Professional Documents

Culture Documents

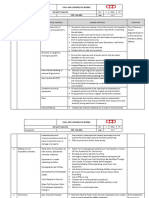

General Safety Guide for Equipment Operation

Uploaded by

richOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Safety Guide for Equipment Operation

Uploaded by

richCopyright:

Available Formats

Please read this guide carefully

1 before operating the equipment General Safety

HELP to the manufacturers and hirer’s instructions.

MOST IMPORTANT - RISK ASSESS!!! If the unit does not operate correctly or you are unhappy with DO check controls and any safety devices for proper response.

Before you commence any work at your chosen work area, you its performance, return it to the nearest Kennards Hire Centre DO make sure you possess a Certificate of Competency issued

should undertake some preliminary hazard identification and for exchange or phone for assistance. Do not attempt repairs by the relevant Regulatory Authority where required to operate

risk control precautions. Ideally more than one person should yourself. particular equipment.

do this. This is undertaken by: DO where possible; operate in a clear work area free from non-

Refer to your hire contract for details of our AFTER HOURS

1. Physically inspecting the work site EMERGENCY NUMBER. essential persons, children, animals or hazards.

2. Reviewing the best way/job steps required to complete the DO ensure that you have a secure footing and clear access and

task SAFETY DO’S

DO take your time; Read this User Guide and any other egress to the work area while on the job.

3. Reviewing the Safe Work Information supplied with the DO ensure the work environment is well lit with all aspects of

equipment Safety Information provided (e.g. decals, manufacturer’s

instructions), completely and in its entirety, BEFORE operating the job easily seen and discernable.

4. Reviewing other reference documentation and expert advice DO ensure correct lifting techniques are used when using or

the equipment.

The hazard identification and control process steps are defined as: transporting any machine or materials.

DO satisfy yourself that you have the correct machine for the

1. Identify the Hazards (eg. 240V power drill use around wet SAFETY DON’TS

areas) job and you know how to properly and safely operate it. (There

are many different types of equipment available to make your DO NOT operate any equipment if you are tired or suffering any

2. Assess the Risk (multi earth paths - possible electrocution) job easy). medical condition, or if under the influence of drugs or alcohol

3. Select the Control Measure (e.g. dry the area; use an RCD; which may cause lethargy or dangers to yourself or others.

use a cordless drill etc) DO ensure you fully understand and are familiar with the

equipment and its operations including uncontrolled or DO NOT hurry and take risks.

4. Re-assess the Risk (risk of electrocution now negligible). This is unexpected movement, emergency shut down/response and

undertaken to ensure that the risk control measures adopted

DO NOT operate equipment without guards correctly fitted.

have not introduced any new risks to the work area. follow instructions provided by the hirer. DO NOT use faulty equipment - if in doubt contact your local

DO ensure that the equipment is assembled and used according Kennards Hire Centre.

PERSONAL PROTECTION EQUIPMENT (PPE) • LPG appliances use up oxygen when in use. Use LPG • Do not use aluminium trestles, ladders or steel wire re-

appliances in well ventilated areas. Lack of oxygen can lead enforced ladders where there is a possibility of coming into

to drowsiness, unconsciousness and death. contact with electrical wires or parts. These trestles and

CERTIFICATE • Do not leave appliances unattended as the LP Gas flame ladders are not suitable for electrical work and shall not be

HEAR NG

PROTECTION

PROTECTIVE

GLOVES

RESPIRATORY

PROTECTION

SAFETY

GLASSES

PROTECT VE

CLOTHING

OF

COMPETENCY may go out leading to gas escape and a possible dangerous used for such.

gas build up. • Ensure that each trestle or ladder is in good condition and

CLOTHING on a firm footing, secured to prevent outward or sideways

ELECTRICAL EQUIPMENT

• Clothes shall be appropriate and close fitting, with no loose movement.

articles such as cuffs, ties, necklaces, rings etc, which can be • Ensure that any electric equipment or extension lead that

you are using has been electrically tested, tagged and dated • Ensure that ladders have a slip resistant base and rungs or

caught in rotating machine parts. steps.

by a competent person within the last 3 months.

