Professional Documents

Culture Documents

Properties Foster C.I. Mastic

Uploaded by

Minh BảoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties Foster C.I. Mastic

Uploaded by

Minh BảoCopyright:

Available Formats

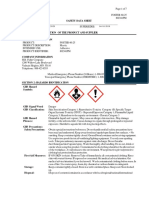

C.I.

Mastic®

60-25/60-26

Product Data Sheet

PROPERTIES FOSTER® C.I. MASTIC®

COLOR: FOSTER® C.I. MASTIC® is a tough, durable, high solids, vapor

Black retarder, asphalt cutback mastic. Because of its low vapor

permeance, it is an ideal surface coating for low temperature

APPLICATION CONSISTENCY: insulation on outdoor applications.

60-25: Trowel

60-26: Heavy duty airless spray C.I. MASTIC® may be used on heated lines, vessels and

equipment in intermittent or dual temperature service to prevent

AVERAGE WEIGHT / U.S. GALLON (ASTM D1475): the entrance of water vapor into the insulation during off

9.4 to 10.0 lbs. (1.13 to 1.20 kg/l) periods or on cold cycles.

AVERAGE NON-VOLATILE (ASTM D2369): C.I. MASTIC® may be used as a solvent-based adhesive for

69% by volume (79% by weight) asphaltic felt vapor retarder jackets on pipe and duct insulation.

COVERAGE RANGE: C.I. MASTIC® meets the requirements for water proofing

Subject to the type of surface being coated. Wet coverages mastics in the TRI-SERVICE SPECIFICATION for

shown below are for smooth, non-porous surfaces. Porous or UNDERGROUND HEAT DISTRIBUTION CONDUIT

rough surfaces will require higher gallonage to attain required SYSTEMS.

dry thickness.

LIMITATIONS

12 gallons per 100 sq. ft. minimum (4.9 l/m2) 0.192 in. wet film Store and apply between 40°F (4°C) and 100°F (38°C).

thickness (4.9 mm).

Always test foil and paper facings for acceptable adhesion

DRYING TIME 73°F (23°C) 50% RH: before using.

Set to Touch: 1/2 to 6 Hours

Through: 7 Days C.I. MASTIC® may weather to a dark gray color.

Outdoor horizontal surfaces must always drain completely. A

WATER VAPOR PERMEANCE (TYPICAL AVERAGE): pitch of at least 1/2” per foot (4 cm/m) is required.

ASTM E96, PROCEDURE A: < 0.015 perms (0.01 metric

perms) at 1/8” (3.2 mm) dry film thickness. Always test plastic materials for compatibility when using a

solvent-based product. Do not use on polystyrene foam.

ASTM F1249: 0.02 perms (0.01 metric perms) at 1/8” (3.2

mm) dry film thickness.

C.I. MASTIC® meets the permeance requirements of ASTM

C755-19 for below ambient vapor retarder coatings.

SERVICE TEMPERATURE LIMITS:

Temperature at coated surface.

-40°F to 180°F (-40°C to 82°C)

WET FLAMMABILITY:

Flash Point: 104°F (40°C)

SURFACE FLAME SPREAD (ASTM E162):

Flame Spread: 145

Applied to 1/4 inch (6.4 mm) inorganic reinforced cement ™ Trademark of H.B. Fuller Construction Products Inc.

board. The flame spread may vary at different product

thicknesses and/or when applied over other surfaces. Visit us on the web at www.fosterproducts.com

HB Fuller Construction Products Inc.

1105 South Frontenac St ○ Aurora, IL 60504 ○ 800-832-9002 ○ fax 800-952-2368

APPLICATION GUIDE

FOR

FOSTER C.I. MASTIC®

®

60-25/60-26

MATERIAL PREPARATION

DO NOT THIN. Stir well, but do not use sticks or boards which would splinter or otherwise contaminate the product. Apply only to

clean, dry, oil-free surfaces. Keep container closed when not in use. Foster ® 60-25 & 60-26 cannot be successfully applied by brush.

