Professional Documents

Culture Documents

Stiff 1951

Uploaded by

Brenda RoblesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stiff 1951

Uploaded by

Brenda RoblesCopyright:

Available Formats

THE INTERPRETATION OF CHEMICAL WATER ANALYSIS BY MEANS

OF PATTERNS

HENRY A. STIFF, JR., MEMBER AIME, ATLANTIC REFINING CO., DALLAS, TEX.

ABSTRACT of dilution or concentration has been reduced to a minimum,

and at the same time distinction between various types of

The classification and correlation of water analysis data

water has been improved. The system is extremely versatile,

presents many problems which can be solved by graphic

yet so simple it can be plotted on ordinary graph paper and

methons. The pattern system, a new type of graphic proce-

adapted to almost any type of filing system.

dure described in this communication, is believed to have

several advantages over older methods. Examples of the appli-

cation of the pattern system to the solution of problems DISCUSSION

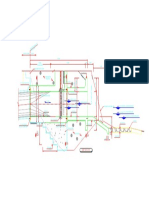

encountered in petroleum production are given. The essential feature of the pattern system is the graph

shown in Fig. L Horizontal lines extending right and left

from a vertical line at zero form the graph. Positive ions are

INTRODUCTION

plotted to the left while negative ions are plotted to the right.

Several graphic methods for presenting analytical water The figure immediately beneath each ion gives the scale. Most

data have been developed and are now in use.""'" It is be- oil field waters can be plotted on a scale where 100 milli-

lieved, however, that a recently developed type of graph equivalents of sodium and chloride and 10 milliequivalents

called the "pattern" offers several advantages over other of each of the other ions are represented by one scale unit.

methods. This system presents a better picture of the total For highly concentrated brines, 1,000 milliequivalents of so-

salt concentration than is usual in such graphs. The effect dium and chloride and 100 milliequivalents of each of the

376 PETROLEUM TRANSACTIONS, AIME Vol. 192, 1951

other ions are represented by' one unit. For convenience

1~'V

sodium, potassium, lithium, etc., ordinarily determined as the

difference between the positive and negative ions, are referred

to as sodium.

It will be noted that the chemical unit of "milliequivalents FRESH WATER SEA WATER OIL FIELD WATER. (WHITMER)

NEALE FIELD. LOUISIANA

per liter" is employed. If the results of the analysis are in

parts per million, they can be readily converted by dividing

by the equivalent weight in milligrams or multiplying by its

reciprocal. Appropriate conversion factors can be found in

standard chemical handbooks:

When the points have been properly placed on the graph,

\I>

OIL FIELD WATER. (PALUXY)

