Professional Documents

Culture Documents

BBL - 3HP - Foot Motor Data Sheet

Uploaded by

S. R. Khare0 ratings0% found this document useful (0 votes)

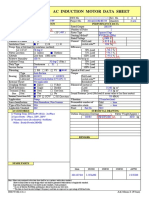

57 views1 pageThis document provides specifications for a 3 phase induction motor with the following key details:

- Manufacturer is Bharat Bijlee Ltd, it is a 2.2 kW, 4 pole motor designed for pump applications in hazardous areas classified as zone 1.

- The motor has an efficiency class of IE2, enclosure type is TEFC, and is suitable for continuous duty with ambient temperature up to 45°C.

- Additional accessories included are RTDs, BTDs, space heaters, and thermisters. The motor is designed to operate on VFD supply up to 5 kHz switching frequency.

Original Description:

BHARAT BIJALEE MOTOR DATA SHEET

Original Title

BBL_3HP_FOOT MOTOR DATA SHEET

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a 3 phase induction motor with the following key details:

- Manufacturer is Bharat Bijlee Ltd, it is a 2.2 kW, 4 pole motor designed for pump applications in hazardous areas classified as zone 1.

- The motor has an efficiency class of IE2, enclosure type is TEFC, and is suitable for continuous duty with ambient temperature up to 45°C.

- Additional accessories included are RTDs, BTDs, space heaters, and thermisters. The motor is designed to operate on VFD supply up to 5 kHz switching frequency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views1 pageBBL - 3HP - Foot Motor Data Sheet

Uploaded by

S. R. KhareThis document provides specifications for a 3 phase induction motor with the following key details:

- Manufacturer is Bharat Bijlee Ltd, it is a 2.2 kW, 4 pole motor designed for pump applications in hazardous areas classified as zone 1.

- The motor has an efficiency class of IE2, enclosure type is TEFC, and is suitable for continuous duty with ambient temperature up to 45°C.

- Additional accessories included are RTDs, BTDs, space heaters, and thermisters. The motor is designed to operate on VFD supply up to 5 kHz switching frequency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Data sheet for motors

Manufacturer Bharat Bijlee Ltd. Customer

Type of motor 3 Phase Induction Motor BBL Enquiry reference No

Quantity Customer P.O.Number

Application PUMP W.O. No. / SAP No.

Tag no. Output kW / pole 2.2 / 4P

BBL type tef. 2J10L473 Frame size MJ100

Installation details Applicable standards (latest edition)

Area classification (Safe / Hazardous) Hazardous Performance: IS/IEC 60034-1 Maintenance IS:900 FLP Motors: IS/IEC 60079-1

Location: indoor/outdoor/deck Indoor Dimensions: IS 1231/IS 2223/IS:8223 VFD FED MOTORS :

Altitude (meters) 1000 or less Vibrations: IS 12075 Application guide: IS 15880

Noise level: IS 12065 Specification : IS 15881

Hazardous area details Supply conditions and permissible variations (grid supply)

Area classification GAS (Zone 1/Zone 2) ZONE I Number of phases Three

Gas group IIA, IIB Voltage (Volts) and permisible variation 415 ±10%

Temp.class T5 Frequency (Hz) and permissible variation 50 ±5%

Type of Explosion protection (FLP/Type

Ex d Combined variation (absolute sum) ±10%

'e'/Type 'n')

Approving authority for hazardous area PESO

Electrical parameters

Starting performance

Method of starting VFD Starting current (%FLC) 600

Load speed (rpm) CUSTOMER TO FURNISH Starting torque (%FLT) 260

Motor GD2 (kgm2) 0.0211 Pull out torque (%FLT) 300

Load GD2(kgm2) CUSTOMER TO FURNISH Locked rotor withstand time (hot/cold) (sec) 15 / 30

Parabolic TS curve Number of consecutive starts (hot/cold) (nos.) 2/3

Load torque-speed curve

provided Load GD2 = Motor GD2

PLEASE FURNISH ALL ABOVE

Starting time at rated voltage (sec)

DETAILS

Running Performance

Efficiency class IE2 Duty and designation Continuous (S1)

Ambient temp./temp.rise by resistance (deg.C) 45 / 75 CDF/Equivalent starts per hour/FI -

TEFC (TOTALLY ENCLOSED FAN

Enclosure Insulation class / utilisation class on DOL F/B

COOLED)

Full load current (FLC) amps. 4.37 Rotor type (Squirrel Cage/ Slip ring ) Squirrel Cage

