Professional Documents

Culture Documents

Effects of A Diamond-Like Carbon Coating On The Frictional Properties of Orthodontic Wires

Uploaded by

Diana Paola FontechaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of A Diamond-Like Carbon Coating On The Frictional Properties of Orthodontic Wires

Uploaded by

Diana Paola FontechaCopyright:

Available Formats

Original Article

Effects of a diamond-like carbon coating on the frictional properties of

orthodontic wires

Takeshi Mugurumaa; Masahiro Iijimab; William A. Brantleyc; Itaru Mizoguchid

ABSTRACT

Objective: To test the hypothesis that a diamond-like carbon coating does not affect the frictional

properties of orthodontic wires.

Materials and Methods: Two types of wires (nickel-titanium and stainless steel) were used, and

diamond-like carbon (DLC) films were deposited on the wires. Three types of brackets, a

conventional stainless steel bracket and two self-ligating brackets, were used for measuring static

friction. DLC layers were observed by three-dimensional scanning electron microscopy (3D-SEM),

and the surface roughness was measured. Hardness and elastic modulus were obtained by

nanoindentation testing. Frictional forces and surface roughness were compared by the Kruskal-

Wallis and Mann-Whitney U-tests. The hardness and elastic modulus of the wires were compared

using Student’s t-test.

Results: When angulation was increased, the DLC-coated wires showed significantly less

frictional force than the as-received wires, except for some wire/bracket combinations. Thin DLC

layers were observed on the wire surfaces by SEM. As-received and DLC-coated wires had similar

surface morphologies, and the DLC-coating process did not affect the surface roughness. The

hardness of the surface layer of the DLC-coated wires was much higher than for the as-received

wires. The elastic modulus of the surface layer of the DLC-coated stainless steel wire was less than

that of the as-received stainless steel wire, whereas similar values were found for the nickel-

titanium wires.

Conclusions: The hypothesis is rejected. A DLC-coating process does reduce the frictional force.

(Angle Orthod. 2011;81:141–148.)

KEY WORDS: Orthodontic wire; Nickel-titanium; Stainless steel; Diamond-like carbon coating;

Frictional properties; Nanoindentation test

INTRODUCTION

Friction (resistance to sliding) between the bracket

and wire (archwire) during orthodontic tooth movement

a

Instructor, Division of Orthodontics and Dentofacial Ortho- is an important factor in clinical orthodontics because a

pedics, Department of Oral Growth and Development, Health

Sciences University of Hokkaido, Hokkaido, Japan.

decrease in friction might shorten the treatment period

b

Associate Professor, Division of Orthodontics and Dentofa- and also improve anchorage control.1 There are two

cial Orthopedics, Department of Oral Growth and Development, types of friction: static and kinetic. Static friction occurs

Health Sciences University of Hokkaido, Hokkaido, Japan. until the force is great enough to overcome the initial

c

Professor, Division of Restorative and Prosthetic Dentistry, resistance to movement of the object; kinetic friction

Ohio State University, Columbus, Ohio.

d

Professor, Division of Orthodontics and Dentofacial Ortho-

then opposes the continuation of movement.1 The

pedics, Department of Oral Growth and Development, Health kinetic friction is irrelevant in orthodontic tooth move-

Sciences University of Hokkaido, Hokkaido, Japan. ment because continuous motion along an archwire

Corresponding author: Dr Masahiro Iijima, Division of Ortho- rarely, if ever, occurs.1 Friction during clinical tooth

dontics and Dentofacial Orthopedics, Department of Oral Growth

movement depends on the size and shape of the wire,2

and Development, Health Sciences, University of Hokkaido,

1757, Kanazawa Ishikari-tobetsu, Hokkaido 061-0293 Japan the bracket type,3,4 the bracket and wire materials,5 the

(e-mail: iijima@hoku-iryo-u.ac.jp) angulation of the wire relative to the bracket,6 the type

Accepted: July 2010. Submitted: May 2010.

of ligation,2 and whether the environment is wet or dry.7

G 2011 by The EH Angle Education and Research Foundation, Kusy and Whitley8 divided friction into three compo-

Inc. nents: (1) friction, static and kinetic, due to contact of

DOI: 10.2319/052110-276.1 141 Angle Orthodontist, Vol 81, No 1, 2011

142 MUGURUMA, IIJIMA, BRANTLEY, MIZOGUCHI

the wire with the bracket surface; (2) binding, created ligating brackets. The wire surfaces were character-

when the tooth tips or the wire flexes so that there is ized by a three-dimensional scanning electron micro-

contact between the wire and the corners of the scope (3D-SEM); the hardness and elastic modulus

bracket; and (3) notching, when permanent deforma- were investigated by nanoindentation testing. It was

tion of the wire occurs at the wire-bracket corner hypothesized that a DLC coating does not affect the

interface. frictional properties of orthodontic wires.

Ever since self-ligating brackets were introduced a

few decades ago, they have become widely used in MATERIALS AND METHODS

clinical orthodontics. A previous study with an in vitro

Materials

model showed that friction at an angulation of 0u was

lower for self-ligating brackets than for a conventional Nickel-titanium wires with a diameter of 0.016 inch

bracket.9 However, when the wire-bracket angulation (Nitinol Super Elastic, 3M Unitek, Monrovia, Calif) and

increased, binding also increased, and the binding was stainless steel wires with a diameter of 0.018 inch or

similar with conventional and self-ligating brackets. cross-section dimensions of 0.019 inch 3 0.025 inch

Recently, a plasma immersion ion implantation (stainless steel archwire, 3M Unitek) were used in this

technique has become quite common in surface- study. One hundred twenty upper canine brackets for

coating to improve the mechanical properties and each of three types were used. The conventional

corrosion resistance of beta-titanium10 and nickel- stainless steel brackets (Victory Series, 3M Unitek)

titanium alloys.11 Ion-implanted nickel-titanium wire had a slot dimension of 0.022 inch, a mesiodistal width