• Long hair shall be constrained through netting, tying or other • Step ladders and trestles should only be used in the fully

• Always disconnect equipment from the power supply before

close fitting apparel. fitting or removing blades, abrasives, drill bits and other open position. Make sure any locking devices on the step

• Always wear all appropriate Personal Protective Equipment attachments. ladder/trestle are secure.

such as safety goggles, ear muffs, safety boots, helmet etc, • DO NOT ever lock switches in “on” position with tape, wire • Ensure that single and extension ladders are placed at a

appropriate for the task or equipment and as indicated. or by any other means. nominal slope of 4 (Vertical) to 1 (Horizontal).

EQUIPMENT • Always ensure that the power outlet you are using is • Ensure that extension ladders extend at least one metre past

• Thoroughly familiarise yourself with the safety precautions protected by an RCD (Residual Current Device) safety switch. any platform to be reached.

associated with the operation of any equipment before Use an approved portable RCD if your power outlet is not • Where possible, stand at least 1 metre below the top of a

attempting to use it. RCD protected. ladder when in a working position.

• Ask for assistance and refer to supplier’s manual(s) if you are • Always check with authorities for location of hidden cabling • Always, restrain/secure ladder, at top and bottom if

not sure of the correct use of the equipment. prior to commencement of cutting or demolition as contact necessary, so that it cannot move in any direction.

• Ensure all equipment guards are in place; operational and all with electrical cabling can cause injury or death. • Do not carry heavy or awkward loads on ladders

cutting tools are sharp. • DO NOT use electrical equipment in “wet” environments. • You should have 3 limbs on the ladder at all times. This does

• Never force tools or use equipment for purposes other than • DO NOT use an electrical extension lead that is longer than not apply to step ladders.

those for which they were designed. 15 metres as a significant voltage drop will occur, potentially • Avoid over-reaching or stretching and keep the body centred

• If making adjustments to equipment or changing compromising personal safety and leading to possible between the side rails at ALL times.

attachments (e.g. when changing a drill bit or blade) isolate equipment damage. • Always use an approved secure handrail system when

the equipment first by unplugging electrical leads, hydraulic • Always uncoil extension leads and remove any twisting to standing on trestle/plank combination 2.0 metres or greater

or pneumatic supply hoses from the energy source. prevent them from overheating during use. above the ground. Where provision of a handrail system is

USING TOOLS & EQUIPMENT • Before using, ensure all electrical leads are not damaged in not reasonably practicable other forms of physical restraints

• When using tools and equipment do not over reach. any way. such as a safety harness and lanyard that are capable of

• Ensure that you have a firm footing and are always ready to • Keep leads off floor, from being pinched or crushed and arresting the fall of a person from a height of more than 2

handle any reaction the equipment may make. away from water and moisture. metres must be used.

• Regular breaks are recommended during lengthy or • DO NOT use electrical appliance where the operation can SCAFFOLDS OR PLATFORMS

repetitious use of tools and equipment. trigger an explosion of gases, vapours, liquids, dusts or other (Also refer to the information on/with the scaffolding)

• Use of equipment may cause collapse of structure in some substances. • Any platform, two metres or more above the ground should

applications (eg trenches, excavations, wall removal etc) and HIGH PRESSURE AIR, WATER AND PAINT have handrails, mid rails and kickboards fitted.

may require installation of approved shoring or other • Do NOT use compressed air for human consumption. • Any scaffold tower with a platform height of four metres or

suitable controls. • Do NOT use compressed air for dusting off or cleaning above can only be assembled, altered or disassembled by a

• Operate engine driven equipment only in well ventilated clothing and/or body. qualified scaffold erector.

areas. Fumes can kill. • Use extreme care when using compressed air, high pressure • All scaffold and platforms must be erected in accordance

• Use of this type of equipment in confined spaces such as water cleaners or airless spray painters. with manufacturer’s instructions.

storage tanks, wells, silos, vats, ducts, tunnels, shafts, pits, • Never use high pressure air to clean any part of your clothes • Maintain non-reach clearances from electrical power lines or

indoors and rooms can result in death. or body. High pressure jets of compressed air can rupture other electrical installations.

