Professional Documents

Culture Documents

K47H Truck-Mounted Concrete Boom Pump Specs

Uploaded by

Oğuzhan OdbayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K47H Truck-Mounted Concrete Boom Pump Specs

Uploaded by

Oğuzhan OdbayCopyright:

Available Formats

K47H TRUCK-MOUNTED CONCRETE

Placing boom

BOOM PUMP

B5RZ 47/43

Pumping unit HP1608EC

HP1808ECX

Driven by PTO or gear box

Chassis 4 axles

Dimensions

Dimensions varying according to truck assembly

K47H TRUCK-MOUNTED CONCRETE

Placing boom

BOOM PUMP

B5RZ 47/43

Pumping unit HP1608EC

HP1808ECX

Main features Driven by PTO or gear box

• Placing boom B5HRZ 47/43, 5 sections, pipeline diameter Chassis 4 axles

125 mm, “RZ” folding system

• 4th and 5th boom sections made of light and resistant CIFA

CARBOTECH composite material. 1st,2nd and 3rd sections made of

high strength steel Pumping unit technical data

• Advantageous assembling on standard 4 axles chassis

• Fully hydraulic outrigger controls on both sides of the truck Model HP1608EC HP1808ECX

• Front “X” style diagonal outriggers with double telescopic opening

and swing-out rear outriggers for a quick and easy set-up also in

narrow areas Max. theorical output m3/h 160 180

• ”Load Sensing” proportional boom control Max. pressure

• “BFC” Best-Flex Cifa supporting system allowing just one on concrete bar 80 83

man to change delivery pipeline easily, quickly and safe

• Concrete flow rate regulator Conc. cylinders mm 230x2100 260x2100

• Safety device on opening inspection hatch (diam. x stroke)

• Pumping units with closed loop HP1608EC or HP1808ECX Concrete hopper capacity l 550 600

• Project conforms to Directive Machinery 2006/42/CE

• 2 Proportional radio control with two boom movement speed,

synthesizer for automatic frequency search, 8 position joy stick and Hydraulic circuit closed closed

concrete flow rate regulator. 20 mt cable

• Double thickness concrete pipes, in high resistant steel and insert

carbide crome - CIFA Long Life Pipes

• Emergency control pad for pumping unit

• Remote controlled electric vibrator placed on the concrete hopper grid Placing boom technical data

• Centralized lubrication system for pumping unit

• Automatic oil lubrication system for pumping pistons Model B5HRZ 47/43

• Additional manual lubrication system for pumping pistons

• Hard plastic outrigger support plates with relative housing Pipeline diameter mm 125

• Rear light on hopper

• Level readers for stabilization control Max. vertical reach m 46,1

• Accessories for cleaning and pipes washing

• Fiber glass hopper covering Max. horizontal distance

• Medium pressure water pump (50l/50bar) (from center of slewing axis) m 41,4

• Emergency pumping unit kit

Min. unfolding height m 8,9

Control system

• Smartronic Gold Section numbers 5

- intergrated color LCD

- counters

1st section opening angle 90°

- pumping unit management

- diagnostic

- capsense rear panel 2nd section opening angle 180°

- ASC (Advanced Stability Control)

3rd section opening angle 180°

Main options

• High pressure water pump 28l / 120 bar 4th section opening angle 237°

• Air compressor for pipeline cleaning

• Centralized lubrification system for placing boom 5th section opening angle 230°

• Air pipeline for placing boom

• Separated emergency engine kit for independent control of the

concrete pumping unit, boom and water pump Rotating angle +/-270°

• Concrete shut-off valve

• Rear camera for easy manoeuvring End hose lenght m 3

• Double thickness boom straight pipes, in high resistant steel and

insert carbide crome - CIFA LLT Long Life Top Technical data and characteristics subject to modifications without notice

• Proportional radio control with display

K47H_ENG_0319

CIFA S.p.A.

via Stati Uniti d’America, 26

20030 Senago (Milano) - Italia

tel.: +39.02.990131 - fax: +39.02.9981157 The declaration of conformity will be supplied with the Use and Maintenance Handbook

www.cifa.com

You might also like

- Truck-Mounted Concrete Boom Pump: Series SeriesDocument2 pagesTruck-Mounted Concrete Boom Pump: Series SeriesHussein SayedNo ratings yet