Full load speed (rpm) 1425 Rotor voltage/rotor current (RV/RA) (Volts/Amps) Not applicable

Full load torque (FLT) kg-m 1.5 Stator/rotor time constant (min) 108/146

Efficiency in % at FL/0.75FL/0.5FL 84.3 84.3 82.5 Power factor at FL/0.75FL/0.5FL 0.83 0.74 0.60

Mechanical parameters

Mounting B3 Mounting dimensions Refer GA drawing

Shaft extention Single cylindrical Direction of rotation viewed from DE Clockwise

Degree of protection IP 55 Suitable for bidirectional rotation Yes

Method of cooling (TEFC/forced cooled/TESC) TEFC (IC 411) Paint type Acid Alkali Proof

Net weight of motor (kgs.) 62 Paint shade 632 as per IS 5

Earthing provision (two terminals on stator body) Yes

Bearings Terminal box

Coupling (Direct/flexible/Belt &

Direct Terminal box location when viewed from DE As per GA drawing

Pulley/Gearbox)

Dimenssions of pulley (OD x width) mm - Direction of cable entry As per GA drawing

Bearings (roller/ball/angular contact) Ball /Ball Cable size and type(Aluminium) 1R X 3C X 2.5SQ MM

Bearing size DE/NDE 6206 2Z C3 / 6206 2Z C3 Earthing provision (one terminal in TB) Yes

Type of lubrication No of phases/Winding connection/number of 3 / STAR / 6

LITHIUM SOAP BASE GREASE

terminals

Accessories

RTDs - 3 numbers simplex (w/o controller) Arrow plate for direction of rotation YES

BTDs - 1 number per bearing (w/o controller) Double compression glands (main cable) YES

Space heaters - single phase 50z, 230V Double compression glands (Space YES

heater/thermisters/RTDs)

Thermisters - PTC , 1 number per phase YES Brake (Type/voltage/torque)

Additional T-Box for Accessories YES

Additional nameplate

Notes:

1)All performance values are subject to IS/IEC 60034-1 tolerances, unless otherwise specified.

2) Motor is suitable for Stress category B as per IEC 60034-18-41

3)Performance values are at rated voltage and rated frequency condition and for DOL starting condition.

4)Motor GD2 = Load GD2 assumed wherever not mentioned.

5)Where starting time is more than 10 seconds, provision of heavy duty relays is mandatory.

6)Kilowatt rating is mandatory and HP is approximate.

7) Accessories provided are marked as "YES"

Notes for motors run on VFD supply

1) Motors suitable to run on VFD supply are designed with an insulation system suitable for withstanding voltage of 1.56 kV (peak phase to phase) and rise time > = 0.1 micro

sec. (for motors with rated voltage up to 415V).

2) The customer/ his system integrator have to ensure that the voltage does not exceed above limit by properly selecting cable length preferably 5 to 10 meters long. For higher

cable lengths, dv/dt filters or sine filters may be required

3) Switching frequency should not exceed 5.0 kHz. Prepared by

4)For constant torque application, voltage boost is necessary for frequencies <= 17Hz. Approved by

Revison

Project: Contractor/Client Date:

Consultant Package

You might also like

- 15 KWDocument3 pages15 KWdesign revacranesNo ratings yet

- DS 132KWDocument1 pageDS 132KWRavi Shankar ChakravortyNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagarsmrutiranjan mohapatraNo ratings yet

- Folha de Dados MOTORESDocument1 pageFolha de Dados MOTORESpedro.inacioNo ratings yet

- 30ke4 2cglstdie22900Document1 page30ke4 2cglstdie22900RBS GROUP ENQUIRIESNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- 7.5 KW 2P B5 FLP Ie2 DS and CurvesDocument4 pages7.5 KW 2P B5 FLP Ie2 DS and Curvesim4uokkNo ratings yet

- DS DPM 21000393 000Document6 pagesDS DPM 21000393 000Rahesh MNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument2 pagesAc Induction Motor Data Sheet: General Specification Performance DataArjun SomaiyaNo ratings yet

- BC 02B - Drawing Dan Data Sheet 75 KW, 4P, B3Document2 pagesBC 02B - Drawing Dan Data Sheet 75 KW, 4P, B3Mauna TunisaNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument7 pagesAc Induction Motor Data Sheet: General Specification Performance DataMayur Gupta0% (1)

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument2 pagesAc Induction Motor Data Sheet: General Specification Performance DataBhavik PrajapatiNo ratings yet

- Mechanical Past Year PaperDocument7 pagesMechanical Past Year PaperKriti PatelNo ratings yet

