WORK INSTRUCTION

[Link]:WI

PAGE 1 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

Sampling Plan Used For Testing

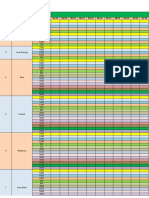

1.0 Raw Material Testing

1.1 For raw material analysis (Rod/Wire), samples will be drawn by laboratory as per the following

plan.

S. Bars

Test Coils

No. Up to 25 26-50 51-90 Over 90

1 Hardness 2 3 5 8 100%

2* Tensile strength & NA NA NA NA 2

%age Reduction in

area

3 Surface Defects 2 3 5 8 100%

4 Internal cracks, 2 3 5 8 100%

Porosity

5 Microstructure 1 1 1 1 1

6 Inclusion Rating 1 1 1 1 1

7 Grain Size 1 1 1 1 1

8 Decarburization 1 1 1 1 1

9 Chemical 2 3 5 8 100%

Composition

10 Hardenability Test 2 3 5 8 100%

11 Coating Thickness 2 3 5 8 100%

12 Upsetting tests NA NA NA NA 100%

(Ref. ASME B18.18-2017)

Note:

1. Even if one sample is rejected the lot will be rejected.

2. The Samples are supposed to pass all test enlisted.

3. * mark test will be conducted at the time of new vendor evaluation or when any problem is

faced at the time of production.

1|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 2 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

2.0 In process Inspection

S. Test Test No. of Samples Frequency

No. Stage

1 Forging Under Head Radius Integrity/ Crack 1 Each Setting

2 Rolling Thread Laps 1 Each Setting

3 Hardening Quench Hardness 1 Every 4 Hours

4 Hardening Microstructure 1 1 Per Shift

5. Hardening Decarburization/ Carburization By 1 1 Per Shift

Microscopic Method

6 Hardening Decarburization/ Carburization By 1 1 Per Week

Hardness Method

The above sampling plan has been arrived after years of experience and without any

customer complaint.

MASTER

COPY

2|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 3 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

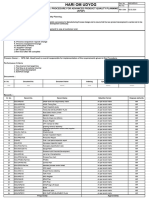

3.0 Sampling Plan for checking Tempered and finished Material for various Test

Enlisted

(Ref ASTM F1470-2019)

Sr. Nature of Test Lot Size

No. Up to 1000 1000-5000 5001-250000:

No of Samples No of Samples No of Samples:

Normal Tightened Normal Tightened Normal Tightened

1 HARDNESS 4 8 6 12 8 16

2 MICROHARDNESS 4 8 6 12 8 16

3 TENSILE STRENGTH 2 4 3 6 4 8

(WEDGE / AXIAL)

4 PROOF LOAD (NUT ) 2 4 3 6 4 8

5 PROOF LOAD 1 2 1 2 1 2

(BOLT & SCREW)

6 DISCONTINUTIES 4 8 6 12 8 16

(MACRO ETCH)

7 HYDROGEN 4 8 6 12 8 16

EMBRITTLEMENT

8 DECARBURIZATION 1 2 1 2 1 2

9 SHEAR 2 4 3 6 4 8

10 TORQUE 2 4 3 6 4 8

11 SALT SPRAY 2 4 3 6 4 8

12 COATING 2 4 3 6 4 8

THICKNESS (NON

DESTRUCTIVE)

13 CASE DEPTH 2 4 3 6 4 8

14 METALLOGRAPHY 1 2 1 2 1 2

15 WASHER HARDNESS 2 4 4 8

NOTE:-

1 If one sample is rejected the lot will be rejected. Up to 1000, where sample size exceeds lot size

100% inspection to be applied.

2 The sampling plan for coating thickness has been made based on experience and no customer

complaint has been received. If any customer complaint is received the sampling plan may be

revised.

3 The sample will be checked for parameters 1,8,14 at tempering stage (2,13 if required) and

3,4,5,6,7,7,10,11,12 at final stage for Finished items.

3|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 4 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

4 Tensile and chemical testings are mandatory at the time of PPAP Stage and in case of any

doubt/ problem. In other cases, a check of hardness and microstructure are considered adequate

for the purpose of clearance of material.

5 If 5 or more consecutive lots are rejected shift to tightened inspection from normal and vice

versa.

6 This sampling plan is applicable if no customer requirement, else sampling plan as per

customer specification will be applicable.

