Professional Documents

Culture Documents

Reliable Easy To Use: Truck-Mounted Concrete Boom Pump

Uploaded by

XiangzhendongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reliable Easy To Use: Truck-Mounted Concrete Boom Pump

Uploaded by

XiangzhendongCopyright:

Available Formats

K56C

v.

TRUCK-MOUNTED CONCRETE

RELIABLE BOOM PUMP

Placing boom K56C

Pumping unit PU1808

EASY TO USE Version

Driven by

4.0

Truck PTO or Gear box

Chassis 4 - 5 axles

Dimensions

Dimensions varying according to truck assembly

K56C K56C

v.

Standard equipment TRUCK-MOUNTED CONCRETE

• Advantageous assembling on 4 axles chassis BOOM PUMP

• Self-supporting frame, torsion free, FEM designed and fatigue tested Placing boom K56C

at the test bench TEC CIFA Pumping unit PU1808

• Placing boom 6RZ 56/52 with 6 sections, “RZ” folding system

Version 4.0

• 2 Proportional radio controls with two speeds boom movement,

Driven by Truck PTO or Gear box

automatic frequency scanner

Chassis 4 - 5 axles

• 20 m emergency cable to connect radio controls.

• Centralized lubrification system for pumping unit

• Hard carbide wear plate and cutting ring for PU pumping units

• Fiberglass hopper covering Pumping unit technical data

• Low pressure water pump (20 Bar / 75 l/min)

• One colour painting white RAL 9010

• 2 Use & Maintenance manuals Model PU1808

• Spare parts and service manual

Maximum theorical output m3/h 180

Control system with truck PTO

Maximum pressure bar 83

• Easytronic Gold: on concrete

LSC (Light Stability Control)

Conc. cylinders

Integrated color LCD mm 260x2100

(diam. x stroke)

Counters

Pumping unit management Concrete hopper capacity l 600

Diagnostic

Control system with gear box Hydraulic circuit Close

• Easytronic Silver:

Integrated color LCD

Counters

Pumping unit management

Diagnostic

Placing boom technical data

Main options Model K56C

• 2 Proportional radio controls HBC (in replacement of the standard)

• High pressure water pump 120 bar / 28 l/min - 40 kg Pipeline diameter mm 125

• Concrete shut off on endhose - 2 kg

(includes air pipeline on placing boom) Maximum vertical reach m 56

• First aid kit for pumping unit

• Emergency button panel for PU pumping unit Maximum horizontal distance m 51

• Additional endhose double stapling (from center of slewing axis)

Minimum unfolding height m 15,8

Section numbers 6

1st section opening angle 90°

2nd section opening angle 180°

MANUFACTURING CIFA HUNAN 3rd section opening angle 180°

TRUCK ASSEMBLY CIFA ITALY 4th section opening angle 240°

TESTING CIFA ITALY 5th section opening angle 195°

CE CERTIFICATION CIFA ITALY 6th section opening angle 210°

WARRANTY CIFA ITALY Rotating angle ±270°

End hose length m 3

Technical data and characteristics subject to modifications without notice

CIFA S.p.A. Factory

K56C_ENG_1217

A ZOOMLION COMPANY CIFA Hunan

via Stati Uniti d’America, 26 Changsha

20030 Senago (Milano) - Italia PRC

tel.: +39.02.990131 - fax: +39.02.9981157

www.cifa.com The declaration of conformity will be supplied with the Use and Maintenance Handbook

You might also like

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNo ratings yet

- K52L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK52L XRZ: Truck-Mounted Concrete Boom PumpAhmed Rashad100% (1)

- Truck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisDocument2 pagesTruck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisAhmad Mahmmad100% (1)

- Circuit Documents: VECTOR S46-61SX Circiut Diagram S46/47SX BR01 S52/55SX S58/61SX TypeDocument90 pagesCircuit Documents: VECTOR S46-61SX Circiut Diagram S46/47SX BR01 S52/55SX S58/61SX TypeEbrahem Ahmed Hafez100% (1)

- SP 3800 Spec SheetDocument4 pagesSP 3800 Spec SheetBambang tejo0% (1)

- Bids for ZLJ5300THBB 40X-5RZ Truck-Mounted Concrete PumpDocument16 pagesBids for ZLJ5300THBB 40X-5RZ Truck-Mounted Concrete PumpNay SoeNo ratings yet

- SCHWING TrainingManual (001 031)Document31 pagesSCHWING TrainingManual (001 031)Petr KosNo ratings yet

- 38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpDocument2 pages38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpBudi PrayitnoNo ratings yet

- Thom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpDocument2 pagesThom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpAlexander LabautNo ratings yet

