Professional Documents

Culture Documents

QDC/3136 Rev 0

Uploaded by

Mohamed Ismath KalideenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QDC/3136 Rev 0

Uploaded by

Mohamed Ismath KalideenCopyright:

Available Formats

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

SECTION 16

PRE- ENGINEERED STRUCTURAL STEEL WORKS

The following clauses amend relevant clauses in Section 16 of QCS, or are additional clauses, as

appropriate

1.0 SPECIFICATIONS FOR PRE-ENGINEERED STRUCTURE

CONTRACTOR shall design, supply and erect the pre-engineered building which shall consist of a

rigid frame structure with light weight insulated sheeting for roof and side cladding. The overall

dimension and level given in the drawings shall be strictly adhered.

Pre-engineered building supplier shall be fully responsible for the complete design of the steel

structure.

Pre-engineered building supplier shall appoint a locally registered Grade A consultant for

verification and confirmation of the steel structural design and submit structural design

undertaking to supervision consultant for information and records.

The design and construction of pre-engineered building shall be in accordance with the following:

1.1 DESIGN:

The pre-engineered building shall be designed in accordance with AISC.

The structure shall be designed to withstand the worst load combination. In addition the

deflection arising out of the application of the worst load combination shall be limited to the

following:

Vertical deflection of the frame members carrying sheeting above = Span/200

Horizontal deflection of frame members = Eaves Height/300

1.2 STEEL SECTIONS:

All hot rolled sections shall comply with ASTM A 572 Grade 50/S355 or equivalent material.

Minimum thickness of plates shall be 6mm.

1.3 WELDING:

All welding shall be done in accordance with AWS D1.1 Structural Welding Code.

1.4 PURLINS, GIRTS AND EAVE STRUTS

Purlins, Girts, and Eave struts shall be cold formed from steel which has a minimum yield strength

of 355 MN/m2.

1. Purlins and girts shall be roll formed Z-section minimum 200mm deep with 63mm flanges, each

flange shall have 17mm stiffening lip formed at 45 to the flange.

QDC/3136 REV 0 Page 21

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

2. Eave struts shall be 200mm deep with a 105mm wide top and bottom flange formed parallel to

the roof slope, each flange shall have 200mm stiffener.

1.5 DESIGN LOADS:

Dead Loads

All dead loads shall be calculated by manufacturer for actual self weight of all elements and

finishes.

Live Loads

Floor live load = 2.5 KN/m2

Collateral Loads

Collateral load is considered as 0.50 KPa.

Temperature Loads

Temperature load is considered as ±41ºC

Wind Loads

Wind loads shall be calculated as per recommendation of ASCE 7-05 with

Basic Wind Speed = 38 m/s

Seismic Loads

Seismic load shall be calculated as per ASCE 7-05 / IBC Code.

Foundation and pedestal design for pre-engineered building is indicative based on assumed

reactions and shall be used as a minimum requirement. The Contractor is fully responsible to

verify and redesign if required, based on the actual reaction and carryout construction of all

foundation and pedestal without any additional cost.

1.6 STRUCTURAL STEEL PAINTING SPECIFICATION

All steel surfaces shall be thoroughly cleaned, grit blasted and painted.

CORROSION PROTECTION FOR STEEL ELEMENTS

All steelwork to be painted with the following materials. Prepare and apply one coat of 50

microns DFT epoxy zinc phosphate primer, 200 microns high build epoxy mid coat and 50

microns polyurethane enamel final coat on general surfaces of metal work.

QDC/3136 REV 0 Page 22

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

SECTION-17

METAL WORK

The following Clauses amend or replace relevant Clauses in Section 17 of QCS, or are additional

Clauses, as appropriate.

PART 1 – GENERAL

1.1 No weldings to be done on site (Except on stair handrail). No Open flame work shall be

executed on site.

1.2 SUBMITTALS

Replace Clause 1.2.1 with following.

1.2.1 SAMPLES

Contractor shall submit sample and mock-up in accordance with relevant provisions of

Section – 1 (QCS) and following.

1. Provide samples of materials to be used in the works, showing the type of material,

sections, thickness of members and factory applied finishes.

2. Samples shall include, but are not limited to:

a. Aluminium window corner sections complete with glazing.

b. Glazing gaskets and weather strips.

c. Hardware, where supplied as part of a completed unit.

3. Provide manufacturer's catalogues and technical literature including details of window

performance standards, fire ratings, thickness of factory-applied finishes and the like.

4. After approval of samples and details and shop drawings, provide samples of items of

purpose made metalwork as required by the ENGINEER, as part of the finished work, and

obtain approval before fabricating the remainder, including

a. Aluminium hinged window/doors.

5. Range samples showing complete range of variation in colour, texture and other

characteristics.

QDC/3136 REV 0 Page 23

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

PART 2 – MATERIAL TYPES AND FINISHES

2.3 ALUMINIUM FINISHES

Delete Sub-clause 2.3.2 and add following.

2.3.2 FINISHES FOR ALUMINIUM AND ALIMINIUM ALLOYS

1. Finish of aluminium works shall be powder coated system to BS 6496 and BS 6497, minimum

coating thickness shall be 60 microns, smooth texture with matt finish.

2. Surface quality of coating shall be smooth and free of flow lines, streaks, blistering and other

imperfections. Coating shall be opaque and shall be uniform in colour and tonality.