SULPHUR BLUfF FIELD, TEX.

~~~~~o,

they are connected by lines as shown in Fig. 2, thus forming

a closed "pattern." These patterns present a variety of shape£ 10

Mg

10

10

504

10

P

rr,:1::

Fe C03

OIL FIELD WATER 10 10 Oil FIELD WATER.

l' ,::r:~:'

(ARBUCKLE) (LOMA NOVA)

SCALE (MEG. PER LITER)

BLOOMER FIELD SEVEN SISTERS FIELD.

KANSAS TEXAS

10

'1: ::: j: :' '1: :' : 10

FIG. 3 - COMMON WATER PATTERNS.

SCALE (MEQ. PER LITER) ordinary graph paper. The use of a printed card contammg

a graph similar to that shown in Fig. 1, and in addition blank

. _ - - - - - - - - - _.... 8paces for pertinent well data, is very convenient for this

work. By this means a large and very useful library of pat-

FIG. 1 - ESSENTIAL FEATURE OF THE PATTERN ANALYSIS SYSTEM.

terns can be built up in a small space.

APPLICATION

N. C1

100 100 The applications of the pattern system are many and varied.

c.

10

HCO

10

It is believed that this system will facilitate the solution of

M< so. .- j-- ---- ... almost any problem in which water analysis is a factor. The

10 10

fe co following examples illustrate its application to various prob-

10 10 lems encountered in petroleuin production.

--

I--- t-- .-

Na C1 Correlation of Producing Formations

100 100

Ca

10

V / HCO

10

Since the pattern tends to maintain its shape upon concen-

Mt.

10

~ \ 10

so, tration or dilution, a formation may be expected to yield

V

'"

Fe CO,

water of a characteristic pattern. A study of the water pat-

10 10 terns can, in many cases, be utilized to identify different pro-

I ducing strata and correlate them in a given locality. In Kan-

FIG. 2 - METHOD OF CONSTRUCTING A PATTERN.

sas, for example, the Arbuckle group of the Ordovician period

can be traced from Ellsworth County down through Barton

and sizes, each easily recognized and remembered and each County and into Stafford County by means of water patterns.

characteristic of a certain water. Fig. 4 shows patterns from Stoltenberg Field (Ellsworth

Fig. 3 shows some common water patterns, including those County), Bloomer Field (Barton County), and Drach and

of fresh water, sea water, chemical solutions and oil field St. John's Fields (Stafford County). The characteristic pat-

brines. The straight line pattern of fresh water shown in the tern of the Arbuckle formation can be easily followed.

first diagram results from the use of a scale ordinarily em-

ployed for oil field brines. Any system of scales thought suit-

able to a particular operation may be used. Single scales, in

which all ions are represented by an equal number of units,

are used in plotting fresh waters, while multiple scales, in

which all ions are not represented by the same number of

units, find application in work with oil field waters. Various

types of multiple scales can be used to advantage in water

treatment work, corrosion control, and injection water studies.

One of the distinctive features of the system is the tendency

of the pattern to maintain its characteristic shape as the sample

becomes dilute. In this way the total salt concentration as

well as the chemical composition of the water is shown by

the pattern.

The availability of various scales makes it possible to select

one which emphasizes the differences and similarities of the

ST. ,JOHN FIELD DRACH FIELD

waters being studied, thereby making direct comparison and SCALE

(MEQ. PER LITER)

correlation between these waters possible.

Ano,Ler very valuable feature of this system is its extreme FIG. ,,- COURSE OF ARBUCKLE FORMATION THROUGH KANSAS

simplicity. The pattern can be constructed by anyone on SHOWN BY WATER PATTERNS.

Vol. 192, 1951 PETROLEUM TRANSACTIONS, AIME 377

~

Detection of a Foreign Water and the

L.:J ~ _I Determination of Its Source

PIT TEST