- SANY C8 Truck Mounted Concrete Pump 20161103Document13 pagesSANY C8 Truck Mounted Concrete Pump 20161103TantyNo ratings yet

- Care & Maintenance - UpdatedDocument7 pagesCare & Maintenance - UpdatedMIDHUN MOHAN.M.P100% (1)

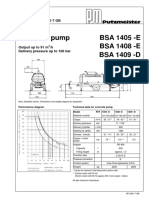

- Stationary Concrete Pump BSA 1407 D: Output Up To 71 M /H Delivery Pressure Up To 106 BarDocument1 pageStationary Concrete Pump BSA 1407 D: Output Up To 71 M /H Delivery Pressure Up To 106 BarJing AytonaNo ratings yet

- SYG5260THB 370C-10: Xiaww 2023-03-02 Xiaww 2023-03-02 Xiaww 2023-03-02Document352 pagesSYG5260THB 370C-10: Xiaww 2023-03-02 Xiaww 2023-03-02 Xiaww 2023-03-02Luong Nguyen DanhNo ratings yet

- CIFA PipeDocument24 pagesCIFA PipeXiangzhendongNo ratings yet

- Electric Cabinet CPL. C46615800 PDFDocument4 pagesElectric Cabinet CPL. C46615800 PDFSubhash KediaNo ratings yet

- Pumps Steeltech ENGDocument9 pagesPumps Steeltech ENGAhmad MahmmadNo ratings yet

- Alle V-Infos EnglischDocument43 pagesAlle V-Infos EnglischMohamed Rashed50% (2)

- S34xen Schwing Pump PDFDocument2 pagesS34xen Schwing Pump PDFAmin KmiNo ratings yet

- Wiring Diagram WaitzingerDocument8 pagesWiring Diagram WaitzingerIonut MoiseNo ratings yet

- Brief Introduction of Pump TruckDocument39 pagesBrief Introduction of Pump Truckkamal100% (1)

- Hydraulic and Electric DiagramDocument20 pagesHydraulic and Electric DiagramEvert Vargas Torrez100% (2)

- Sect 1 Technical Data PDFDocument20 pagesSect 1 Technical Data PDFdcoronado0487100% (1)

- S36X Boom Pump Jan 2022Document11 pagesS36X Boom Pump Jan 2022Sinamm Engineering LimitedNo ratings yet

- 34 Meter Data SheetDocument4 pages34 Meter Data SheetFawzi AlzubairyNo ratings yet

- Ergonic 3 CE Brochure enDocument7 pagesErgonic 3 CE Brochure enyang manNo ratings yet

- Edoc - Pub Se Radiomatic Adcon ExchangeDocument18 pagesEdoc - Pub Se Radiomatic Adcon ExchangeFabian Cortes SerranoNo ratings yet

- S42 SXBrochureDocument4 pagesS42 SXBrochureRamy El GammalNo ratings yet

- Spare Parts For. Schwing Concrete Pumps. Section 2Document16 pagesSpare Parts For. Schwing Concrete Pumps. Section 2CosminNo ratings yet

- Concrete Pump KCP - 58zx170Document164 pagesConcrete Pump KCP - 58zx170KCJBAR productionNo ratings yet

- Truck-Mounted Concrete Pump: Placing Boom B6RZ 50 Driven by Gearbox PTO Chassis 3 AxlesDocument2 pagesTruck-Mounted Concrete Pump: Placing Boom B6RZ 50 Driven by Gearbox PTO Chassis 3 AxlesNader AljabaliNo ratings yet

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument6 pagesS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuNo ratings yet

- Concrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBDocument2 pagesConcrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBBourenaneNo ratings yet

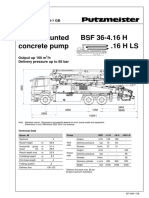

- Putzmeister BSF 36-4Document2 pagesPutzmeister BSF 36-4Abdallah Tarek100% (1)

- Ficha Tecnica k36z ClassicDocument2 pagesFicha Tecnica k36z ClassicManuel VidarteNo ratings yet

- S 52 SX PDFDocument6 pagesS 52 SX PDFsmishra22220% (1)

- Concrete Pump BSA 1405 - E BSA 1408 - E BSA 1409 - D: Data Sheet BP 2081-7 GBDocument2 pagesConcrete Pump BSA 1405 - E BSA 1408 - E BSA 1409 - D: Data Sheet BP 2081-7 GBMahmoud Taher El KhorzatyNo ratings yet

- Novam SeriesDocument35 pagesNovam Serieshidraulica inteligenteNo ratings yet

- S43X Bro2013 PDFDocument4 pagesS43X Bro2013 PDFMei Astuti Dwi RachmawatiNo ratings yet

