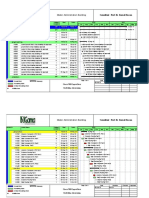

PROJECT QUALITY PLAN (PQP) SUBMITTAL CHECKLIST

Contract No. : PQP Ref. :

Contractor : PQP Ver. :

Consultant : PQP Date :

Contract Title : Reviewed By :

Project Manager Review Date :

Review (By

Available Adequate

Item & No. Description / Requirement Remarks Consultant/Cl

Y/N Y/N

ient)

A1 PQP Index

A2 PQP Revision status

A3 PQP Approval Signatures

A4 PQP Distribution List. Distribution shall be as per the

CONTRACT.

A

PQP

A5 PQP scope

A6 Details of CONTRACTOR’s procedure for preparing,

reviewing, approving, revising and re-issuing the PQP during

the CONTRACT

B1 Details on how the CONTRACTOR’s Corporate Quality

Management System shall be applied and implemented in the

B

QMS

project, as applicable.

C1 Detailed Contract Scope of Work.

Scope of

C

Works

C2 Contract Program of Works (Schedule).

D1 Identification of all main work activities and sub-activities to

be controlled by the PQP.

Main activities &

sub-contracted

D2 Identification of activities that will be carried out by sub-

activities

D

contractors. State details of sub-contractors Quality

Management System and how it will be monitored and

controlled by the main CONTRACTOR.

E1 Organizational Chart specific to the CONTRACT identifying

functions and job title of all management and staff down to

Organizational structure

foreman level.

E E2 Schedule of responsibilities for all key functions utilized in the

project as shown in the organization chart including

responsibilities of the Management Representative and

QA/QC personnel.

F1 List of QMS Procedures & Manuals

QMS Documents applicable to this contract

F2 List of Drawings and Shop Drawings

F3 List of Method Statements (MS)

F4 List of Work Instructions (WI)

F5 List of Inspection & Test Plans (ITP) or Quality Control

F Plans (QCP)

F6 List of Forms and Formats with unique numbers

F7 Sub-Contractor Procedures, MS, WI, ITP, QCP, Drawings,

Forms, etc. In case no sub-contractors are required on this

contract, this should be indicated in the PQP (see D2 above).

G1 Internal Audit Procedure

Audit Plans (Int. &

G2 Internal / external Audit Plans

G

Ext.)

G3 External Audit Schedule of Sub-contractors

1 of 3

� PROJECT QUALITY PLAN (PQP) SUBMITTAL CHECKLIST

Contract No. : PQP Ref. :

Contractor : PQP Ver. :

Consultant : PQP Date :

Contract Title : Reviewed By :

Project Manager Review Date :

Review (By

Available Adequate

Item & No. Description / Requirement Remarks Consultant/Cl

Y/N Y/N

ient)

Where the services of a Third Party Certification is required

by the CONTRACT, the Project Quality Plan shall include :

Inspection (TPI)

Third Party

H H1 Details of the services that will provided by TPI.

H2 List and details of the TPI Certification Authority.

I1 A project specific Document Control Procedure shall be

prepared to control the issue, distribution, change, review,

location, and/or withdrawal of all documentation, drawings,

Document Control

procedures, submittals, correspondences, etc., that are related

I to the project.

I2 Document Control Procedure detailing the preparation of

Test Pack and As-built Documentation Dossier towards

handover.

J1 A documented procedure for Control of Non-Conforming

Products establishing that product/s (goods or services) that

Non-Conforming

does not conform to requirements stipulated in the

Products

J CONTRACT is identified and controlled to prevent its

unintended use or delivery.

K1 A documented procedure for Corrective Actions shall be

established by the CONTRACTOR.

Corrective

Actions

L1 A documented procedure for Preventive Actions

establishing system to identify and plan actions to eliminate

Preventive

Actions

L the cause of potential nonconformities and to prevent their

occurrence.

M1 A documented procedure for Record Control shall be

established by the CONTRACTOR and his sub-contractors to

Record Control

define the controls required for the identification, storage,

M protection, retrieval, retention time, and disposition of records.

N1 A documented procedure or system shall be identified in the

PQP with regards to Inspection, Measuring and Test

Inspection &

Measuring

N Equipment

O1 Material, sub-contractors and suppliers shall be selected from

ADDC's approved vendors list (as per ADDC contract

Procurement Control

documents), and where not detailed, from the contractor's own

approved vendors list.

O

O2 Procurement schedule for all important contract materials

showing all critical dates such as submittal, approval, order

and site expected dates. Dates will be based on program of

works.

2 of 3

� PROJECT QUALITY PLAN (PQP) SUBMITTAL CHECKLIST

Contract No. : PQP Ref. :

Contractor : PQP Ver. :

Consultant : PQP Date :

Contract Title : Reviewed By :

Project Manager Review Date :

Review (By

Available Adequate

Item & No. Description / Requirement Remarks Consultant/Cl

Y/N Y/N

ient)

P1 Materials submittal schedule

P2 Drawings submittal schedule

Submittals &

Approvals

P P3 Procurement schedule

P4 Approved Subcontractors schedule (as applicable)

Q1 Procedure or system for progress monitoring and reporting

including but not limited to MS, WI, procedures, drawings,

Progress &

Reporting

Q material procurement, construction, commissioning, etc.

R1 A procedure, system or statement is required so that Client

shall have the right to inspect at all times all tools,

instruments, materials, staging, equipment, templates, work

technique, etc., used or to be used in the performance of the

R

Client

WORKS. This shall include pre-inspection meetings.

R2 A statement from the contractor ensuring his adherence to

Client projects, quality and HSE procedures.

S1 Quality Improvement program or Lessons Learned system /

procedure to improve existing practices must be implemented

Lessons Learned

as an integrated part of the contract. Format for Lessons

S Learned and relevant action plan to be provided in the PQP

and results be reported as part of the close-out report.

T1 HSE Plan prepared and submitted by Contractor.

T

HSE

Quality policy and QMS certificate (copies) for :

ISO 9001:2000 Policy &

U1 Contractor

Certificate

U

U2 Sub-contractor (if applicable)

Shaded items denote deficiencies and improvements that are required to the submitted PQP to render it acceptable and in line with Client quality requirements.

Acceptable Improve Not Acceptable

PQP Status :

3 of 3