3. Coatings shall be guaranteed for 10 years.

2.4 CARBON STEEL FINISHES

2.4.1 Delete Clause 2.4 and replace with following.

1. Steel surfaces shall receive following system.

a) Surface preparation to BS 7773.

b) Primer – fast curly epoxy primer coat.

c) Intermediate coat- high build epoxy-polyamide paint.

d) Topcoat: aliphatic acrylic polyurethane paint.

(Refer to section 26 for paint specs)

2. All fabrication shall be done prior to finishing. All welds shall be grounded smooth and finished to

match adjacent surfaces.

Surface quality shall be free of flow lines, sags, dry spray and imbedded particles.

2.4.2 STAINLESS STEEL FINISHES

1. Stainless steel shall comply with BS 1449 Part 2.

2. Unless specified otherwise stainless steel shall be type 316 and finish shall be 3B brush polished

finish.

3. Finish shall be free from blemishes, scratches and other defects.

QDC/3136 REV 0 Page 24

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

PART 3 – METAL DOORS AND WINDOWS

3.1 DETAILED SPECIFICATION

Delete entire Clause and add following.

Extruded aluminium members shall be fabricated from designated treated alloy 6063 TS to BS

1474.

All screws, nuts bolts, reverts, washers and other fastenings shall be stainless steel (Type 316

S16).

The units shall be fabricated at the manufacturer’s works as far as possible and delivered

complete and ready for installation. Aluminium windows shall be to BS 4873, BS 1474, BS 3987,

BS 6496 and BS EN 485.

The overall sizes of assembled units shall be maintained within a tolerance of +_ 1.5 mm. Frame

assemblies shall be square with a maximum difference in the diagonals of 4 m. The finished units

to be free from all sharp edges, burrs and the like.

Joints in frames shall be made by screw spleen, shear block or other approved system capable of

accommodating the thermal movement of the unit and providing tightly fitting and inconspicuous

joints.

The main web of the aluminium windows outer frame should not be less than 1.6 mm thick and

2.0 mm for doors. Aluminium Sections shall be minimum 100 mm wide. Frames to be self-draining

and no holes for fastenings shall be located in the external channel at sill level.

All opening units shall be fully weather stripped using siliconized woven polypropylene, wool pile

or neoprene retained in dovetailed or undercut grooves formed in the aluminium extrusions. The

weather-stripping should be capable of being removed without disturbing the glazing system and

without removing the outer frame from the structure.

The design of the units should permit re-glazing without the need to remove the outer frame

from the structure.

All hardware shall be supplied and fixed by the unit manufacturer, and should match the finish of

the surfaces of the units and be replaceable without removing the outer frame from the

structure. Fasteners shall be designated so that they cannot be released from the outside by the

insertion of a thin blade or other simple tool.

QDC/3136 REV 0 Page 25

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Windows and external doors shall meet the performance requirements of “severe (a) exposure”,

that is a maximum three second gust speed of 180 kph and probable maximum wind loading of

2300 N/mm2, when tested in accordance with BS 6375, BD 5386.

Horizontal sliding units shall be supported on rustproof and dustptproof bearing devices that may

easily be repaired or replaced and that prevent contact between the unit and the track. Horizontal

and vertical sliding units shall separated and not slide upon each other.

No window shall be openable or removable from the outside when it is fastened in a closed

position except by the use of special tools or by breaking part of the window or door.

All opening windows shall be fitted with fly screens.

All unit surfaces which will be visible in the finished work shall be protected after manufacture by

low tack tape or other suitable means capable of being removed after exposure to the high

temperatures prevalent in Qatar to leave clean, undamaged surfaces.

Sill frames to slope outward (level frames shall not be allowed).

Weepholes shall be provided.

3.2 FLYSCREENS

1. Fly screens shall be fabricated in accordance with Clause 3.1.

2. The frames shall fabricate from substantial, rigid sections and be easily removable from the

window to permit maintenance, cleaning and repair. The frames shall allow the replacement of the

mesh and shall match finish (powder coated) of window unit.

3. The frames shall be infilled with 0.6 mm aluminium wire woven to a 1.5 mm mesh, stretched

tightly and evenly, and free from visible joints.

4. Fly screens shall be fixed to inner face of Aluminium sections.

Add following Sub-clauses.

3.3 STEEL DOORS

a) Frame construction: Frame shall be constructed of 1.4mm (16 gauges) hot dip galvanised steel

sheet ASTM A426, G90 for door of 44mm thickness. All bends shall be framed with true sharp radii.

Minimum frame size shall be 140mmx 44 mm or more, as suitable for wall thickness.

QDC/3136 REV 0 Page 26

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

b) Steel flush doors shall be 44mm thick constructed from 1.4mm (16guage) thick hot dip

galvanised steel sheet ASTM A426, G90. 1.4mm thick steel top and bottom channels shall

be provided welded to door skins at 140mm centres. Top channel shall be flush and

bottom channel inverted. Door leaf shall be provided with a closed cell waterproof

foamed-in-place polyurethane core of 24kg/cu.mt. Density completely filling inside of the

door. The doors shall meet the following

Performance Standards:

‘U’ Factor - 0.079

‘R’ Factor - 12.64

Sound resistance ‘STC’ - 31

In general, steel doors shall comply with ANSI/SDI-100 and ANSI A151.1.

c) Doors shall be finished with factory applied corrosion inhibiting protective coating and

stove enameled/ powder coated polyester painted and supplied complete with basic

hardware

d) Fire rated steel doors shall be fire rated as per documentation. Doors shall bear the

appropriate fire labels, complying with the test requirements mentioned in NFPA 242 and

UL 10(b).

e) Steel frame shall be with specially formed grooves for housing of intumescent seals and

strips for fire rated doors.