FLAMMABLE LIQUIDS eardrums, damage eyes, cause skin to peel or enter the • Ensure that scaffold is in good condition and on a firm

• Use extreme care when filling fuel tanks - vapours can be bloodstream through the skin. footing. Adjust leg locks as necessary.

explosive. • Never point or direct high pressure water or spray paint • Only use mobile scaffolds on hard flat surfaces. Unless the

• Ensure that the motor is turned off when filling. equipment at any part of any person regardless whether it is scaffold incorporates adjustable legs the surface must be

energised or not. Inactivated equipment may still contain level.

• Keep fuel containers at least 3 metres away from where you pressurised material. High pressure liquid streams may

will be starting the equipment. • Always lock castor wheels before use.

facilitate toxic substances to enter the skin and cause blood • Never sIt, stand or climb on handrail or kickboards.

• Ensure fuel cannot come into contact with hot engine parts poisoning.

such as the exhaust. • Never move scaffold while personnel are on platform. Also

• Ensure the correct Personal Protective Equipment (PPE) as secure tools and equipment before moving.

• NEVER smoke in the vicinity of, and keep sources of sparks shown on the specific safety information sheet is used when

away from any flammable liquid. • Always climb on the inside of scaffold using ladders.

undertaking work involving the operation of any pressurised

• Where possible, keep an appropriate fire extinguisher nearby equipment. • Never exceed Safe Working Load of scaffold or platform.

during operations utilising flammable liquids • To ensure correct use of PPE when using hazardous • Inspect the scaffold daily and before commencing work and

LPG substances (eg paint, thinners) obtain a Material Safety Data report any damage or problems to your local Kennards Hire

Sheet (MSDS) from your supplier. The MSDS also provides centre - DO NOT use the equipment if it is damaged or has

• LP Gas is highly explosive when mixed with air; keep it well any parts missing.

away from open flame or sources of sparks. LP Gas is other valuable health and safety information pertaining to

heavier than air and will displace air at lower levels - even the product you are using

though you may not be able to smell it, LPG may still be TRESTLES AND LADDERS

present. (Also refer to the information on/with the trestle or ladder)

• Keep cylinders vertical and firmly secured at all times (eg • Ladders should only be used as a means of access to or

storage, transport, use). egress from a work area and not used as a platform.

• If testing appliances for leaks - always use soapy water, • Do not use trestles as ladders; they must only be used to

NEVER a naked flame. support any plank upon which a person has to work.

This operating and safety brochure is intended as a guide only for the safe operation of this equipment. It does not override license requirements nor

is it a substitute for a structured operating lesson.

If you are unsure about any aspect of the equipment or its capabilities or if you are in doubt as to its proper usage, feel free to consult our trained

employees for instruction or the answers to any questions you may have regarding the safe operation of this equipment. www.kennards.com.au

You might also like

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Health and Safety Manual - Company TemplateDocument55 pagesHealth and Safety Manual - Company TemplatezahidNo ratings yet

- Presentation Safety InductionDocument76 pagesPresentation Safety Inductionanisaan100% (4)

- TB1140 (514400002 ) Wet1140 DC (Cn3e000)Document514 pagesTB1140 (514400002 ) Wet1140 DC (Cn3e000)sszms100% (5)

- Safety Induction EssentialsDocument42 pagesSafety Induction EssentialsAdeel Ahmed100% (2)

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- LPG InstallationDocument24 pagesLPG InstallationHaris LatifNo ratings yet

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDocument6 pagesS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærNo ratings yet

- ACS Foundations of Chemical Safety and Risk ManagementDocument99 pagesACS Foundations of Chemical Safety and Risk ManagementKEVIN BRIAN GABALESNo ratings yet

- NWC Corporate Projects Risk Assessment Forms: Confined SpaceDocument4 pagesNWC Corporate Projects Risk Assessment Forms: Confined SpaceNowfal Habeeb50% (2)

- Cosh 1Document3 pagesCosh 1Aila Lene GumalingNo ratings yet

- Appendix 18 Steam Blowing JSADocument3 pagesAppendix 18 Steam Blowing JSAzhang75% (12)

- Risk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksDocument6 pagesRisk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksemmyNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- 1026 Int Diploma IA1 v2Document40 pages1026 Int Diploma IA1 v2jiks_i4u89% (9)

