Professional Documents

Culture Documents

15 KW

Uploaded by

design revacranes0 ratings0% found this document useful (0 votes)

18 views3 pagesOriginal Title

15kw

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views3 pages15 KW

Uploaded by

design revacranesCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

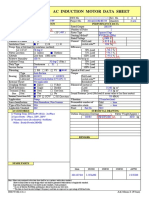

Data sheet for motors

Manufacturer M/s. Bharat Bijlee Ltd. Customer M/s. BRANDCO

Type of motor 3 phase Induction Motor W.O. No. / SAP No. - / 152515/80

Quantity 5 Revision R0

Application CUSTOMER TO FURNISH BBL Enquiry reference No -

Tag no. - Output kW / Pole 15 / 4

BBL type tef. Frame size 160L

Installation details Applicable standards (latest edition)

Area classification (safe / hazardous) Industrial safe area Performance: IS/IEC 60034-1 Maintenance IS:900

Location: indoor/outdoor/deck Indoor Dimensions: IS 1231/IS 2223/IS:8223

Altitude (meters) 1000 or less Vibrations: IS 12075

Noise level: IS 12065

Hazardous area details Supply conditions and permissible variations (grid supply)

Area classification GAS (Zone 1/Zone 2) N.A. Number of phases Three

Gas group N.A. Voltage (volts) and permisible variation 415 ±10%

Temp.class N.A. Frequency (hz) and permissible variation 50 ±5%

Type of Explosion protection (FLP/Type 'e'/Type 'n') N.A. Combined variation (absolute sum) ±10%

Approving authority for hazardous area N.A.

Electrical parameters

Starting performance

Method of starting DOL Starting current (%FLC) 650

Load speed (rpm) 1440 Starting torque (%FLT) 225

Motor GD2 (kgm2) 0.193 Pull out torque (%FLT) 280

Load GD 2 (kgm2) 0.193 Locked rotor withstand time (hot/cold) (sec) 8 / 16

Load torque-speed curve Variable torque

Starting time at rated voltage (sec) 1.00

Running Performance

Efficiency class - Duty and designation S4

Ambient temp./temp.rise by resistance (deg.C) 45 / 75 CDF/Equivalent starts per hour/FI 40% / 150

TEFC (TOTALLY ENCLOSED

Enclosure Insulation class / utilisation class on DOL F/B

FAN COOLED)

Full load current (FLC) amps. 30.7 Rotor type (SCR/SR) SCR

Full load speed (rpm) 1440 Rotor voltage/rotor current (RV/RA) (Volts/Amps) Not applicable

Full load torque (FLT) kg-m 10.15 Stator/rotor time constant (min) 72/97

Efficiency in % at FL 86.0 Power factor at FL 0.79

Mechanical parameters

Mounting B5 Mounting dimensions Refer GA drawing

Shaft extention STD DOUBLE EXTN. Direction of rotation viewed from DE Clockwise

Degree of protection IP 55 Suitable for bidirectional rotation Yes

Method of cooling (TEFC/forced cooled/TESC) TEFC (IC 411) Paint type Acrylic

Net weight of motor (kg) 101 Paint shade RAL 5000

110 Earthing provision (two terminals on stator body) Yes

Bearings Terminal box

Coupling (Direct/flexible/Belt & Pulley/Gearbox) Direct Terminal box location when viewed from DE As per GA drawing

Dimenssions of pulley (OD x width) mm - Direction of cable entry As per GA drawing

Bearings (roller/ball/angular contact) Ball /Ball Cable size and type(Aluminium) As per GA drawing

Bearing size DE/NDE 6309 2Z C3/6209 2Z C3 Earthing provision (one terminal in TB) Yes

Type of lubrication GREASE/UNIREX N3-ESSO. No of phase/Winding connection/number of terminals 3 / DELTA / 6

Accessories provided

RTDs - 3 numbers simplex(w/o controller) - Arrow plate for direction of rotation -

BTDs - 1 number per bearing(w/o controller) - FLP cable sealing box for gas group I -

Space heaters - single phase 50z, 230V - FLP plug and socket -

Thermisters - PTC , 1 number per phase - Double compression glands (main cable) -

Additional nameplate - Double compression glands (Space heater/Thermisters/RTDs) -

Brake (Type/voltage/torque) -

Notes:

1) All performance values are subject to IS/IEC 60034-1 tolerances, unless otherwise specified.

2) Performance values are at rated voltage and rated frequency condition and for DOL starting condition.

3) Motor GD2 = Load GD2 assumed wherever not mentioned.

4) Where starting time is more than 10 seconds, provision of heavy duty relays is mandatory.

5) Kilowatt rating is mandatory and HP is approximate.

