Professional Documents

Culture Documents

Gasification of Biomass and Waste

Uploaded by

Suprio KamalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gasification of Biomass and Waste

Uploaded by

Suprio KamalCopyright:

Available Formats

Biomass gasification research in the Combustion and Catalysis Laboratory (CCL) is under the direction of

Marco J. Castaldi. Contact: mcastaldi@che.ccny.cuny.edu

Gasification of Biomass and Waste

Gasification presents a promising technology for converting solids, such as biomass or waste, into

useful fuels. Gasification involves heating the solid in the presence of another gas such as air, N2,

CO2, or H2O. Unlike combustion, gasification involves only partial oxidation of the fuel, since

reactants are introduced in sub-stoichiometric amounts. The primary product is synthesis gas,

which is composed of CO and H2 (and by-products such as CO2 and small hydrocarbons). Synthesis

gas can be used to make other fuels such as gasoline, methane, or diesel fuel via Fischer-Tropsch

synthesis. One of the current issues with biomass gasification is that two primary by-products are

produced: ash and tar. Ash is a solid residue composed of minerals and metals from the raw

material that did not enter the gas phase. Tar is a mixture of heavy hydrocarbons that must be

removed as they can cause problems for downstream equipment. Ash is a high surface area

material that contains both carbon and minerals and metals which are often used as catalysts.

Therefore, ash has the potential to be a catalyst for decomposition of the tars which are produced

from biomass gasification. It has been shown that the properties of ash may vary based on the

gasification process by which it is created (temperature, reactive gas, heating rate). This work

investigates the potential to use ash to catalyze decomposition of tar.

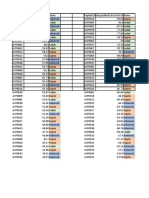

Results to date

Ash was generated in a fluidized bed reactor

under different conditions and its properties

were analyzed. It is important for catalysts to

have high surface area. The surface area of the

ash was found to be highly dependent on the

gasification atmosphere, as well as the time and

temperature of gasification, as shown in Figure

1. This shows that increasing gasification

temperature or gasification time leads to higher

surface area. The physical properties of the ash

were also analyzed using an Environmental

Scanning Electron Microscope (ESEM).

Gasification was performed in the microscope by heating the sample to 1000 oC under different

gasification atmospheres (CO2, H2O, and air) and the sample was observed throughout gasification.

Images of the

samples at 1000oC

are shown in Figure

2. Sintering is

observed for

gasification under

steam (Figure 2A)

and air (Figure 2B)

but not with CO2 (Figure 2C). This is important if the ash is to be used as a catalyst since sintering

should be avoided in order to maintain a high surface area catalyst. The catalytic activity of the ash

was tested in a thermo-gravimetric analyzer (TGA). It was of interest to see if the ash could catalyze

decomposition of different hydrocarbons, since ultimately it will be used to decompose aromatics

which are the primary component of tar. Methane and propane were introduced into the TGA and

the temperature was increased and mass gain was measured. Mass gain is representative of

reaction taking place where the hydrocarbon decomposes into solid carbon on the catalyst surface

and H2 or other light gases. Figure 3 shows the mass gain of an ash sample when heated under N2,

CH4, and C3H8. With nitrogen,

there is a slight mass loss,

reflecting the decomposition of

the ash as it is heated. Under

methane mass gain at high

temperatures indicates carbon

deposition on the surface.

Propane, being a more reactive

hydrocarbon than methane,

shows higher mass gain at

higher temperatures. This

indicates that the ash has the

ability to catalyze

decomposition of

hydrocarbons, and may be a

good candidate for decomposition of tars from gasification of biomass.

Current and future work

Currently, we are working on developing an understanding of how the properties of the ash impact

its catalytic activities. We are also doing more detailed characterization to better understand how

the gasification process impacts the properties of the ash. In future work, we will test the catalytic

activity of the ash with tar surrogates and attempt to relate the properties of the ash to its catalytic

activity in order to design a process with highly active ash.