WELL

~

TEST

Oil wells are completed so as to yield a minimum of water,

but a break in the cement or a leak in the casing may allow

A WELL

B FRESH

WATER extraneous water to enter. Water yielded by a well in the nor-

I

<r q q

WELL mal course of operation is usually bottom water, that is, water

~

from the producing formation, while water entering through

a leak or cement break may come from some other strata.

If sufficient information is available on the composition of the

waters in the area, the source of a foreign water may be dis-

covered, and its exclusion brought about with a minimum of

~f~

trouble and expense.

Ca

100

Mg

100

Heo,

100

SO.

100

~"'ffi.

Ca

100

Mg

100

HC03

~oo

SO.

100

~f~

Ca

100

Mg

100

HeOl

100

504

100

~r

Ca

10

Mg

10

IiC03

10

10

SO,

Fig. 7 presents a case in which water patterns were used to

determine the source of water entering a well. Well No. 1

Fe CO! Fe CO, Fe COl Fe COl

had been producing water of a consistent pattern from forma·

100 100 100 100 100 100 10 10

tion A since its completion, when suddenly the water pattern

changed. Another well in the field was producing from forma-

tion B which was located about 150 ft above A. This formation

FIG. 5 - PATTERN ANALYSIS USED AS A TRACER. had, of course, been cemented off during completion of Well

Tracer Problems

It is often possible to trace the passage of water through

V<:JJ<J>

a sand by a study of the patterns obtained from properly

spaced test holes along its path. In the case presented in Fig.

5, seepage of salt water from a disposal pit into a fresh water

well was suspected. Shallow test holes were drilled at A and B NORMAL PATTeRN CHANGED PATTERN NORMAL PATTERN

and allowed to fill by seepage. Samples were taken, the water WELL "I

FORMATION A

WELL "I

SHOWING ENTRANCE

WELL"Z

FORMATION B

analyzed, and the patterns plotted. The appearance of the OF FOREIGN WATER

disposal pit pattern, somewhat reduced in size, definitely

established seepage in the direction of the well. When a sam-

ple from the fresh water well plotted on a magnified scale

gave the same pattern as the pit, contamination became

evident.

Drill Stem Testing

<:JJ c:J7 \P ZS%A 75'1. B

FORMATIONS A AmJl. B.

50'1. A 50'!. B

PAl"TERNS PRODUCED BY VARIOUS MIXTURES OF WATERS FROM

IT CAN BE SEEN THAT THE ABNORMAL

PATiERN IN WEll -\ RESULTS FROM A MIXTURE OF APPROXIMATEL'l

75 '1. A 25% B

25"0 A 11A1il 75"08.

Because of the uncertainty regarding contamination of water

samples by drilling mud encountered in drill stem testing; ~~ Ifo~

attempts to establish the formation from which such samples

originate are often unsuccessful. In some cases, however, this

information is extremely helpful. Because of the ease with

which one pattern can be compared with another, the pattern

system is especially useful for this purpose. Fig. 6 shows the

V PATTERN OF WELl"

AFTER WORKOVER SCALE

Ca

10

Mg

10

Fe

10

HC03

10

504

10

C03

10

(MEO. PER LITER)

results of a case where pattern analysis was successfully uti- FIG. 7 - DETECTION OF FOREIGN WATER AND DETERMINATION OF

lized to determine the formation from which a drill stem test ITS SOURCE.

sample originated.

No'- 1. The patterns of various mixtures of A and H were cal-

culated and plotted as shown. It then became evident that

~

the new pattern resulted from a mixture of approximately

25 per cent water from forll1ation A and 75 per cent water

from formation B. It was therefore concluded that foreign

WELL "I KNOWN PRODUCTION

FROM COCKFIELD FORMATION

water was entermg from formation B either through a casing

leak or through a break in the cement. Accordingly, the cas-

~

ing was pressure tested and since no leak was found, a cement

job was undertaken. At the conclusion of this operation the