- Truck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisDocument2 pagesTruck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisAhmad Mahmmad100% (1)

- K41L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK41L XRZ: Truck-Mounted Concrete Boom PumpAtaa AssaadNo ratings yet

- K52L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK52L XRZ: Truck-Mounted Concrete Boom PumpAhmed Rashad100% (1)

- MK24 4 PDFDocument2 pagesMK24 4 PDFAugusto Figueroa MeloNo ratings yet

- Truck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisDocument2 pagesTruck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisHussein SayedNo ratings yet

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNo ratings yet

- Reliable Easy To Use: Truck-Mounted Concrete Boom PumpDocument2 pagesReliable Easy To Use: Truck-Mounted Concrete Boom PumpXiangzhendong100% (1)

- Truck-Mixer Pump "Magnum" MK28L-80/115 RH: Placing Boom Pumping Unit Concrete Mixer Driven by ChassisDocument2 pagesTruck-Mixer Pump "Magnum" MK28L-80/115 RH: Placing Boom Pumping Unit Concrete Mixer Driven by ChassisVasiliy PavliukNo ratings yet

- Bomba de ConcretoDocument2 pagesBomba de ConcretoAlfonso ChNo ratings yet

- K38L - ENG - 0610 Mobilna Pumpa CifaDocument2 pagesK38L - ENG - 0610 Mobilna Pumpa CifanostrodamusNo ratings yet

- Catalogo Detallado QH441Document39 pagesCatalogo Detallado QH441JesusFloresRodriguezNo ratings yet

- OOF Upport Arrier: Capacity HydraulicsDocument4 pagesOOF Upport Arrier: Capacity HydraulicsDietz LaNo ratings yet

- Course Drill 39hr Bucyrus System Hydraulic Lubrication Air Mechanical Training PDFDocument179 pagesCourse Drill 39hr Bucyrus System Hydraulic Lubrication Air Mechanical Training PDFBruno CecattoNo ratings yet

- Asphalt CompactionDocument2 pagesAsphalt CompactionsanjayNo ratings yet

- Brochure Hm150 MailDocument8 pagesBrochure Hm150 MailDan Banul100% (1)

- MK28L EngDocument2 pagesMK28L EngJakub SkrzypczykNo ratings yet

- Pumpe TankStorage enDocument8 pagesPumpe TankStorage enlex lutorNo ratings yet

- Variable Pumps For Closed Loop Operation Type Hv-02Document36 pagesVariable Pumps For Closed Loop Operation Type Hv-02Eric CNo ratings yet

- 5 Pump Failure AnalysisDocument44 pages5 Pump Failure Analysisgurivi201No ratings yet

- 50105R Boom Truck SpecsDocument11 pages50105R Boom Truck Specsmiguel marcialNo ratings yet

- Elliott Boom Trucks 10 To 18 TonsDocument47 pagesElliott Boom Trucks 10 To 18 TonsPaula PlataNo ratings yet

- Bombas de Hormigon Everdigm Ecp63cs 5Document4 pagesBombas de Hormigon Everdigm Ecp63cs 5mustafa özkanNo ratings yet

- T4BHDocument4 pagesT4BHHerald MisaelNo ratings yet

- JohnDeere 1070G 1170G SpecDocument6 pagesJohnDeere 1070G 1170G SpecBeny StephenNo ratings yet

- Series T90: Transit Mixer Drive SystemDocument22 pagesSeries T90: Transit Mixer Drive SystemEngkus KuswayaNo ratings yet

- MST 5 S Series Product PresentationDocument67 pagesMST 5 S Series Product PresentationNelson Andrade Velasquez100% (1)

- Thom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpDocument2 pagesThom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpAlexander LabautNo ratings yet

- High-capacity concrete pump truckDocument4 pagesHigh-capacity concrete pump truckerick la madridNo ratings yet

- Series: Pumping Unit Technical DataDocument2 pagesSeries: Pumping Unit Technical DataRolandas GaudėšiusNo ratings yet

