNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetBiju_PottayilNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Chlorokote FinishDocument2 pagesChlorokote FinishKhirod KroutNo ratings yet

- H2O AluShieldDocument6 pagesH2O AluShieldndoye amarNo ratings yet

- Thermaline 4674: Selection & Specification DataDocument3 pagesThermaline 4674: Selection & Specification DataFreddy Carl FredricksenNo ratings yet

- Phenoline 187 Primer & Finish: Selection & Specification DataDocument5 pagesPhenoline 187 Primer & Finish: Selection & Specification DataQuy RomNo ratings yet

- Product Data: Carboguard 190 HDocument2 pagesProduct Data: Carboguard 190 HClarkFedele27100% (1)

- Lab Session 2:: PolishingDocument6 pagesLab Session 2:: PolishingaliNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- Thermaline 450 EP: Selection & Specification DataDocument3 pagesThermaline 450 EP: Selection & Specification DataGMSNo ratings yet

- Tuffkote: Epigard HB ZP PrimerDocument2 pagesTuffkote: Epigard HB ZP PrimerSHATABDI- DELNo ratings yet

- HR 48 (Trivalent Temper Resistant Chromate Passivation)Document4 pagesHR 48 (Trivalent Temper Resistant Chromate Passivation)Sinar Cemaramas AbadiNo ratings yet

- 650e PDFDocument7 pages650e PDFsonchemenNo ratings yet

- Plasite 7159 HAR: Selection & Specification DataDocument4 pagesPlasite 7159 HAR: Selection & Specification DataRobertoNo ratings yet

- Atoms, Compounds and Stoichiometry WorksheetDocument4 pagesAtoms, Compounds and Stoichiometry WorksheetMenaga A/P IlangkovanNo ratings yet

- Issue48 LimoncelloDocument4 pagesIssue48 LimoncelloSalvador VaghiNo ratings yet

- SNC 2dw DR Chemistry SpringDocument4 pagesSNC 2dw DR Chemistry Springapi-234678275No ratings yet

- Equinox Test Certificate: SOP-ENV-01-00 & SOP-MCB-39-00Document3 pagesEquinox Test Certificate: SOP-ENV-01-00 & SOP-MCB-39-00pavanranguduNo ratings yet

- Ec6 - Daman & DiuDocument25 pagesEc6 - Daman & DiuChirag Kothiya100% (1)

- CHM3201 SCL1Document3 pagesCHM3201 SCL1nini myungNo ratings yet

- Acids, Bases, Buffer Practice FRQDocument4 pagesAcids, Bases, Buffer Practice FRQTom JohnsonNo ratings yet

- Analysis of Volhard's MethodDocument9 pagesAnalysis of Volhard's MethodKingsley WongNo ratings yet

- Project Report On Mass Balance of RR3 Grade of GreaseDocument116 pagesProject Report On Mass Balance of RR3 Grade of GreaseAkash Dhobale100% (2)

- Processed Ekspor Mineral 2000 2010Document11 pagesProcessed Ekspor Mineral 2000 2010Khalis Mahmudah100% (1)

- Acid Base Lab ReportDocument6 pagesAcid Base Lab ReportYEEHSHIN JILL GAYONo ratings yet

- 604 Dr. Fixit PrimesealDocument2 pages604 Dr. Fixit Primesealkkundan52No ratings yet

- 2) Benzene Multiple Choice QuestionsDocument3 pages2) Benzene Multiple Choice QuestionsAnonymous pgjIAZo77% (13)

- General Values For ChemicalsDocument9 pagesGeneral Values For ChemicalsAakash SharmaNo ratings yet

- Chemical Bonding Review WorksheetDocument2 pagesChemical Bonding Review WorksheetCatherine JeaneNo ratings yet

- 2021 WTS 12 Organic ChemistryDocument56 pages2021 WTS 12 Organic ChemistryGladwell PhetlaNo ratings yet

- HPM Steel For MoldDocument15 pagesHPM Steel For MoldcadcamtaiNo ratings yet

- Chemistry Lab ManualDocument53 pagesChemistry Lab ManualAshish RoshanNo ratings yet

- PlasticsDocument21 pagesPlasticsJaypee MontealegreNo ratings yet

- Penthouse Fall 1996Document2 pagesPenthouse Fall 1996John M. CavoteNo ratings yet

- Lesson Plan For Salts and SolubilityDocument2 pagesLesson Plan For Salts and SolubilityLimbert Edwin BustillosNo ratings yet

- Design and Fabrication of Pyrolysis UnitDocument3 pagesDesign and Fabrication of Pyrolysis UnitInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quinoline: A Versatile Heterocyclic: Saudi Pharmaceutical JournalDocument12 pagesQuinoline: A Versatile Heterocyclic: Saudi Pharmaceutical JournalDavid DelgadoNo ratings yet

- Jo GradeDocument40 pagesJo GradeEvonne TanNo ratings yet

- Bunker Fuel Oil Specifications2010Document5 pagesBunker Fuel Oil Specifications2010onejako12No ratings yet

- Monel Alloy K500 UNS N05500 WeldingRod Stockiest & Suppliers in IndiaDocument2 pagesMonel Alloy K500 UNS N05500 WeldingRod Stockiest & Suppliers in IndiaOZAIRTRADELINKNo ratings yet

- Astm A897 - A897m-22Document11 pagesAstm A897 - A897m-22anant11235No ratings yet

- Complete: ChemistryDocument26 pagesComplete: ChemistryDavid DarkoNo ratings yet

- Lawson Products, Inc - Open Gear Wire RopeDocument3 pagesLawson Products, Inc - Open Gear Wire Ropejaredf@jfelectric.com100% (1)

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)