6) Accessories provided are marked as "YES"

7) Motors suitable to run on VFD supply are designed with an insulation system suitable for withstanding voltage of 1.56 kV (peak

Prepared

phase to phase ) rise time > = 0.5 micro sec. for motors with rated voltage upto 415V. The customer/ his system integrator has to SUS

by

ensure that voltage does not exceed this limit. For constant torque application, voltage boost is necessary for frequencies <= 10Hz.

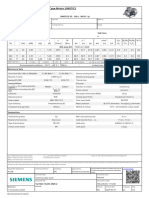

DRG. NAME.- SPEED Vs T0RQUE & CURRENT CHARACTERISTICS

SPEED Vs T0RQUE & CURRENT CHARACTERISTICS

CUSTOMER : M/s. BRANDCO

SAP NO: 152515/80

kW: 15 POLE : 4 VOLTS : 415 QTY : 5

650

600

550

500

450 CURRENT SPEED CHAR AT 100% VOLTAGE

F

U

L CURRENT SPEED CHART AT 80% VOLTAGE

L

400

T Vs N at 100% V

L

O 350

A T Vs N at 80% V

D

T 300

O

R

Q

U

E 250

&

C 200

U

R

R

E

N 150

T

100

50

0

0 10 20 30 40 50 60 70 80 90 100

% SYNCHRONUS SPEED

PREP APPD DATE

SUS DHB 28.02.2015

REVISION R0 SIGN

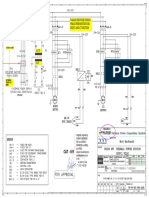

DRG. NAME.-

STARTING CURRENT VS STARTING TIME AND THERMAL WITHSTAND TIME.

CUSTOMER: M/s. BRANDCO

SAP NO: 152515/80

kW : 15 POLE : 4 VOLTS : 415 QTY : 5

10000

tst AT 80%V TWT-HOT

TWT-COLD tst AT 100%V

1000

100

THERMAL WITHSTAND

TIME (sec)

10

0.1

0 50 100 150 200 250 300 350 400 450 500 550 600 650

% FULL LOAD CURRENT

L. R.CURRENT at 100% voltage : 650 % OF FLA THERMAL WITHSTAND TIME(sec):

Starting time at 100% voltage= 1 sec AT100% RATED VOLTAGE (HOT) : 8

Starting time at 80% voltage= 2 sec AT100% RATED VOLTAGE (COLD): 16

PREP APPD DATE

SUS DHB 28.02.2015

REVISION R0 SIGN

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BBL - 3HP - Foot Motor Data SheetDocument1 pageBBL - 3HP - Foot Motor Data SheetS. R. KhareNo ratings yet

- Folha de Dados MOTORESDocument1 pageFolha de Dados MOTORESpedro.inacioNo ratings yet

- DS 132KWDocument1 pageDS 132KWRavi Shankar ChakravortyNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument2 pagesAc Induction Motor Data Sheet: General Specification Performance DataArjun SomaiyaNo ratings yet

- Motor 63kw Saponificación ABBDocument15 pagesMotor 63kw Saponificación ABBarguri2006No ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- ABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksDocument8 pagesABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksIngenieria DyconNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument2 pagesAc Induction Motor Data Sheet: General Specification Performance DataBhavik PrajapatiNo ratings yet

- DS DPM 21000393 000Document6 pagesDS DPM 21000393 000Rahesh MNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- 30ke4 2cglstdie22900Document1 page30ke4 2cglstdie22900RBS GROUP ENQUIRIESNo ratings yet

- BC 02B - Drawing Dan Data Sheet 75 KW, 4P, B3Document2 pagesBC 02B - Drawing Dan Data Sheet 75 KW, 4P, B3Mauna TunisaNo ratings yet

- 7.5 KW 2P B5 FLP Ie2 DS and CurvesDocument4 pages7.5 KW 2P B5 FLP Ie2 DS and Curvesim4uokkNo ratings yet

- CG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorDocument1 pageCG Power and Industrial Solutions Limited: Data Sheet of 3 Phase Induction MotorprasadNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- CG Power and Industrial Solutions Limited: Page 1 of 1 Page 1 of 1Document1 pageCG Power and Industrial Solutions Limited: Page 1 of 1 Page 1 of 1prasadNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 Pravi kumarNo ratings yet

- ht500 12rrr 5811rbDocument3 pagesht500 12rrr 5811rbعلي عبد الحكيم المردعيNo ratings yet

- Motor Data Sheet 1.5 KW 4 PoleDocument1 pageMotor Data Sheet 1.5 KW 4 Poleganeshengineering2007No ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagarsmrutiranjan mohapatraNo ratings yet