- Max Output:170M /H Max Pressure:8.3/12Mpa Driven By:PtoDocument2 pagesMax Output:170M /H Max Pressure:8.3/12Mpa Driven By:PtodhmartiniNo ratings yet

- Concrete Mixer Hydrostatic Transmission ComponentsDocument17 pagesConcrete Mixer Hydrostatic Transmission ComponentsVEERAMANINo ratings yet

- Catalogo Autobomba ECP37ZXDocument4 pagesCatalogo Autobomba ECP37ZXSara Sarmiento EcheverryNo ratings yet

- MF 050 VC Concrete Sprayer Technical SpecificationsDocument10 pagesMF 050 VC Concrete Sprayer Technical SpecificationsAlfred UBOKONo ratings yet

- OOF Upport Arrier: CapacityDocument4 pagesOOF Upport Arrier: CapacityDietz LaNo ratings yet

- Pneumatic Hoists Pendant/Wall Mounted Controls/Air Service EquipmentDocument1 pagePneumatic Hoists Pendant/Wall Mounted Controls/Air Service EquipmentAhmedNo ratings yet

- Heavy Duty Base Machine For Foundation Work: Model: BME800HDDocument16 pagesHeavy Duty Base Machine For Foundation Work: Model: BME800HDAirtonSotoNo ratings yet

- Brochure Tank FarmDocument7 pagesBrochure Tank FarmSagar DasNo ratings yet

- Coil Tubing Course - Level - 1Document60 pagesCoil Tubing Course - Level - 1Prakash JadhavNo ratings yet

- Spraymec 8100 VC 100075525 USA & CanadaDocument11 pagesSpraymec 8100 VC 100075525 USA & CanadaEzequielNo ratings yet

- Datablad BSA 1409 DDocument2 pagesDatablad BSA 1409 DdhmartiniNo ratings yet

- K41 EngDocument2 pagesK41 EngRealmak Awa50% (2)

- Gk4tzjqmnqvf0uvhmanitowoc 11000-1 110-Ton Crawler Crane NetworkDocument24 pagesGk4tzjqmnqvf0uvhmanitowoc 11000-1 110-Ton Crawler Crane Networkubeydullah coşkunNo ratings yet

- Especificaciones ROC L6Document2 pagesEspecificaciones ROC L6Daniel Ricardo Páez AlvarezNo ratings yet

- Sennebogen Material Handlers Spec 2170beDocument12 pagesSennebogen Material Handlers Spec 2170bemarionabil998No ratings yet

- Excavator-Specific Hydraulic System SolutionsDocument4 pagesExcavator-Specific Hydraulic System SolutionsYulianto JoeNo ratings yet

- Manitowoc 10000A-1: Product GuideDocument24 pagesManitowoc 10000A-1: Product Guideubeydullah coşkunNo ratings yet

- Series: Pumping Unit Technical DataDocument2 pagesSeries: Pumping Unit Technical DataAtaa AssaadNo ratings yet

- TDS Alpha 20 (EN) V5Document2 pagesTDS Alpha 20 (EN) V5Carlos Francisco F'ArNo ratings yet

- Barredora Superior Broom DT80CTDocument2 pagesBarredora Superior Broom DT80CTSantiago SalinasNo ratings yet

- 28Z-M Brochure USDocument6 pages28Z-M Brochure USعالم الصيانة معدات ثقيلة ومعدات خرسانةNo ratings yet

- Boomer 104-1432 PDFDocument4 pagesBoomer 104-1432 PDFanon_478395499No ratings yet

- PuztmeisterDocument3 pagesPuztmeisterEdgar Quispe LaricoNo ratings yet

- VTP - BrochureDocument4 pagesVTP - BrochureAnonymous CMS3dL1TNo ratings yet

- KVM 32Xl KVM 32Xg: Truck-Mounted Concrete Pump With 4-Section Placing Boom and Detachable Boom OptionDocument6 pagesKVM 32Xl KVM 32Xg: Truck-Mounted Concrete Pump With 4-Section Placing Boom and Detachable Boom OptionJonathan Guzmán MendozaNo ratings yet