well was again put on production and at the end of several

WELL "3 DST AT 7260 - 67

months the pattern was again similar to that of formation A.

PRODUCTION SHOWN TO BE

FROM COCKFIELD FORMATION

BY COMPARISON OF WATER PATTERNS

~Z~:~03

10

Mg

10

SO.

CONCLUSIONS

The pattern analysis system presented in this paper offers

10 10 a simple, practical means of characterizing, comparing, and

Fe

10

C03

10

correlating ground waters. It is particularly useful in facili·

tating the solution of many petroleum production problems,

SCALE (MEQ. PER LITER)

but can be used to advantage in the study of any question in

FIG. 6 - PATTERN ANALYSIS USED IN DRILL STEM TESTING. which water analysis is a factor.

378 PETROLEUM TRANSACTIONS, AIME Vol. 192, 1951

ACKNOWLEDGMENT 2. Reistle, C. E.: U. S. Bureau of Mines Technical Paper 404

The author wishes to thank The Atlantic Refining Co. for (1927) .

permission to publish this paper, and to acknowledge the 3. Parker, J. S.; and Southwell, C. A. P.: Journal of Insti·

advice and encouragement given him by J. H. Sullivan and tution of Petroleum Technologists, London (1929) 15, 138·

C. M. Pounders. 182.

Credit for the drawings is extended to Gene Nigh. 4. Corps, E. V.: Proc. World Petro Congress 1 (1933) 338.

5. Lange, A. L.: Handbook of Chemistry, Handbook Publish.

REFERENCES ers, Inc., Sandusky, O. (1946) 757.

1. Tickell, E. G.: Report of the California State Oil and Gas

Supervisor (1921) 6, (9). 5.

* * *

Vol. 192, 1951 PETROlEUM TRANSACTIONS, AIME 379

You might also like

- The Interpretation of Chemical Water Analysis by MeansDocument4 pagesThe Interpretation of Chemical Water Analysis by MeansAnahy ResénndizNo ratings yet

- Spe 10104 PaDocument9 pagesSpe 10104 Pakerron_rekhaNo ratings yet

- Spe 9723 PaDocument14 pagesSpe 9723 PaCarlos Carrillo VillavicencioNo ratings yet

- Radio Data Reference Book Jessop 1967Document148 pagesRadio Data Reference Book Jessop 1967Cubelinho ResuaNo ratings yet

- Spe 12170 PaDocument12 pagesSpe 12170 PaMery GutierrezNo ratings yet

- Plasma-Driven Permeation of Deuterium in NickelDocument4 pagesPlasma-Driven Permeation of Deuterium in NickelasdfNo ratings yet

- SPE 154567 Polymer Flooding A 500-cp OilDocument13 pagesSPE 154567 Polymer Flooding A 500-cp OilBichara DjimetNo ratings yet

- Popular Electricity 1909 03Document131 pagesPopular Electricity 1909 03sezaroNo ratings yet

- Kinpactor APC-1-514KDocument10 pagesKinpactor APC-1-514Kdannymay95No ratings yet

- Nabor - Linear Acuifer BehaviorDocument3 pagesNabor - Linear Acuifer BehaviorBD AmyNo ratings yet

- SurfaceDocument20 pagesSurfaceHernandez CitlalyNo ratings yet

- An Xi'S Study of The Interac'Iion of Oxygen With ZirconiumDocument15 pagesAn Xi'S Study of The Interac'Iion of Oxygen With ZirconiumJose David CastroNo ratings yet

- Arden1968 Chapter OrganicPoisoningOfAnionExchangDocument25 pagesArden1968 Chapter OrganicPoisoningOfAnionExchangnermeen ahmedNo ratings yet

- Capillary Pressure Techniques: Application To Exploration and Development GeologyDocument14 pagesCapillary Pressure Techniques: Application To Exploration and Development Geologyc_b_umashankarNo ratings yet

- Spe 9723 PaDocument14 pagesSpe 9723 PaFelipe RamírezNo ratings yet

- Asphaltene Deposition in Production Facilities: Ruksana Thawer, David C.A. Nicoli, Graeme DickDocument6 pagesAsphaltene Deposition in Production Facilities: Ruksana Thawer, David C.A. Nicoli, Graeme DickCarlos A MoyaNo ratings yet

- Articulos Yacimientos de GasDocument27 pagesArticulos Yacimientos de GasChristian Narváez BarajasNo ratings yet

- Originally Published AsDocument7 pagesOriginally Published AsAlfredo Arroyo SanchezNo ratings yet

- CaseStudy 1Document12 pagesCaseStudy 1Syazwani PuteriNo ratings yet

