Professional Documents

Culture Documents

Liebherr Truck Mounted Concrete Pumps en PDF

Uploaded by

Ridwanda HimawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebherr Truck Mounted Concrete Pumps en PDF

Uploaded by

Ridwanda HimawanCopyright:

Available Formats

Truck Mounted Concrete Pumps

Optimum Conveyance of Concrete

More profit by way of investment

Sound investment –

Financial savings over the long term

Maximum life-expectancy and reduced servicing costs ensure smooth and cost-effective operation

over many years. Superior resale prices are an additional customer benefit.

2 Truck Mounted Concrete Pumps

There are many reasons for choosing a Liebherr

truck mounted concrete pump

When purchasing from Liebherr, you are guaranteed high-

performance „Made in Germany“ products for the most

exacting requirements. With utmost importance attached to

quality, we only install components supplied by renowned

manufacturers. Extensive test series and field testing, as

well as material inspections ensure long life-expectancy of

the concrete pumps. The innovative pump units, hydraulic

system and state-of-the-art control ensures cost-effective

operation of the concrete pump.

Numerous technical details simplify servicing: For example,

easier and quicker replacement of wear parts.

Innovative technology, such as the support system, provides Over the long-term, a concrete pump from Liebherr will prove

advantages during everyday operation. a profitable investment as the outlay for servicing and energy

costs yield a positive overall balance with regard to life cycle

costs.

The higher resale value of German quality products from

Liebherr proves yet another positive aspect in the total cost

balance.

Rugged Optimised servicing requirements High-Tech

The rugged design ensures reliable operation Various design details simplify the Advanced structural designs and state-of-

over several years with low operating costs. replacement of wear parts, thus optimising the-art manufacturing technologies produce

servicing. a dependable, sturdy construction for the

toughest of everyday applications.

Truck Mounted Concrete Pumps 3

The distributor booms

Uniform movements

Design of the distributor booms ensures uniform, low-vibration operation during the placing of

concrete.

4 Truck Mounted Concrete Pumps

Distributor booms from Liebherr are Pipe bends are predominantly the

available in roll-fold, Z-fold or multi-fold same, making the storage of wear

designs (depending on the respective parts easier. Due to their large radius

type) featuring three, four or five boom (R=275), the pipe bends reduce resist-

elements. ance in the concrete line.

Reduced boom width

The balanced weight distribution result- High pressure filtering in the boom en-

ing from alternating pipeline guidance sures exceptionally clean hydraulic oil

on the left-hand and right-hand boom to improve operational safety. Consid-

side, as well as the torsional resistant erably smaller particles can be filtered

steel structure, ensures low-vibration out in the high-pressure range.

guidance of the boom. Arrangement of

the pipeline close to the boom, com-

bined with the large-sized pins and

hydraulic cylinders contribute to a safe

and consistent guidance of the boom.

Sturdy Powerful Compact

Liebherr booms are sturdier with improved Largely-dimensioned hydraulic cylinders Reduced boom width is highly advantageous

torsional resistance due to their welding and sturdy hinged pins ensure even and when inserting into openings in buildings.

system. vibration-free movements, contributing to

a longer life-expectancy.

Truck Mounted Concrete Pumps 5

Innovative outriggers

Flexible and safe support

The XXT-outrigger allows particular flexibility when supporting in spatially restricted conditions.

6 Truck Mounted Concrete Pumps

Liebherr offers various support systems, ensuring an ideal

configuration solution for every respective requirement. The

XXT is particularly innovative and is exclusive to Liebherr,

providing specific advantages for everyday applications on

the building site:

With the narrow support option, the front outriggers can be

extended up to the front of the vehicle, allowing a greater

working range of up to 70 % (green). In particular, pumping

concrete over the operator‘s cab is extremely advantageous.