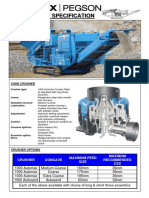

- XA400 - TerexPegson Specs PDFDocument14 pagesXA400 - TerexPegson Specs PDFjet snake100% (4)

- 1000 Maxtrak SpecificationDocument6 pages1000 Maxtrak SpecificationYeco MachineryNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Method Statement for Lifting Operations at Gas Pipeline ProjectDocument12 pagesMethod Statement for Lifting Operations at Gas Pipeline ProjectRachel Flores85% (26)

- Ecology Presantation 5Document166 pagesEcology Presantation 5Oğuzhan OdbayNo ratings yet

- Ecology Presentation 3Document108 pagesEcology Presentation 3Oğuzhan OdbayNo ratings yet

- User Instructions JockeyDocument36 pagesUser Instructions JockeyOğuzhan OdbayNo ratings yet

- Ecology PresentationDocument113 pagesEcology PresentationOğuzhan OdbayNo ratings yet

- Ecology Presentation - 1Document155 pagesEcology Presentation - 1Oğuzhan OdbayNo ratings yet

- Presented by Aritra Banerjee B070543CEDocument43 pagesPresented by Aritra Banerjee B070543CEfausto giovannardiNo ratings yet

- An Experimental Investigation For External RC Shear Wall ApplicationsDocument10 pagesAn Experimental Investigation For External RC Shear Wall ApplicationsOğuzhan OdbayNo ratings yet

- Ecology Presentation 2Document175 pagesEcology Presentation 2Oğuzhan OdbayNo ratings yet

- Contractor Support For Machine Applied Concrete RepairsDocument7 pagesContractor Support For Machine Applied Concrete RepairsOğuzhan OdbayNo ratings yet

- Fuel Tank Product PDFDocument1 pageFuel Tank Product PDFOğuzhan OdbayNo ratings yet

- Heydaraliyevculturalcentre 180131094714 PDFDocument23 pagesHeydaraliyevculturalcentre 180131094714 PDFSoundarya SuryaNo ratings yet

- Wire FabricDocument0 pagesWire FabricelmajzoubNo ratings yet

- Strengthening Method of Concrete StructureDocument13 pagesStrengthening Method of Concrete StructureOğuzhan OdbayNo ratings yet

- Technical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Document41 pagesTechnical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Lawrence Miguel FerrerNo ratings yet

- E07TRANSFORMERS CleanDocument12 pagesE07TRANSFORMERS CleanADE SUTRISNANo ratings yet

- Strengthening of Shear Wall With High PerformanceDocument9 pagesStrengthening of Shear Wall With High PerformanceOğuzhan OdbayNo ratings yet

- Overview of Green BuildingsDocument12 pagesOverview of Green Buildingsdoriangray661No ratings yet

- Hza PS - 16 e PDFDocument20 pagesHza PS - 16 e PDFDlorah OalZepolNo ratings yet

- Murfor UKDocument63 pagesMurfor UKmendoncajamNo ratings yet

- Neodur Level Au: Underlayment CT-C30-F5Document1 pageNeodur Level Au: Underlayment CT-C30-F5Oğuzhan OdbayNo ratings yet

- Planning Design and Construction Strategies For Green BuildingDocument67 pagesPlanning Design and Construction Strategies For Green Buildingbruce leeNo ratings yet

- Cast in Channel Brochure B - 17 1 E PDFDocument92 pagesCast in Channel Brochure B - 17 1 E PDFOğuzhan OdbayNo ratings yet

- TCM 70Document9 pagesTCM 70Oğuzhan OdbayNo ratings yet

- Green BuildingDocument46 pagesGreen BuildingSachithHiroshanaWijethungaNo ratings yet

- Planning Design and Construction Strategies For Green BuildingDocument67 pagesPlanning Design and Construction Strategies For Green Buildingbruce leeNo ratings yet

- MP EM Ass 17: Ampere's Law and Magnetic MaterialsDocument15 pagesMP EM Ass 17: Ampere's Law and Magnetic MaterialsBlueAstro91% (11)