3.4 SECTIONAL DOORS

Door leaf

Shall be made of double-skinned, hot-galvanized steel sections 625/750 mm high. Depth 42 mm,

insulated, foam-filled with PU-foam acc. to DIN 4102 and DIN 18164. Stucco-textured on interior

and exterior, uniform division with horizontal ribbing in a 125 mm grid. Thermal insulation U = 1.0

W/m² K, wind load: class 3 (except for doors with wicket door or wider than 4000 mm).

Door sections with finger trap protection on the outside and inside.

Bottom door section with double-lip hollow profile seal as bottom seal, top door section with lintel

seal. Seals made of EPDM.

Surface of door leaf polyester-primer coated, made of coil coating material in preferred colour

(without surcharge) on exterior

Track application

Counterbalance via a torsion spring assembly behind the lintel, with torsion springs, with cable

drums and side pull cables. Parking of door sections partially vertical behind lintel, partially

horizontal. Door safeguarded against falling if the torsion spring breaks through the use of TÜV-

certified safety devices.

QDC/3136 REV 0 Page 27

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Glazing

Compound glazing type A, from approx. 1660 mm above FFL, consisting of plastic frame, with

synthetic double panes, clear, 33 mm, with coating for maximum scratch resistance, clear view per

panel

Wicket door with trip-free threshold

Opening outwards, matching the sectional door, incl. special hinges that hold the door leaf elements

and door sections flush, with double buffer sealing. With overhead door closer incl. restrained

opening. (For electrical sectional door operation, a wicket door safety unit is required.)

Anodised wicket door frame in accordance with DIN 17611 in E6/EV1 anodised/natural finish.

Lever handle set, offset/flat, prepared for profile cylinder

Door closer with slide rail and hold-open device for wicket door.

3.5 SLIDING DOOR WITH ACCESS CONTROL UNIT

For automatic sliding door, the operating system shall be heavy duty and with access control unit,

Complying following minimum requirements.

a. Extruded aluminium fascia with cushion to endure noise free operation.

b. Options board to allow interfacing to building management system for door status, people in

and out, door locked and door malfunctions.

c. Chain drive with adequate tensile strength.

d. Microprocessor logic controller.

e. Failsafe with automatic reset.

f. Adjustable hanger bar assembly.

g. Durable self-cleaning tracks.

h. Battery for fail-safe system.

i. Gear box and gears machined steel that allows for completely uniform wear.

j. Consultant-rated stall-proof motor.

k. Mode keypad.-

3.6 HANDRAIL & RAILINGS

CONTRACTOR shall supply and fix proprietary stainless steel handrails and railings from

‘Tribenbacher Telemetal (TT)-Germany’ or from other equal and approved manufacturer, where

shown and as detailed on the drawings.

CONTRACTOR shall submit shop drawings for the approval of ENGINEER prior to fabrication to

ENGINEER approval. Product data in the form of manufacturer’s technical data, specifications and

installation instruction shall be submitted as required by ENGINEER.

Shop drawings shall show, but not restricted to the following:

Component dimensions, profiles, material specifications, accessory details

QDC/3136 REV 0 Page 28

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Method of assembly, erection and anchoring, jointing

Division of panels, construction details, dimensions

3.7 MECHANICAL EQUIPMENT SUPPORTS

Shall be constructed from normal mild steel sections, hot mill finished, sized to suit

imposed loads and dimensions of equipment and assembled to details and dimensions

indicated on approved shop drawings in welded construction.

Provide necessary fastenings system to mounting surface according to case. Hanging to

walls is to be with mortar pointing of dovetail slotted ends of steel members. Mortar is to

consist of 300 kg ordinary Portland cement to 1 m3 sand with addition of approved liquid-

type setting accelerating admixture.

Finish is to be epoxy based system as specified in Section 16. Colour is to be selected by

the ENGINEER.

3.7 PLASTER ACCESSORIES

Metal laths, angle beads, corner beads, plaster stops; control joint beads etc. shall be in

Galvanized steel.

3.8 SLEEVES

CONTRACTOR shall provide sleeves at all playground to receive poles. Poles to be

supplied by CLIENT.

3.9 LOUVERS AND VENTS

The documentation and work under this Section shall be carried out in accordance with

codes and procedures established in the General Requirement and complimented with

details in this Section of Particular Specifications, to the ENGINEER approval.

3.9.1 GENERAL

A. This Section includes the following:

1. Fixed, extruded – aluminium louvers.

B. Structural Performance: Provide exterior metal louvers capable of withstanding the

effects of loads and stresses from wind and normal thermal movement without

evidencing permanent, deformation of louver components including blades, frames, and

supports; noise or metal fatigue caused by louver blade rattle of flutter; or permanent

damage to fasteners and anchors.

QDC/3136 REV 0 Page 29

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

C. Submit Product Data: For each type of product specified.

D. Submit Shop Drawings: For louver units and accessories. Include plans; elevations;

sections; and details showing profiles, angles, and spacing of louver blades. Show unit

dimensions related to wall opening construction; fee area for each size indicated; profiles

of frames at jambs, heads, and sills; and anchorage details and locations.

E. For installed louvers and vents indicated to comply with design loadings, include

Structural analysis data signed and sealed by the qualified professional ENGINEER

responsible for their preparation.

F. Submit Samples for initial Section: Manufacturer’s colour charts showing the full range of

colours available for units with factory-applied colour finishes.

