Professional Documents

Culture Documents

Centrifugal Compressor Systems

Uploaded by

Daniel Yoworld0 ratings0% found this document useful (0 votes)

39 views10 pagesOriginal Title

ICE2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views10 pagesCentrifugal Compressor Systems

Uploaded by

Daniel YoworldCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 10

Centrifugal Compressor Systems

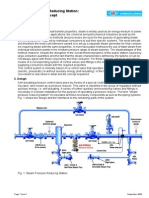

Proper centrifugal compressor symbol should be selected first, as shown in figure-1.

Normally, acentrifugal compressor is accompanied by a Knock Out Drum (KOD) at the

compressor suction and an aftercooler at the compressor discharge, as per a typical compressor

PFD. Symbols for these equipments should also be placed on the P&ID before proceeding ahead.

All the equipment symbols should be selected from the legend sheets of a particular project.

All the nozzles on the compressor, suction drums and aftercooler should then be correctly

represented with size and flanges. This includes inlet and outlet nozzles and equipment drains /

vents as shown in the typical P&ID in figure-1.

Centrifugal compressor suction KOD is intended for removing the entrained liquids

before sending gas to the compressor. Demister, mesh pad etc. are used in the knock out drum to

efficiently remove the liquid droplets.

Compressor aftercoolers are generally air coolers and the related fan, motor etc. should

be clearly indicated on the P&ID. If cooling water is used, proper symbol for a heat exchanger

should be used.

Inlet, outlet lines for each equipment, anti-surge line, drain/vent lines, line to the relief

valve etc. are the next to be drawn up. Line number, material class, size etc. is to be correctly

assigned to each of the lines.

Isolation valves, spectacle blinds, spacers etc. to be used for maintenance should be

drawn up next on various lines between the equipments. Requirement for isolation valves,

spectacle blind, spaces etc. depend on the project standards, which should be followed while

indicating these on the P&ID. Sometimes, to minimize the number of isolation valves between

the equipment, they can be placed only at the suction KOD inlet which is inlet of the centrifugal

compressor system and discharge of the aftercooler which turns out to be the outlet of the

centrifugal compressor system. Spectacle blinds or spacers can be used for isolation between

individual equipments for quick maintenance. This is simply a guideline and project standards

need to be followed when indicating the isolation requirements.

A check valve should be normally provided on the compressor discharge to avoid reverse

flow when the pump is not in operation.

Pressure relief valves can be provided on the compressor discharge line, downstream to

the check valve, to protect the equipments downstream of compressor.

Pressure gauges should be provided on suction and discharge of the compressor. Level

gauges need to be located on the compressor suction knock out drum and temperature gauges on

inlet, outlet lines for the aftercooler.

Pressure transmitters should be provided on compressor suction and discharge line. A

flow transmitter should be provided on compressor suction line. Signals from these transmitters

are sent to an ‘Anti-Surge Controller’. Based on the gas flow and differential pressure head

developed by the compressor, the anti-surge controller operates the anti-surge valves to prevent

compressor surge condition.

An anti-surge line from the aftercooler discharge to the suction KOD inlet should be

provided for anti-surge control. When the compressor approaches surge condition (low flow,

high differential head), the anti-surge valves open up to lower the pressure differential and

circulate higher gas flow.

Sometimes, a performance controller can be included in the centrifugal compressor

system to control the rotating speed (RPM) of the compressor based on inlet pressure, flow etc.

in order to achieve optimum performance. Performance controller will typically adjust the

motor/turbine speed.

Level transmitters provided on the suction knock out drum are responsible for liquid level

control in the drum. Alarms are usually provided for high and high high liquid level conditions.

Temperature transmitter can be provided on aftercooler for temperature control by

sending a signal to adjust the fan speed of the aircooler.

Emergency Shutdown (ESD) valves can be provided on inlet / outlet lines of the

compressors system to isolate whole system in case of a shutdown. The inlet line of the suction

KOD corresponds to inlet of the compressor system. Aftercooler discharge and liquid outlet of

suction knock out drum correspond to the outlet lines of the compressor system. Shutdown

valves can be located on these lines as shown in figure-1.

Drains and vents to be provided on the suction / discharge lines, compressor casing,

suction Knock Out Drum, air cooler body etc. for completely draining/venting compressor and

associated piping, for maintenance.