(Neo Sentally Ionguard, GAC International, Islandia, of 3.2 mm and no built-in torque or tip. The In-Ovation

NY) and beta-titanium wire (Low Friction TMA, Ormco, self-ligating brackets (GAC International) had a slot

Orange, Calif) are commercially available. Previous dimension of 0.022 inch, a mesiodistal width of 3.0 mm

studies12 with an in vitro model have shown that ion- and no built-in torque or tip. The Damon Q self-ligating

implanted wires (nickel-titanium and beta-titanium) brackets (Ormco, Orange, Calif) had a slot dimension

produce less frictional forces during tooth movement, of 0.022 inch, a mesiodistal width of 2.8 mm, 0u torque,

although another randomized clinical trial on initial and +5u angulation.

alignment13 showed that there were no significant

differences between ion-implanted nickel-titanium wire DLC-coating Procedure

and nonimplanted nickel-titanium wire. Another sur-

DLC films were deposited on the nickel-titanium and

face-coating technique with diamond-like carbon

stainless steel wires using the plasma-based ion

(DLC), which offers excellent properties such as

implantation/deposition (PBIID) method. All wires were

extreme hardness, low friction coefficients, and high

fixed with a custom-made jig in the PBIID equipment

wear-resistance14 is becoming increasingly important

(PEKURIS-HI, Kurita Seisakusho, Kyoto, Japan), and

in industrial applications, and the application of a DLC

deposition was carried out at a target voltage of 5 kV

film to orthodontic appliances offers the potential of

under a pressure of 1.33 3 1023 Pa and an acetylene

greatly improving frictional properties and corrosion

gas atmosphere for 400 minutes.16

resistance. A recent study showed that DLC films

protect against the diffusion of nickel and its release at

Friction Test

the surface of nickel-titanium archwires, and that these

films are noncytotoxic in a corrosive environment.14 The static frictional force generated with each wire/

Another research group investigated the effect of DLC bracket combination was measured under dry condi-

coating on the static and kinetic friction of stainless tions and at room temperature (25uC) using a custom-

steel, copper nickel-titanium, and beta-titanium wires, fabricated friction-testing device attached to a univer-

and found that DLC coatings of copper nickel-titanium sal testing machine (EZ Test, Shimadzu, Kyoto,

and beta-titanium produced less frictional resistance Japan) with a load cell of 20 N (Figure 1a). The

than found for as-received wires.15 However, they did custom-fabricated friction-testing device was designed

not study the mechanical properties and morphology of according to the descriptions by Redlich et al.3 and

the DLC layer, which greatly influences the frictional Cha et al.17 Each bracket was bonded with a nonfilled

properties. adhesive resin (Superbond, Sun Medical, Shiga,

The purpose of this study was to investigate the Japan) to a stainless steel plate using a bracket-

effect of a DLC coating on the frictional properties of mounting device (Figure 1b through d), which could

orthodontic nickel-titanium and stainless steel wires. give an accurate angulation to the nearest degree. In

Static friction of the as-received and DLC-coated wires this study, an angulation of 0u or 10u was selected to

was measured with a custom-fabricated friction-testing position the bracket. The stainless steel plate with the

device for a conventional bracket and two types of self- bracket was attached to the friction-testing device, and

Angle Orthodontist, Vol 81, No 1, 2011

DIAMOND-LIKE CARBON COATING OF ORTHODONTIC WIRES 143

Figure 1. Friction-testing system. (a) Custom-fabricated friction-testing device attached to a universal testing machine. (b), (c), and (d) Bracket-

mounting device. A, grip; B, bracket/wire combination specimen; C, stainless steel plate; D, weight (150 g); and E, angle measurement device.

a 5-cm segment of wire was then ligated to the bracket at five different areas for each wire was calculated by

with an elastomeric ligature (AlastiK Easy-to-Tie software that was supplied with 3D-SEM.

Ligatures, 3M Unitek), except that the self-ligating

brackets were tested in a closed position. The upper Nanoindentation Test

end of the wire was fixed in a grip that was attached to

The external surfaces of the as-received and DLC-

the load cell, and the lower end of the wire was fixed to coated wires were fixed to the specimen stage for the

a 150-g weight. Each wire was drawn through the nanoindentation test using adhesive resin. All nanoin-

bracket at a cross-head speed of 10 mm/min for a dentation testing was carried out at 28uC (ENT-1100a,

distance of 5 mm. The static frictional force was Elionix) using a Berkovich indenter. The measurement

determined from load-displacement curves.1 The points were selected using the optical microscope and

sample size for each bracket/wire combination and charge-coupled device (CCD) camera coupled to the

for the two bracket angulations (0u or 10u) was 10. A nanoindentation test apparatus. Each test consisted of

total of 360 brackets were used in this study. three segments: 10 seconds for loading to the peak

value, a 1-second hold at the peak load, and 10 seconds

3D-SEM Observation and Measurement of the for unloading. Two peak loads, 5 mN and 100 mN, were

Surface Roughness used for measurements. The maximum depth of

To observe the DLC layer in cross-section, repre- indentation, hardness, and elastic modulus were calcu-

sentative DLC-coated nickel-titanium and stainless lated by software that was supplied with the nanoinden-

steel wires were encapsulated in epoxy resin (Epofix, tation apparatus, using equations in ISO Standard

Struers, Copenhagen, Denmark) and polished using a 14577.18 The sample size for each wire was 10.

series of silicon carbide abrasive papers and a final

slurry of 0.05-mm alumina particles; argon ion etching Statistical Analysis

was carried out using an ion shower apparatus (EIS- Statistical analysis was performed using the Statis-

200ER, Elionix, Tokyo, Japan). The DLC layers were tical Package for Social Science software (version

observed by 3D-SEM (ERA-8900, Elionix) with four- 16.0J for Windows, SPSS Inc, Chicago, Ill). The data

channel secondary electron detectors. were examined for normality with the Levene’s test.

