Professional Documents

Culture Documents

Care & Maintenance - Updated

Uploaded by

MIDHUN MOHAN.M.POriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Care & Maintenance - Updated

Uploaded by

MIDHUN MOHAN.M.PCopyright:

Available Formats

BASIC CARE

& MAINTENANCE

25. June 2013 © Putzmeister Concrete Machines Pvt. Ltd. Page1

Operation care

During Operation :

Assembly Check Criterion

General All lubrication points lubricate as required

Transfer tube Switching shaft bearings and seal no cement-colored oil and grease

mixture or slurry cement may escape

Bearings and seal on the pressure from the bearings

connection

Page3

Hopper Mixer shaft bearings and seal

Instruments Monitor all in the normal range

© Putzmeister Concrete Machines Pvt. Ltd.

After Operation :

Assembly Activities and checks Criterion

General Cleaning

All lubrication points sufficient lubrication

Water box Drain off water

Transfer tube Check inner wall and wear ring no mechanical wear

Check sealing gap gap < 1 mm

Coupling and seal ring on pressure

25. June 2013

Delivery line grease

pipe

Inspection checks (as & when required)

ASSEMBLY ACTIVITY / MAINTENANCE CARD

Hydraulic Replace the fluid filter

system Replace hydraulic hoses

Tighten / change flared screwed joints

Core pump Tighten bolts on the spacer flange

Page4

Replace the delivery pistons

Measure wall thickness

© Putzmeister Concrete Machines Pvt. Ltd.

Adjust the transfer tube

Transfer tube Replace the spectacle wear plate

Tighten the clamping bolts on the switch lever

Replace switching shaft bearings and seals

Pressure connection - replace bearings and seals

Agitator Replace bearings and seals

25. June 2013

Full transmission oil change

Do’s & Don'ts for BSA

Do’s

Before starting the machine check all the oil levels (Hydraulic & engine) .

Fill fresh water in the water box .

Follow all the safety regulations religiously.

Page5

Keep the grill and water box cover close when the machine is in operation.

© Putzmeister Concrete Machines Pvt. Ltd.

At the end of the pour, clean all the pipelines & end hose with water pressure .

Use genuine spare parts from manufacturer / OEM for trouble free operation .

Follow the maintenance schedules to cut down on repair costs.

Always store pipeline seals with the coating of hydraulic oil .

25. June 2013

Do’s & Don'ts for BSA

Don'ts

Do not work on the machine while in the running condition .

Do not open the hopper grill when the machine is in running condition .

Do not open any delivery pipe or hydraulic pipe during operation .

Page6

Never mix two different grades of hydraulic oils .

© Putzmeister Concrete Machines Pvt. Ltd.

Do not try to remove chock by forward pumping .

Never disturb pressure setting .You may risk human life & the machine .

Do not leave machine unattended during concreting or when in operation .

25. June 2013

Recommended daily checks

Level check: Before starting the engine, check hydraulic oil level, engine oil level &

coolant oil level in the radiator diesel tank. If required, top-up the respective oils

Operation check: Start the engine & run it for 5 minutes for warm up of the oil, check

operation of the drive cylinder , S-tube shifting , no. of strokes , high pressure & accumulator

pre charged pressure .

Page7

Lubrication/Greasing: Ensure that all lubrication points are lubricated properly & if required

re-lubricate before shifting the machine to the site .

© Putzmeister Concrete Machines Pvt. Ltd.

Filter functions: Dirty filters reduce the flow considerably & hence damage may occur in

the hydraulic system.

The filter element must be replaced if the vacuum meter indicator is in the red zone at

more than 30°C fluid temperature and the fastest stroke time.

25. June 2013

Care & maintenance

Breaks in between pumping

You should avoid breaks in pumping as far as possible as the concrete in the delivery line

can start to set or can become segregated due to vibration of machine.

Never leave delivery line under pressure.

Relieve the delivery line during short breaks in delivery by reverse pumping briefly.

Move the concrete at short intervals by forward and reverse pumping.

Pump the concrete back into the hopper before long breaks in pumping.

Page8

© Putzmeister Concrete Machines Pvt. Ltd.

After completion of concrete pumping

Clean the hopper, concrete cylinder thoroughly with pressurized water.

Clean the pipeline by passing one or two sponge ball.

Lubricate all the points in the hopper area with the help of centralized manual

lubrication system .

Drain the water from the water box.