Foster® 60-25 cannot be applied by spray.

APPLICATION

Prime dusty insulation or porous cements with 60-25 or 60-26 cut 50/50 with mineral spirits. Proper and complete flashing is required.

Follow flashing specifications. If a decorative coating is to be used over the C.I. MASTIC®, allow a minimum of 30 days drying time

before application.

OUTDOOR AND HEAVY DUTY SERVICE

Apply a tack coat of Foster® C.I. MASTIC® at a thickness of 1/16 inch (1.6 mm). This is equivalent to 4 gallons per 100 square feet

(1.61 l/m2). Embed Foster® MAST-A-FAB® White Membrane into wet tack coat. Smooth membrane to avoid wrinkles and overlap all

seams at least 2 inches (5 cm). Apply a finish coat of C.I. MASTIC® at a minimum thickness of 1/8 inch (3.2 mm). This is equivalent to

8 gallons per 100 square feet (3.3 l/m2). This finish coat shall be applied no later than 1 hour after the tack coat and shall completely

cover the membrane. This application shall provide a minimum dry film thickness of 129 mils (3.3 mm).

HEAVY DUTY APPLICATIONS – UP TO 50% GREATER TENSILE STRENGTH

Apply as above, substituting CHIL-GLAS® #5 as the reinforcing membrane. Note that the membrane weave pattern will show through

the dried mastic.

TROWEL

Use clean tools and equipment. Work in long, even strokes to ensure uniform thickness. Wet tools in mineral spirits (flammable)

occasionally to prevent build-up of dried mastic.

SPRAY

C.I. MASTIC® 60-26 may be airless spray applied using heavy duty pneumatic pumps. Store 60-26 in a heated area. The material

temperature should be at least 70°F (21°C) before spraying. For spray equipment information, please consult Airless Spray

Recommendations or contact your spray equipment supplier. Average viscosity range: 100,000 – 150,000 cps.

CLEAN UP

Clean tools and equipment with mineral spirits (flammable) or chlorinated solvent (non-flammable).

INSPECTION

Where available, it is suggested to use a National Insulation Association (NIA) certified (or other similarly certified) mechanical

insulation inspector throughout the project to inspect and verify the materials and total insulation system have been installed correctly

in accordance with the specifications.

CUSTOMER SERVICE: (800) 832-9002

IMPORTANT: HB Fuller Construction Products Inc. warrants that each of its products will be manufactured in accordance with the specifications in effect on the date of

manufacture. WE MAKE NO OTHER WARRANTIES AND EXPRESSLY DISCLAIM ANY WARRANTIES OF MERCHANTIBILITY OR FITNESS FOR A PARTICULAR

PURPOSE. If a product fails to meet this limited warranty, purchaser’s sole and exclusive remedy is replacement of the product or, at our option, refund of the purchase

price. OUR ACCEPTANCE OF ANY ORDERS FOR THE PRODUCT IS EXPRESSLY CONDITIONAL UPON PURCHASER’S ASSENT TO THE TERMS ON THE

APPLICABLE INVOICE.

ADEQUATE TESTS: The information contained herein we believe is correct to the best of our knowledge and tests. The recommendations and suggestions herein are made

without guarantee or representation as to results. We recommend that adequate tests be performed by you to determine if this product meets all of your requirements. The

warranted shelf life of our products is twelve months from date of shipment to the original purchaser or as otherwise provided on the certificate of analysis.

For professional use only. Keep out of reach of children.

Consult Safety Data Sheet and container label for further information.

