Professional Documents

Culture Documents

WI - Preavaling Torque Testing

Uploaded by

vipulsharma655Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WI - Preavaling Torque Testing

Uploaded by

vipulsharma655Copyright:

Available Formats

WORK INSTRUCTION DOC. NO.

WI-

DPI/PR/27

Test Procedure for The Testing of Prevailing Torque &

Break way Torque of crimping Nut

PAGE 1 of 3

1.0 PURPOSE :

To detail the procedure of Test Procedure for Performance of Prevailing Torque & Break way

Torque of crimping Nut.

2.0 SCOPE :

To determine the mechanical & performance for prevailing torque type steel nuts when

tested at ambient temperature.

3.0 DESCRIPTION : ACTIVITY/ REFERENCE ISO-2320:2015 ,Volvo 7141,441

3.1 Take random samples as per Below Sampling Plan from each lot & 5 pieces test

during settings installation on machine.

Lot Size ( Pieces) No of test

5 to 50 2

51 to 500 3

501 to 35000 5

Over 35000 8

WORK INSTRUCTION DOC. NO. WI-

DPI/PR/27

Test Procedure for The Testing of Prevailing Torque &

Break way Torque of crimping Nut

PAGE 2 of 3

3.2 The Prevailing torque of Screws occurring during the first Installation shall not

exceed the Maximum prevailing-on Torque specified when tested as specified in 4.3. The

breakaway torque and prevailing-off torque occurring during the first & Fifth removal

shall not be less then minimum torques specified.

3.3 Test Procedure –This test can be realizes automatically on an appropriate testing

device or manually with adequate hand tools like torque wrenches.

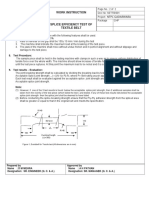

The test bolt/screw placed in the testing device such that the protrusions through the

prevailing torque feature of the nut after seating in according to figure 1.

The nut to be tested is engaged by hand on the bolt/screw thread until the prevailing torque

feature is engaged. The end of the test bolt/screw shall not protrude through the nut before

testing The thread length for tightening shall be four to seven pitches according to figure

1.

The starting point of the installation phase corresponds to the start up of the tightening

device.

The rotation shall be continuous and uniform from point 1 until the test clamp force is

reached. Torque at maximum clamp force shall be recorded.

The seating point shall be determined between point 1 and point 2, the prevailing torque

shall be measured.

The nut is then rotated off by the application of a reverse torque until the clamp force in

the test bolt/screw is reducing to zero. The prevailing –off torque (break way torque)

occurring while the nut is rotated through the next 3600 of rotation shall be measured.

The nut is then disassembled until the initial angular position has reached the starting point

During the removal of the nut, the rotating shall be continuous & uniform from the test

clamp force to point 1.

After the complete removal of the nut, the nut & bolt threads shall not be damaged.

Figure 1: Test setup & nut when seated

WORK INSTRUCTION DOC. NO. WI-

DPI/PR/27

Test Procedure for The Testing of Prevailing Torque &

Break way Torque of crimping Nut

PAGE 3 of 3

4 Record the observations in logbook register & if the measurement value meet the

table 7 values it will pass otherwise fail.

Dharambeer

vipulsharma Jp lohan

ISSUED & Rathee

PREPARED VERIFIED &

BY: APPROVED CONTROLLE

S.M.E. / FUNC.

Lab QA BY: D BY: M.R.

HEAD

ISSUE/REV.NO: ISSUE/REVISION DATE:

You might also like

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- TTLA0664Document539 pagesTTLA0664Angga Nur Cahyanto100% (1)

- Statistical Power Analysis for the Behavioral SciencesFrom EverandStatistical Power Analysis for the Behavioral SciencesRating: 4.5 out of 5 stars4.5/5 (6)

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- FAT Procedure 12m DoorDocument5 pagesFAT Procedure 12m DoorBjørnar HuseNo ratings yet

- Hitachi Zaxis 200 240 270 3 Class Training Text Performance TroubleshootingDocument20 pagesHitachi Zaxis 200 240 270 3 Class Training Text Performance Troubleshootingjohnathan100% (46)