- Mechanical Past Year PaperDocument7 pagesMechanical Past Year PaperKriti PatelNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument7 pagesAc Induction Motor Data Sheet: General Specification Performance DataMayur Gupta0% (1)

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- KPX K12PDocument5 pagesKPX K12PDerek ChenNo ratings yet

- ABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDocument1 pageABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit Remarksarash esmaeiliNo ratings yet

- Datasheet M3BP315SMC6Document3 pagesDatasheet M3BP315SMC6Purchasing StanindoNo ratings yet

- FG Wilson 15 kVA SpecsheetDocument2 pagesFG Wilson 15 kVA SpecsheetRutvik HegdeNo ratings yet

- 380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)Document3 pages380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)chris110No ratings yet

- 1LE7503-3AB23-4AA4-Z L53 Datasheet enDocument2 pages1LE7503-3AB23-4AA4-Z L53 Datasheet enjoy baruaNo ratings yet

- M3BP315MLB6 110KW PDFDocument1 pageM3BP315MLB6 110KW PDFPablo CorreaNo ratings yet

- Data Sheet: Flameproof Induction MotorDocument2 pagesData Sheet: Flameproof Induction Motorpradeep tangiralaNo ratings yet

- 37kW, 4P, IMB3, Brake Motor DatasheetDocument1 page37kW, 4P, IMB3, Brake Motor DatasheetsyamprasadNo ratings yet

- Data-Sheet Curves - 500KW - Brahmani DamDocument7 pagesData-Sheet Curves - 500KW - Brahmani DammanishabariyaNo ratings yet

- S4030 600F111001FVDocument290 pagesS4030 600F111001FVШибко ЯрикNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- Copeland CR22K6E PFV 875 Submittal SheetDocument3 pagesCopeland CR22K6E PFV 875 Submittal SheetDraganNo ratings yet

- Specification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014Document16 pagesSpecification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014aqweqeqweNo ratings yet

- 1LE7501 0DB22 3AA4 Datasheet enDocument1 page1LE7501 0DB22 3AA4 Datasheet enDNo ratings yet

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- SA12A90 - F10 Data Sheet On-OffDocument1 pageSA12A90 - F10 Data Sheet On-Offanbarasan100% (1)

- Motor datasheets-LV (ABB)Document9 pagesMotor datasheets-LV (ABB)Sandeep PartiNo ratings yet

- CEP Motor Data Sheet - Rev-06Document8 pagesCEP Motor Data Sheet - Rev-06AMIT BISWASNo ratings yet

- 1LE7501-2AB53-5AA4 Datasheet enDocument1 page1LE7501-2AB53-5AA4 Datasheet enTusharNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PSHYAM SHARMANo ratings yet

- 1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enDocument2 pages1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enTien NguyenNo ratings yet

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- DatasheetDocument1 pageDatasheetPioneer Fluid SolutionsNo ratings yet

- 160L-4 15kW 400V 60Hz B3 DatasheetDocument2 pages160L-4 15kW 400V 60Hz B3 DatasheetTareq JildehNo ratings yet

- 1LE7501-2AB53-5DA4 Datasheet enDocument1 page1LE7501-2AB53-5DA4 Datasheet enersanjeeb_456No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4jitendra patelNo ratings yet

- KP-9P (YD380D) Generating Set Technical Data SheetDocument5 pagesKP-9P (YD380D) Generating Set Technical Data SheetKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- EL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018Document2 pagesEL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018mafevalle4201No ratings yet

- ABB Motors and Generators Technical Data Sheet - DOL: No. Data Unit RemarksDocument6 pagesABB Motors and Generators Technical Data Sheet - DOL: No. Data Unit RemarksIvan Lim PLNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3282B Simotics SD - 280M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3282B Simotics SD - 280M - Im B3 - 4 Pravi kumarNo ratings yet

- Elect ReportDocument1 pageElect Reportdesign revacranesNo ratings yet

- Approved Approved Cat I Cat - IiDocument7 pagesApproved Approved Cat I Cat - Iidesign revacranesNo ratings yet

- Vendor List - NTPCDocument6 pagesVendor List - NTPCdesign revacranesNo ratings yet

- Brochure ProductsDocument14 pagesBrochure Productsdesign revacranesNo ratings yet

- 3076 Hand ChainDocument15 pages3076 Hand Chaindesign revacranesNo ratings yet

- Ipe SectionsDocument1 pageIpe Sectionsdesign revacranesNo ratings yet

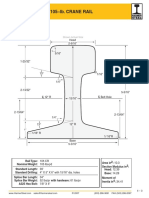

- IRS-52 RailDocument2 pagesIRS-52 Raildesign revacranesNo ratings yet

- 807A1 2014 Latest As On May 2018Document2 pages807A1 2014 Latest As On May 2018design revacranesNo ratings yet