- Open ChannelsDocument19 pagesOpen ChannelsJulius ValerioNo ratings yet

- PETROLEUM TRANSACTIONS Water Flooding Model Explains Down-Structure BehaviorDocument6 pagesPETROLEUM TRANSACTIONS Water Flooding Model Explains Down-Structure BehaviorarispriyatmonoNo ratings yet

- The Miser'S T/R Loop Antenna: MiserlyDocument3 pagesThe Miser'S T/R Loop Antenna: MiserlyTariq ZuhlufNo ratings yet

- Quantitative DopplerDocument4 pagesQuantitative DopplerBarthélemy HoubenNo ratings yet

- Part 2 of 2 FINALDocument38 pagesPart 2 of 2 FINALMohamed ElabbasyNo ratings yet

- An I&a-Red Study of The Hydrates of Sodium Carbonate: Acta, 1961, VolDocument4 pagesAn I&a-Red Study of The Hydrates of Sodium Carbonate: Acta, 1961, Volxibs2009No ratings yet

- Advanced Dam Engineering 05 (124-164)Document41 pagesAdvanced Dam Engineering 05 (124-164)chandra adriawanNo ratings yet

- Petsoc 87 05 03Document12 pagesPetsoc 87 05 03Andres MarinNo ratings yet

- lee1981Document16 pageslee1981andi suntoroNo ratings yet

- Well Test Previous Year QuestionDocument13 pagesWell Test Previous Year QuestionDiptoNo ratings yet

- Expt 9Document5 pagesExpt 9alaa AlobeidyeenNo ratings yet

- A. and M. DivisionDocument17 pagesA. and M. DivisionBahman MatouriNo ratings yet

- Saturation Distribution and Injection Pressure For A Radial Gas-Storage ReservoirDocument5 pagesSaturation Distribution and Injection Pressure For A Radial Gas-Storage ReservoirOluwatosinImisioluwaAjiboyeNo ratings yet

- Boeing Blended WingletDocument45 pagesBoeing Blended Wingletsubha_aeroNo ratings yet

- Development and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil SystemsDocument6 pagesDevelopment and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil Systemsoppai.gaijinNo ratings yet

- Lewis F. Moody, Friction Factor For Pipe Flow, 1944Document19 pagesLewis F. Moody, Friction Factor For Pipe Flow, 1944Lion Rock0% (1)

- Effect of Vertical Fractures On Reservoir Beha vior-Compressible-Fluid CaseDocument8 pagesEffect of Vertical Fractures On Reservoir Beha vior-Compressible-Fluid CaseSarahi MayaNo ratings yet

- 13279-Pa (Gould Et Al)Document13 pages13279-Pa (Gould Et Al)Ameer HussainNo ratings yet

- Versatile Three-Phase CorrelationsDocument14 pagesVersatile Three-Phase Correlationsra dolNo ratings yet

- Me409 Compressible Fluid Flow, September 2020Document3 pagesMe409 Compressible Fluid Flow, September 2020avinashNo ratings yet

- Soma Sundar An 1984Document10 pagesSoma Sundar An 1984igiliNo ratings yet

- RBF 5Document19 pagesRBF 5SM ConsultantsNo ratings yet

- Otten 1976Document4 pagesOtten 1976Rafael SalgadoNo ratings yet

- UT1 FGHDocument1 pageUT1 FGHDeep AceNo ratings yet

- Elbel 1988Document5 pagesElbel 1988clemmy3658No ratings yet

- Rocket Thrust Ofhc: Cyclic Fatigueanlysis Chambers: Copper Chamber Low Cycle FnigwDocument67 pagesRocket Thrust Ofhc: Cyclic Fatigueanlysis Chambers: Copper Chamber Low Cycle FnigwВиктор ГорбенкоNo ratings yet

- WataniaDocument1 pageWataniaMuhamed Elsayed - ZalatNo ratings yet

- Havela and OdhDocument8 pagesHavela and OdhSig BahaNo ratings yet

- B.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationDocument16 pagesB.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationTrần Vũ HạNo ratings yet

- Net Pay Cutoffs From Capillary Pressure : Andy MayDocument20 pagesNet Pay Cutoffs From Capillary Pressure : Andy MayMarcelo Ayllón RiberaNo ratings yet

- Subject:Earthstructure: Building ConstructionDocument3 pagesSubject:Earthstructure: Building ConstructionmuhanadNo ratings yet

- Fairbairn and Robertson (1956) - LL and Dye AdsorptionDocument8 pagesFairbairn and Robertson (1956) - LL and Dye AdsorptionPinipini PujaNo ratings yet

- Menyunting Dari PenelitiDocument7 pagesMenyunting Dari PenelitiACNo ratings yet

- Water Demand Analysis UpdateDocument28 pagesWater Demand Analysis UpdaterarasriwindhuNo ratings yet