To observe and characterize the external surfaces of Since the data for the mean static frictional force were

the as-received and DLC-coated wires, all specimens not normally distributed, values were compared using

were sputter-coated with platinum and examined using the Kruskal-Wallis test and the Mann-Whitney U-test.

3D-SEM. The Ra value, the arithmetic mean of the Significance was predetermined at P , .0167. Since

height of peaks and depth of valleys from a mean line, the data for surface roughness were also not normally

was used for values of the surface roughness. The Ra distributed, mean values were compared by the Mann-

Angle Orthodontist, Vol 81, No 1, 2011

144 MUGURUMA, IIJIMA, BRANTLEY, MIZOGUCHI

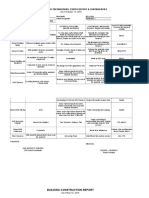

Figure 2. Static frictional forces for angulations of 0u and 10u for conventional and self-ligating brackets with as-received and DLC-coated wires.

Comparisons are presented for each bracket in the three types of wires. Left side, Damon Q; middle, In-Ovation; and right side, Victory brackets.

* P , .0167 by Mann-Whitney U-test; ns indicates nonsignificant.

Whitney U-test (P , .05). Since the data were normally frictional forces increased in all of the bracket-wire

distributed for the maximum depth of indentation, combinations, and the DLC-coated nickel-titanium and

hardness, and elastic modulus, mean values for the stainless steel wires showed significantly less frictional

as-received and DLC-coated wires were compared force than as-received wires, except for some wire/

using Student’s t-test (P , .05). bracket combinations. Both self-ligating brackets

showed significantly less frictional force than the

conventional bracket at 0u angulation. When angula-

RESULTS

tion was increased to 10u, both self-ligating brackets

Table 1 and Figure 2 show static frictional forces for had significantly less frictional force than the conven-

angulations of 0u and 10u for conventional and self- tional bracket for the as-received wires, except for the

ligating brackets and for as-received and DLC-coated Damon Q bracket/as-received 0.019 inch 3 0.025 inch

wires. When the angulation was increased to 10u, the stainless steel wire combination (P 5 .063).

Angle Orthodontist, Vol 81, No 1, 2011

DIAMOND-LIKE CARBON COATING OF ORTHODONTIC WIRES 145

Table 1. Static Frictional Forces for 0u and 10u Angulations of Conventional (Victory) and Self-Ligating Brackets (Damon Q, In-Ovation) to As-

Received and DLC-Coated Wiresa

Friction Force (gf)

As-Received DLC-Coating

Angulation,

Degree Bracket Wire Mean SD Mean SD P Value

0 Damon Q .016-in NiTi 6.63 2.15 6.12 1.32 .796

.018-in SS 7.39 1.88 6.88 1.23 .631

.019-in 3 .025-in SS 6.63 1.78 9.43 1.23 .003

In-Ovation .016-in NiTi 6.88 1.72 6.88 2.42 .971

.018-in SS 7.14 1.61 6.37 1.8 .481

.019-in 3 .025-in SS 46.65 8.92 46.65 7.11 .739

Victory .016-in NiTi 125.68 26.14 98.66 13.17 .011

.018-in SS 123.13 33.59 79.03 7.88 .0001

.019-in 3 .025-in SS 120.58 16.04 101.97 11.71 .015

10 Damon Q .016-in NiTi 54.55 14.08 31.61 5.79 .001

.018-in SS 139.19 40.7 110.89 15.91 .063

.019-in 3 .025-in SS 298.01 45.82 254.42 37.19 .019

In-Ovation .016-in NiTi 41.3 11.82 26 3.56 .0001

.018-in SS 117.52 43.64 88.21 11.41 .063

.019-in 3 .025-in SS 235.04 41.76 187.88 22.1 .002

Victory .016-in NiTi 191.45 30.2 113.95 14.47 .0001

.018-in SS 211.08 29.55 182.78 22.48 .043

.019-in 3 .025-in SS 353.84 68.57 336 42.96 .739

a

DLC indicates diamond-like carbon; NiTi, nickel-titanium; and SS, stainless steel.

Figure 3 shows representative SEM photomicro- roughness shown in Table 2 confirmed that the

graphs for cross-sectioned DLC-coated stainless steel nickel-titanium wires had greater surface roughness

and nickel-titanium wires. The figure clearly shows that than the stainless steel wires, and the DLC-coating

the thin DLC layers on the wire surfaces have a process did not affect the surface roughness (P 5

thickness of approximately 0.5 mm. .548).

Figure 4 shows 3D-SEM images of stainless steel The mean values and standard deviations for the

and nickel-titanium wires. The as-received and DLC- maximum depth of indentation hmax, hardness, and

coated wires had similar surface morphologies for both elastic modulus obtained in the nanoindentation tests

the stainless steel and nickel-titanium wires. On the on the wire surfaces (5 and 100 mN peak load) are

other hand, the surface morphology of the nickel- listed in Table 3. The mechanical properties obtained

titanium wires was rougher than that of the stainless with a 5 mN peak load are mainly for the DLC layers

steel wires. Quantitative analysis of the surface because the hmax of the 5 mN peak load was less than

Figure 3. SEM photomicrographs of cross-sectioned (a) stainless steel and (b) nickel-titanium wires. DLC layers formed on the wires are evident.

Original magnification 20,0003. E indicates epoxy resin; D, DLC layer; and W, wire.

Angle Orthodontist, Vol 81, No 1, 2011

146 MUGURUMA, IIJIMA, BRANTLEY, MIZOGUCHI

Figure 4. Images of stainless steel and nickel-titanium wires obtained with four-channel 3D-SEM. (a) As-received stainless steel wire. (b) DLC-

coated stainless steel wire. (c) As-received nickel-titanium wire. (d) DLC-coated nickel-titanium wire. Original magnification 10003.