- Motor EfficiencyDocument12 pagesMotor Efficiencydesign revacranesNo ratings yet

- 105-lb. CRANE RAIL: Head 2-9/16"Document1 page105-lb. CRANE RAIL: Head 2-9/16"design revacranesNo ratings yet

- 036 Siga-UmDocument6 pages036 Siga-UmzezohomeNo ratings yet

- The Chattering Problem in Sliding Mode SystemsDocument8 pagesThe Chattering Problem in Sliding Mode SystemsBhaskar BiswasNo ratings yet

- January 2015 (IAL) MS - Unit 3 Edexcel Physics A-LevelDocument10 pagesJanuary 2015 (IAL) MS - Unit 3 Edexcel Physics A-LevelDaianna PeirisNo ratings yet

- Data Minggu 4Document876 pagesData Minggu 4Gh4n113 IdNo ratings yet

- Duropal Worktop Collection UK & Ireland 2021-2024Document19 pagesDuropal Worktop Collection UK & Ireland 2021-2024VivanNo ratings yet

- Lalmonirhat Social Services Office - 26 - 09 - 19 - LegendDocument1 pageLalmonirhat Social Services Office - 26 - 09 - 19 - LegendTauhid RahmanNo ratings yet

- Earthquake Design Presentation (M.sleiman)Document20 pagesEarthquake Design Presentation (M.sleiman)JunnoKaiserNo ratings yet

- FTM-3100R: Operating ManualDocument36 pagesFTM-3100R: Operating ManualMarcos Chiorato100% (1)

- Lab Open Ended Dry Sieve AnalysisDocument9 pagesLab Open Ended Dry Sieve Analysiskhairul hisyamNo ratings yet

- Draft SOP For Usage of Tree PrunerDocument2 pagesDraft SOP For Usage of Tree PrunerAkhilesh Kumar Singh100% (1)

- HBN PVC Free Alternatives ChartDocument24 pagesHBN PVC Free Alternatives ChartaggibudimanNo ratings yet

- Venkataraman RDocument2 pagesVenkataraman RVenkat RamanNo ratings yet

- The CPL Exams: CHUF - CPL Human Factors ExaminationDocument5 pagesThe CPL Exams: CHUF - CPL Human Factors Examinationgreg mNo ratings yet

- Gas Turbine Functional DescriptionDocument20 pagesGas Turbine Functional Descriptioncbmanaus100% (1)

- Inventory Database - All Parts Inc (8/20/20)Document2,835 pagesInventory Database - All Parts Inc (8/20/20)All Parts Inc.No ratings yet

- Flocculation and ClarifiersDocument17 pagesFlocculation and ClarifiersOnelNo ratings yet

- Vtu HR Project On Employee Job Satisfaction.Document70 pagesVtu HR Project On Employee Job Satisfaction.Naveen Babu DNo ratings yet

- Display Nec NL6448BC33 74 PreDocument30 pagesDisplay Nec NL6448BC33 74 PrehenryvyperNo ratings yet

- Bill of Materials Computation SheetDocument45 pagesBill of Materials Computation SheetNicole RodilNo ratings yet

- Flash 8Document75 pagesFlash 8rickoNo ratings yet

- JUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Document44 pagesJUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Juan Alberto RomeroNo ratings yet

- Catalog RAFI Components 2015Document663 pagesCatalog RAFI Components 2015Amd Mamd100% (1)

- Maglev Trains: Trains That Fly On AirDocument21 pagesMaglev Trains: Trains That Fly On AirkudupudinageshNo ratings yet

- MCC Landscape Pre Commencement and Construction Hold PointsDocument3 pagesMCC Landscape Pre Commencement and Construction Hold PointsBillyNo ratings yet

- Final ProjectDocument90 pagesFinal ProjectPreet KaurNo ratings yet

- Porosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering ADocument7 pagesPorosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering AgiokniessNo ratings yet

- SAP BI BO Presentation TorrentDocument36 pagesSAP BI BO Presentation TorrentRajab Ali Jiwani100% (1)

- Airport Practice Note 9 - Wildlife Hazard Management at AirportsDocument96 pagesAirport Practice Note 9 - Wildlife Hazard Management at AirportsexpairtiseNo ratings yet

- Simoco TSF2000Document2 pagesSimoco TSF2000Paolo UssiNo ratings yet

- Chapter 17 Product RecoveryDocument2 pagesChapter 17 Product RecoveryCarlos Miguel DacaimatNo ratings yet