100% found this document useful (3 votes)

9K views7 pagesMethod Statement Pull Out Test

This document provides a method statement for conducting a pull out test of a pendant system using a Hydrajaw pull out tester. It describes the tester equipment, installation procedure of anchors, and testing process. Anchors are installed into concrete then fitted with hexagon bolts and secured in the pull out tester jaws. Load is gradually applied and maintained for 1 minute to observe anchor movement before recording results. The objective is to determine anchor adequacy to support required tensile loads.

Uploaded by

intannaz2Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

9K views7 pagesMethod Statement Pull Out Test

This document provides a method statement for conducting a pull out test of a pendant system using a Hydrajaw pull out tester. It describes the tester equipment, installation procedure of anchors, and testing process. Anchors are installed into concrete then fitted with hexagon bolts and secured in the pull out tester jaws. Load is gradually applied and maintained for 1 minute to observe anchor movement before recording results. The objective is to determine anchor adequacy to support required tensile loads.

Uploaded by

intannaz2Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Name of Product: This section describes the specific product used in the test, highlighting its specifications and suitable applications.

- Installation Procedures: Provides detailed steps for the installation process of the anchors.

- Substrate Suitability: Defines the conditions under which the product can be effectively used on particular substrates.

- Features of Product: Highlights the features of the RSS Shield Anchor, emphasizing its design for specific mechanical purposes.

- Testing Apparatus: Lists the equipment required for executing the pull-out test safely and accurately.

- Testing Procedures: Outlines the procedural steps necessary to conduct the pull-out tests under specified conditions.

- Hydrajaw Pull Out Test Method Statement: Describes the purpose and usage of the Hydrajaw Pull-Out Tester for conducting tests effectively.

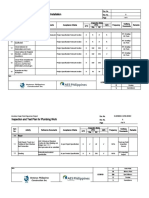

- Sample of Fixing Hexagon Head Bolt to Pull Out Tester: Demonstrates the process of securely fixing the hexagon head bolt used in the testing apparatus.

- Diagram of Test Equipment Setup: Illustrated guide showing the setup of the test equipment components and their configuration.

- Testing Procedures: Details the standardized general guidelines and procedural steps for conducting pull-out tests.