300 nm for both stainless steel and nickel-titanium DISCUSSION

wires. The hardness for the DLC-coated stainless steel

Frictional force between the bracket and the wire

and nickel-titanium wires obtained with the 5 mN load

during orthodontic tooth movement is an important

was much higher than that of the as-received stainless

factor in clinical orthodontics, and if the frictional force

steel (P 5 .0001) and nickel-titanium wires (P 5

can be decreased, the efficiency of tooth movement

.0001). On the other hand, the elastic modulus for the

can be improved. The frictional forces increased when

DLC-coated stainless steel wire obtained with a 5 mN

the angulation was increased for all of the bracket-wire

load was less than that of the as-received stainless

combinations in this study, and this is consistent with

steel wire (P 5 .0001). The hardness and elastic

previous studies.3,17 In this study, although the stain-

modulus for nickel-titanium wires obtained with a

less steel wire showed smoother and harder surface

100 mN load were similar for DLC-coated and as-

characteristics than the nickel-titanium wire, the

received wires.

stainless steel wires had greater frictional forces than

the nickel-titanium wires. The stainless steel wires had

Table 2. Average Surface Roughness (Ra Value) for Stainless wider cross-section dimensions and a higher value of

Steel and Nickel-Titanium Wires the elastic modulus than the nickel-titanium wires, and

Surface Roughness, mm this should have affected binding and notching.

DLC coatings are becoming increasingly important

As-Received DLC-Coating

in industrial and biomedical applications.19,20 Hardness

Wire Mean SD Mean SD P Value

is often the most noted property of DLC coatings. It can

Stainless steel 0.035 0.01 0.032 0.004 .548 be challenging to determine the true mechanical

Nickel-titanium 0.094 0.009 0.088 0.013 .548

properties of a material that exists only as a thin

Angle Orthodontist, Vol 81, No 1, 2011

DIAMOND-LIKE CARBON COATING OF ORTHODONTIC WIRES 147

Table 3. Summary of Mechanical Properties for As-Received and DLC-Coated Wires Obtained by the Nanoindentation Test

As-received DLC-coating

Wire Peak Load, mN Mean SD Mean SD P Value

Stainless steel 5 hmax, nm 157.37 6.17 146.75 5.03 .001

Hardness, GPa 11.62 0.99 17.58 1.67 .0001

Elastic modulus, GPa 277.39 16.33 194.44 9.09 .0001

100 hmax, nm 958.88 56.59 891.42 24.17 .005

Hardness, GPa 6.15 0.84 7.18 0.52 .004

Elastic modulus, GPa 143.26 11.21 158.65 2.1 .0001

Nickel-titanium 5 hmax, nm 253.12 13.22 215.34 4.39 .0001

Hardness, GPa 4.72 0.56 9.11 0.51 .0001

Elastic modulus, GPa 82.87 6.27 74.87 2.84 .002

100 hmax, nm 1273.95 46.91 1275.61 76.99 .954

Hardness, GPa 3.73 0.32 3.85 0.54 .538

Elastic modulus, GPa 63.56 3.44 60.28 4.97 .104

coating less than a few micrometers thick. The recent ets produced almost 0 g for 0u angulation, excluding

development of the nanoindentation technique, which the In-Ovation bracket/0.019 inch 3 0.025 inch stain-

offers nanometer-scale resolution, has allowed such less steel wire combination. However, this condition

measurements to be successfully performed.21 Most (0u angulation) never occurs clinically. When angula-

DLC films are harder than most metallic materials, and tion was increased to 10u, the In-Ovation bracket

DLC coating by the PBIID gives hardness values showed a lower rate of increase in the frictional force

ranging from 6 GPa to 20 GPa depending on the than the Damon Q bracket, even though the In-Ovation

deposition conditions.19,20 In this study, the hardness bracket has a wider mesiodistal width than the Damon

values of the DLC layer on the stainless steel Q bracket. The results of this study showed that a self-

(17.6 GPa) and nickel-titanium wires (9.1 GPa) were ligating bracket/DLC-coated wire combination is ben-

determined by the nanoindentation test and were eficial for orthodontic tooth movement.

significantly higher than the hardness values of the

surface layers on the as-received stainless steel CONCLUSIONS

(11.6 GPa) and nickel-titanium wires (4.7 GPa). This

N The surfaces of nickel-titanium and stainless steel

study clearly demonstrated that the DLC-coating

orthodontic wires can be successfully modified by

process reduces frictional force. The harder surface

the PBIID method to create a DLC layer.

of the DLC-coated wires not only reduces friction but

N The DLC-coating process reduces the frictional force

also reduces the effects of binding and notching. In

for these wires in brackets.

addition, the DLC layer on the stainless steel and

N The DLC layer has a higher hardness value than the

nickel-titanium wires showed a lower elastic modulus

as-received wires.

than the surface layer on the as-received wires. DLC-

N Self-ligating brackets produce less frictional force

coated wires with a lower elastic modulus might show

than the conventional stainless steel bracket.

superior flexibility, which is a desirable characteristic of

an orthodontic wire. Further research is needed to

evaluate the flexibility of the DLC-coated orthodontic ACKNOWLEDGMENTS

wires. The authors thank Masahiko Sugihara and Yoshimi Nishimura

The basic advantages of self-ligating brackets at Kurita Seisakusho for their expert technical assistance with

involve the elimination of certain utilities or materials the DLC-coating procedure, and Yukiko Omata and Yoichiro

such as elastomeric modules, along with the process Morita at Elionix for kindly performing the SEM observations.

or tools associated with their application.4 In addition, it

has been proposed that due to bracket-wire engage- REFERENCES

ment, light forces and reduced friction can be attained 1. Burrow SJ. Friction and resistance to sliding in orthodontics:

with a desirable outcome on the rate of orthodontic a critical review. Am J Orthod Dentofacial Orthop. 2009;135:

tooth movement.22 However, a recent study concluded 442–447.

that a self-ligating bracket was no better during initial 2. Bazakidou E, Nanda RS, Duncanson MG Jr, Sinha P.