- Florida Existing Building Code 2007Document125 pagesFlorida Existing Building Code 2007Ray HufaultNo ratings yet

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Drug and Alcohol Policy CAN enDocument43 pagesDrug and Alcohol Policy CAN enrv0014No ratings yet

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- National Building Code and Construction Health and Safety in NigeriaDocument21 pagesNational Building Code and Construction Health and Safety in NigeriaOresegun Adedapo100% (10)

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Jsa-004 Pressure WasherDocument4 pagesJsa-004 Pressure WasherDamien MonizeNo ratings yet

- Grouting Brochure PDFDocument12 pagesGrouting Brochure PDFVittorioNo ratings yet

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- General Safety: Please Read This Guide Carefully Before Operating The EquipmentDocument2 pagesGeneral Safety: Please Read This Guide Carefully Before Operating The EquipmentDenny ChermingNo ratings yet

- 11 Concrete Mixer PDF PDFDocument1 page11 Concrete Mixer PDF PDFekkyagungNo ratings yet

- Concrete saw safety guideDocument1 pageConcrete saw safety guideRanjan KumarNo ratings yet

- General Safety Concrete Vibrator Safety InstructionsDocument1 pageGeneral Safety Concrete Vibrator Safety InstructionsMontadhar HaithamNo ratings yet

- Workshop One NotesDocument43 pagesWorkshop One NotesMos AlvoNo ratings yet

- Safety and Compliance Manual: Warning!Document12 pagesSafety and Compliance Manual: Warning!Gerber CardonaNo ratings yet

- Workshop One Notes-1Document40 pagesWorkshop One Notes-1jeff madibaNo ratings yet

- Jsa FormatDocument6 pagesJsa FormatMohdHuzairiRusliNo ratings yet

- 27 Lighting Tower Floodlig PDFDocument1 page27 Lighting Tower Floodlig PDFAnwar MohamedNo ratings yet

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliNo ratings yet

- Rsde1, Rsde2, Rsde2/A DX4000 & DX5000: High Filtration Dust ExtractorsDocument20 pagesRsde1, Rsde2, Rsde2/A DX4000 & DX5000: High Filtration Dust ExtractorsedwardmbartonNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Pressure Powered Pump Ppec: Installation and Maintenance InstructionsDocument11 pagesPressure Powered Pump Ppec: Installation and Maintenance InstructionsR Ibnu Arif Wibowo,S.TNo ratings yet

- Safety guide equipmentDocument1 pageSafety guide equipmentAbdus SamadNo ratings yet

- Vibrating Plate Compactor Safety Instructions PDFDocument1 pageVibrating Plate Compactor Safety Instructions PDFNoufal PattambiNo ratings yet

- MBAV SWP Safe Use Nail Gun 2019Document4 pagesMBAV SWP Safe Use Nail Gun 2019adminNo ratings yet

- Jha ExcavationDocument11 pagesJha ExcavationMohd Firdaus OthmanNo ratings yet

- Working at Heghts: Fall Arrest PlanDocument4 pagesWorking at Heghts: Fall Arrest PlanTifelo MotlhankeNo ratings yet

- Golden Rules Poster UKDocument1 pageGolden Rules Poster UKSaran rasayaNo ratings yet

- 7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftDocument6 pages7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftPedro ViegasNo ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Job Safety for PlumbersDocument2 pagesJob Safety for PlumbersNaresh KumarNo ratings yet

- AHA Painting WorkDocument3 pagesAHA Painting Workanilkumaranoop74No ratings yet

- Operator's Manual: Register Your MachineDocument32 pagesOperator's Manual: Register Your MachineJUANNo ratings yet

- Final Steam Blowing PermitF03Document4 pagesFinal Steam Blowing PermitF03Mostafa AbdullahNo ratings yet

- Risk Assessment B.ingDocument1 pageRisk Assessment B.ingkristina panjaitanNo ratings yet

- Notes 4Document12 pagesNotes 4moraine.hills3No ratings yet

- JSA FOR CONCREATE AND CIVILWORKSDocument7 pagesJSA FOR CONCREATE AND CIVILWORKSAnna JisabaNo ratings yet

- JSA: Drawworks Repair Job Safety AnalysisDocument1 pageJSA: Drawworks Repair Job Safety Analysisghada gattouchNo ratings yet