Advantages of the XXT-outrigger

• Direct power transmission from boom to outrigger

• No forces directed towards the frame/chassis by the distributor boom

• Only simple telescoping of front outrigger necessary

• Front and rear support arm rotatable around the same centre of

rotation

• Optimum possibilities for narrow support

• Flexible set-up possibilities

• Weight reduction

Optimum stability Narrow support XXA

The sturdy support guarantees maximum Working over the roof of the operator's cab The stability control system XXA guarantees

stability and safe operation. possible, even with the narrow support a reliable and safe operation in every

option. situation. Depending on the position of the

outrigger system and the boom only safe

movements are allowed.

Truck Mounted Concrete Pumps 7

The powerful pump units

Maximum pump output – Smooth running

The hopper geometry and the size of the suction openings ensure maximum pump output with

an outstanding degree of efficiency. The double end-of-stroke damping of the S-pipe changeover

cylinder facilitates a particularly smooth and quiet operation.

8 Truck Mounted Concrete Pumps

Improved concrete flow

The shape of the discharge hopper and the large-sized suction

openings at the cylinder contribute towards unobstructed

pump operation and outstanding suction performance. The

left and right-hand agitator paddles are powered by separate

motors, therefore no connection shaft is required between

the paddles.

Reduced soiling

The discharge hopper is designed with smooth surfaces

and no protruding edges. Deposits of residual concrete are

kept to a minimum and cleaning is completed quickly and

smoothly.

Flawless insertion of the concrete due to consistent concrete flow

without deflections at the end of the hose.

Powerful changeover Easy replacement of wear plate Optimum hopper shape

Largely-dimensioned hydraulic cylinders The sturdy S-pipe is designed to ensure a The optimised hopper shape benefits

allow a powerful change-over with hydraulic long service life. A split spectacle wear plate concrete flow and minimises concrete

pressures of up to 320 bar. Double end- can be easily replaced without having to deposits.

of-stroke damping guarantees smooth and dismantle the S-pipe.

quiet running.

Truck Mounted Concrete Pumps 9

The control: Safe and highly sensitive

Complete control

All commands can be transferred to the machine from any unobstructed operator position using the

state-of-the-art radio remote-control. The boom can thus be manoeuvred smoothly and practically

across the building site.

10 Truck Mounted Concrete Pumps

Colour display

The radio remote-control features a colour display, on which

various operating conditions may be viewed, for example the

XXA stability control during the supporting procedure (see Fig.).

Alternatively, operation is also possible via proportional

cable-operated remote-control wherever radio control is

not permitted on respective application site, for example in

military zones.

Protection against corrosion Improved operational safety

All housings for the control are made of stainless steel. Additionally, Liebherr truck mounted concrete pumps feature

alternative control options, guaranteeing continued pumping

in all situations.

• O = Normal control mode

(operation via sensors and controller)

• B = Emergency mode I: Operation without sensors

(hydraulic pressure relay)

• A = Emergency mode II: Operation without controller

(backup control via relay in the switch cabinet)

Truck Mounted Concrete Pumps 11

Fittings and accessories

1 2

3 4

5 6

7 8

12 Truck Mounted Concrete Pumps

Your wish is our command

Liebherr offer an extensive selection of fittings and acces-

sories. An optimum solution can be configured for your truck

mounted pump to satisfy all requests and requirement.

More storage space

Regardless of the respective configuration of the machine,

Liebherr can provide various options for storage facilities.

This will ensure that all materials being transported on the

vehicle can be tidily arranged in its own safe storage space.

Convenient for everyday operations

9

For example, a high-pressure lance or the spraying equip-

ment can ease the daily routine of cleaning, saving both time

and money.

The list of fittings supplied by Liebherr is extremely extensive.

We are therefore always available to offer any advice in this

regard.

10

11

1 LED working floodlight

2 High-pressure cleaner

3 Hinged fall arrester

4 Spraying equipment

5 Box for delivery notes

6 Magnetic rotating beacon

7 Pipe or hose storage

8 Hose storage on the support arm

9 Square timbers and support plates

10 Cleaning opening

11 Pinch valve on end hose and pneumatic end hose release

mechanism

12 12 Pivoting pipe bend

Truck Mounted Concrete Pumps 13

Utilisation on a global scale ...