Foster PDS 60-25, 60-26 R1119

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Free ConvectionDocument4 pagesFree ConvectionLuthfy AditiarNo ratings yet

- Aircraft Flight Control SystemDocument25 pagesAircraft Flight Control Systemthilina jayasooriyaNo ratings yet

- Grua Grove 530e 2 Manual de PartesDocument713 pagesGrua Grove 530e 2 Manual de PartesGustavo100% (7)

- A Detailed Lesson PlanDocument5 pagesA Detailed Lesson PlanIsaac-elmar Agtarap74% (23)

- Xylan 80-510-G3196 Pfa BeDocument2 pagesXylan 80-510-G3196 Pfa BeSYED MAZHARNo ratings yet

- The Ethics of Peacebuilding PDFDocument201 pagesThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- High Speed Power TransferDocument33 pagesHigh Speed Power TransferJAYKUMAR SINGHNo ratings yet

- Pds Foster 65-05 F.R.C.I. MasticDocument2 pagesPds Foster 65-05 F.R.C.I. MasticHanafi MansorNo ratings yet

- Foster Weatherite Mastic: Technical Data SheetDocument2 pagesFoster Weatherite Mastic: Technical Data SheetAhmed SaadNo ratings yet

- Properties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetDocument2 pagesProperties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetOscar ZelayaNo ratings yet

- Foster 32 17Document2 pagesFoster 32 17mohabadel87No ratings yet

- Properties Foster Sealfas Coating AF (Fungus Resistant) : Product Data SheetDocument2 pagesProperties Foster Sealfas Coating AF (Fungus Resistant) : Product Data SheetGiftson ImmanuelNo ratings yet

- Asphalt Technical Data SheetDocument1 pageAsphalt Technical Data SheetEmran MiaNo ratings yet

- Foster 32-19™: Properties Foster Duct-Fas™ Duct SealantDocument2 pagesFoster 32-19™: Properties Foster Duct-Fas™ Duct SealantOmar DiampuanNo ratings yet

- 1050 Plastigard 100 Percent Acrylic High Build CoatingDocument1 page1050 Plastigard 100 Percent Acrylic High Build Coatingjustin trochezNo ratings yet

- Foster BUTYLAR NXT PDS R1019Document2 pagesFoster BUTYLAR NXT PDS R1019Pawan ChaturvediNo ratings yet

- Electrical Works For Restarant Al Maha Camp - Foster Empire EstateDocument104 pagesElectrical Works For Restarant Al Maha Camp - Foster Empire Estateafzal empirestateNo ratings yet

- Foster PDS 30 36 R0221Document2 pagesFoster PDS 30 36 R0221Abdel Mongy AhmedNo ratings yet

- Foster 32-17Document2 pagesFoster 32-17Mostafa AymanNo ratings yet

- Foster PDS 95 50 R0816Document2 pagesFoster PDS 95 50 R0816Ramy Abd Elkhalek Shahin100% (1)

- tHORO STRUCTURITE PRIMER - v3Document2 pagestHORO STRUCTURITE PRIMER - v3Ankita Baban GavadeNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- Product Overview: Polysulfide Rubber CompoundDocument2 pagesProduct Overview: Polysulfide Rubber CompoundPedro Jose Sanchez BuesaquilloNo ratings yet

- Foster: Properties Foster S.M. AdhesiveDocument2 pagesFoster: Properties Foster S.M. AdhesiveDpnsHomeNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Masterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneDocument3 pagesMasterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembranehemantrulzNo ratings yet

- Properties Foster S.M. Adhesive: Product Data SheetDocument2 pagesProperties Foster S.M. Adhesive: Product Data SheetAamer Abdul MajeedNo ratings yet

- Foster: Properties Foster Sealfas CoatingDocument2 pagesFoster: Properties Foster Sealfas Coatingquang trinhNo ratings yet

- PDS Foster 30 45 Foamseal SealantDocument4 pagesPDS Foster 30 45 Foamseal SealantKumarNo ratings yet

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Foster PDS 32 17 R0519 1Document2 pagesFoster PDS 32 17 R0519 1Nashal KkNo ratings yet