G. Submit Samples for Verification: Of each type of metal finish required, prepared on

Samples of same thickness and material indicated for final Work. Where finishes involve

normal color and texture variations, include Sample sets showing the full range of

variations expected.

H. Professional ENGINEER Qualifications: A professional ENGINEER who is legally qualified to

practice in jurisdiction where Project is located and who is experienced in providing

Engineering services of kind indicated. Engineering services are defined as those

performed for installations of louvers that are similar to those indicated for this Project in

material, design, and extent.

I. Source Limitations: Obtain louvers and vents through one source from a single

manufacturer where alike in one or more respects regarding type, design, or factory-

applied colour finish.

3.10 METAL SHEETING AND ACCESSORIES

METAL COMPOSITE PANEL WALL AND ROOF CLADDING

Supports: Cold rolled side purlins.

Bearing width: Min 60mm intermediate and panel ends.

FM 4881 for external wall panels.

FM 4880 for internal wall panels and ceilings.

Reaction to fire classification according to BS EN 13501–1: 2007 + A1: 2009: B-s1, d0.

Panels:

External facings:

Material: Metallic protected Aluminium to 3105 or manufacturer standard grade.

Thickness: 0.7mm nominal.

Finish / colour: PVDF 3 layer coating / RAL colour range.

Internal facings:

QDC/3136 REV 0 Page 30

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Material: Metallic protected Aluminium to 3105 or manufacturer standard grade.

Thickness: 0.5mm nominal.

Finish / colour: PES .25 micron / RAL 9002.

Core insulation: HCFC, CFC, HFC free LPCB certificated IPN insulation core.

Panel thickness: 60mm core (PIR) with a U value of 0,31 W/m2K

Male / female panel joint sealant:

Site applied weather seal set in rebate.

Non-setting gun-grade, Saudal Silirub S or similar, site applied at the end of each panel where

flashings pass over the joint.

Bridging seal across panel joint in line with internal air seal to be non-setting gun-grade,

Saudal Silirub S or similar.

Fasteners: As determined by clause 220A.

Number and location:

For panels: As determined by clause 197A, but with each panel fixed to each support using

not less than one fastener at panel ends and two fasteners at intermediate supports, located

through tongue section, as recommended by cladding manufacturer.

Thermal conductivity max initial value of 0.026 W/mK when tested in accordance to BS EN

13165:2012

Air leakage rate of 3m3/hr/m2 at 50 Pa,

Manufacturers: Subject to compliance with requirements, provide products manufactured by

an approved equal.

Note: (For pipe inspection building)

External facings:

Material: Metallic protected Aluminium to 3105 or manufacturer standard grade.

Thickness: 0.7mm nominal.

Finish / colour: PVDF 3 layer coating / RAL colour range.

Panel thickness: 60mm minimum core (PIR) with a U value of 0,31 W/m2K

3.9.2 MATERIALS

A. Aluminium Extrusions: ASTM B 221, alloy 6063-T5 or T-52.

B. Fasteners: Of same basic metal and alloy as fastened metal or 300 series stainless

steel, unless otherwise indicated. Do not use metals that are incompatible with

jointed materials.

1. Use types and sizes to suit unit installation conditions.

2. Use Philips flat-head screws for exposed fasteners, unless otherwise indicated.

QDC/3136 REV 0 Page 31

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

C. Anchors and Inserts: Of type, size, and material required for loading and installation

indicated. Use nonferrous metal or hot-dip galvanized anchors and inserts for

exterior installations and elsewhere as needed for corrosion resistance. Use toothed

steel or expansion bolt devices for drilled-in-place anchors.

D. Bituminous Paint: Cold-applied asphalt mastic complying with SSPC-Paint 12 but

containing no asbestos fibers, or cold-applied asphalt emulsion complying with ASTM

D 1187.

3.9.3 FABIRCATION, GENERAL

A. Assemble louvers in factory to minimize field splicing and assembly. Disassemble units

as necessary for shipping and handling limitations. Clearly mark units for reassembly

and coordinated installation.

Maintain equal louver blade spacing to produce uniform appearance.

Fabricate frames, including integral sills, to fit openings of sizes indicated, with

allowances made for fabrication and installation tolerances, adjoining materials’

tolerances, and perimeter sealant joints.

Include supports, anchorages, and accessories required for complete assembly.

Join frame members to one another and to fixed louver blades with fillet welds

concealed from view, unless otherwise indicated or size of louver assembly makes

bolted connections between frame members necessary.

3.9.4 FABIRCATION, GENERAL

A. Louver Construction:

1. Provide fixed-blade louvers with extruded-aluminium frames and blades.

2. Continuous, Horizontal, Drainable-Blade Louvers: Fabricated with close fitting, field-

made splice joints in blades designed to permit expansion and contraction without

deforming blades for framework and with mullions recessed from front edges of

blades so blades have continuous appearance.

3. Aluminium Finish: Factory finish: Factory finish of aluminium surfaces shall be super-

durable electrostatically applied polyester powder coating system.

QDC/3136 REV 0 Page 32

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

3.10 ACCESS LADDER

3.10.1 Location: as indicated on drawings

3.10.2 Components: Stiles 50mm dia CHS steel, bent to form a shallow “U” shape.

Weld 150mm diameter, 15mm thick steel plate fixing plates to each end of the stiles. Spacing of

stiles to be 550mm centre to centre. The distance from the face of the wall to the nearest

vertical face of the stile shall not be less than 200mm.Rungs: 20mm diameter solid steel bar

welded to each stile. Rungs shall be spaced equally not less than 250mm and not more than

300mm apart.