14 Truck Mounted Concrete Pumps

Truck Mounted Concrete Pumps 15

Concrete technology from Liebherr

Liebherr provide a comprehensive range which encompasses the whole of concrete technology from a single source, from

the production of concrete, to concrete transport and installing concrete on the building site. More than 60 years of experi-

ence and continued further development has guaranteed Liebherr status as a globally-renowned provider in the concrete

production sector.

Many years of experience System solutions from a single source

Featuring capacities of 5 to 15 m³ nominal volume for the The conveyor belt mounted on the truck mixer is also per-

transport of concrete, the fixed-mounted truck mixers pro- fectly suited for applications on smaller building sites. Featur-

vided by Liebherr are compatible with all established chas- ing a radius of up to 16.4 m, the conveyor belt is operational

sis. Configuration as a semi-trailer is available in 9 to 15 m³ in no time. As well as concrete, the conveyance of materials

nominal volume. An extremely comprehensive accessories such as sand and gravel is also possible.

catalogue completes the range.

Quality and state-of-the-art technologies

The correct solution for every requirement Liebherr concrete mixing plants are employed reliably and

Printed in Germany by Eberl Print BK LMT-820312805_3.0-02.19_enGB

Liebherr truck mounted concrete pumps featuring various cost-effectively on a worldwide scale. The product range in-

configurations with boom sizes of up to 50 metres radius cludes stationary plants in horizontal and vertical configura-

are perfectly designed for cost-effective supply of concrete tions, as well as mobile mixing plants for short term building

onto the building site. Powerful stationary concrete pumps site applications. Liebherr‘s own mixing systems, capable of

are available as trailer concrete pumps or as self moving discharge rates between 30 and 300 m³, are installed in the

concrete pumps mounted on a crawler. The concrete pump concrete mixing plants. Liebherr also provide optimum solu-

range also includes concrete distributors or climbing booms. tions for residual concrete. The residual concrete recycling

Truck mixer concrete pumps are ideal for smaller building plants are available in „trough“ and „screw“ type series and

sites. feature washing outputs of between 10 and 22 m³ per hour.

Subject to technical modifications.

www.liebherr.com

Liebherr-Mischtechnik GmbH

Postfach 145, D-88423 Bad Schussenried

+49 7583 9 49-0, Fax +49 7583 9 49-3 96

www.liebherr.com, E-Mail: info.lmt@liebherr.com

You might also like

- Uputstvo Za Beton PumpuDocument155 pagesUputstvo Za Beton PumpuPredrag StojanovicNo ratings yet

- Share Swaraj Parts Price List - BZR - 15.09.2020Document508 pagesShare Swaraj Parts Price List - BZR - 15.09.2020सरोज यादव50% (2)

- Hydraulic and Electric DiagramDocument20 pagesHydraulic and Electric DiagramEvert Vargas Torrez100% (2)

- SCHWING TrainingManual (001 031)Document31 pagesSCHWING TrainingManual (001 031)Petr KosNo ratings yet

- SCHWING TrainingManual (229 261)Document33 pagesSCHWING TrainingManual (229 261)Petr Kos67% (3)

- Boom Pump & ServiceDocument55 pagesBoom Pump & ServiceAhmed AbdallahNo ratings yet

- Engine Service Training (DP222CA, DP222CB, DP222CC)Document70 pagesEngine Service Training (DP222CA, DP222CB, DP222CC)Quang PhamNo ratings yet

- Alle K-Infos EnglischDocument134 pagesAlle K-Infos EnglischasalinaspadillaNo ratings yet

- Gulf Lubricants Company ProfileDocument32 pagesGulf Lubricants Company ProfileIng Kelvys Gonzalez100% (2)

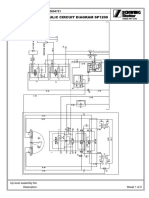

- Hydralic Circit For SP1200 PumpDocument2 pagesHydralic Circit For SP1200 PumpAhesanShaikhNo ratings yet

- Electric Cabinet CPL. C46615800 PDFDocument4 pagesElectric Cabinet CPL. C46615800 PDFSubhash KediaNo ratings yet

- Transit Mixer PresentationDocument16 pagesTransit Mixer Presentationsaimun100% (1)