- Performance CheckDocument603 pagesPerformance CheckSergio Muñoz Barrios100% (1)

- Ferrolinks Flywheel Inspection ReportsDocument10 pagesFerrolinks Flywheel Inspection ReportsChellaPandianNo ratings yet

- Wheel Loader Performance StandardsDocument533 pagesWheel Loader Performance StandardsKonstantinNo ratings yet

- Perform Pick Up Drop Off Test of Relay: Prepared By: B.R.PrajapatiDocument4 pagesPerform Pick Up Drop Off Test of Relay: Prepared By: B.R.PrajapatiBhavik PrajapatiNo ratings yet

- Mvtp11-Ct Supervision RelayDocument2 pagesMvtp11-Ct Supervision RelayTHILAKKUMARNo ratings yet

- FQP Equipment Erection1Document1 pageFQP Equipment Erection1Vikram DalalNo ratings yet

- Commissioning Standard Test Formats for Transformer Differential RelayDocument20 pagesCommissioning Standard Test Formats for Transformer Differential RelayrajeshNo ratings yet

- Mbch12-Differential RelayDocument4 pagesMbch12-Differential RelayTHILAKKUMARNo ratings yet

- Part No/ Rev NoDocument2 pagesPart No/ Rev NoVikas Kundu100% (1)

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- Test Report - Milltests-Sample-1Document13 pagesTest Report - Milltests-Sample-1NathanNo ratings yet

- 1200 6 TroubleshootingDocument441 pages1200 6 TroubleshootingVinod Gupta100% (2)

- Mvax31-Trip Circuit SupervisionDocument2 pagesMvax31-Trip Circuit SupervisionTHILAKKUMARNo ratings yet

- Anti FoamDocument7 pagesAnti FoamMohammad MohseniNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- Examination Procedure For Lifting Beam InspectionDocument5 pagesExamination Procedure For Lifting Beam InspectionTrust Emma50% (2)

- MCTI Current Check Relay TestDocument2 pagesMCTI Current Check Relay TestTHILAKKUMARNo ratings yet

- Pile Load Test ProcedureDocument24 pagesPile Load Test ProcedureRamkumar K100% (4)

- Troubleshooting Training 870Document545 pagesTroubleshooting Training 870guillermo springNo ratings yet

- Operational Performance Test Sections and Component ChecksDocument66 pagesOperational Performance Test Sections and Component ChecksVu HoiNo ratings yet

- PAUT ProcedureDocument50 pagesPAUT ProcedureAvijit Debnath100% (1)

- Operational Performance Test: Section 4Document66 pagesOperational Performance Test: Section 4Tú Xuân Lương100% (1)

- 10076002D00 - PB500 Electrical Safety Test and Buzzer Card Charge ProcedureDocument9 pages10076002D00 - PB500 Electrical Safety Test and Buzzer Card Charge ProcedureDaniel MarquesNo ratings yet

- Zx330 Series (Ttla0481) Performance Check-TroubleshootingDocument277 pagesZx330 Series (Ttla0481) Performance Check-TroubleshootingUn'galluNo ratings yet

- Method of Statement For Transformers: Owner/Client Owner'S Engineer ContractorDocument12 pagesMethod of Statement For Transformers: Owner/Client Owner'S Engineer ContractorPandrayar Maruthu100% (3)

- Documentos TecnicosDocument16 pagesDocumentos TecnicosDomingo esteban perez ceballoNo ratings yet

- Performance Check Troubleshooting (TTLA0749)Document243 pagesPerformance Check Troubleshooting (TTLA0749)Devid Waladan SholehanNo ratings yet

- TripleeeeDocument12 pagesTripleeeeDomingo esteban perez ceballoNo ratings yet

- ElectricidadDocument9 pagesElectricidadDomingo esteban perez ceballoNo ratings yet

- MOS TransformerTestingRoutineTestDocument5 pagesMOS TransformerTestingRoutineTestRangith RamalingamNo ratings yet

- 066 LW Tensile Tester v2.0 PDFDocument4 pages066 LW Tensile Tester v2.0 PDFMarkusNo ratings yet