- Sulution Manual - Well Logging For Earth ScientistsDocument15 pagesSulution Manual - Well Logging For Earth Scientistsferhatc560% (2)

- Tutorialviscousflow 2Document2 pagesTutorialviscousflow 2Hariss LuqmanNo ratings yet

- 1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDocument23 pages1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDaniel Alejandro Jara PaineanNo ratings yet

- Sca1998 51Document5 pagesSca1998 51abdounouNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Angular Dispersion and Dispersive PowerDocument6 pagesAngular Dispersion and Dispersive PowerShivkant SinghNo ratings yet

- Design Thinking WorkshopsDocument2 pagesDesign Thinking WorkshopspraveenalluruNo ratings yet

- Online30 9 2019 PDFDocument17 pagesOnline30 9 2019 PDFmostafa AL-MasoudyNo ratings yet

- Comparative effect of phosphatic fertilizers on tobacco yield and qualityDocument27 pagesComparative effect of phosphatic fertilizers on tobacco yield and qualityAizaz AliNo ratings yet

- Midterm2 PDFDocument3 pagesMidterm2 PDFTrường Tùng LýNo ratings yet

- Learning and Reference Guide: 5265602-1EN Rev.3 (2008/08/28)Document340 pagesLearning and Reference Guide: 5265602-1EN Rev.3 (2008/08/28)joseNo ratings yet

- Dot MapDocument7 pagesDot MapRohamat MandalNo ratings yet

- Biology Lesson PlanDocument1 pageBiology Lesson PlanGeorge ApidiNo ratings yet

- Forum 4-1Document2 pagesForum 4-1Aubrey ArizoNo ratings yet

- Gpe 4 - Module 1 - Word GamesDocument10 pagesGpe 4 - Module 1 - Word GamesLADY JANE ANE�ONNo ratings yet

- Fractured Fairytale Unit-Year 7 Leah 2012Document12 pagesFractured Fairytale Unit-Year 7 Leah 2012api-111350055No ratings yet

- Project Execution Strategy for Barwa City Phase 2Document17 pagesProject Execution Strategy for Barwa City Phase 2marydell12No ratings yet

- Bay of BengalDocument18 pagesBay of BengalKarl GustavNo ratings yet

- Perceptual Mapping with Multidimensional ScalingDocument70 pagesPerceptual Mapping with Multidimensional Scalingpankaja_16No ratings yet

- Spring EquinoxDocument17 pagesSpring EquinoxkkpereiraNo ratings yet

- Seepage and Flow NetsDocument60 pagesSeepage and Flow NetsMavenNo ratings yet

- Prealgebra 2nd Edition Miller ONeill Hyde 007338447X Test BankDocument16 pagesPrealgebra 2nd Edition Miller ONeill Hyde 007338447X Test Bankmatthew100% (21)

- 5 SetDocument34 pages5 SetQuynh NguyenNo ratings yet

- Why NAM remains relevant todayDocument2 pagesWhy NAM remains relevant todaySourabh PawarNo ratings yet

- IMDG Part3 PDFDocument148 pagesIMDG Part3 PDFSherwin Delfin CincoNo ratings yet

- 2018 Article 3585Document14 pages2018 Article 3585timosp1973No ratings yet

- Failure Case Studies in Civil EngineeringDocument135 pagesFailure Case Studies in Civil Engineeringpratip_b100% (2)

- Modelling Swelling Rock Behaviour in TunnellingDocument5 pagesModelling Swelling Rock Behaviour in TunnellingsuperwxrNo ratings yet

- JEE(Main) 2023 Answer Key ChallengeDocument9 pagesJEE(Main) 2023 Answer Key ChallengeCHAKRI BABLUNo ratings yet

- Syllabus Sibos CLTDocument5 pagesSyllabus Sibos CLTgopimicroNo ratings yet

- Marimekko's Approach to Sustainability and Global OperationsDocument3 pagesMarimekko's Approach to Sustainability and Global OperationsHannah Van GeeresteinNo ratings yet

- The Oxford History of MexicoDocument837 pagesThe Oxford History of MexicoLety Corona100% (5)

- Flash and False SetDocument2 pagesFlash and False Setpxt90100% (3)

- Understanding Factors in Second Language AcquisitionDocument9 pagesUnderstanding Factors in Second Language AcquisitionfatemehNo ratings yet

- Idea Proposal Format E-Yantra Innovation Challenge 2020-21: Project NameDocument5 pagesIdea Proposal Format E-Yantra Innovation Challenge 2020-21: Project NameNishant MishraNo ratings yet