- 38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpDocument2 pages38m Truck-Mounted Concrete Pump - SY5295THB 380C-8 SANY Concrete PumpBudi PrayitnoNo ratings yet

- A008125E - Single Rexroth 12vdc PDFDocument2 pagesA008125E - Single Rexroth 12vdc PDFaldo100% (2)

- S36X Boom Pump Jan 2022Document11 pagesS36X Boom Pump Jan 2022Sinamm Engineering LimitedNo ratings yet

- Edoc - Pub Se Radiomatic Adcon ExchangeDocument18 pagesEdoc - Pub Se Radiomatic Adcon ExchangeFabian Cortes SerranoNo ratings yet

- Liebherr Short Description DPVD FR PDFDocument4 pagesLiebherr Short Description DPVD FR PDFMohamed SalamNo ratings yet

- SCHWING ExpandedPumpParts CatalogDocument8 pagesSCHWING ExpandedPumpParts CatalogRoberto Maggiolo100% (2)

- Truck Mounted+Concrete+PumpDocument14 pagesTruck Mounted+Concrete+PumpSashkaRade Malesevic33% (3)

- Brosur Reckat 2017 PDFDocument12 pagesBrosur Reckat 2017 PDFRidwanda HimawanNo ratings yet

- S42 SXBrochureDocument4 pagesS42 SXBrochureRamy El GammalNo ratings yet

- Stationary Concrete Pumps en G 16345-0 PDFDocument20 pagesStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PARONo ratings yet

- SinoPumpingCatalogue PDFDocument26 pagesSinoPumpingCatalogue PDFChristian Slate100% (1)

- Truck MTD Conc Pump - FinalDocument50 pagesTruck MTD Conc Pump - Finalpgiaut100% (4)

- Meg - Concrete Pump Spare PartsDocument78 pagesMeg - Concrete Pump Spare PartsmegmachineryNo ratings yet

- KCP Parts Catalog 2019Document9 pagesKCP Parts Catalog 2019Jaison McDonaldNo ratings yet

- C.P Training Module Levl.2 HydraulicDocument56 pagesC.P Training Module Levl.2 HydraulicEslam Mansour100% (1)

- Schwing KVM 34X BrochureDocument4 pagesSchwing KVM 34X BrochureFlorinMacoveiNo ratings yet

- Service Manual: Extra-Capacity High-Capacity VarifeedDocument158 pagesService Manual: Extra-Capacity High-Capacity Varifeedroparts cluj0% (1)

- BP 3763 enDocument9 pagesBP 3763 enKhaled Kamel100% (1)

- Check Book 2010 (GB)Document88 pagesCheck Book 2010 (GB)Aly Abdelhamed100% (1)

- Ruler Vs Rpvot Fluitec Doc1003Document3 pagesRuler Vs Rpvot Fluitec Doc1003api-221802169100% (1)

- BT Lifter - LHM230Document26 pagesBT Lifter - LHM230Efrain AvilaNo ratings yet

- No.814 99500-98L00-01E DF350A Service Manual Cover For PS Printing (18mm) 5/1 2017/05/27 DIC619 Pantone 303C Pantone 485 Pantone 294 BlackDocument27 pagesNo.814 99500-98L00-01E DF350A Service Manual Cover For PS Printing (18mm) 5/1 2017/05/27 DIC619 Pantone 303C Pantone 485 Pantone 294 BlackFilipe PratasNo ratings yet

- Liebherr Plant 0001 - 04 - 05 - 16022016 - en - 820295005 - 122020 - DWDocument172 pagesLiebherr Plant 0001 - 04 - 05 - 16022016 - en - 820295005 - 122020 - DWMohamed Nasr100% (2)

- Cifa Concrete Pump Manual: Read/DownloadDocument2 pagesCifa Concrete Pump Manual: Read/DownloadMohamed Hussein67% (6)

- ManualArchive 210603847 Operating InstructionsDocument599 pagesManualArchive 210603847 Operating InstructionsJhoersino TurpoNo ratings yet