Evaluation of frictional resistance in esthetic brackets.

alignment than a conventional bracket.4 In the present

Am J Orthod Dentofacial Orthop. 1997;112:138–144.

study, both self-ligating brackets produced significantly 3. Redlich M, Mayer Y, Harari D, Lewinstein I. In vitro study of

less frictional forces in both angulations (0u or 10u) frictional force during sliding mechanics of ‘‘reduced-friction’’

than the conventional bracket. The self-ligating brack- brackets. Am J Orthod Dentofacial Orthop. 2003;124:69–73.

Angle Orthodontist, Vol 81, No 1, 2011

148 MUGURUMA, IIJIMA, BRANTLEY, MIZOGUCHI

4. Miles PG, Weyant RJ, Rustveld L. A clinical trial of Damon 2 Ni-Ti archwires for initial alignment. Clin Orthod Res.

vs conventional twin brackets during initial alignment. Angle 1998;1:12–19.

Orthod. 2006;76:480–485. 14. Kobayashi S, Ohgoe Y, Ozeki K, Hirakuri K, Aoki H.

5. Saunders CR, Kusy RP. Surface topography and frictional Dissolution effect and cytotoxicity of diamond-like-carbon

characteristics of ceramic brackets. Am J Orthod Dentofa- coating on orthodontic archwires. J Mater Sci Mater Med.

cial Orthop. 1994;106:76–87. 2007;18:2263–2268.

6. Frank CA, Nikolai RJ. A comparative study of frictional 15. Bentahar Z, Barouins M, Clin M, Bouhammar N, Boussiri K.

resistance between orthodontic bracket and archwire. Tribological performance of DLC-coated stainless steel,

Am J Orthod Dentofacial Orthop. 1980;78:593–609. TMA and Cu-NiTi. Int Orthod. 2008;6:335–342.

7. Thorstenson G, Kusy R. Influence of stainless steel inserts 16. Aisenberg S, Chabot R. Ion-beam deposition of thin films of

on the resistance to sliding of esthetic brackets with second- diamondlike carbon. J Appl Phys. 1971;42:2953–2958.

order angulation in the dry and wet states. Angle Orthod. 17. Cha J, Kim K, Hwang C. Friction of conventional and silica-

2003;73:167–175. insert ceramic bracket in various bracket-wire combinations.

8. Kusy RP, Whitley JQ. Influence of archwire and bracket Angle Orthod. 2007;77:100–107.

dimensions on sliding mechanics: derivations and determi- 18. ISO 14577-1. Metallic materials – Instrumented indentation

nations of the critical contact angles for binding. Eur J Orthod. test for hardness and materials parameters- Part 1: Test

1999;21:199–208. method. 1st ed. International Organization for Standardiza-

9. Thorstenson G, Kusy R. Comparison of resistance to sliding tion; 2002.

between difference self-ligating brackets with second-order 19. Sridharan K, Anders S, Nastasi M, Walter KC, Anders A,

angulation in the dry and saliva state. Am J Orthod Monterio OR, Ensinger W. Nonsemiconductor application of

Dentofacial Orthop. 2002;121:472–482. PIII&D. In: Anders A, ed. Handbook of Plasma Immersion

10. Kusy RP, Tobin EJ, Whitley JQ, Sioshansi P. Frictional Ion Implantation and Deposition. New York, NY: Wiley &

coefficients of ion-implanted alumina against ion-implanted Sons. 2000.

beta-titanium in the low load, low velocity, single pass 20. Fontaine J, Donnet C, Erdemir A. Fundamentals of the

regime. Dent Mater. 1992;8:167–172. tribology of DLC coating. In: Donnet C, Erdemir A, eds.

11. Yeung KW, Poon RW, Liu XY, et al. Corrosion resistance, Tribology of Diamond-like Carbon Films. New York, NY:

surface mechanical properties, and cytocompatibility of Springer; 2008:139–154.

plasma immersion ion implantation-treated nickel-titanium 21. Alcock JP, Barbour ME, Sandy JR, Ireland AJ. Nanoinden-

shape memory alloys. J Biomed Mater Res A. 2005;75: tation of orthodontic archwires: the effect of decontamination

256–267. and clinical use on hardness, elastic modulus and surface

12. Wichelhaus A, Geserick M, Hibst R, Sander FG. The effect roughness. Dent Mater. 2009;25:1039–1043.

of surface treatment and clinical use on friction in NiTi 22. Pandis N, Eliades T, Bourauel C. Biomechanics of self-ligation:

orthodontic wires. Dent Mater. 2005;21:938–945. analysis of forces and moments exerted by self-ligation

13. Cobb NW, Kula KS, Phillips C, Proffit WR. Efficiency of brackets. In: Eliades T, Pandis N, eds. Self-ligation in

multi-strand steel, superelastic Ni-Ti and ion-implanted Orthodontics. West Sussex, UK: Wiley-Blackwell; 2009:33–44.

Angle Orthodontist, Vol 81, No 1, 2011

You might also like

- Advances in WiresDocument47 pagesAdvances in WiresHarshita DabasNo ratings yet

- Wjoud 9 387Document7 pagesWjoud 9 387KhalilNo ratings yet

- Effect of Coating On Properties of Esthetic Orthodontic Nickel-Titanium WiresDocument7 pagesEffect of Coating On Properties of Esthetic Orthodontic Nickel-Titanium WiresJacqueline Ortiz RNo ratings yet

- Alcock 2009Document5 pagesAlcock 2009Lalo MojicaNo ratings yet

- Jos 2 61Document6 pagesJos 2 61Bethiza CamposNo ratings yet

- Nickel-Titanium (NiTi) Arch Wires - The Clinical Significance of Super ElasticityDocument9 pagesNickel-Titanium (NiTi) Arch Wires - The Clinical Significance of Super Elasticityplazari07No ratings yet