- CEP Motor Data Sheet - Rev-06Document8 pagesCEP Motor Data Sheet - Rev-06AMIT BISWASNo ratings yet

- ht500 12rrr 5811rbDocument3 pagesht500 12rrr 5811rbعلي عبد الحكيم المردعيNo ratings yet

- 380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)Document3 pages380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)chris110No ratings yet

- Motor Data For 22942Document1 pageMotor Data For 22942zo-kaNo ratings yet

- CG Power and Industrial Solutions Limited: Page 1 of 1 Page 1 of 1Document1 pageCG Power and Industrial Solutions Limited: Page 1 of 1 Page 1 of 1prasadNo ratings yet

- S4030 600F111001FVDocument290 pagesS4030 600F111001FVШибко ЯрикNo ratings yet

- Motor 63kw Saponificación ABBDocument15 pagesMotor 63kw Saponificación ABBarguri2006No ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- M3BP315MLB6 110KW PDFDocument1 pageM3BP315MLB6 110KW PDFPablo CorreaNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- Data-Sheet Curves - 500KW - Brahmani DamDocument7 pagesData-Sheet Curves - 500KW - Brahmani DammanishabariyaNo ratings yet

- ABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksDocument8 pagesABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksIngenieria DyconNo ratings yet

- Technical Data Sheet-DOL - SubmitDocument1 pageTechnical Data Sheet-DOL - Submithar singkawangNo ratings yet

- ABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDocument1 pageABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit Remarksarash esmaeiliNo ratings yet

- GP16TGDocument2 pagesGP16TGharry sosaNo ratings yet

- Motor Data Sheet 1.5 KW 4 PoleDocument1 pageMotor Data Sheet 1.5 KW 4 Poleganeshengineering2007No ratings yet

- Datasheet M3BP315SMC6Document3 pagesDatasheet M3BP315SMC6Purchasing StanindoNo ratings yet

- Motor Data For 131038 PDFDocument1 pageMotor Data For 131038 PDFMashudi FikriNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 Pravi kumarNo ratings yet

- Specification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014Document16 pagesSpecification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014aqweqeqweNo ratings yet

- 160L-4 15kW 400V 60Hz B3 DatasheetDocument2 pages160L-4 15kW 400V 60Hz B3 DatasheetTareq JildehNo ratings yet

- ID Fan Motor Data Sheet, Rev. 1Document8 pagesID Fan Motor Data Sheet, Rev. 1Suman GhoshNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- LIW Final DatasheetDocument1 pageLIW Final Datasheetparth sapariaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4jitendra patelNo ratings yet

- Data Sheet DolDocument3 pagesData Sheet DolJuan Alberto Cayetano GomezNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument3 pages(cm3) (MM) (MM) (KG) (°C) : Compressor Applicationأبو زينب المهندسNo ratings yet

- Abb Data Sheet 37 KW (Rev.01) PDFDocument4 pagesAbb Data Sheet 37 KW (Rev.01) PDFAviz Gumaya IINo ratings yet

- BC 01A - Drawing Dan Data Sheet 37 KW 4P B3Document2 pagesBC 01A - Drawing Dan Data Sheet 37 KW 4P B3Mauna TunisaNo ratings yet

- Ficha Técnica Motor TechtopDocument1 pageFicha Técnica Motor TechtopLUISA FERNANDA SALDARRIAGA VASCONo ratings yet

- 45KW 4P DatasheetDocument5 pages45KW 4P Datasheetvitthal01No ratings yet

- BC 07B - Drawing Dan Data Sheet 15 KW, 4P, B5Document2 pagesBC 07B - Drawing Dan Data Sheet 15 KW, 4P, B5Mauna TunisaNo ratings yet

- Datasheet 22kW PDFDocument3 pagesDatasheet 22kW PDFMuhammad AgengNo ratings yet

- 01 KFR-25GW-NA13 Service ManualDocument36 pages01 KFR-25GW-NA13 Service ManualtaryoNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- ABB Motor Data RHDocument3 pagesABB Motor Data RHschetgillermo02No ratings yet

- KPX K12PDocument5 pagesKPX K12PDerek ChenNo ratings yet

- Motor Data For 35094Document1 pageMotor Data For 35094zo-kaNo ratings yet

- ABB Motors and Generators Technical Data Sheet - DOL: No. Data Unit RemarksDocument9 pagesABB Motors and Generators Technical Data Sheet - DOL: No. Data Unit RemarksArgenis UlloaNo ratings yet