You might also like

- Ignition and Combustion Reaction: Hisao Makino, Hirofumi Tsuji, and Ryoichi KuroseDocument5 pagesIgnition and Combustion Reaction: Hisao Makino, Hirofumi Tsuji, and Ryoichi Kurosehuyphuca2No ratings yet

- Unique Gasifier For Hydrogen Prod 2Document15 pagesUnique Gasifier For Hydrogen Prod 2Arumugam RamalingamNo ratings yet

- Coal Gasification Using AspenDocument6 pagesCoal Gasification Using AspenTaniadi Suria100% (1)

- Bi-Reforming of Methane From Any Source With Steam and Carbon Dioxide Exclusively To Metgas (CO-2H2) For Methanol and Hydrocarbon SynthesisDocument3 pagesBi-Reforming of Methane From Any Source With Steam and Carbon Dioxide Exclusively To Metgas (CO-2H2) For Methanol and Hydrocarbon SynthesisDang Putthea100% (1)

- Antal 2003Document22 pagesAntal 2003halimitbNo ratings yet

- Episode 3: Production of Synthesis Gas by Steam Methane ReformingDocument31 pagesEpisode 3: Production of Synthesis Gas by Steam Methane ReformingSAJJAD KHUDHUR ABBASNo ratings yet

- 208 1132 1 PB PDFDocument9 pages208 1132 1 PB PDFOnCo TallaNo ratings yet

- Mitigation of CO2 by Chemical ConversionDocument21 pagesMitigation of CO2 by Chemical Conversiona_abbaspourNo ratings yet

- CO2 Conversion To CO by Auto-Thermal Catalyst-Assisted Chemical LoopingDocument9 pagesCO2 Conversion To CO by Auto-Thermal Catalyst-Assisted Chemical LoopingNguyễn TuânNo ratings yet

- Catalysts 10 01240 v2Document24 pagesCatalysts 10 01240 v2Khalil SukurNo ratings yet

- Biological Conversion of Synthesis Gas Into Fuels: KlassonDocument8 pagesBiological Conversion of Synthesis Gas Into Fuels: KlassonYessid Vitola MebarakNo ratings yet

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDocument9 pagesSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatNo ratings yet

- Chemical Engineering JournalDocument10 pagesChemical Engineering JournalSebastian LopezNo ratings yet

- Emission Reduction Measures for Pollutants from Biomass CombustionDocument5 pagesEmission Reduction Measures for Pollutants from Biomass CombustionmanuelNo ratings yet

- Decarbonize The Natural GasDocument4 pagesDecarbonize The Natural GasGabriel ColmontNo ratings yet

- Answer 5b NGPDocument10 pagesAnswer 5b NGPSARTHAK BAPATNo ratings yet

- ZEOLIT 13X A Gholipour2016Document27 pagesZEOLIT 13X A Gholipour2016Malasari NasutionNo ratings yet

- Fuel Processing Technology: Hau-Huu Bui, Liang Wang, Khanh-Quang Tran, Øyvind SkreibergDocument8 pagesFuel Processing Technology: Hau-Huu Bui, Liang Wang, Khanh-Quang Tran, Øyvind SkreibergPaulo FragaNo ratings yet

- On How Mild Oxidation Affects The Structure of Carbons Comparative Analysis by DifferentDocument27 pagesOn How Mild Oxidation Affects The Structure of Carbons Comparative Analysis by DifferentGeorge LazarNo ratings yet

- IBA Carbonation 2006 B128 73 RefDocument7 pagesIBA Carbonation 2006 B128 73 RefMike LiuNo ratings yet

- Thermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsDocument12 pagesThermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsRajendraNo ratings yet

- Synthesis GasDocument8 pagesSynthesis GasTotok IswantoNo ratings yet

- Incineration - Gasification - PyrolysisDocument65 pagesIncineration - Gasification - Pyrolysistatchanok1525No ratings yet