- Mixer CifaDocument12 pagesMixer Cifapablopela100% (1)

- A11vo 60 LRDH2Document1 pageA11vo 60 LRDH2xxshNo ratings yet

- M550L User's Manual: Radio Remote ControlDocument28 pagesM550L User's Manual: Radio Remote ControlTSDCNo ratings yet

- Liebherr Brochure Boom Pumps enDocument20 pagesLiebherr Brochure Boom Pumps enVikash PanditNo ratings yet

- 34 Meter Data SheetDocument4 pages34 Meter Data SheetFawzi AlzubairyNo ratings yet

- S 52 SX PDFDocument6 pagesS 52 SX PDFsmishra22220% (1)

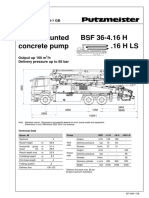

- Truck-Mounted BSF 36-4.16 H Concrete Pump .16 H LS: Data Sheet BP 4394-1 GBDocument2 pagesTruck-Mounted BSF 36-4.16 H Concrete Pump .16 H LS: Data Sheet BP 4394-1 GBJonathan Guzmán MendozaNo ratings yet

- Care & Maintenance - UpdatedDocument7 pagesCare & Maintenance - UpdatedMIDHUN MOHAN.M.P100% (1)

- Truck-Mounted Concrete Pump With RZ4 Placing BoomDocument6 pagesTruck-Mounted Concrete Pump With RZ4 Placing BoomSHAILESH PATELNo ratings yet

- K52L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK52L XRZ: Truck-Mounted Concrete Boom PumpAhmed Rashad100% (1)

- S34xen Schwing Pump PDFDocument2 pagesS34xen Schwing Pump PDFAmin KmiNo ratings yet

- Truck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisDocument2 pagesTruck-Mounted Concrete Boom Pump: Placing Boom Pumping Unit Driven by ChassisAhmad Mahmmad100% (1)

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument6 pagesS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuNo ratings yet

- KVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsDocument2 pagesKVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsMihnea-Bogdan Nicolaescu100% (1)

- MK24 4 PDFDocument2 pagesMK24 4 PDFAugusto Figueroa MeloNo ratings yet

- Alle V-Infos EnglischDocument43 pagesAlle V-Infos EnglischMohamed Rashed50% (2)

- Wiring Diagram WaitzingerDocument8 pagesWiring Diagram WaitzingerIonut MoiseNo ratings yet

- Bids For The 40X5RZDocument16 pagesBids For The 40X5RZNay SoeNo ratings yet

- CIFA PipeDocument24 pagesCIFA PipeXiangzhendongNo ratings yet

- SP 3800 Spec SheetDocument4 pagesSP 3800 Spec SheetBambang tejo0% (1)

- Reliable Easy To Use: Truck-Mounted Concrete Boom PumpDocument2 pagesReliable Easy To Use: Truck-Mounted Concrete Boom PumpXiangzhendong100% (1)

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNo ratings yet

- SANY C8 Truck Mounted Concrete Pump 20161103Document13 pagesSANY C8 Truck Mounted Concrete Pump 20161103TantyNo ratings yet

- Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument4 pagesTruck-Mounted Concrete Pump With 4-Section Placing BoomDiego VgNo ratings yet

- Thom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpDocument2 pagesThom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpAlexander LabautNo ratings yet

- PublicationDocument22 pagesPublicationLazar MiladinovicNo ratings yet

- Pumps Steeltech ENGDocument9 pagesPumps Steeltech ENGAhmad MahmmadNo ratings yet

- Sermac SCL130ADocument2 pagesSermac SCL130AVasiliy PavliukNo ratings yet

- Power Air Preheater Ljungstrom Air Preheaters PDFDocument16 pagesPower Air Preheater Ljungstrom Air Preheaters PDFNaveen ChodagiriNo ratings yet

- Cost-Effective Concrete Transport: Truck Mixer Generation 05Document12 pagesCost-Effective Concrete Transport: Truck Mixer Generation 05EslamAldenAbdoNo ratings yet