- 1LE1002-1CA13-4FA4 Datasheet enDocument1 page1LE1002-1CA13-4FA4 Datasheet enmaciejNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- A New Mathematical Model and Control of A Three-Phase AC-DC Voltage Source ConverterDocument8 pagesA New Mathematical Model and Control of A Three-Phase AC-DC Voltage Source ConverterVenktesh MishraNo ratings yet

- Advanced DWDM TrainingDocument144 pagesAdvanced DWDM TrainingCarlosNo ratings yet

- Owner's ManualDocument32 pagesOwner's ManualAlexis De FuegoNo ratings yet

- GE 1x F Series Installation ManualDocument100 pagesGE 1x F Series Installation ManualSelwinNo ratings yet

- Hydrostatic SensorDocument11 pagesHydrostatic SensorASTERIXNo ratings yet

- Data Sheet Mosfet STD17NF03LDocument11 pagesData Sheet Mosfet STD17NF03LdouglasNo ratings yet

- Regulation - 2010: K.S.Rangasamy College of Technology, Tiruchengode - 637 215Document3 pagesRegulation - 2010: K.S.Rangasamy College of Technology, Tiruchengode - 637 215Latta SakthyyNo ratings yet

- SmartModule2 GuideDocument2 pagesSmartModule2 GuideRyan BandaNo ratings yet

- MSRX Polycarbonate Enclosure Charge Controller: Product ManualDocument25 pagesMSRX Polycarbonate Enclosure Charge Controller: Product ManualGESELL CABEZASNo ratings yet

- Building A Bicycle Generator PDFDocument5 pagesBuilding A Bicycle Generator PDFryanNo ratings yet

- Technical Guide Abb MotorDocument38 pagesTechnical Guide Abb Motorvadi_hatwar100% (7)

- DENT 3563: Telecommunication EngineeringDocument38 pagesDENT 3563: Telecommunication EngineeringSanji KarunaNo ratings yet

- 2019 Walmart Inc V Tesla Energy Operations Inc Summons Complaint 1Document114 pages2019 Walmart Inc V Tesla Energy Operations Inc Summons Complaint 1Graham50% (2)

- Solar Cell Losses and Design: Arno SmetsDocument17 pagesSolar Cell Losses and Design: Arno SmetsGianmarco PeñaNo ratings yet

- WEJLOK Wedge Connector: Features and BenefitsDocument1 pageWEJLOK Wedge Connector: Features and BenefitsVictor DoyoganNo ratings yet

- SeminarDocument22 pagesSeminarziyam mukadamNo ratings yet

- QuickdrawDocument32 pagesQuickdrawNoe JimenezNo ratings yet

- Decibel NotationDocument7 pagesDecibel NotationRyan Anthony AndalNo ratings yet

- AMT Pangaea U2 User Manual ENG (v.1)Document4 pagesAMT Pangaea U2 User Manual ENG (v.1)올돌이아빠No ratings yet

- Equipotenciales Phywe 13029.88Document2 pagesEquipotenciales Phywe 13029.88JonhGonzálezNo ratings yet

- BQ Barrier GateDocument2 pagesBQ Barrier GatenanubmatNo ratings yet

- Signal Integrity - LeventhalDocument110 pagesSignal Integrity - Leventhaldtprotest01No ratings yet

- Lexus rx400h - Hybrid - 2007Document27 pagesLexus rx400h - Hybrid - 2007dodofreddNo ratings yet

- Special CelllsDocument14 pagesSpecial Celllspdnoob100% (4)

- STI-College Global City Senior High SchoolDocument35 pagesSTI-College Global City Senior High SchoolHannagen SabanganNo ratings yet

- Sungrow SG10.0RT Datasheet ENDocument2 pagesSungrow SG10.0RT Datasheet ENnofal aliNo ratings yet

- Mcguire Nuclear Station Ufsar Chapter 8Document70 pagesMcguire Nuclear Station Ufsar Chapter 8Nathan BlockNo ratings yet

- Application Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveDocument3 pagesApplication Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveMiguel Angel Cortes PrietoNo ratings yet

- 1.5KE Series 1N6267 A 1N6303A - Vishay (TransZorb Transiente Voltage Suppressors)Document7 pages1.5KE Series 1N6267 A 1N6303A - Vishay (TransZorb Transiente Voltage Suppressors)Rubio Marra da SilvaNo ratings yet

- DELTA - IA-MDS - VFD-EL - C - EN - 20210420 MICRO DriveDocument12 pagesDELTA - IA-MDS - VFD-EL - C - EN - 20210420 MICRO DriveJulian Ruiz SalazarNo ratings yet