- In Vitro Evaluation of Frictional Force of A Novel Elastic Bendable OrthodonticDocument9 pagesIn Vitro Evaluation of Frictional Force of A Novel Elastic Bendable OrthodonticSantiago Valencia RicoNo ratings yet

- Effects of torque on friction of self-ligating bracketsDocument8 pagesEffects of torque on friction of self-ligating bracketsmanuela castroNo ratings yet

- Newer Orthodontic Archwires: Imparting Efficacy To EstheticsDocument4 pagesNewer Orthodontic Archwires: Imparting Efficacy To EstheticsSelvaArockiamNo ratings yet

- Widu 1999Document7 pagesWidu 1999johnNo ratings yet

- Eliades 2007Document10 pagesEliades 2007Beatriz ChilenoNo ratings yet

- Corrosion Resistance and Mechanical Properties of Titanium Nitride Plating On Orthodontic WiresDocument7 pagesCorrosion Resistance and Mechanical Properties of Titanium Nitride Plating On Orthodontic WiresFadhil VisraNo ratings yet

- Comparative study clarifies best material for partial denture claspsDocument22 pagesComparative study clarifies best material for partial denture claspsPradusha RevuruNo ratings yet

- New Orthodontic Arch Wires Under 40 CharactersDocument49 pagesNew Orthodontic Arch Wires Under 40 CharactersnivethaseshaNo ratings yet

- Microstructures of BrazingsDocument9 pagesMicrostructures of BrazingsLucas SerenaNo ratings yet

- Pernos Prefabricaddoss Metalicos. ComparacionesDocument10 pagesPernos Prefabricaddoss Metalicos. ComparacionesYvelisse LoraNo ratings yet

- White Coated Niti WiresDocument8 pagesWhite Coated Niti WiresSai KrupaNo ratings yet

- Influence of Different Posts and Cores On MarginalDocument10 pagesInfluence of Different Posts and Cores On Marginalfebriani serojaNo ratings yet

- Sailer I Et Al. 2009 (JOMI)Document9 pagesSailer I Et Al. 2009 (JOMI)Alla MushkeyNo ratings yet

- Articulo CorrosiónDocument8 pagesArticulo CorrosiónJacqueline Ortiz RNo ratings yet

- CJV 017Document9 pagesCJV 017malifaragNo ratings yet

- Jurnal Ortho 1Document10 pagesJurnal Ortho 1Santika IndahsariNo ratings yet

- Kiara Kirpalani - Force Deflection Comparison of Various Heat-Activated Superelastic Nickel-Titanium Archwires - An StudyDocument6 pagesKiara Kirpalani - Force Deflection Comparison of Various Heat-Activated Superelastic Nickel-Titanium Archwires - An StudyDr Kiara KirpalaniNo ratings yet

- Friction Behavior of The Wire Material Gummetal 2021Document14 pagesFriction Behavior of The Wire Material Gummetal 2021Santiago Valencia RicoNo ratings yet

- Choi 2015Document9 pagesChoi 2015Abad SalcedoNo ratings yet

- Na Orces Between Bracket and Are: Bonn, West GermanyDocument8 pagesNa Orces Between Bracket and Are: Bonn, West GermanyGoutam NookalaNo ratings yet

- Properties of Materials Used in Orthopaedic FixationDocument3 pagesProperties of Materials Used in Orthopaedic FixationSabrina RosoiuNo ratings yet

- Cantiliver PosibleDocument8 pagesCantiliver PosibleGary FukcoreNo ratings yet

- Eur J Orthod 2012 Yoshida 493 7Document5 pagesEur J Orthod 2012 Yoshida 493 7manikantatssNo ratings yet

- Orthodontic WiresDocument35 pagesOrthodontic WiresSadhu Abhijeet100% (1)

- Frictional MechanicsDocument68 pagesFrictional Mechanicschirag sahgalNo ratings yet

- The Electrochemical Oxide Growth Behaviour On Titanium in Acid PDFDocument18 pagesThe Electrochemical Oxide Growth Behaviour On Titanium in Acid PDFClaudiaOllivveiraNo ratings yet

- Orthodontic Wires and Its Corrosiondthe Specific Case of Stainless Steel and Beta-TitaniumDocument7 pagesOrthodontic Wires and Its Corrosiondthe Specific Case of Stainless Steel and Beta-TitaniumjihaanNo ratings yet

- Newer Orthodontic Arch WiresDocument81 pagesNewer Orthodontic Arch WiresMothi Krishna100% (1)

- The efficacy of polyether-ether-ketone wire as a retainer following orthodontic treatmentDocument11 pagesThe efficacy of polyether-ether-ketone wire as a retainer following orthodontic treatmentsvamderNo ratings yet

- Deflection Test Forces of Orthodontic Wire MaterialsDocument7 pagesDeflection Test Forces of Orthodontic Wire Materialsyuni madjidNo ratings yet

- Advancements in Arch WireDocument14 pagesAdvancements in Arch WireKrishna SharmaNo ratings yet

- 02-Characteristics and Porcelain Bond Strength of (Ti, Al) N Coating On Dental AlloysDocument6 pages02-Characteristics and Porcelain Bond Strength of (Ti, Al) N Coating On Dental Alloysshaoyun ZHOUNo ratings yet

- Bond Strength of Various Bracket Base Designs: Original ArticleDocument6 pagesBond Strength of Various Bracket Base Designs: Original ArticleFrancisco MolinaNo ratings yet

- Two-Body Wear Comparison of Zirconia Crown, Gold Crown, and Enamel Against ZirconiaDocument8 pagesTwo-Body Wear Comparison of Zirconia Crown, Gold Crown, and Enamel Against ZirconiaJuan Andres EspinozaNo ratings yet