For purging the compressor system, a nitrogen connection can be provided right after the

first isolation valve on the suction KOD inlet line.

Separator Vessels

1. Proper vessel symbol should be selected first of all, as shown in the presented drawing.

This should be selected from the list of equipment symbols on the legend sheets of a

particular project.

2. Separator vessel internals should then be indicated as per proper symbols on the legend

sheets. These internals can be inlet vane, vortex breaker on the outlet lines, demister pads

on gas outlets, weir plate separating the oil and water compartments etc.

3. All the nozzles on the separator vessel should then be correctly represented with size and

flanges. This includes inlet and outlet nozzles, drains, vents, PSV connection and

instrument nozzles, as shown in the sample drawing presented here. Typical

instrumentation on the vessel would be level gauges and transmitters on oil and water

compartments of the vessel plus pressure gauge and transmitters linked to pressure control

or alarms as applicable.

4. Inlet and outlet lines are the next to be drawn up. Line number, material class, size etc. is

to be correctly assigned to each of the lines.

5. Isolation valves, spectacle blinds, spacers etc. to be used for maintenance should be

drawn up next on the inlet / outlet lines. The spectacle blinds, spacers etc. are usually

connected right next to the isolation valves and equipment nozzles, as indicated in the

sample drawing presented here.

6. Instrumentation on the vessel should be drawn up next. Typically this would include

level gauges, level transmitters, pressure gauges, pressure transmitters as per requirement

for control, alarm and trip if applicable. The sample drawing presented here only indicates

transmitters, but generally they are accompanied by gauges for local indication and also

transmitters for alarms and trips.

7. Various control valves should be drawn up next wherever applicable. Sample drawing

indicates level control on oil and water outlet lines. Plus pressure control is indicated on the

vapor outlet to flare. These control valves should be equipped with either a bypass or

handwheel as per project standards, to continue vessel operation in case of control valve

maintenance.

8. Drains should be provided either on the vessel or on the bottom outlet lines for complete

draining of the vessel and associated piping for maintenance purpose. Sample drawing has

indicated drains on the outlet lines through which the vessel and piping can be completely

drained. Usually the vessel also has nozzles connecting it directly to the draining system.

9. Vents can be present either on the vessel itself or on the vapor outlet line, so that the

vessel and associated piping can be completely vented for maintenance. Vent connected

directly to vessel is indicated in the sample drawing.

10. In most cases the vessel is provided with a blanketing gas connection. This blanketing

connection can be with or without pressure control. Although not indicated in the sample

drawing, it is important to consider the blanketing gas connection to the vessel.

11. For purging the vessel with nitrogen, a connection can be provided directly on the vessel.

In some cases purging can be done with steam.

12. All the guidelines given here are very general and may be modified as per specific

requirements of any particular project.

Pig Receiver

Pig launchers and receivers are commonly used in upstream oil and gas industry for periodic

cleaning of pipelines carrying crude oil, natural gas and water from oil wells. A pig is a bullet

shaped object which fits the pipeline from inside. The pig launcher launches the pig into pipeline

and the upstream pressure pushes the pig to other end of the pipeline where it is received by the

pig launcher. Hence generally arrangement for pig launchers and receivers are essentially the

same, except for the difference between ‘Kicker line’ position for launchers and receivers. The

sample drawing presents this general arrangement common to pig launchers and receivers.

1. Proper equipment symbol for pig launcher (vertical or horizontal) should be

selected first of all, as shown in the presented drawing. This should be selected from the list

of equipment symbols on the legend sheets of a particular project.

2. The major and minor barrels of the pig trap should be indicated as shown in the sample

drawing. Minor barrel size is equal to pipeline size and the major barrel size is slightly

larger.

3. All the nozzles on the pig launcher should then be correctly represented with size and

flanges. This includes door on the launcher, pig outlet to pipeline, kicker line, balancing

line, PSV connection, purge, vent, drain and instrument nozzles, as shown in the sample

drawing presented here. Typicalinstrumentation on the pig launcher would be pressure

gauges and transmitters and pig indicators to know if the pig has been launched (or arrived

in the case of pig receivers).

4. Different lines connected to the pig launcher are the next to be drawn up. Line number,

material class, size etc. is to be correctly assigned to each of the lines.