25. June 2013

You might also like

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- KVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsDocument2 pagesKVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsMihnea-Bogdan Nicolaescu100% (1)

- Thom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpDocument2 pagesThom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpAlexander LabautNo ratings yet

- ManualArchive 210603847 Operating InstructionsDocument599 pagesManualArchive 210603847 Operating InstructionsJhoersino TurpoNo ratings yet

- S 52 SX PDFDocument6 pagesS 52 SX PDFsmishra22220% (1)

- Sect 1 Technical Data PDFDocument20 pagesSect 1 Technical Data PDFdcoronado0487100% (1)

- SP 3800 Spec SheetDocument4 pagesSP 3800 Spec SheetBambang tejo0% (1)

- Reliable Easy To Use: Truck-Mounted Concrete Boom PumpDocument2 pagesReliable Easy To Use: Truck-Mounted Concrete Boom PumpXiangzhendong100% (1)

- PuztmeisterDocument3 pagesPuztmeisterEdgar Quispe LaricoNo ratings yet

- Plugin-PM 261 enDocument11 pagesPlugin-PM 261 enscientist mahaleNo ratings yet

- Bids for ZLJ5300THBB 40X-5RZ Truck-Mounted Concrete PumpDocument16 pagesBids for ZLJ5300THBB 40X-5RZ Truck-Mounted Concrete PumpNay SoeNo ratings yet

- THEAM - Concrete Conveyor Instruction ManualDocument40 pagesTHEAM - Concrete Conveyor Instruction ManualGregNo ratings yet

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument6 pagesS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuNo ratings yet

- Greaves BP350E Concreate PuumpDocument8 pagesGreaves BP350E Concreate PuumpMohan Charanchath0% (1)

- Pumps Steeltech ENGDocument9 pagesPumps Steeltech ENGAhmad MahmmadNo ratings yet

- SANY C8 Truck Mounted Concrete Pump 20161103Document13 pagesSANY C8 Truck Mounted Concrete Pump 20161103TantyNo ratings yet

- 38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpDocument2 pages38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpBudi PrayitnoNo ratings yet

- Truck-Mounted Concrete Pump BSF 20-4.09 HDocument2 pagesTruck-Mounted Concrete Pump BSF 20-4.09 HJeff Neurauter100% (1)

- S36X Boom Pump Jan 2022Document11 pagesS36X Boom Pump Jan 2022Sinamm Engineering LimitedNo ratings yet

- Aquarius Engineers Pvt. Ltd.Document18 pagesAquarius Engineers Pvt. Ltd.pranshamiNo ratings yet

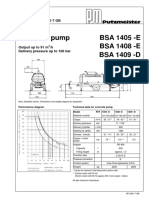

- Stationary Concrete Pump BSA 1407 D: Output Up To 71 M /H Delivery Pressure Up To 106 BarDocument1 pageStationary Concrete Pump BSA 1407 D: Output Up To 71 M /H Delivery Pressure Up To 106 BarJing AytonaNo ratings yet

- SYG5260THB 370C-10: Xiaww 2023-03-02 Xiaww 2023-03-02 Xiaww 2023-03-02Document352 pagesSYG5260THB 370C-10: Xiaww 2023-03-02 Xiaww 2023-03-02 Xiaww 2023-03-02Luong Nguyen DanhNo ratings yet

- Concrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBDocument2 pagesConcrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBBourenaneNo ratings yet

- SCHWING TrainingManual (001 031)Document31 pagesSCHWING TrainingManual (001 031)Petr KosNo ratings yet

- KCPDocument1 pageKCPLenin GullapalliNo ratings yet

- Stationary Concrete Pumps en G 16345-0 PDFDocument20 pagesStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PARONo ratings yet

- K52L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK52L XRZ: Truck-Mounted Concrete Boom PumpAhmed Rashad100% (1)

- Liebherr Truck Mounted Concrete Pumps en PDFDocument16 pagesLiebherr Truck Mounted Concrete Pumps en PDFRidwanda HimawanNo ratings yet

- Concrete Pump BSA 1405 - E BSA 1408 - E BSA 1409 - D: Data Sheet BP 2081-7 GBDocument2 pagesConcrete Pump BSA 1405 - E BSA 1408 - E BSA 1409 - D: Data Sheet BP 2081-7 GBMahmoud Taher El KhorzatyNo ratings yet

- HZS25 Concrete Batching Plant PDFDocument2 pagesHZS25 Concrete Batching Plant PDFHenan NF Mechanical Installation Co., Ltd.100% (2)

- MANUAL (Español)Document458 pagesMANUAL (Español)jose100% (1)

- Liebherr Brochure Boom Pumps enDocument20 pagesLiebherr Brochure Boom Pumps enVikash PanditNo ratings yet

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNo ratings yet

- HYDAC Understanding Hydraulics3 JAN 2015Document3 pagesHYDAC Understanding Hydraulics3 JAN 2015marc271986No ratings yet