- Chapter 6Document16 pagesChapter 6drvenumadhavreddyNo ratings yet

- 2023 ZHOU Effects of Various Coating Methods On The Mechanical Physycal and Aesthetic Properties of Gummetal Archwires in Vitro StudyDocument15 pages2023 ZHOU Effects of Various Coating Methods On The Mechanical Physycal and Aesthetic Properties of Gummetal Archwires in Vitro StudyMarcelo Antonio DamianNo ratings yet

- 00 Power ChainsDocument7 pages00 Power Chainsplazari07No ratings yet

- Dental Research Journal: Effect of Electrical Spot Welding On Load Defl Ection Rate of Orthodontic WiresDocument5 pagesDental Research Journal: Effect of Electrical Spot Welding On Load Defl Ection Rate of Orthodontic WiresELIS JOHANA PATERNINA MOGUEANo ratings yet

- Effect of Electropolishing Profile Nickel-Titanium Rotary Instruments On Cyclic Fatigue Resistance, Torsional Resistance, and Cutting EfficiencyDocument4 pagesEffect of Electropolishing Profile Nickel-Titanium Rotary Instruments On Cyclic Fatigue Resistance, Torsional Resistance, and Cutting EfficiencyPatiiTéllezNo ratings yet

- Effect of Different Surface Treatments of Titanium Surfaces On The Shear Bond Strength Between Titanium and Zirconia SurfacesDocument7 pagesEffect of Different Surface Treatments of Titanium Surfaces On The Shear Bond Strength Between Titanium and Zirconia SurfacesRanj KhaznadarNo ratings yet

- Article in Press TSF Special IssueDocument6 pagesArticle in Press TSF Special IssueBiosuntaoNo ratings yet

- 10 Review JaiswalDocument7 pages10 Review JaiswalAniket PotnisNo ratings yet

- 3 SS FrictionDocument7 pages3 SS FrictionJohnNo ratings yet

- Mechanical Properties of NiTi and CuNiTi Shape-Memory Wires Used in Orthodontic Treatment. Part 1: Stress-Strain TestsDocument9 pagesMechanical Properties of NiTi and CuNiTi Shape-Memory Wires Used in Orthodontic Treatment. Part 1: Stress-Strain TestsClaudiaNo ratings yet

- An Overview of Orthodontic WiresDocument5 pagesAn Overview of Orthodontic Wiresdr arjunNo ratings yet

- Comparing Fracture Resistance of Metal Posts Fabricated by Casting, CAD/CAM, and 3D PrintingDocument6 pagesComparing Fracture Resistance of Metal Posts Fabricated by Casting, CAD/CAM, and 3D PrintingTiago CostaNo ratings yet

- 1 s2.0 S030057122300146X MainDocument4 pages1 s2.0 S030057122300146X MainMairaMaraviChavezNo ratings yet

- Out 1 PDFDocument3 pagesOut 1 PDFInddah NiiNo ratings yet

- Mechanical Evaluation of Peek Compared With Zirconia As A Dental Implant MaterialDocument6 pagesMechanical Evaluation of Peek Compared With Zirconia As A Dental Implant MaterialDiaa M. ZahranNo ratings yet

- Effects of Surface Coating: and Comparison of Existing Metal Impalnts With TantalumDocument14 pagesEffects of Surface Coating: and Comparison of Existing Metal Impalnts With TantalumbmkrameshNo ratings yet

- 1 s2.0 S009923992100474X MainDocument6 pages1 s2.0 S009923992100474X MainusrazvanNo ratings yet

- Plasma Etching Processes for Interconnect Realization in VLSIFrom EverandPlasma Etching Processes for Interconnect Realization in VLSINicolas PossemeNo ratings yet

- Arquitectura Del SueñoDocument10 pagesArquitectura Del SueñoDiana Paola FontechaNo ratings yet

- Stability of Transverse Expansion in The Mandibular ArchDocument6 pagesStability of Transverse Expansion in The Mandibular ArchManena RivoltaNo ratings yet

- Art Exp Mandibular 2Document11 pagesArt Exp Mandibular 2Diana Paola FontechaNo ratings yet

- Art Exp Mandibular3Document13 pagesArt Exp Mandibular3Diana Paola FontechaNo ratings yet

- ART - EXP.MAND.8.Three Dimensional Evaluation of Mandibular Midline Distraction A Systematic ReviewDocument32 pagesART - EXP.MAND.8.Three Dimensional Evaluation of Mandibular Midline Distraction A Systematic ReviewDiana Paola FontechaNo ratings yet

- 2-Sleep Apnea PDFDocument17 pages2-Sleep Apnea PDFAmro YounisNo ratings yet

- Arquitectura Del SueñoDocument10 pagesArquitectura Del SueñoDiana Paola FontechaNo ratings yet

- ART - EXP.MAND.7.Postretention Changes in Mandibular CrowdingDocument11 pagesART - EXP.MAND.7.Postretention Changes in Mandibular CrowdingDiana Paola FontechaNo ratings yet

- Paget's Disease of Bone: Torrijos Eslava ADocument2 pagesPaget's Disease of Bone: Torrijos Eslava ADiana Paola FontechaNo ratings yet

- Mechanics of Tooth Movement: or SmithDocument14 pagesMechanics of Tooth Movement: or SmithRamesh SakthyNo ratings yet

- Peterson's Principles of Oral and Maxillofacial Surgery 2nd Ed 2004Document1,477 pagesPeterson's Principles of Oral and Maxillofacial Surgery 2nd Ed 2004Hakan Iyisu89% (63)

- Downs1948 PDFDocument29 pagesDowns1948 PDFDiana Paola FontechaNo ratings yet

- Lillian B. MVSS, N.i) .S., XS.," kRORA, ILL: (1786) U-As OneDocument21 pagesLillian B. MVSS, N.i) .S., XS.," kRORA, ILL: (1786) U-As OneDiana Paola FontechaNo ratings yet

- 5.-T-Loop Position and Anchorage ControlDocument7 pages5.-T-Loop Position and Anchorage ControlVerónica Patricia Anicama ChávezNo ratings yet