5. Kicker line is used to pressurize the upstream side of pig so it can be launched. In case of

receiver, kicker line provides an outlet for fluids arriving in the pig trap. Normally when

pigging is not being performed, kicker line is closed using normally closed valve.

6. Balancing line connecting the kicker line to minor barrel of the pig launcher, helps lower

the pressure differential so that sudden shooting of the pig will not damage downstream

automatic valves.

7. A bypass line of the pig launcher is the normal route for the fluids when pigging is not

taking place. This section upstream to the shutdown valve at beginning of pipeline can be

protected against overpressure as indicated in the sample drawing.

8. The hand operated valve (HV) on the bypass line is used to create a pressure differential

for launching the pig (also for receiving the pig). A pressure differential indicator (PDI) has

to be available to the HV operator to monitor the pressure differential.

9. On the outlet of the pig launcher, another hand operated automatic valve is provided to

open up the launcher upon pressurization.

10. The pig launcher (and receiver) are also protected against overpressure with a PSV which

discharges to flare. Typical representation of PSVs can be referred to in another article.

11. Isolation valves, spectacle blinds, spacers etc. to be used for maintenance should be

drawn up next, on various lines to and from the pig trap. The spectacle blinds, spacers etc.

are usually connected right next to the isolation valves and equipment nozzles, as indicated

in the sample drawing presented here.

12. Drains should be provided either on major or minor barrel or on both for complete

draining of the pig trap after the pig is launched or received. Sample drawing has indicated

drains on both the barrels. These drains are connected to the closed drain system.

13. Vents to flare and to atmosphere are required on pig launchers. Venting to flare for

depressurization of the pig launcher can be achieved using bypass on the relief valve. For

maintenance, when pig is not in operation it can be vented to atmosphere.

14. A utility connection is required to purge the pig launcher / receiver after the pigging is

done and the pig trap is depressurized and drained. A nitrogen connection should normally

be provided as indicated in the sample drawing.

15. Most of the guidelines mentioned for pig launchers also hold good for pig receivers.

16. All the guidelines given here are very general and may be modified as per specific

requirements of any particular project.

Particle size control of detergents in mixed flow

Industrial plant for Distillation of Sulphate Turpentine

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Typical 3-Phase Separator P&ID ArrangementDocument35 pagesTypical 3-Phase Separator P&ID ArrangementMARK LESTER REALNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Typical P&ID Arrangement For Centrifugal Compressor SystemsDocument2 pagesTypical P&ID Arrangement For Centrifugal Compressor SystemsajaysapruNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Typical Compressor ArrangementDocument2 pagesTypical Compressor ArrangementkaitokidH3MNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Compressor Symbol Centrifugal CompressorDocument3 pagesCompressor Symbol Centrifugal CompressorPriscilla VidyaNo ratings yet

- Centrifugal Compressor P&ID GuideDocument4 pagesCentrifugal Compressor P&ID Guidenaveenbaskaran1989100% (1)

- 3 Phase SeparatorDocument3 pages3 Phase SeparatorjgkrishnanNo ratings yet

- Typical P&ID for Centrifugal Compressor SystemsDocument7 pagesTypical P&ID for Centrifugal Compressor SystemsmsaroladanNo ratings yet

- PID for 3-Phase SeparatorsDocument2 pagesPID for 3-Phase SeparatorsKmt_AeNo ratings yet

- Pressure Safety ValvesDocument11 pagesPressure Safety ValveschianhhoNo ratings yet

- Typical PDocument1 pageTypical PSIL BlackoutNo ratings yet

- Typical P&ID Arrangement For 3 Phase Separator Vessels - EnggcyclopediaDocument2 pagesTypical P&ID Arrangement For 3 Phase Separator Vessels - EnggcyclopediaPrie TeaNo ratings yet

- Typical P&ID Pump ArrangementDocument2 pagesTypical P&ID Pump ArrangementKurian Jose100% (1)

- PRDS PRS DSH Systems Operation and Installation ManualDocument125 pagesPRDS PRS DSH Systems Operation and Installation Manual윤병택No ratings yet

- Anti-Surge Valve Piping For Gas CompressorDocument3 pagesAnti-Surge Valve Piping For Gas CompressoriaftNo ratings yet

- PrdsDocument0 pagesPrdssandi1111No ratings yet

- Designing Steam Pressure Reducing StationsDocument7 pagesDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaNo ratings yet