- Live Testing - Take 5 Rev EDocument2 pagesLive Testing - Take 5 Rev EVicky JiNo ratings yet

- Site Inspection & Test ProcedureDocument7 pagesSite Inspection & Test ProcedureNguyễn ĐứcNo ratings yet

- p443 - Line DistanceDocument31 pagesp443 - Line Distancem khNo ratings yet

- OCP - 08 Bus BarDocument8 pagesOCP - 08 Bus BarNaveedNo ratings yet

- Procedure For Hardness TestingDocument8 pagesProcedure For Hardness TestingVinayaga MoorthiNo ratings yet

- 3600-Performance Test &troubleshootingDocument209 pages3600-Performance Test &troubleshootingVeri sugianto50% (2)

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- PT9016 - Mechanical TestDocument8 pagesPT9016 - Mechanical TestlincolnluizNo ratings yet

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- Pre-Commissioning Tests for SwitchgearDocument16 pagesPre-Commissioning Tests for SwitchgearVijaya KumarNo ratings yet

- OCP - 04 Isolator (SWYD)Document7 pagesOCP - 04 Isolator (SWYD)NaveedNo ratings yet

- 04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDocument18 pages04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDangolNo ratings yet

- 7ut - Transformer Diff Relay TestDocument25 pages7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- Transformer MaintenanceDocument68 pagesTransformer MaintenanceBayeNo ratings yet

- The Determination of Uncertainties in Creep Testing To European Standard Pren 10291Document37 pagesThe Determination of Uncertainties in Creep Testing To European Standard Pren 10291viverefeliceNo ratings yet

- Method Statement Pull Out TestDocument7 pagesMethod Statement Pull Out TestAyda JohariNo ratings yet

- Indra: Load Test Procedure For Lifting DevicesDocument8 pagesIndra: Load Test Procedure For Lifting Devicesmed chabaneNo ratings yet

- Packing Standard Components ListDocument3 pagesPacking Standard Components Listvipulsharma655No ratings yet

- Quality plan for Yathartha Yantra UdyogDocument2 pagesQuality plan for Yathartha Yantra Udyogvipulsharma655No ratings yet

- Sampling Plan for Lots up to 150,000 UnitsDocument1 pageSampling Plan for Lots up to 150,000 Unitsvipulsharma655No ratings yet

- Deep Precision Industries: Decarb ReportDocument1 pageDeep Precision Industries: Decarb Reportvipulsharma655No ratings yet

- HouskeepingDocument3 pagesHouskeepingvipulsharma655No ratings yet

- Universal Precision Screws: Standards Chemical CompositionDocument20 pagesUniversal Precision Screws: Standards Chemical Compositionvipulsharma655No ratings yet

- Wi For Chech TRG WI-04-100Document2 pagesWi For Chech TRG WI-04-100vipulsharma655No ratings yet

- ML of OperationsDocument24 pagesML of Operationsvipulsharma655No ratings yet

- Sampling PlanDocument8 pagesSampling Planvipulsharma655No ratings yet

- Grainflow Examination ProcedureDocument4 pagesGrainflow Examination Procedurevipulsharma655No ratings yet

- Wi - Hardness TestingDocument8 pagesWi - Hardness Testingvipulsharma655No ratings yet

- Aspect-Impact For LabDocument1 pageAspect-Impact For Labvipulsharma655No ratings yet

- Testing Lab, Deep Precision Industries: DOC. NO. WI-13Document2 pagesTesting Lab, Deep Precision Industries: DOC. NO. WI-13vipulsharma655No ratings yet

- Deep Precision Industries, Rohtak Work Instruction For Thread LapsDocument2 pagesDeep Precision Industries, Rohtak Work Instruction For Thread Lapsvipulsharma655No ratings yet

- Sign Manual or The ASHRAE Fundamentals Handbook Chapter On Duct Design, Such FitDocument1 pageSign Manual or The ASHRAE Fundamentals Handbook Chapter On Duct Design, Such FitNhat Hoa QuangNo ratings yet

- BSB Profile Range - ENDocument81 pagesBSB Profile Range - ENGaneshNo ratings yet