- Journal ColorDocument10 pagesJournal Colorghasem DNo ratings yet

- A Review On Direct Methane Conversion To Methanol by PlasmaDocument10 pagesA Review On Direct Methane Conversion To Methanol by Plasmaapi-3728640100% (1)

- Coal Gasification NotesDocument5 pagesCoal Gasification NotesshyamNo ratings yet

- The Oxidation of Soot A Review of Experiments, Mechanisms and Modesl - Stanmore-Etal - 2001Document22 pagesThe Oxidation of Soot A Review of Experiments, Mechanisms and Modesl - Stanmore-Etal - 2001Hemanth KappannaNo ratings yet

- The Kinetics of Gasification and Reactor TheoryDocument12 pagesThe Kinetics of Gasification and Reactor TheoryJose Luiz QueirozNo ratings yet

- 2F-1 Kinetic Modelling of Biomass Gasification and CombustionDocument20 pages2F-1 Kinetic Modelling of Biomass Gasification and Combustionizzet1969No ratings yet

- Coal Direct Chemical Looping Combustion: Experimental Investigation and Assesment of Operating ConditionsDocument11 pagesCoal Direct Chemical Looping Combustion: Experimental Investigation and Assesment of Operating ConditionsAzharuddin Ehtesham FarooquiNo ratings yet

- Carbon capture processesDocument8 pagesCarbon capture processesﺄڪۧہۙرم ﺄلہعہلہوي، 'ۦNo ratings yet

- Blend de Carvão Rico em VitrinitaDocument9 pagesBlend de Carvão Rico em VitrinitaMatheus AugustoNo ratings yet

- Activated Carbon Production From Low Ash Subbituminous Coal With CO, ActivationDocument8 pagesActivated Carbon Production From Low Ash Subbituminous Coal With CO, ActivationJeferson Meira Dos SantosNo ratings yet

- J Fuel 2018 09 075Document9 pagesJ Fuel 2018 09 075Roni GustiwaNo ratings yet

- Laboratory Scale Pyrolysis of Organic FR PDFDocument5 pagesLaboratory Scale Pyrolysis of Organic FR PDFLotfi BrahimNo ratings yet

- Note 1475054739Document10 pagesNote 1475054739Thiyaga RajanNo ratings yet

- Carbon Capture Powered by Solar EnergyDocument6 pagesCarbon Capture Powered by Solar EnergyDiana Carolina Hernandez PuentesNo ratings yet

- Co-Al2O3 and Co-Re-Al2O3Document7 pagesCo-Al2O3 and Co-Re-Al2O3Daniel Z JucaNo ratings yet

- Gasification of Coal: A Guide to the Chemical Reactions and MechanismsDocument67 pagesGasification of Coal: A Guide to the Chemical Reactions and MechanismsAris Raymond GirsangNo ratings yet

- Gasification of CoalDocument28 pagesGasification of CoalAris Raymond GirsangNo ratings yet

- Fauth 2005Document19 pagesFauth 2005Jeff DiffNo ratings yet

- J Fuproc 2019 106121Document7 pagesJ Fuproc 2019 106121Roni GustiwaNo ratings yet

- Energy Conversion and Management: Xiaoyuan Zheng, Chong Chen, Zhi Ying, Bo WangDocument7 pagesEnergy Conversion and Management: Xiaoyuan Zheng, Chong Chen, Zhi Ying, Bo WangJhonatan Romero HuarcayaNo ratings yet

- CO2 Resources ConvertionDocument10 pagesCO2 Resources ConvertionIvan SetiawanNo ratings yet

- Activated Carbon From Cherry StonesDocument6 pagesActivated Carbon From Cherry StonesQussay AhmedNo ratings yet

- Thermodynamic EquilibriumDocument6 pagesThermodynamic Equilibriumprav.saradaNo ratings yet