- Check Book 2010 (GB)Document88 pagesCheck Book 2010 (GB)Aly Abdelhamed100% (1)

- KVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsDocument2 pagesKVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsMihnea-Bogdan Nicolaescu100% (1)

- SCHWING ExpandedPumpParts CatalogDocument8 pagesSCHWING ExpandedPumpParts CatalogRoberto Maggiolo100% (2)

- Truck Mounted S17 S20 Bro2016 - 0Document4 pagesTruck Mounted S17 S20 Bro2016 - 0sdahgNo ratings yet

- Sermac SCL130ADocument2 pagesSermac SCL130AVasiliy PavliukNo ratings yet

- Operating Instructions RRC, Sender Spectrum3 enDocument26 pagesOperating Instructions RRC, Sender Spectrum3 enWiwa Hernandez Donoso100% (1)

- Greaves BP350E Concreate PuumpDocument8 pagesGreaves BP350E Concreate PuumpMohan Charanchath0% (1)

- Truck-Mounted Concrete Pump BSF 20-4.09 HDocument2 pagesTruck-Mounted Concrete Pump BSF 20-4.09 HJeff Neurauter100% (1)

- MANUAL (Español)Document458 pagesMANUAL (Español)jose100% (1)

- Wear Ring05085 - GBDocument4 pagesWear Ring05085 - GBMahmoud Saleh100% (3)

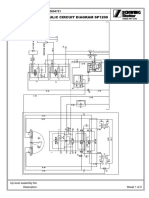

- Hydralic Circit For SP1200 PumpDocument2 pagesHydralic Circit For SP1200 PumpAhesanShaikhNo ratings yet

- Truck MTD Conc Pump - FinalDocument50 pagesTruck MTD Conc Pump - Finalpgiaut100% (4)

- La Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDDocument34 pagesLa Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDEvert Vargas Torrez100% (1)

- Truck-mounted BSF 36-4.16 H concrete pumpDocument2 pagesTruck-mounted BSF 36-4.16 H concrete pumpJonathan Guzmán MendozaNo ratings yet

- Transit Mixer PresentationDocument16 pagesTransit Mixer Presentationsaimun100% (1)

- Parts & Accessories SourceDocument28 pagesParts & Accessories Sourceshen fred50% (2)

- Plugin-PM 261 enDocument11 pagesPlugin-PM 261 enscientist mahaleNo ratings yet

- HBT80C-1818DIII Trailer-Mo Safety ManualDocument60 pagesHBT80C-1818DIII Trailer-Mo Safety ManualLinzaw Win100% (1)

- KVM 42 Truck-mounted concrete pump with 4-section placing boomDocument4 pagesKVM 42 Truck-mounted concrete pump with 4-section placing boomDiego VgNo ratings yet

- Truck-Mounted Concrete Boom Pump: Series SeriesDocument2 pagesTruck-Mounted Concrete Boom Pump: Series SeriesHussein SayedNo ratings yet

- K47H Truck-Mounted Concrete Boom Pump SpecsDocument2 pagesK47H Truck-Mounted Concrete Boom Pump SpecsOğuzhan OdbayNo ratings yet

- Bomba de ConcretoDocument2 pagesBomba de ConcretoAlfonso ChNo ratings yet

- Spare Parts Manual for ZOOMLION 33X-4Z Truck-Mounted Concrete PumpDocument808 pagesSpare Parts Manual for ZOOMLION 33X-4Z Truck-Mounted Concrete PumpXiangzhendongNo ratings yet

- Perkins 830 II Parts Manual2Document428 pagesPerkins 830 II Parts Manual2XiangzhendongNo ratings yet

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- BEML Bull Dozer Parts Inventory ListingDocument354 pagesBEML Bull Dozer Parts Inventory ListingXiangzhendongNo ratings yet

- 油缸配件1catalogDocument9 pages油缸配件1catalogXiangzhendongNo ratings yet

- Mayco Pumps Concrete 0708 BrochureDocument8 pagesMayco Pumps Concrete 0708 BrochureXiangzhendongNo ratings yet

- CIFA Truck Pumps Easy to Use Reliable SeriesDocument12 pagesCIFA Truck Pumps Easy to Use Reliable SeriesXiangzhendongNo ratings yet

- CIFA PipeDocument24 pagesCIFA PipeXiangzhendongNo ratings yet

- CIFA's Story of Innovation and Global GrowthDocument2 pagesCIFA's Story of Innovation and Global GrowthXiangzhendongNo ratings yet

- CIFA Truck Pumps Easy to Use Reliable SeriesDocument12 pagesCIFA Truck Pumps Easy to Use Reliable SeriesXiangzhendongNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument8 pagesDepartment of Transportation Federal Aviation AdministrationsandyNo ratings yet

