3/24/2020 Inspection lot creation : sample size calculation - Product Lifecycle Management - Community Wiki

Welcome to the new version of SAP Community Wiki: Learn What's New? and what has changed.

Dashboard / … / Quality Inspection (QM-IM)

Inspection lot creation : sample size calculation

Created by Nancy Guo, last modified on Apr 24, 2015

Purpose

Explains how sample size (field QALS-GESSTICHPR) is calculated during inspection lot creation.

Overview

This document introduces what settings influence sample size calculation and the logic about how the sample size is

determined during lot creation.

<Settings>

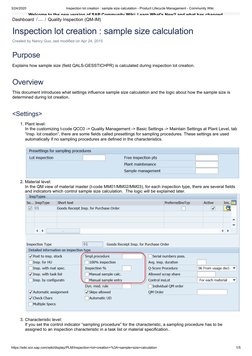

1. Plant level:

In the customizing t-code QCC0 -> Quality Management -> Basic Settings -> Maintain Settings at Plant Level, tab

“Insp. lot creation”, there are some fields called presettings for sampling procedures. These settings are used

automatically if no sampling procedures are defined in the characteristics.

2. Material level:

In the QM view of material master (t-code MM01/MM02/MM03), for each inspection type, there are several fields

and indicators which control sample size calculation. The logic will be explained later.

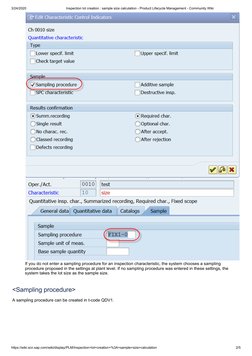

3. Characteristic level:

If you set the control indicator “sampling procedure” for the characteristic, a sampling procedure has to be

assigned to an inspection characteristic in a task list or material specification..

[Link] 1/5

�3/24/2020 Inspection lot creation : sample size calculation - Product Lifecycle Management - Community Wiki

If you do not enter a sampling procedure for an inspection characteristic, the system chooses a sampling

procedure proposed in the settings at plant level. If no sampling procedure was entered in these settings, the

system takes the lot size as the sample size.

<Sampling procedure>

A sampling procedure can be created in t-code QDV1.

[Link] 2/5

�3/24/2020 Inspection lot creation : sample size calculation - Product Lifecycle Management - Community Wiki

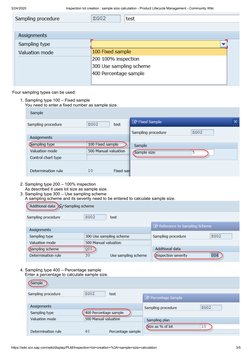

Four sampling types can be used:

1. Sampling type 100 – Fixed sample

You need to enter a fixed number as sample size.

2. Sampling type 200 – 100% inspection

As described it uses lot size as sample size.

3. Sampling type 300 – Use sampling scheme

A sampling scheme and its severity need to be entered to calculate sample size.

4. Sampling type 400 – Percentage sample

Enter a percentage to calculate sample size.

[Link] 3/5

�3/24/2020 Inspection lot creation : sample size calculation - Product Lifecycle Management - Community Wiki

The sampling types are defined in the customizing t-code QCC0 -> Quality Management -> Basic Data -> Define Sample

Determination. You can read the documentation here to know more.

<Calculation logic>

There are two possibilities for determining the sample size:

The sample size is entered by the user

If the sample size is to be entered manually during the inspection, you must set the indicators “Manual sample

entry” and “Manual sample calc.” in the material master. Please note the indicator “Manual sample entry” is only

taken into account for an inspection that is carried out without a task list or material specification.

The sample size is calculated automatically by the system

If the sample size is to be calculated automatically, a distinction must be made between the following two cases:

1. Inspection without an inspection plan or material specification

To calculate the sample size, you can set the fields “sampling procedure” or “inspection percentage” in the material

master. They are only relevant, when you carry out an inspection without reference to a task list or material

specification.

The indicator “100% inspection” can also be set in the material master. See the F1 help of this field to know more

about this indicator. The note 213505 explains why sample size is 1 although this indicator is set.

2. Inspection with an inspection plan or material specification

The sample size is calculated on the basis of the sampling procedure defined at the characteristic level of the

inspection plan or material specification.

If a sampling procedure was not defined in the inspection plan or material specification, the system uses the

predefined sampling procedure stored in customizing at plant level to determine the sample size.

If a sampling procedure is not specified in Customizing, the lot size is used as the sample size for the

characteristic.

Attention:

If you set the indicator for a 100% inspection in the material master record, this has priority over all other

procedures defined to calculate the inspection size.

If several characteristics use different sampling procedures, the highest sample size of the characteristics is used

as the inspection lot sample size.

The following document introduces how sample drawing procedure influences the lot sample size in physical

sample management.

Physical Samples Management in SAP QM

Related Content

Function modules:

QDSE_DYNAMIC_SAMPLING

QDTA_SAMPLE_FUNCTION_READ

QDRS_FIXED_SAMPLE

[Link] 4/5

�3/24/2020 Inspection lot creation : sample size calculation - Product Lifecycle Management - Community Wiki

QDRS_100_PER_CENT_SAMPLE

QDRS_SAMPLING_PLAN_SAMPLE

QDRS_PERCENTAGE_SAMPLE

QDRS_100_PER_CENT_INSP_W_SKIP

QDRS_100_PER_CENT_INSPECTION

T-codes:

QAC3 – Reset sample calculation

Related Documents

Physical Samples Management in SAP QM

Related SAP Notes/KBAs

213505 - Sample size 1 for 100% inspection

372271 - Sample size 0 for inspection lot creation

1853950 - Sample size displays 32,767 in transaction code QE11

No labels

Privacy Terms of Use Legal Disclosure Copyright

Trademark Cookie Preferences

[Link] 5/5