- PDS FOSTER - 30-45N - Foamseal Sealant PDFDocument2 pagesPDS FOSTER - 30-45N - Foamseal Sealant PDFHanafi MansorNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- X-Tech UraFloor CSDocument2 pagesX-Tech UraFloor CSLONG LASTNo ratings yet

- Aster ARD: Product DataDocument2 pagesAster ARD: Product DataEka pawitra sutaNo ratings yet

- Basf Masterseal 540 TdsDocument2 pagesBasf Masterseal 540 TdsPremasiri KarunarathnaNo ratings yet

- Chemstat ESDDocument3 pagesChemstat ESDpadmanabh alatNo ratings yet

- Foster PDS 95 44 R0722Document2 pagesFoster PDS 95 44 R0722Osama KheadryNo ratings yet

- Roofseal TDS 166 1 PDFDocument3 pagesRoofseal TDS 166 1 PDFvikash singh tomarNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- Masterseal 540Document2 pagesMasterseal 540Nguyen Chi Thanh100% (1)

- 01 Mascoat Industrial Application InstructionsDocument7 pages01 Mascoat Industrial Application Instructionsböhmit100% (1)

- TDS-Foster 95-44 EN PDFDocument2 pagesTDS-Foster 95-44 EN PDFEshaghNo ratings yet

- 05 - TDS - Mastertop 300Document4 pages05 - TDS - Mastertop 300Vimal KakNo ratings yet

- Rex ThaneDocument4 pagesRex Thanesas999333No ratings yet

- Foster PDS 32 19 R0415Document2 pagesFoster PDS 32 19 R0415Simoncarter LawNo ratings yet

- PCI Lastogum v3Document2 pagesPCI Lastogum v3Jaga NathNo ratings yet

- Mastertop 564Document2 pagesMastertop 564Doby Yuniardi100% (1)

- Elastiseal Sealant 95-88: PropertiesDocument2 pagesElastiseal Sealant 95-88: PropertiesMyluv MyluvNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- BASF Mastertop 538 DSDocument3 pagesBASF Mastertop 538 DSSaud PathiranaNo ratings yet

- Master EmacoDocument3 pagesMaster EmacoSmookers HeavenNo ratings yet

- Asian Paints SmartCare Flexi Seal PUDocument4 pagesAsian Paints SmartCare Flexi Seal PUNational WaterproofingNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- C-Series Application Guide - Piston Coat C-186Document1 pageC-Series Application Guide - Piston Coat C-186claudioNo ratings yet

- High Temperature CoatingsDocument12 pagesHigh Temperature CoatingsWagiyanto MulyaNo ratings yet

- MasterProtect 300FC - 1Document2 pagesMasterProtect 300FC - 1Mohand EliassNo ratings yet

- DR - Fixit Flexi PU 270IDocument4 pagesDR - Fixit Flexi PU 270IKiran KumarNo ratings yet

- MasterProtect 300 Asean v3-0415Document2 pagesMasterProtect 300 Asean v3-0415Muhammad Fadhil ImansyahNo ratings yet

- Product Data Sheet: WF AC-603Document1 pageProduct Data Sheet: WF AC-603Kamalakar SastryNo ratings yet

- Mbrace Laminate LM, MM, HM TDSDocument3 pagesMbrace Laminate LM, MM, HM TDSDoug WeirNo ratings yet

- Masterbrace® Lam (Formerly Known As Mbrace® Laminate)Document2 pagesMasterbrace® Lam (Formerly Known As Mbrace® Laminate)KY PengNo ratings yet

- Samshield XL1500 - 2100Document3 pagesSamshield XL1500 - 2100pandey71087No ratings yet

- Properties Foster Fire Resistive Anti-Abrasion Coating Water BasedDocument2 pagesProperties Foster Fire Resistive Anti-Abrasion Coating Water BasedMinh BảoNo ratings yet