- Hf2 77ebDocument12 pagesHf2 77ebPetrovici Remus100% (1)

- Appendix 1 Vents DrainsDocument8 pagesAppendix 1 Vents Drainskad-7No ratings yet

- BOP Accumulator UnitsDocument18 pagesBOP Accumulator Unitsjosegutierrez88201050% (2)

- Chiller Testing Procedure Rev 1Document15 pagesChiller Testing Procedure Rev 1Ali AimranNo ratings yet

- Control Valves ArrangementDocument11 pagesControl Valves ArrangementPrasanna kumar subudhi100% (1)

- Instruction Manual Air CompressorDocument13 pagesInstruction Manual Air Compressornguyenvanhai1903198156% (9)

- GEA Wiegand Jet PumpsDocument2 pagesGEA Wiegand Jet Pumpsvvraman9586No ratings yet

- HL2-90 Compressor Instr ManualDocument12 pagesHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Typical Pid Arrangement Heat ExchangerDocument1 pageTypical Pid Arrangement Heat Exchanger이가람No ratings yet

- Blanket Gas Regulator Selection and GuidelinesDocument3 pagesBlanket Gas Regulator Selection and GuidelinesdzungNo ratings yet

- Pig Launcher and ReceiverDocument5 pagesPig Launcher and ReceiverEbby Onyekwe88% (8)

- T&C Procedure For Air Conditioning Chiller SystemDocument11 pagesT&C Procedure For Air Conditioning Chiller SystemAli AimranNo ratings yet

- General Engineering Knowledge For Marine EngineersDocument31 pagesGeneral Engineering Knowledge For Marine EngineersSrini VasanNo ratings yet

- Petroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesDocument14 pagesPetroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesUnknown Gamer467No ratings yet

- Relief Valve and Trip Testing ProceduresDocument16 pagesRelief Valve and Trip Testing ProceduresDharshica MohanNo ratings yet

- BMT7L1-Fluid Power Automation LabDocument37 pagesBMT7L1-Fluid Power Automation LabvamshimohanNo ratings yet

- Best Practice Guide For Power Transformer Maintenance EEPDocument1 pageBest Practice Guide For Power Transformer Maintenance EEPashutosh ambeyNo ratings yet

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Steam Jet Spindle Operated ThermocompressorDocument3 pagesSteam Jet Spindle Operated ThermocompressorjfejfeNo ratings yet

- Vacuum and Heat Transfer Barometric Condenser ManualDocument11 pagesVacuum and Heat Transfer Barometric Condenser ManualNick Smith100% (1)

- PT18PCMTL5 - Applied Hydraulics & Pneumatics LabDocument37 pagesPT18PCMTL5 - Applied Hydraulics & Pneumatics LabvamshimohanNo ratings yet

- Flow 7 DiagramsDocument12 pagesFlow 7 DiagramsIne Florez PalaciozNo ratings yet

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- Ngineering ATA: Field Testing of FansDocument5 pagesNgineering ATA: Field Testing of FansMohamed TahounNo ratings yet

- P&ID Guidelines Pumps Heat ExchangersDocument1 pageP&ID Guidelines Pumps Heat ExchangersVraja KisoriNo ratings yet

- 150 70-nm2 1Document12 pages150 70-nm2 1Eduardo JoseNo ratings yet

- General Guidelines of Pump Piping LayoutDocument8 pagesGeneral Guidelines of Pump Piping LayoutbainNo ratings yet

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- Plant Layout-CompressorsDocument19 pagesPlant Layout-Compressorshalder_kalyan9216No ratings yet

- Section I-Balance of Plant - Introduction & Coverage 1.0Document20 pagesSection I-Balance of Plant - Introduction & Coverage 1.0fkghkNo ratings yet

- HP BypassDocument15 pagesHP Bypass150819850No ratings yet

- CVHE TeardownDocument30 pagesCVHE Teardownbgottlieb42095% (19)

- Dry ValveDocument12 pagesDry ValveSayed MohamedNo ratings yet

- Hydranautics-TAB142-LDocument9 pagesHydranautics-TAB142-LMax JunghannsNo ratings yet

- Dosing PumpDocument10 pagesDosing PumpniceseshaNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- A Block Flow DiagramDocument35 pagesA Block Flow DiagramJerry SimonNo ratings yet