Height: as shown on drawings.

Fixings:

4nos. M20 masonry anchor bolts to each fixing plate. Provide packers to the depth of the

render coat to prevent cracking of the finishes.

Note – The ladder shall have wall fixings to both the top and bottom of the stiles and shall

not extend to roof level. Intermediate fixings shall be provided as required to ensure the

stability of the ladder

Fabrication: All steel to be fully welded. All welds to be ground smooth.

Finish: Hot dip galvanize ladder after welding.

Enamel paint, color to be approved by the engineer

3.13 TRANSLUCENT PANELS

1. Translucent Panels shall be 1.5mm thick fiberglass reinforced polyester to the profile.

2. Color of the panel shall be white with smooth surface finish with a light

transmitting capacity of 60 % ± 5%.

3. Light panels have low heat transmission with a minimum U value of 1.09 and shall be

fire resistant .

3.14 EAVE GUTTERS AND DOWN SPOUTS

1. Eave gutters shall be box shaped, color coated, 0.6 mm nominal thickness,

minimum200mm wide, made of Hot dip zinc coated steel with 25 micron PVDF

coating. Gutters shall be lined with 2mm thick GRP lining.

2. Downspouts shall be rectangular shaped, color coated, 0.5mm nominal

thickness.

Downspouts shall have a 45-degree elbow at the bottom and shall be supported by

attachment to the wall. Down spout number and sizes shall be recommended by PEB

Contractor and supported with calculations.

QDC/3136 REV 0 Page 33

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

3.15 COLOR

Color of all metal parts and accessories shall be to approval of Engineer. Contractor

shall obtain approval on actual color samples prior to fabrication.

3.16 DOCK LEVELLER

Dock leveller shall be hinged lip dock leveller. Self-supporting steel joint construction

with electro-hydraulic unit, in accordance with the valid regulations such as DIN EN

1398.

Dimensions:

Exterior width: 2600 mm

Exterior length: 3525mm

Height: 650 mm

Hinged lip: 405 mm

Height adjustment:

Levelling at FFL: + 200mm

Levelling under FFL: - 450 mm

In accordance with DIN EN 1398, a max. Slope of 12.5% (approx. 7°) is permissible.

Design:

Flexible dock leveller construction with 2-cylinder technology, platform made of

profiled, anti-slip steel, 6/8 mm thick, with hinged lip made of profiled, anti-slip steel,

12/14 mm thick, with gradient, with open, self-cleaning lip hinge.

Fitting conditions:

Fitting on a sufficiently stable, level, and vertical/flush subsurface, without brickwork,

plastering, or concreting.

Hinged lip / telescopic lip

Hinged lip type S, chamfered 100 mm on each side

Nominal load

Rated load acc. to DIN EN 1398 60 kN

Use of forklifts with hard (PU/Vulkollan) wheels limits loading capacity for electric lift

trucks to 40 kN.

Surface

Sand-blasted, anodized and coated with a 2-C-PUR paint in RAL 5002

Ultramarine blue.

Operator

Electro-hydraulic operator

Motor power: 1.1 - 1.5 kW

Connecting voltage: 400 V

QDC/3136 REV 0 Page 34

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Control

Surcharge control unit 460 S

Operator accessories

Magnet switch for electric locking with air lock doors or loading ramps (fitted to the

guide rail)

3.17 DOCK SHELTER

Flexible dock shelter as a dock-height model with link arm construction and reinforced

flaps in accordance with BS EN 1398. Dimensions to be as per Door drawings.

Construction:

The supporting construction consists of a 3-sided front and rear frame made of

galvanized steel profiles and the flexible frame connection is established with 2

horizontally arranged link arm constructions made of galvanized steel profiles.

The side and top flaps, as well as the side and top cladding, are fixed with weather strip

locating profiles made of anodized aluminum.

Flaps:

The approx. 3-mm thick top and side flaps consist of double-layer, elastic plastic flaps

with substrate fabric. The substrate fabric of the side flaps is a double polyester inlay

(monofilament). The side flaps have a spring effect and thus increase sealing around the

vehicle. The top flap is secured against flipping and is made of a dual-layer, reinforced

substrate fabric with polyester multifilament threads. The flap edges are tightened with

straps. Each side flap has 1 marker stripe for orientation purposes.

The side and top cladding on the dock shelter consists of a single-layer elastic substrate

fabric with polyester threads and plastic coating. A water run-off is integrated in the top

cladding.

Colors for marker stripes:White or yellow

3.18 LIFTING BARRIER SPECIFICATION

Barrier shall be from ‘Came’ or ‘Elkosta’ or other approved equal.

Barriers shall have the following minimum and shall be to the approval of CLIENT

REPRESENTATIVE.

Maintenance free Gear Motor.

Shall have self-locking gear motor to positively lock the barrier in the closed position.

Built-in release system shall be with key.

Shall be configured for easy installation of access control and safety accessories.

Shall be configured for installation and connection of an emergency battery supplies

power to the system in case of power failure.

Shall be available in galvanised steel with a polyester painted finish.

The Electronic control system of the barrier shall have the following features.

Shall be able to adjust barrier speed to suit the level of traffic at the installation site.

QDC/3136 REV 0 Page 35

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

Shall be able to adjust final approach speed for gentle impact-even when barrier is set

to move quickly.

Shall have obstacle detection system in order to stop barrier closing in case of

obstacles.