- Spirax Sarco 01150200 ManualDocument12 pagesSpirax Sarco 01150200 Manualantonio sanchezNo ratings yet

- Ridgid CD 100Document271 pagesRidgid CD 100SmisliNestoNo ratings yet

- INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR PRESSURE REDUCING VALVESDocument12 pagesINSTALLATION AND MAINTENANCE INSTRUCTIONS FOR PRESSURE REDUCING VALVESManutenção [Gemacom Tech]No ratings yet

- Workshop SafetyDocument25 pagesWorkshop SafetyAhmed SalehNo ratings yet

- ABC-EWP-JSA-PRS1-01 (Rev.0) Relocation of Existing Security FacilitiesDocument29 pagesABC-EWP-JSA-PRS1-01 (Rev.0) Relocation of Existing Security FacilitiesRABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- Takeuchi Excavator TB153FR CJ2E000 WM 06860Document686 pagesTakeuchi Excavator TB153FR CJ2E000 WM 06860rok.feleNo ratings yet

- DML305 Cast Iron 6 Speed Midi Lathe: Original Instruction ManualDocument28 pagesDML305 Cast Iron 6 Speed Midi Lathe: Original Instruction ManualwiiiNo ratings yet

- Flo s92-93 Om 01-2010Document14 pagesFlo s92-93 Om 01-2010Elemsa InstalacionesNo ratings yet

- Offshore CVDocument4 pagesOffshore CVAmaan KhanNo ratings yet

- MSDS Ehc45Document10 pagesMSDS Ehc45HF HTNo ratings yet

- Quick Start Guide: 4400 Series Thermal PrinterDocument72 pagesQuick Start Guide: 4400 Series Thermal Printerpetemac40No ratings yet

- Lab Safety Design & PracticesDocument52 pagesLab Safety Design & PracticesJagannath MaaleNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument8 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingmynulNo ratings yet

- MSDS Solar Panel 4Document9 pagesMSDS Solar Panel 4Basir Abu FaqihNo ratings yet

- PLDT Circuit Job Hazard AnalysisDocument2 pagesPLDT Circuit Job Hazard AnalysisDarwin AlvarezNo ratings yet

- SAG - Commercial Cooking NC IV PDFDocument5 pagesSAG - Commercial Cooking NC IV PDFKen OsumoNo ratings yet

- Soltex® Additive: Safety Data SheetDocument9 pagesSoltex® Additive: Safety Data SheetAndrew ArNo ratings yet

- Safety Management Systems (SMS) in Aviation Maintenance - A Report CardDocument2 pagesSafety Management Systems (SMS) in Aviation Maintenance - A Report Carddiana_veronicaNo ratings yet

- Dornan Engineering - Canary Wharf Daily Report Night Shift Template ElecDocument2 pagesDornan Engineering - Canary Wharf Daily Report Night Shift Template ElecDa BossNo ratings yet

- Suspension Fluid SdsDocument10 pagesSuspension Fluid SdsGilarHerlianaPutraNo ratings yet

- Managaem Groups AssignmentDocument16 pagesManagaem Groups Assignmentephrem DestaNo ratings yet

- Sample Thesis About Fire PreventionDocument6 pagesSample Thesis About Fire Preventionheatherharveyanchorage100% (2)

- Chemical Terrorism DisasterDocument164 pagesChemical Terrorism DisasterAnshu ShahNo ratings yet

- PM/Technical/09 Hid - Safety Report Assessment Guide: Chemical WarehousesDocument46 pagesPM/Technical/09 Hid - Safety Report Assessment Guide: Chemical WarehousesanaazizNo ratings yet

- P3U en M G006 IEC Web PDFDocument426 pagesP3U en M G006 IEC Web PDFКонстантин ГригорьевNo ratings yet

- Construction Safety Requirements ManualDocument94 pagesConstruction Safety Requirements ManualThe BRT ConsultNo ratings yet

- Afi 48-137Document24 pagesAfi 48-137bweaver700No ratings yet

- KCM SHE POLICY Rev 15Document1 pageKCM SHE POLICY Rev 15Dr.Atef RagabNo ratings yet