- Combustion in Porous Media : BY Prof. Dr. Mohammed Hamdan & Eng. Nabeel Abo ShabanDocument22 pagesCombustion in Porous Media : BY Prof. Dr. Mohammed Hamdan & Eng. Nabeel Abo ShabanDamy ManesiNo ratings yet

- A Comparative Study of Ni Catalysts Supported On Al2O - 2022 - International JouDocument17 pagesA Comparative Study of Ni Catalysts Supported On Al2O - 2022 - International JouSaepulloh Rahmat SolehudinNo ratings yet

- Use of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A ReviewDocument7 pagesUse of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A Reviewkashipuranataraj69No ratings yet

- High-Pressure Methane and Carbon Dioxide Adsorption on CoalsDocument24 pagesHigh-Pressure Methane and Carbon Dioxide Adsorption on CoalsSonali SwagatikaNo ratings yet

- An Understanding of The Behaviour of Anumber of Element Phases Impacting On A Commercial-Scale Sasol-Lurgi FBDB GasifierDocument26 pagesAn Understanding of The Behaviour of Anumber of Element Phases Impacting On A Commercial-Scale Sasol-Lurgi FBDB GasifierSergio Cuitiño SaldiviaNo ratings yet

- BF ThermoDocument5 pagesBF ThermoLucky AliNo ratings yet

- 15 Sorption and Textural Properties of Activated Carbon DerivedDocument12 pages15 Sorption and Textural Properties of Activated Carbon DerivedArunachaleshwarNo ratings yet

- Van Der Lans - Parameters On Nitrogen OxideDocument29 pagesVan Der Lans - Parameters On Nitrogen OxideNelson RodriguesNo ratings yet

- 141 Mohebbi 2015Document14 pages141 Mohebbi 2015naseemNo ratings yet

- Research Article: A Novel Study of Methane-Rich Gas Reforming To Syngas and Its Kinetics Over Semicoke CatalystDocument7 pagesResearch Article: A Novel Study of Methane-Rich Gas Reforming To Syngas and Its Kinetics Over Semicoke CatalystMia AdhaNo ratings yet

- 2013 Roussiere CatRefMethaneinPresenceofCO2andH2OatHighPress DR Rernat KIT FinalDocument238 pages2013 Roussiere CatRefMethaneinPresenceofCO2andH2OatHighPress DR Rernat KIT FinalVishal RasaniyaNo ratings yet

- Experiment 6Document15 pagesExperiment 6JAN JERICHO MENTOYNo ratings yet

- Molecular Thermodynamics Week 2 Lecture Assessment Questions: Ideal Gases Equations of State PV Diagrams Molecular InteractionsDocument4 pagesMolecular Thermodynamics Week 2 Lecture Assessment Questions: Ideal Gases Equations of State PV Diagrams Molecular Interactionskalpesh_dNo ratings yet

- Reforming UnitDocument2 pagesReforming UnitSuprio KamalNo ratings yet

- Best Dock ResultDocument1 pageBest Dock ResultSuprio KamalNo ratings yet

- Peptide ID Weighted Score Binding Residue Bond Length M - Protein PeptideDocument20 pagesPeptide ID Weighted Score Binding Residue Bond Length M - Protein PeptideSuprio KamalNo ratings yet

- ReagentsDocument2 pagesReagentsSuprio KamalNo ratings yet

- Statistical Molecular Thermodynamics: Equations of State and Partition FunctionsDocument4 pagesStatistical Molecular Thermodynamics: Equations of State and Partition FunctionsSuprio KamalNo ratings yet

- Computer Aided Drug Design Program | Monsoon 2019Document2 pagesComputer Aided Drug Design Program | Monsoon 2019Suprio KamalNo ratings yet

- Homework Week 1: Electronic Excited StateDocument4 pagesHomework Week 1: Electronic Excited StateSuprio KamalNo ratings yet

- Contribution Form Upon Completion and Report Submission OnDocument2 pagesContribution Form Upon Completion and Report Submission OnSuprio KamalNo ratings yet

- Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics For Roofing and WaterproofingDocument6 pagesSampling and Testing Bitumen-Saturated Felts and Woven Fabrics For Roofing and WaterproofingSuprio KamalNo ratings yet

- Week 2 HomeworkDocument5 pagesWeek 2 HomeworkDaniel Alejandro Rojas ToroNo ratings yet

- Chap-10 Materials and Fabrication SelectionDocument51 pagesChap-10 Materials and Fabrication SelectionSuprio KamalNo ratings yet

- Shawon 2016Document13 pagesShawon 2016Suprio KamalNo ratings yet

- .I ) ''O .Q .. 1. (Oj : Date: 16/07/2016Document42 pages.I ) ''O .Q .. 1. (Oj : Date: 16/07/2016Suprio KamalNo ratings yet

- Vapor Cloud Explosions: What Can You Do?Document1 pageVapor Cloud Explosions: What Can You Do?Suprio KamalNo ratings yet

- Chapter 7Document27 pagesChapter 7Muhaiminul IslamNo ratings yet

- 2015 2016 - L 4 - T 1 - CheDocument52 pages2015 2016 - L 4 - T 1 - CheBiplab SarkerNo ratings yet

- Chapter 7Document27 pagesChapter 7Muhaiminul IslamNo ratings yet

- Process Dynamics and Control 3rd Ed.: Chapter 4 Class LectureDocument25 pagesProcess Dynamics and Control 3rd Ed.: Chapter 4 Class LectureMuhaiminul IslamNo ratings yet

- Mws Gen Int TXT Simpson13 PDFDocument12 pagesMws Gen Int TXT Simpson13 PDFSelviana ArifikaNo ratings yet

- Process Dynamics and Control 3rd Ed.: Chapter 4 Class LectureDocument25 pagesProcess Dynamics and Control 3rd Ed.: Chapter 4 Class LectureMuhaiminul IslamNo ratings yet

- Chapter 7Document27 pagesChapter 7Muhaiminul IslamNo ratings yet

- Process Dynamics and Control: Chapter 5 Class LectureDocument24 pagesProcess Dynamics and Control: Chapter 5 Class LectureMuhaiminul Islam0% (1)

- Equilibrium Staged Separations WankatDocument3 pagesEquilibrium Staged Separations WankatSuprio Kamal100% (1)

- Process Dynamics and Control 3rd Ed.: Chapter 4 Class LectureDocument25 pagesProcess Dynamics and Control 3rd Ed.: Chapter 4 Class LectureMuhaiminul IslamNo ratings yet

- Chapter 7Document27 pagesChapter 7Muhaiminul IslamNo ratings yet

- Theoretical Models of Chemical Processes: Dr. M. A. A. Shoukat Choudhury 1Document36 pagesTheoretical Models of Chemical Processes: Dr. M. A. A. Shoukat Choudhury 1Maruf KhanNo ratings yet

- J Xphs 2015 12 001Document9 pagesJ Xphs 2015 12 001Suprio KamalNo ratings yet

- User Manual of Gaussian 09Document18 pagesUser Manual of Gaussian 09Suprio Kamal100% (1)

- Chemistry Grade 10 Mixtures and SeparationDocument45 pagesChemistry Grade 10 Mixtures and SeparationTrudy- Ann CaineNo ratings yet

- Organic Syntheses Collective Volume 2Document813 pagesOrganic Syntheses Collective Volume 2caltexas88% (8)

- Chemy 101 1st 19-20 Test 1 Key CDocument8 pagesChemy 101 1st 19-20 Test 1 Key CmNo ratings yet

- Introduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsDocument81 pagesIntroduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsMichael KaoNo ratings yet

- Synthesis Paper Title: BiofuelsDocument24 pagesSynthesis Paper Title: Biofuelspati_deeps234No ratings yet