- Equilibrium ClarifiedDocument8 pagesEquilibrium ClarifiedDiana Paola FontechaNo ratings yet

- Evaluation of Continuous Arch and Segmented Arch Leveling Techniques in Adult Patients-A Clinical Study PDFDocument6 pagesEvaluation of Continuous Arch and Segmented Arch Leveling Techniques in Adult Patients-A Clinical Study PDFDiana Paola FontechaNo ratings yet

- On Mechanical Properties of Square and Rectangular Stainless Steel Wires Tested in Torsion PDFDocument11 pagesOn Mechanical Properties of Square and Rectangular Stainless Steel Wires Tested in Torsion PDFDiana Paola FontechaNo ratings yet

- Elastic Flexural Properties of Multistranded Stainless Steel Versus Conventional Nickel Titanium ArchwiresDocument8 pagesElastic Flexural Properties of Multistranded Stainless Steel Versus Conventional Nickel Titanium ArchwiresDiana Paola FontechaNo ratings yet

- Elastic Properties of Alternative Versus Single-Stranded Leveling ArchwiresDocument14 pagesElastic Properties of Alternative Versus Single-Stranded Leveling ArchwiresDiana Paola FontechaNo ratings yet

- Effect of Ion Implantation of TMA Archwires On The Rate Of...Document4 pagesEffect of Ion Implantation of TMA Archwires On The Rate Of...Diana Paola FontechaNo ratings yet

- Elastic Flexural Properties of Multistranded Stainless Steel Versus Conventional Nickel Titanium ArchwiresDocument8 pagesElastic Flexural Properties of Multistranded Stainless Steel Versus Conventional Nickel Titanium ArchwiresDiana Paola FontechaNo ratings yet

- Analytical Mechanics and Analysis of Orthodontic Tooth MovementDocument3 pagesAnalytical Mechanics and Analysis of Orthodontic Tooth MovementDiana Paola FontechaNo ratings yet

- Effect of Ion Implantation of TMA Archwires On The Rate Of...Document4 pagesEffect of Ion Implantation of TMA Archwires On The Rate Of...Diana Paola FontechaNo ratings yet

- European Business in China Position Paper 2017 2018 (English Version)Document408 pagesEuropean Business in China Position Paper 2017 2018 (English Version)Prasanth RajuNo ratings yet

- AWS Cloud Practicioner Exam Examples 0Document110 pagesAWS Cloud Practicioner Exam Examples 0AnataTumonglo100% (3)

- L Williams ResumeDocument2 pagesL Williams Resumeapi-555629186No ratings yet

- General Biology 2-Week 2-Module 4-Evidence of EvolutionDocument16 pagesGeneral Biology 2-Week 2-Module 4-Evidence of EvolutionFEMALE Dawal LaizaNo ratings yet

- PAPERBOARD QUALITYDocument8 pagesPAPERBOARD QUALITYaurelia carinaNo ratings yet

- Ek Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics GemDocument1 pageEk Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics Gemmahsa.molaiepanahNo ratings yet

- Telecommunications TechnicianDocument4 pagesTelecommunications Technicianapi-78381064No ratings yet

- Appliance Saver Prevents OverheatingDocument2 pagesAppliance Saver Prevents OverheatingphilipNo ratings yet

- Decembermagazine 2009Document20 pagesDecembermagazine 2009maria_diyah4312No ratings yet

- Google Search StringsDocument12 pagesGoogle Search StringsPrashant Sawnani100% (1)

- Angelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannDocument374 pagesAngelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannEusebius325100% (2)

- 19 Unpriced BOM, Project & Manpower Plan, CompliancesDocument324 pages19 Unpriced BOM, Project & Manpower Plan, CompliancesAbhay MishraNo ratings yet

- Athenaze 1 Chapter 7a Jun 18th 2145Document3 pagesAthenaze 1 Chapter 7a Jun 18th 2145maverickpussNo ratings yet

- Seismic Design of Steel Structures: Updates of Eurocode 8Document107 pagesSeismic Design of Steel Structures: Updates of Eurocode 8antonio111aNo ratings yet

- Casestudy3 Hbo MaDocument2 pagesCasestudy3 Hbo Ma132345usdfghjNo ratings yet

- LogDocument119 pagesLogcild MonintjaNo ratings yet

- Copy Resit APLC MiniAssignmentDocument5 pagesCopy Resit APLC MiniAssignmentChong yaoNo ratings yet

- Request For Proposal Construction & Phase 1 OperationDocument116 pagesRequest For Proposal Construction & Phase 1 Operationsobhi100% (2)

- GD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreDocument1 pageGD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreVinay ManjuNo ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- QP P1 APR 2023Document16 pagesQP P1 APR 2023Gil legaspiNo ratings yet

- Victor Mejia ResumeDocument1 pageVictor Mejia Resumeapi-510300922No ratings yet

- Lecture 29: Curl, Divergence and FluxDocument2 pagesLecture 29: Curl, Divergence and FluxKen LimoNo ratings yet

- Staining TechniquesDocument31 pagesStaining TechniquesKhadija JaraNo ratings yet

- Steel Glossary RBC Capital GoodDocument10 pagesSteel Glossary RBC Capital Goodrajesh pal100% (1)

- Philippine Police Report Suicide InvestigationDocument2 pagesPhilippine Police Report Suicide InvestigationPAUL ALDANA82% (34)

- Serendipity - A Sociological NoteDocument2 pagesSerendipity - A Sociological NoteAmlan BaruahNo ratings yet

- Class Opening Preparations Status ReportDocument3 pagesClass Opening Preparations Status ReportMaria Theresa Buscato86% (7)

- Oral Medication PharmacologyDocument4 pagesOral Medication PharmacologyElaisa Mae Delos SantosNo ratings yet

- K230F Equipment ManualsDocument166 pagesK230F Equipment ManualsHui ChenNo ratings yet