- 058120-000 TL-49 sn1001+ E.PSDocument115 pages058120-000 TL-49 sn1001+ E.PSwillooohNo ratings yet

- CIFA PipeDocument24 pagesCIFA PipeXiangzhendongNo ratings yet

- Check Book 2010 (GB)Document88 pagesCheck Book 2010 (GB)Aly Abdelhamed100% (1)

- Transit Mixer PresentationDocument16 pagesTransit Mixer Presentationsaimun100% (1)

- Address: Gazeteciler Sitesi, Dergiler Sok. No:13 P.K. 34394 EsentepeDocument10 pagesAddress: Gazeteciler Sitesi, Dergiler Sok. No:13 P.K. 34394 EsentepeelkonwebNo ratings yet

- S34xen Schwing Pump PDFDocument2 pagesS34xen Schwing Pump PDFAmin KmiNo ratings yet

- 34 Meter Data SheetDocument4 pages34 Meter Data SheetFawzi AlzubairyNo ratings yet

- Alle K-Infos EnglischDocument134 pagesAlle K-Infos EnglischasalinaspadillaNo ratings yet

- Elkomix-60 Quickmaster With Conveyor - StojanovicDocument5 pagesElkomix-60 Quickmaster With Conveyor - StojanovicBorivoje StojanovicNo ratings yet

- C.P Training Module Levl.2 HydraulicDocument56 pagesC.P Training Module Levl.2 HydraulicEslam Mansour100% (1)

- HL220 270 Silent GBDocument1 pageHL220 270 Silent GBpnsanatNo ratings yet

- Cement Mixer Model Mx-80 Owner'S/Operator'S - Parts ManualDocument12 pagesCement Mixer Model Mx-80 Owner'S/Operator'S - Parts Manualrelh62No ratings yet

- SL - No Part No Part Name: Spares Qty For 2 Each of Jsp40 & JSP70Document4 pagesSL - No Part No Part Name: Spares Qty For 2 Each of Jsp40 & JSP70Babu RajamanickamNo ratings yet

- Electric Cabinet CPL. C46615800 PDFDocument4 pagesElectric Cabinet CPL. C46615800 PDFSubhash KediaNo ratings yet

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enDocument8 pages376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevNo ratings yet

- CC112 Complete ManualDocument19 pagesCC112 Complete ManualKarolMichaelSaavedraContrerasNo ratings yet

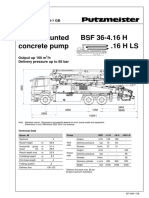

- Truck-mounted BSF 36-4.16 H concrete pumpDocument2 pagesTruck-mounted BSF 36-4.16 H concrete pumpJonathan Guzmán MendozaNo ratings yet

- A5000 Users Manual AsahiDocument72 pagesA5000 Users Manual AsahiBobNo ratings yet

- M550L User's Manual: Radio Remote ControlDocument28 pagesM550L User's Manual: Radio Remote ControlTSDCNo ratings yet

- sp500 Specs 011419Document1 pagesp500 Specs 011419Henrique AidaNo ratings yet

- Mixer CifaDocument12 pagesMixer Cifapablopela100% (1)

- Hydralic Circit For SP1200 PumpDocument2 pagesHydralic Circit For SP1200 PumpAhesanShaikhNo ratings yet

- TK 20 Equipo 719Document13 pagesTK 20 Equipo 719jorgeNo ratings yet

- Bomba Myers D35-20DVDocument12 pagesBomba Myers D35-20DVdiroperacionesNo ratings yet

- Belt Filter PressDocument5 pagesBelt Filter PressMaku RajkumarNo ratings yet

- 330D-336D Testing and Adjusting (RENR9585-11) PDFDocument176 pages330D-336D Testing and Adjusting (RENR9585-11) PDFDiego Alonso Huaraca Baleriano100% (3)

- Electrical Motors - StatorsDocument16 pagesElectrical Motors - StatorsMIDHUN MOHAN.M.PNo ratings yet

- Basics On Electrical Operation and ControlDocument41 pagesBasics On Electrical Operation and ControlMIDHUN MOHAN.M.PNo ratings yet

- Bosch CatDocument148 pagesBosch CatMIDHUN MOHAN.M.PNo ratings yet

- Stationary Pumping and Pipeline LayoutDocument22 pagesStationary Pumping and Pipeline LayoutMIDHUN MOHAN.M.PNo ratings yet

- Change Air Filters RegularlyDocument41 pagesChange Air Filters RegularlyMIDHUN MOHAN.M.PNo ratings yet