- Sarens: GroupDocument4 pagesSarens: GroupBui Hoang DucNo ratings yet

- Assignment 1Document4 pagesAssignment 1Ziyad Awali100% (1)

- T SB 0385 09Document6 pagesT SB 0385 09goomba100% (1)

- Tugas Bahasa InggrisDocument2 pagesTugas Bahasa InggrisAnis Rita PratiwiNo ratings yet

- Ford Racing Focus Parts Performance Comparison for 2.0L Zetec EngineDocument1 pageFord Racing Focus Parts Performance Comparison for 2.0L Zetec EngineandrewNo ratings yet

- P112 - 115 WP HinoDocument4 pagesP112 - 115 WP HinoWilmer VasquezNo ratings yet

- JF 011 eDocument7 pagesJF 011 eЮрій Полтавець75% (4)

- of SuperchargerDocument18 pagesof SuperchargerNEERAJNo ratings yet

- 8 21 31 Fuel Oil SystemDocument30 pages8 21 31 Fuel Oil SystemTansu MavunacıNo ratings yet

- Bosch AeroEco Wiper Blades - The Difference is ClearDocument12 pagesBosch AeroEco Wiper Blades - The Difference is Clearharari itirNo ratings yet

- Agila RPO Code ListDocument2 pagesAgila RPO Code ListGaby VasileNo ratings yet

- EC360B LC Ec360B NLC: Volvo ExcavatorDocument12 pagesEC360B LC Ec360B NLC: Volvo ExcavatorHalil KaraNo ratings yet

- TVS Apache RTR 180 Cylinder Head Assembly Parts CatalogueDocument70 pagesTVS Apache RTR 180 Cylinder Head Assembly Parts CatalogueGoutam Biswas100% (1)

- 303-14 Electronic Engine Controls - Removal and Installation - Fuel Rail Pressure FRP SensorDocument5 pages303-14 Electronic Engine Controls - Removal and Installation - Fuel Rail Pressure FRP SensorCARLOS LIMADANo ratings yet

- Tier 3: Engine Power Max Operating Weight Bucket Capacity E245CDocument20 pagesTier 3: Engine Power Max Operating Weight Bucket Capacity E245CGoran MatovicNo ratings yet

- Service Engines and Accessories: TecumsehpowerDocument33 pagesService Engines and Accessories: TecumsehpowerMichael MartinNo ratings yet

- Catalog GATELOCK PDFDocument7 pagesCatalog GATELOCK PDFCico LisadonNo ratings yet

- Chapter 1 Engine: SpecificationsDocument9 pagesChapter 1 Engine: Specificationsmdias_650100No ratings yet

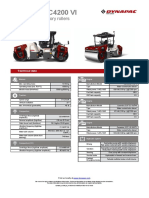

- Dynapac CC4200 VI Double Drum Vibratory Roller SpecsDocument2 pagesDynapac CC4200 VI Double Drum Vibratory Roller SpecsJaherNo ratings yet

- YOKOHAMA Motorsport Catalogue 2021Document6 pagesYOKOHAMA Motorsport Catalogue 2021Anthony Da Silva GuglielmettoNo ratings yet

- Pulp Hero - Pulp Vehicle SourcebookDocument29 pagesPulp Hero - Pulp Vehicle SourcebookRuben100% (3)

- Hybrid Electric Vehicles: Johan Driesen K.U.Leuven - ESAT/ELECTADocument67 pagesHybrid Electric Vehicles: Johan Driesen K.U.Leuven - ESAT/ELECTATanawat ThanthongNo ratings yet

- 五十铃isuzu Hatichi 4hk1 6hk1 ManualDocument351 pages五十铃isuzu Hatichi 4hk1 6hk1 Manual蔡苏100% (2)

- JCB Parts CatalogueDocument629 pagesJCB Parts CatalogueRajan Mullappilly92% (26)

- EngineDocument14 pagesEngineChandraranga De SilvaNo ratings yet

- WB156-5 y WB 156PS-5 Retros KomatsuDocument10 pagesWB156-5 y WB 156PS-5 Retros KomatsuEdith perezNo ratings yet

- Mazda Demio Owner's Manual (Page 348 of 358) ManualsLibDocument1 pageMazda Demio Owner's Manual (Page 348 of 358) ManualsLibNipun MendisNo ratings yet

- Honda Jazz 2005Document33 pagesHonda Jazz 2005jeckiyuwono100% (2)

- Electricalcomponentlocations 131222071900 Phpapp02Document91 pagesElectricalcomponentlocations 131222071900 Phpapp02petcucatalinnNo ratings yet