Technical Specification

Weight: 47Kg minimum

Voltage:

230V A.C

24V D.C

Motor current

230V: 15 max

24V: 1.3max

Motor Power: 300V

Duty Cycle (%): Intensive use

Reduction ration:1/202

Torque: 200Nm

Operating time (s): 2-6

4.0 CHAIN LINK FENCING

To the general requirements of BS 1722 Part 13, constructed as shown on the Drawings

and comprising:

Mesh : PVC coated galvanized steel wire, 50mm mesh, 2.50/

3.5mm diameter

Lines wires : Plastics coated galvanized steel 3.00/4.00mm diameter

Tying wires : Plastics coated steel 1.40/2.00mm diameter

Posts, rails and

braces : Galvanized seamless steel tube to BS 6323 or hot dipped

Galvanised solid tee and angle sections, To be paint finished.

Truss rods : Galvanised mild steel wire to BS 1052, 3.8mm diameter to be paint

finished.

Fittings : Galvanised pressed steel or malleable iron adjustable

Couplings and fasteners, caps and fittings to be paint finished.

Post are to be placed at maximum 3m centres with feet set 900mm into 500 x 500 x

1000mm deep concrete bases.

4.1 CHAIN LINK FENCES & GATE:

CONTRACTOR shall supply and fix proprietary chain link fencing system & gate by ‘Link

Middle East’ or ‘Guardian Fencing And Security Systems Co. Ltd.’. The fencing shall be anti-

intruder and heavy duty type and shall have PVC coated 50 mm –diamond shaped fence

QDC/3136 REV 0 Page 36

ARCHITECTURAL & CIVIL SPECIFICATION CONSTRUCTION , COMPLETION AND MAINTENANCE

OF PROPOSED WAREHOUSE & WORKSHOP, OFFICE

BUILDING , PIPEINSPECTION AREA AND OPEN YARD

DEVELOPMENT AT RLIC SI-14

fabric in galvanized steel, line posts, intermediate posts, corner & end posts, straining

posts, braces, truss rods, stretcher bars, bands etc. all complete as per manufacturer’s

details./+

The gate shall be in galvanized steel sections and finished in powder coated polyester

finish all as per manufacturer’s details integrated with the chain link fencing of heavy duty

construction, to approval of Engineer.

CONTRACTOR shall submit shop / manufacturer’s drawings for the approval of the

ENGINEER prior to installation.

Shop drawings shall show Component dimensions, profiles material specification, Method

of assembly, erection and anchoring joints and the like.

Fencing shall be minimum 2.4 m high and shall have 4 m wide double leaf gate with

locking facility. Posts shall be maximum 3.0m c/c.

Temporary Fencing for site security during construction shall be minimum 3.0 m high with

dust screen at locations identified by Engineer with minimum 2 gates 5m wide.

QDC/3136 REV 0 Page 37

You might also like

- Technical Specifications: A. General ConditionsDocument4 pagesTechnical Specifications: A. General ConditionsKurein ReotutarNo ratings yet

- Architectural SpecificationDocument5 pagesArchitectural SpecificationJustine Alexis IngresoNo ratings yet

- Architectural SpecificationDocument2 pagesArchitectural SpecificationDorey BalisiNo ratings yet

- General Construction Technical SpecificationsDocument4 pagesGeneral Construction Technical SpecificationsStephanie VilloceroNo ratings yet

- Technical Specifications 20feb2020Document6 pagesTechnical Specifications 20feb2020paul remodoNo ratings yet

- Specification For PermitDocument3 pagesSpecification For PermitErnie ConcepcionNo ratings yet

- Building Specifications ProjectDocument5 pagesBuilding Specifications ProjectAlan CamposNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Construction SpecificationsDocument10 pagesConstruction SpecificationsDarwin AquinoNo ratings yet

- Roof Framing SpecificationDocument10 pagesRoof Framing SpecificationLittleRedNo ratings yet

- 10 28 13 - Toilet Accessories PDFDocument6 pages10 28 13 - Toilet Accessories PDFmasoodaeNo ratings yet

- Particular Specifications Plumbing and Sanitary Work: 1.0 GeneralDocument19 pagesParticular Specifications Plumbing and Sanitary Work: 1.0 GeneralCherryl Chrissie JamesNo ratings yet

- Jan Laurence G. Gatchalian: I. General Scope of Architectural ServicesDocument4 pagesJan Laurence G. Gatchalian: I. General Scope of Architectural ServicesRosario De Jesus - GatchallanNo ratings yet

- UAP Doc 401 Owner Architect AgreementDocument3 pagesUAP Doc 401 Owner Architect AgreementAlven T Bactad0% (1)

- Item 1009Document3 pagesItem 1009Ester MarianNo ratings yet

- MR.& Mrs. Jun Marc Nobleza South Forbes Properties Sta. Rosa - Silang, TagaytayDocument11 pagesMR.& Mrs. Jun Marc Nobleza South Forbes Properties Sta. Rosa - Silang, TagaytayAnonymous LQVRIPusNo ratings yet

- Construction Specifications LongDocument7 pagesConstruction Specifications LongLimar SetatraNo ratings yet

- SPECIFICATIONSDocument6 pagesSPECIFICATIONSWalter Garcia100% (1)

- Technical Specifications MechanicalDocument6 pagesTechnical Specifications MechanicalJanice SubidoNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- Site handover confirmation letterDocument1 pageSite handover confirmation letterAkshay BankarNo ratings yet

- Proposed 3-Storey Residence Technical SpecsDocument7 pagesProposed 3-Storey Residence Technical SpecsHannah Cesaree Mae TadeoNo ratings yet