- TRITON™ CF-21 Surfactant: Product InformationDocument2 pagesTRITON™ CF-21 Surfactant: Product InformationRidwanda HimawanNo ratings yet

- Split System: Air ConditionersDocument13 pagesSplit System: Air ConditionersRidwanda HimawanNo ratings yet

- Company Profil KS Dan Data Dukungnya PDFDocument107 pagesCompany Profil KS Dan Data Dukungnya PDFRidwanda HimawanNo ratings yet

- Sandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationDocument4 pagesSandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationPablo Luis Ojeda PaezNo ratings yet

- Duty Cycle Error Codes - Mercedes-Benz ForumDocument11 pagesDuty Cycle Error Codes - Mercedes-Benz Forumfilonzi85No ratings yet

- EBZ55 Road Header - Extremely Mini-TunnelDocument7 pagesEBZ55 Road Header - Extremely Mini-TunnelJhonatan rincon martinezNo ratings yet

- Toro 38180 Snowthrower Parts CatalogDocument16 pagesToro 38180 Snowthrower Parts CatalogDanNo ratings yet

- Tiggo-7 Specification ProchDocument1 pageTiggo-7 Specification ProchMohamed Anter El-khoulyNo ratings yet

- Design Feature of WAGONSDocument6 pagesDesign Feature of WAGONSVikashNo ratings yet

- Engineering Operation & Maintenance: Plastic PumpDocument24 pagesEngineering Operation & Maintenance: Plastic PumpCirilo Marcos RossiNo ratings yet

- InstallationManual Atrack At5Document13 pagesInstallationManual Atrack At5dgham wajdiNo ratings yet

- Jeep Wrangler LED Headlights With White Halo & Turn SignalsDocument1 pageJeep Wrangler LED Headlights With White Halo & Turn SignalsIMZGAN O WAWTIL (D HMAD SOUSSI)No ratings yet

- 03FireHose BROOKSDocument14 pages03FireHose BROOKSLuis Orlando Cosme JiménezNo ratings yet

- Service Manual Yamaha Scorpio Chapter 7 ElectricalDocument47 pagesService Manual Yamaha Scorpio Chapter 7 Electricaljolang46No ratings yet

- Piper Seneca & Aztec Training SyllabusDocument3 pagesPiper Seneca & Aztec Training SyllabusNathaniel LuraNo ratings yet

- Check For Intermittent ProblemsDocument2 pagesCheck For Intermittent ProblemsYomar NegronNo ratings yet

- Master 4500 MD Treatment Plant Spare PartsDocument4 pagesMaster 4500 MD Treatment Plant Spare PartsPaul LauNo ratings yet

- C05541 HD85V5 WebDocument4 pagesC05541 HD85V5 WebFravian JoshuaNo ratings yet

- 11.112.11.C-0017-2 C32-O&M Manual Seawater PumpDocument132 pages11.112.11.C-0017-2 C32-O&M Manual Seawater PumprodrigourrutiaaNo ratings yet

- Wafer Lock ReadingDocument75 pagesWafer Lock ReadingIngo Fellner100% (1)

- WP20Document8 pagesWP20Victor BiacoloNo ratings yet

- Diagram of Lubricating Points DWR Front StandDocument7 pagesDiagram of Lubricating Points DWR Front StandPoposki PetreNo ratings yet

- Engine Mechanical Service DataDocument3 pagesEngine Mechanical Service DataJavier AguilarNo ratings yet

- 6068TF258Document2 pages6068TF258Desron SamuelNo ratings yet

- 2017 Ninja ZX-10R ABS KRT Edition Starter MotorDocument3 pages2017 Ninja ZX-10R ABS KRT Edition Starter MotorVer ArocenaNo ratings yet

- Furniture Catalog For IDAp ProjectsDocument13 pagesFurniture Catalog For IDAp ProjectsSheik HassanNo ratings yet

- 00SRZA398 - KDB - GCenterRAW - Manufacturing Specification of Welding Robot Sy...Document12 pages00SRZA398 - KDB - GCenterRAW - Manufacturing Specification of Welding Robot Sy...Sandro LourençoNo ratings yet