- Wire FabricDocument0 pagesWire FabricelmajzoubNo ratings yet

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- BR HighFlowDocument4 pagesBR HighFlowRocky SarmientoNo ratings yet

- Sika Anchorfix 1 - Pds en PDFDocument6 pagesSika Anchorfix 1 - Pds en PDFgEnka 040790No ratings yet

- Chopping and Pumping of Difficult Mediums: Landia Chopper Pumps Never Give UpDocument8 pagesChopping and Pumping of Difficult Mediums: Landia Chopper Pumps Never Give UpFernando SanchezNo ratings yet

- Pruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CDocument22 pagesPruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CFerreira Anibal ParedesNo ratings yet

- Lyson Cat PREMIUM-2020Document36 pagesLyson Cat PREMIUM-2020Hicham AminiNo ratings yet

- q456 Tankship Dangerous LiquidsDocument12 pagesq456 Tankship Dangerous LiquidsJohn MondalaNo ratings yet

- YGSL-120R Operation ManualDocument54 pagesYGSL-120R Operation ManualzebarsNo ratings yet

- Centrifugal PumpsDocument6 pagesCentrifugal Pumpshenkis73No ratings yet

- Curve Char ADocument3 pagesCurve Char AvantaNo ratings yet

- Basics of Hydraulic and Mechanical Press MachineDocument19 pagesBasics of Hydraulic and Mechanical Press MachineVishal Koul75% (4)

- Drilling terms and their translationsDocument14 pagesDrilling terms and their translationsGEORGENo ratings yet

- Water Balance and Water Conservation in Thermal Power StationsDocument6 pagesWater Balance and Water Conservation in Thermal Power StationsSoumya MohantyNo ratings yet

- XFP SubmersiblePumps E10238Document8 pagesXFP SubmersiblePumps E10238vutrung23113163No ratings yet

- Peerless 1108 VertTurbinePump OLSDocument45 pagesPeerless 1108 VertTurbinePump OLSAngel De La Torre CollNo ratings yet

- Vehicle Hoist and Lubrication EquipmentDocument92 pagesVehicle Hoist and Lubrication EquipmentSunil NepalNo ratings yet

- Product Information VDROO32-50: Project Name Station NumberDocument6 pagesProduct Information VDROO32-50: Project Name Station NumberFerass EL QASRYNo ratings yet

- Kursus Asas Rekabentuk Sistem Pam Pengairan PertanianDocument28 pagesKursus Asas Rekabentuk Sistem Pam Pengairan PertanianMohd Safarul Izmi0% (1)

- Summer Training Project ReportDocument19 pagesSummer Training Project ReportMonty KushwahaNo ratings yet

- Yuken Hydraulic OPUDocument18 pagesYuken Hydraulic OPUsujan723No ratings yet

- Method Statement For Post Fixed Rebar Drill & Fix With Chemical AnchorDocument14 pagesMethod Statement For Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Calibration of Flow MetersDocument65 pagesCalibration of Flow MetersAyyanrajNo ratings yet

- Treadle Pump Kel. 4Document20 pagesTreadle Pump Kel. 4Dzalika PerbangsariNo ratings yet

- List - of - Approved - Makes-21-27Document7 pagesList - of - Approved - Makes-21-27VISHAL SINGHNo ratings yet

- Diagrama Electrico PM200 PerfiladoraDocument2 pagesDiagrama Electrico PM200 PerfiladoraPlstina RamsNo ratings yet

- HYGUARD Safety CouplingsDocument32 pagesHYGUARD Safety CouplingsropmachadoNo ratings yet

- Displace 3D Presentation Open Day 09.06Document28 pagesDisplace 3D Presentation Open Day 09.06Ghadames in Our HeartNo ratings yet

- MAN B&W Diesel ECSDocument15 pagesMAN B&W Diesel ECSmicudan100% (1)

- Hole Cleaning-Total Best PracticesDocument13 pagesHole Cleaning-Total Best PracticesMohamed AbozeimaNo ratings yet

- ABB Drives For Water and Wastewater: ACQ580, 0.75 To 500 KWDocument52 pagesABB Drives For Water and Wastewater: ACQ580, 0.75 To 500 KWElvis QuispeNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kevin TtitoNo ratings yet