- SDS Foster 30 16Document6 pagesSDS Foster 30 16Minh BảoNo ratings yet

- QCVN17-2013 An Toan Cong Viec Han Hoi - RDocument29 pagesQCVN17-2013 An Toan Cong Viec Han Hoi - RMinh BảoNo ratings yet

- Properties Foster Fire Resistive Anti-Abrasion Coating Water BasedDocument2 pagesProperties Foster Fire Resistive Anti-Abrasion Coating Water BasedMinh BảoNo ratings yet

- SDS Foster 30 16Document6 pagesSDS Foster 30 16Minh BảoNo ratings yet

- Foster SDS 60 25 R0220Document7 pagesFoster SDS 60 25 R0220Minh BảoNo ratings yet

- Properties Foster Fire Resistive Anti-Abrasion Coating Water BasedDocument2 pagesProperties Foster Fire Resistive Anti-Abrasion Coating Water BasedMinh BảoNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- (En) SHC107-84 PART B (Ver.7.3)Document8 pages(En) SHC107-84 PART B (Ver.7.3)Minh BảoNo ratings yet

- Polyurethane Storage&Caution PDFDocument1 pagePolyurethane Storage&Caution PDFMinh BảoNo ratings yet

- BM KpiDocument1 pageBM KpiMinh BảoNo ratings yet

- Lifting OperationsDocument7 pagesLifting OperationsMinh BảoNo ratings yet

- Sousa2019 PDFDocument38 pagesSousa2019 PDFWilly PurbaNo ratings yet

- Handout Waste Catch BasinDocument2 pagesHandout Waste Catch BasinJonniel De GuzmanNo ratings yet

- Support Vector Machine Master ThesisDocument7 pagesSupport Vector Machine Master Thesistammymajorsclarksville100% (2)

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 pagesEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiNo ratings yet

- Dummy 13 Printable Jointed Figure Beta FilesDocument9 pagesDummy 13 Printable Jointed Figure Beta FilesArturo GuzmanNo ratings yet

- Chapter 4 Signal Flow GraphDocument34 pagesChapter 4 Signal Flow GraphAbhishek PattanaikNo ratings yet

- MCC333E - Film Review - Myat Thu - 32813747Document8 pagesMCC333E - Film Review - Myat Thu - 32813747Myat ThuNo ratings yet

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDocument5 pagesSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNo ratings yet

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocument1 pageConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelNo ratings yet

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Document4 pagesKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975No ratings yet

- Wiska Varitain - 0912Document18 pagesWiska Varitain - 0912Anonymous hHWOMl4FvNo ratings yet

- Kaun Banega Crorepati Computer C++ ProjectDocument20 pagesKaun Banega Crorepati Computer C++ ProjectDhanya SudheerNo ratings yet

- Brochure - OasisDocument24 pagesBrochure - OasisVivek RNo ratings yet

- DOT RequirementsDocument372 pagesDOT RequirementsMuhammadShabbirNo ratings yet

- Eng03 Module Co4Document14 pagesEng03 Module Co4Karl Gabriel ValdezNo ratings yet

- Banin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahDocument4 pagesBanin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahKajen PatiNo ratings yet

- All Nobel Prizes in LiteratureDocument16 pagesAll Nobel Prizes in LiteratureMohsin IftikharNo ratings yet

- Nationalism, Feminism, and Modernity in PalestineDocument26 pagesNationalism, Feminism, and Modernity in PalestinebobandjoerockNo ratings yet

- MC4 CoCU 6 - Welding Records and Report DocumentationDocument8 pagesMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Penelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Document25 pagesPenelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Asti SherlyanaNo ratings yet

- ProjectDocument32 pagesProjectroshan jaiswalNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet

- Cella Di Carico Sartorius MP77 eDocument3 pagesCella Di Carico Sartorius MP77 eNCNo ratings yet

- The Handmaid's TaleDocument40 pagesThe Handmaid's Taleleher shahNo ratings yet