Sampling Plan Used For Vendor and Final Inspection

Draw Samples as per the following Sampling Inspection System*

AQL SAMPLING INSPECTION PLAN FOR THREADED FASTENERS

1. General Dimensional/Visual/Duds

ISO 2859-1 (1999) / IS: 2500 Part I, 2000 (R2017) - General Inspection Level-I, Dimensional &

Std. Room S-2, Profile Projector related parameter S-1

(Refer Table I)

SINGLE SAMPLING PLAN

NOTE: -- FOR MAJOR AND MINOR DEFECTS REFER APPENDIX--A

The description of the sampling plan is given as following:

For visual and Attribute parameters = General inspection level - I

For Dimensional & standard Room parameters = Special inspection level –II

For Profile Projector related Parameters = Level - III

LOT SIZE VISUAL AND ATTRIBUTE DIMENSIONAL AND DIMENSION RELATED

PARAMETERS LEVEL – I GEOMETRICAL TO PROFILE

(PROCESS OPERATION PARAMETERS LEVEL II PROJECTOR LEVEL III

PARAMETERS) LEVEL II (PREVIOUS

OPERATION PARAMETERS)

SAMPLE ACCEPTANC SAMPLE ACCEPTANCE SAMPLE ACCEPTANCE

SIZE E SIZE SIZE

26~90 5 0 3 0 3 0

91~150 8 0 3 0 3 0

4|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 5 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

151~280 13 0 5 0 3 0

281~500 20 0 5 0 3 0

501~1200 32 0 5 0 5 0

1201~3200 50 0 8 0 5 0

3200~ 80 0 13 0 5 0

• ABOVELot size upto 25 Nos. needs 100% inspection.

• During initial production control, 100% Visual Inspection and double of normal sampling

plan for dimensional parameters.

• Rework lot must be 100% Visual inspection and double of normal sampling plan for

dimensional parameters.

APPENDIX A

CLASSIFICATION OF DEFECTS

Sl. Type of Fasteners Major Defects Minor Defects

No.

1. Hexagon socket head Width across flats Thread length

cap screws thread pitch diameter Screw length, shank diameter

( IS : 2269-2006) Thread major diameter Height of head

(ISO 4762:2004) fillet radius Concentricity

Depth of socket End of screws

Perpendicularity of head

of shank

2. Grub screws do Do

( socket head )

(IS:2388-1963)

3. Precision and Thread major diameter Thread pitch diameter undersize

semi precision Thread pitch diameter o/s Thread length

hexagon bolts and Bolt length,

screws Width of across flat Shank diameter, height

(IS:1364-2002) neck diameter

ISO-4014-1999) end of screw

perpendicularity of head

5|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 6 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

To shank

4. Hexagon bolts and do do

screws (IS:2389-1968)

5. Hexagon bolts do do

(IS:3138-1966)

6. Knurled thumb Thread major diameter Head diameter, slot width

screws Thread pitch diameter slot depth, thread pitch

(IS:3726-1966) screw length, thread

oversize length, knurling pitch

end of screw , head thickness

diameter undersize

perpendicularity of head

to shank

7. Precision and Width across flats Thread pitch diameter oversize

semi-precision thread pitch undersize thread minor diameter oversize

hexagon nuts thread minor diameter

(IS-1364-1967) undersize thickness

(ISO-4032-1986)

8. Slotted and castle Width across flats Thickness width of slot

nuts thread pitch undersize slot head diameter

(IS:2232-1967) thread minor diameter thread pitch diameter oversize

undersize thread minor diameter oversize

9. Hexagon nuts Width across flats Thread pitch diameter

(IS:3138-1966) thread pitch undersize oversize, thread minor

thread minor diameter diameter oversize,

undersize Thickness

10. Knurled nuts thread pitch undersize Knurled diameter

(IS:3460-1966) thread minor diameter Knurling pitch, thickness,

undersize thread pitch diameter oversize

thread minor

diameter oversize

6|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 7 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

11. Studs Thread major diameter All other dimensional

(IS:1862-1967) thread pitch characterstics Diameter oversize

12 12 Corner Screw Thread major diameter Thread pitch diameter undersize

ASME B18.2.1 Thread pitch diameter o/s Thread length

Width of across flat Bolt length,

neck diameter Shank diameter, height

end of screw

perpendicularity of head

To shank

Nick Marks

MASTER

COPY

DOCUMENT CHANGE HISTORY:

ISSUE/[Link]. EFFECTIVE DATE NATURE OF AMENDMENT PAGE

7|Page

� WORK INSTRUCTION

[Link]:WI

PAGE 8 OF 8

WORK INSTRUCTION TO DRAW SAMPLES FOR TESTING

VENDOR AND FINAL INSPECTION

VERIFIED & ISSUED &

PREPARED BY:

APPROVED BY: S.M.E. / CONTROLLED BY: M.R.

DEPTT. HEAD

FUNC. HEAD

ISSUE/REV. NO. : 01/03 ISSUE/REVISION DATE :27.02.2020

MASTER

COPY

8|Page