- Building-Specifications Reynal RamosDocument5 pagesBuilding-Specifications Reynal Ramoserwin sarmientoNo ratings yet

- Proposed Two Specification WritingDocument4 pagesProposed Two Specification WritingKelly Santiago100% (1)

- Construction Specifications in The PhilippinesDocument4 pagesConstruction Specifications in The Philippinessunny sunflowerNo ratings yet

- General Specification: B. Plans and SpecificationsDocument5 pagesGeneral Specification: B. Plans and Specificationsmichael nabusNo ratings yet

- SPECIFICATIONS FOR BUILDING CONSTRUCTIONDocument3 pagesSPECIFICATIONS FOR BUILDING CONSTRUCTIONEfren ElegadoNo ratings yet

- Signage Rules and RegulationsDocument20 pagesSignage Rules and RegulationsDonna MelgarNo ratings yet

- Proposed Interior Fit-Out for Department of Tourism ShowroomDocument4 pagesProposed Interior Fit-Out for Department of Tourism ShowroomJo BompatNo ratings yet

- Residential BOM and SpecsDocument4 pagesResidential BOM and SpecsMary Ann LictaoaNo ratings yet

- Product Presentation2018Document57 pagesProduct Presentation2018Roger Anjao100% (1)

- Specification and Digest For Plumbing and Sanitary WorksDocument21 pagesSpecification and Digest For Plumbing and Sanitary WorksSeichi SorianoNo ratings yet

- Acp Cladding Option 3Document1 pageAcp Cladding Option 3SACHIDANANDA SNo ratings yet

- 16 Division SpecsDocument20 pages16 Division SpecsVincent Honasan100% (1)

- Gen Specs ArchiDocument3 pagesGen Specs ArchiElaine BinoyaNo ratings yet

- Structural Specifications for City BuildingDocument11 pagesStructural Specifications for City BuildingEd AnchetaNo ratings yet

- Proposed Two-Storey Residential Project SpecsDocument2 pagesProposed Two-Storey Residential Project SpecsLerie Lou R. PenarroyoNo ratings yet

- 4-Story Commercial and Residential Building SpecificationsDocument5 pages4-Story Commercial and Residential Building SpecificationsKURONo ratings yet

- Section VI. SpecificationsDocument11 pagesSection VI. SpecificationsDEUS PHILIP DURANNo ratings yet

- SpecificationsDocument24 pagesSpecificationsjakiri cerdina100% (1)

- Division 16 SampleDocument170 pagesDivision 16 SampleRodrigue BarbarNo ratings yet

- BusvsDuct Brown 13 PDFDocument2 pagesBusvsDuct Brown 13 PDFmathianandmNo ratings yet

- Table of Contents: Section 2.01 Section 2.02 Section 2.03Document162 pagesTable of Contents: Section 2.01 Section 2.02 Section 2.03aaaayyyynnnnNo ratings yet

- Toledo Water Treatment Facility Renovation Project SummaryDocument190 pagesToledo Water Treatment Facility Renovation Project SummaryAdam SniffNo ratings yet

- Proposed Residential ProjectDocument9 pagesProposed Residential ProjectCarlo EloyNo ratings yet

- Project Specifications Abuab SINGLE ATTACHEDDocument6 pagesProject Specifications Abuab SINGLE ATTACHEDmaria cristina santosNo ratings yet

- General notes and specifications for one-storey residenceDocument5 pagesGeneral notes and specifications for one-storey residenceJillian Flaire VillarNo ratings yet

- 01.28.19 Bom - Boq 4TH Floor Emapta Office Fitout - Ee, Mech, Plum & Structured CablingDocument10 pages01.28.19 Bom - Boq 4TH Floor Emapta Office Fitout - Ee, Mech, Plum & Structured CablingKenneth John DeondoNo ratings yet

- Tech - Specs Maricar PandaDocument56 pagesTech - Specs Maricar PandaLəonardo SasingNo ratings yet

- SSPDocument53 pagesSSPAlbert NamoroNo ratings yet

- Architects GuidelinesDocument55 pagesArchitects GuidelinesCharlon RamiscalNo ratings yet

- Building Laws Study GuideDocument5 pagesBuilding Laws Study GuideNikki Angela Lirio BercillaNo ratings yet

- Technical Specifications-PlumbingDocument52 pagesTechnical Specifications-Plumbingpandey71087100% (1)

- General and Technical Specification Section 1.0-GeneralDocument3 pagesGeneral and Technical Specification Section 1.0-GeneralTarhata KalimNo ratings yet

- Sample General SpecificationsDocument4 pagesSample General SpecificationsRoshiel LargadoNo ratings yet

- Construction Bill of QuantitiesDocument7 pagesConstruction Bill of QuantitiesMichael Parohinog Gregas67% (3)

- Mechanical Services SpecsDocument83 pagesMechanical Services SpecsMohamed EidNo ratings yet

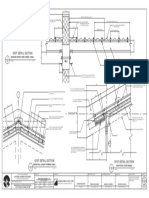

- Spot Detail Section: (Roofing Sheets and Corbel Conn.)Document1 pageSpot Detail Section: (Roofing Sheets and Corbel Conn.)Robert Christopher NiebresNo ratings yet

- Construction Specifications: General ConditionsDocument2 pagesConstruction Specifications: General ConditionsKatrina GaygayNo ratings yet

- Arch-3.1-Aluminium Doors and WindowsDocument3 pagesArch-3.1-Aluminium Doors and WindowsSherazNo ratings yet