- Articulo 1 Inmovilización Alginato PDFDocument6 pagesArticulo 1 Inmovilización Alginato PDFCarolina MorenoNo ratings yet

- KVS Science MCQ Book for Classes 6-8Document148 pagesKVS Science MCQ Book for Classes 6-8Vennila SenthilNo ratings yet

- Grados de HPCDocument3 pagesGrados de HPCpops3No ratings yet

- Taisox 8001Document2 pagesTaisox 8001Le Minh TuanNo ratings yet

- - (Appendix B Lennard–Jones Constants) PDFDocument2 pages- (Appendix B Lennard–Jones Constants) PDFYaiselle FelicianoNo ratings yet

- Penn Students Design Propane to Acrylic Acid ProcessDocument231 pagesPenn Students Design Propane to Acrylic Acid ProcessCluisantony Jayco DizeNo ratings yet

- Understanding Carboxylic Acid DerivativesDocument36 pagesUnderstanding Carboxylic Acid DerivativesArricson HunterNo ratings yet

- Course: Chemical Process Technology Lecture - 7 Topic: Pesticides Industries Course Code: SECH3071Document10 pagesCourse: Chemical Process Technology Lecture - 7 Topic: Pesticides Industries Course Code: SECH3071rutvikNo ratings yet

- Combined PH WorksheetsDocument9 pagesCombined PH WorksheetsNeen NaazNo ratings yet

- Chapter 8 Chemistry Class 11Document27 pagesChapter 8 Chemistry Class 11Ravinder singhNo ratings yet

- D240-Standard Test Method For Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimeterDocument9 pagesD240-Standard Test Method For Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimeterrezaNo ratings yet

- Sugar IndustryDocument50 pagesSugar Industryzohaib ul hassanNo ratings yet

- Purchase and Sales Report 2006-2007Document54 pagesPurchase and Sales Report 2006-2007subhashkabdoiNo ratings yet

- Grevillea RobustaDocument6 pagesGrevillea RobustaJeyabalaganesh GNo ratings yet

- United States Patent: (10) Patent N0.: Anciaux Et Al. (45) Date of PatentDocument8 pagesUnited States Patent: (10) Patent N0.: Anciaux Et Al. (45) Date of PatentHabib Maulana YasmintoNo ratings yet

- ArrMaz Brochure 2008Document12 pagesArrMaz Brochure 2008sukrukayaNo ratings yet

- Bhopal Gas Tragedy: World's Worst Industrial DisasterDocument6 pagesBhopal Gas Tragedy: World's Worst Industrial DisasterMukul Jangid0% (1)

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityDocument117 pagesGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- Ni-Boron System - 10.1.1.1089.3097Document12 pagesNi-Boron System - 10.1.1.1089.3097tp singhNo ratings yet

- Sal de ZeiseDocument5 pagesSal de ZeiseValeria BelénNo ratings yet

- SS3 Holiday DelightDocument10 pagesSS3 Holiday DelightsunliasNo ratings yet

- Accepted Manuscript: Trends in Analytical ChemistryDocument48 pagesAccepted Manuscript: Trends in Analytical ChemistryMarco RaveloNo ratings yet

- Chapter 2 - Alkanes PDFDocument54 pagesChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANNo ratings yet

- Whalley, J. The Cast Ell Ani Diadem. 2005Document2 pagesWhalley, J. The Cast Ell Ani Diadem. 2005Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocument12 pagesProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1No ratings yet

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (63)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- Gathering Moss: A Natural and Cultural History of MossesFrom EverandGathering Moss: A Natural and Cultural History of MossesRating: 4.5 out of 5 stars4.5/5 (347)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishFrom EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishRating: 4 out of 5 stars4/5 (30)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (222)

- Winged Obsession: The Pursuit of the World's Most Notorious Butterfly SmugglerFrom EverandWinged Obsession: The Pursuit of the World's Most Notorious Butterfly SmugglerRating: 3.5 out of 5 stars3.5/5 (67)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)