- Basic First Aid: Facilities Planning & Management UW-Eau ClaireDocument47 pagesBasic First Aid: Facilities Planning & Management UW-Eau ClairederdouriNo ratings yet

- Destroy diesel engine with just 100-200 grams of dustDocument13 pagesDestroy diesel engine with just 100-200 grams of dustMIDHUN MOHAN.M.PNo ratings yet

- Kumiko Jigs Japanese Woodworking PDFDocument9 pagesKumiko Jigs Japanese Woodworking PDFJaime Montiel100% (1)

- Astm C1396 C1396M-17Document8 pagesAstm C1396 C1396M-17Stefano CamillucciNo ratings yet

- Xeno Energy XL-060F Spec SheetDocument1 pageXeno Energy XL-060F Spec SheetRadiation Monitoring RadonNo ratings yet

- DR Vatsal Patel AhmedabadDocument30 pagesDR Vatsal Patel AhmedabadSayali PhansekarNo ratings yet

- S6000-Operation-Manual SkyliftDocument50 pagesS6000-Operation-Manual SkyliftSetiawan Tuhu basukiNo ratings yet

- Ch02 World Trade An Overview 1Document32 pagesCh02 World Trade An Overview 1XIKAMNo ratings yet

- NCERT Solutions For Class 8 Science Chapter 6Document4 pagesNCERT Solutions For Class 8 Science Chapter 6D Rong saNo ratings yet

- Real-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshDocument8 pagesReal-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshGetachew BekeleNo ratings yet

- Rohail Hassan: ObjectiveDocument3 pagesRohail Hassan: ObjectiveNoumanKhanNo ratings yet

- Methyl methacrylate allergy case study in dentistry studentDocument3 pagesMethyl methacrylate allergy case study in dentistry studentDaniela CapitanuNo ratings yet

- CIA Patho 1Document23 pagesCIA Patho 1Suhas H GNo ratings yet

- FIITJEE SAMPLE PAPER – 2018 (Big Bang Edge Test / Talent Recognition Exam) for Class 10 (Paper 2Document17 pagesFIITJEE SAMPLE PAPER – 2018 (Big Bang Edge Test / Talent Recognition Exam) for Class 10 (Paper 2msreddy86No ratings yet

- Oval Lake Hospital: Managing Your Data With Data ToolsDocument7 pagesOval Lake Hospital: Managing Your Data With Data ToolsJacob SheridanNo ratings yet

- Technical ReportDocument184 pagesTechnical Reportomen2ng88% (17)

- Mathematics JEE Main Chapter Wise DPPDocument513 pagesMathematics JEE Main Chapter Wise DPPMurali100% (1)

- Chennai Public School: CH 3 Coordinate Geometry Multiple AssessmentDocument3 pagesChennai Public School: CH 3 Coordinate Geometry Multiple Assessment11F10 RUCHITA MAARANNo ratings yet

- FF4 58 Service Manual ERQU40E3HUSDocument20 pagesFF4 58 Service Manual ERQU40E3HUSCarmen Adriana Garcia MendozaNo ratings yet

- Bone MarrowDocument6 pagesBone Marrow:)No ratings yet

- Студената войнаDocument421 pagesСтудената войнаauroradentata0% (1)

- Basic CourseDocument97 pagesBasic CourseAhmed KhairyNo ratings yet

- Provisional RestorationsDocument9 pagesProvisional RestorationsshivaprasadmNo ratings yet

- Leptospirosis National Guidelines - Sri LankaDocument56 pagesLeptospirosis National Guidelines - Sri LankaBrainy-Paykiesaurus LuminirexNo ratings yet

- Ashok M.tech CompleteDocument65 pagesAshok M.tech CompleteAshok BhatiaNo ratings yet

- GX7000 New CatalogeDocument20 pagesGX7000 New CatalogeyohanesNo ratings yet

- Industrial Attachment at Meghna Knit Composite Ltd.Document137 pagesIndustrial Attachment at Meghna Knit Composite Ltd.Riasat Alam50% (2)

- ANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODDocument9 pagesANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODmuhammad yaminNo ratings yet

- Joe Rozencwajg InterviewDocument17 pagesJoe Rozencwajg InterviewGold SunriseNo ratings yet

- Mintek Ar 2011Document76 pagesMintek Ar 2011Algradi MosheerNo ratings yet

- TELchart ECS Manual en Rev 1 - 24Document233 pagesTELchart ECS Manual en Rev 1 - 24Old Yeller100% (1)

- Dolphin Facts For Kids Ilovepdf CompressedDocument1 pageDolphin Facts For Kids Ilovepdf CompressedtechboostmrktgNo ratings yet