- Marbu Contracting Company W. L. L.: FeedbackDocument1 pageMarbu Contracting Company W. L. L.: FeedbackMohamed Ismath KalideenNo ratings yet

- QCS 2014 01-1 General IntroductionDocument10 pagesQCS 2014 01-1 General IntroductionFreeOccupiedNo ratings yet

- Marbu Contracting Company W. L. L.: Document HistoryDocument1 pageMarbu Contracting Company W. L. L.: Document HistoryMohamed Ismath KalideenNo ratings yet

- Marbu Contracting Company W. L. LDocument1 pageMarbu Contracting Company W. L. LMohamed Ismath KalideenNo ratings yet

- Section 1 GeneralDocument8 pagesSection 1 GeneralBishop Ojonuguwa AmehNo ratings yet

- Elemental PlanningDocument2 pagesElemental PlanningMohamed Ismath KalideenNo ratings yet

- Block Work DetailsDocument3 pagesBlock Work DetailsMohamed Ismath KalideenNo ratings yet

- Assessment Criteria - WRITING TASK 2 - Band DescriptorsDocument1 pageAssessment Criteria - WRITING TASK 2 - Band DescriptorsIbrahim Babatunde Oladapo100% (1)

- Design of Reinforced MasonryDocument71 pagesDesign of Reinforced MasonryOliver Pocdol AmantilloNo ratings yet

- Sample House Construction Cost Estimate PhilippinesDocument6 pagesSample House Construction Cost Estimate PhilippinesBryan Bristol77% (39)

- Usdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideDocument2 pagesUsdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideMohd Shahrul Irwan Mohd ZinNo ratings yet

- Department of Agriculture and Food: MARCH 2006Document29 pagesDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcNo ratings yet

- TTMJDocument8 pagesTTMJmichele inguscioNo ratings yet

- Sample Construction SpecificationsDocument5 pagesSample Construction SpecificationsAllan Bautista100% (1)

- 4 Hour Fire Protection & Blast Protection SystemsDocument20 pages4 Hour Fire Protection & Blast Protection SystemssechooNo ratings yet

- Sloping Roof Top of A Residential BuildingDocument34 pagesSloping Roof Top of A Residential BuildingAnjaliNo ratings yet

- CIVIL SPECIFICATIONSDocument222 pagesCIVIL SPECIFICATIONSSolomon Balemezi100% (1)

- BCM User GuideDocument12 pagesBCM User GuideSan AungNo ratings yet

- FIS Client Guide Office Fit Out and Refurbishment 2018 DESKTOP QUALITY File100896Document44 pagesFIS Client Guide Office Fit Out and Refurbishment 2018 DESKTOP QUALITY File100896Mohamed987No ratings yet

- Raft Foundation DesignDocument16 pagesRaft Foundation DesignGeniuskuga Kugas50% (2)

- PW 371Document150 pagesPW 371Patrick SilberbauerNo ratings yet

- 23 0711 - Thermal Insulation PDFDocument12 pages23 0711 - Thermal Insulation PDFMohamed FawzyNo ratings yet

- PD 1096 National Building Code QuestionsDocument9 pagesPD 1096 National Building Code QuestionsRoselyn SameraNo ratings yet

- Concrete Construction Article PDF - Slurry Wall ConstructionDocument4 pagesConcrete Construction Article PDF - Slurry Wall ConstructionFELICITY MONTEFALCONo ratings yet

- Design of RC Structures Exam: Water Tank, Slab, Beam & Column DesignDocument12 pagesDesign of RC Structures Exam: Water Tank, Slab, Beam & Column DesignHeta PanchalNo ratings yet

- Plat BuildingsbuildingsDocument51 pagesPlat Buildingsbuildingsnpwal100% (1)

- FCRC BCA Fire Safety Requirements For Shopping CentresDocument53 pagesFCRC BCA Fire Safety Requirements For Shopping CentresjalajjainmanitNo ratings yet

- CPCCCM1013A Plan and Organise Work LRDocument53 pagesCPCCCM1013A Plan and Organise Work LRziga100% (1)

- RLB UK Riders Digest 2011Document69 pagesRLB UK Riders Digest 2011Rodolfo AlquezaNo ratings yet

- Building Structures As ArchitectureDocument303 pagesBuilding Structures As Architectureravi varma100% (1)

- Architectural PLans-CC Issue I-5-7 Brubang Crescent Rydalmere - CFT-151738Document48 pagesArchitectural PLans-CC Issue I-5-7 Brubang Crescent Rydalmere - CFT-151738christopher.sunNo ratings yet

- Bamboo Construction PDFDocument99 pagesBamboo Construction PDFMNIT Architecture100% (1)

- Ecumenical Church DesignDocument12 pagesEcumenical Church DesignJazze Lauren50% (2)

- MSC 0706Document38 pagesMSC 0706Sixto MillanoNo ratings yet

- Absco Shed 23141R Domestic 20 04 11 PDFDocument17 pagesAbsco Shed 23141R Domestic 20 04 11 PDFAlejandroNo ratings yet

- Riverwalk Extension Elevator StructuralDocument29 pagesRiverwalk Extension Elevator StructuralUriel Galvan CarrilloNo ratings yet

- 3 Vergara v. Sonkin PDFDocument2 pages3 Vergara v. Sonkin PDFAnna VeluzNo ratings yet

- PVC Ceiling Wall Panels Best Low Price India SupplierDocument12 pagesPVC Ceiling Wall Panels Best Low Price India SupplierOnesmas TwinomugishaNo ratings yet