- Engineering Report For Composite Repair On Enang 48 E Well Flowline-Live-0Document7 pagesEngineering Report For Composite Repair On Enang 48 E Well Flowline-Live-0Chukwuma Emmanuel OnwufujuNo ratings yet

- Mineral Resources, Environmental Issues, and Use: ArticleDocument8 pagesMineral Resources, Environmental Issues, and Use: ArticleDonNo ratings yet

- DRC Conflict Minerals and Cell Phone ProductionDocument39 pagesDRC Conflict Minerals and Cell Phone ProductionAbdias GarciasNo ratings yet

- Eazistrip Reinforcement Continuity SystemsDocument12 pagesEazistrip Reinforcement Continuity SystemscormolioNo ratings yet

- Australia Catalogue 2015Document36 pagesAustralia Catalogue 2015Hen Drix LevaNo ratings yet

- Chile Leader in Metals That Facilitate The Future Inglexxs Digital FinalDocument71 pagesChile Leader in Metals That Facilitate The Future Inglexxs Digital FinalConrado ChavesNo ratings yet

- Brosur Fortress 2021Document1 pageBrosur Fortress 2021ilhamNo ratings yet

- Predicting Product PDFDocument12 pagesPredicting Product PDFStudy in an easy wayNo ratings yet

- Plastic Granules Recycling MachineDocument8 pagesPlastic Granules Recycling MachineSOMINI ENTERPRISESNo ratings yet

- Destiny SIWES ReportDocument40 pagesDestiny SIWES ReportApuede Ikhianosimhe Daniel86% (7)

- Double-V-Weld Consumption Formula in Excel SheetDocument6 pagesDouble-V-Weld Consumption Formula in Excel SheetvinothNo ratings yet

- Electrochemistry: Chemistry 30 WorksheetsDocument49 pagesElectrochemistry: Chemistry 30 Worksheetsdan anna stylesNo ratings yet

- Amecoil InsertDocument2 pagesAmecoil InsertyauctionNo ratings yet

- Standard Method StatementDocument23 pagesStandard Method StatementNithin MathaiNo ratings yet

- Auto Route Pro+ B18 Manual: ©axiom Tool Group, Inc. All Rights Reserved. Rev. 10/2019Document58 pagesAuto Route Pro+ B18 Manual: ©axiom Tool Group, Inc. All Rights Reserved. Rev. 10/2019francois xavier chizeNo ratings yet

- Rodillo JCB VMT 160Document14 pagesRodillo JCB VMT 160Noelia GarcíaNo ratings yet

- ITCC American Cataloge FinalDocument82 pagesITCC American Cataloge FinalzahirNo ratings yet

- Kamal Shaft PVT LTDDocument8 pagesKamal Shaft PVT LTDMayur LadwaNo ratings yet

- Design Analysis of Dually Operated Fish Feed PelleDocument6 pagesDesign Analysis of Dually Operated Fish Feed PellePalak AgarwalNo ratings yet

- DemagDocument1 pageDemagDhaval PanchalNo ratings yet

- ISO 7599 INTERNATIONAL STANDARD. Anodizing of Aluminium and Its Alloys General Specifications For Anodic Oxidation Coatings On AluminiumDocument28 pagesISO 7599 INTERNATIONAL STANDARD. Anodizing of Aluminium and Its Alloys General Specifications For Anodic Oxidation Coatings On Aluminium杜文欽No ratings yet

- SEC lugs connectors specificationDocument30 pagesSEC lugs connectors specificationMohamed NasrNo ratings yet

- Pre-Fabrication by Kanika JainDocument42 pagesPre-Fabrication by Kanika Jainkanika jainNo ratings yet

- Single FittingDocument11 pagesSingle FittingmontanovillarroelfabiolalourdeNo ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument19 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- CA02 ParchamentoJVMDocument6 pagesCA02 ParchamentoJVMJohnrey ParchamentoNo ratings yet

- Pannevis Brochure FinalDocument20 pagesPannevis Brochure FinalAnonymous XFK4lezBvNo ratings yet

- MASTER - Publications 15 PDFDocument1 pageMASTER - Publications 15 PDFgioNo ratings yet