- Plant Layout (Relief Valve)Document10 pagesPlant Layout (Relief Valve)Mee WinNo ratings yet

- Introduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDocument3 pagesIntroduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDheeraj ShuklaNo ratings yet

- PRC Certified Plant Mechanic exam in Lucena CityDocument1 pagePRC Certified Plant Mechanic exam in Lucena CityDaniel YoworldNo ratings yet

- Chapters 51-100Document325 pagesChapters 51-100Daniel YoworldNo ratings yet

- Cooling and Heating Load CalculationDocument48 pagesCooling and Heating Load CalculationDaniel YoworldNo ratings yet

- OpenBlox-Whitepaper 9.13.26 AMDocument31 pagesOpenBlox-Whitepaper 9.13.26 AMDaniel YoworldNo ratings yet

- LPG - Sluz - 2022 Jan 02 13Document22 pagesLPG - Sluz - 2022 Jan 02 13Daniel YoworldNo ratings yet

- Zhang Xuan Defends Qiu Yu from AssaultDocument41 pagesZhang Xuan Defends Qiu Yu from AssaultDaniel YoworldNo ratings yet

- Chapter IDocument7 pagesChapter IDaniel YoworldNo ratings yet

- Industrial Plant For Distillation of Sulphate TurpentineDocument5 pagesIndustrial Plant For Distillation of Sulphate TurpentineDaniel YoworldNo ratings yet

- Centrifugal Compressor SystemsDocument5 pagesCentrifugal Compressor SystemsDaniel YoworldNo ratings yet

- Industrial Plant For Distillation of Sulphate TurpentineDocument5 pagesIndustrial Plant For Distillation of Sulphate TurpentineDaniel YoworldNo ratings yet

- MD1Document6 pagesMD1Daniel YoworldNo ratings yet

- Service Oriented Architecture Proposed for Batch Control ProcessesDocument5 pagesService Oriented Architecture Proposed for Batch Control ProcessesDaniel YoworldNo ratings yet

- Particle Size Control of Detergents in Mixed Ow Spray DryersDocument7 pagesParticle Size Control of Detergents in Mixed Ow Spray DryersDaniel YoworldNo ratings yet

- Table of ContentsDocument7 pagesTable of ContentsDaniel YoworldNo ratings yet

- Diesel Plant Sizing and Performance Analysis of A Remote Wind-Diesel MicrogridDocument8 pagesDiesel Plant Sizing and Performance Analysis of A Remote Wind-Diesel MicrogridshadyNo ratings yet

- Bibliography PDFDocument1 pageBibliography PDFDaniel YoworldNo ratings yet

- Whole Paper FinalDocument101 pagesWhole Paper FinalDaniel YoworldNo ratings yet

- Duaso ElementsDocument202 pagesDuaso ElementsAnonymous hndZWISrhYNo ratings yet

- Steam Turbine Electricity Generation Plants: Aeolipile, A ReactionDocument10 pagesSteam Turbine Electricity Generation Plants: Aeolipile, A ReactionDaniel YoworldNo ratings yet

- Hydroelectric Performance EvaluationDocument72 pagesHydroelectric Performance EvaluationDaniel Yoworld100% (1)

- Grouped Data (Mean, Median and Mode)Document16 pagesGrouped Data (Mean, Median and Mode)Daniel YoworldNo ratings yet

- Plate Contractor Design FundamentalsDocument21 pagesPlate Contractor Design FundamentalsMiraj savaniNo ratings yet

- The Water Sourcebooks Grade Level 9 12 PDFDocument855 pagesThe Water Sourcebooks Grade Level 9 12 PDFTheMothershipNo ratings yet

- Thermally Driven Heat Pumps For Heating and Cooling - Annett KühnDocument244 pagesThermally Driven Heat Pumps For Heating and Cooling - Annett KühnAndrés MonteroNo ratings yet

- Redwood Viscometer ExperimentDocument4 pagesRedwood Viscometer ExperimentSudarshan Ghotekar100% (1)

- Water - Its Structure and PropertiesDocument1 pageWater - Its Structure and PropertiesRobert BuiNo ratings yet

- Gas Rate Equation: P P C QDocument2 pagesGas Rate Equation: P P C QSagar DadhichNo ratings yet

- Simulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerDocument6 pagesSimulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerMoca PhoenixNo ratings yet

- Plasma & BoseDocument25 pagesPlasma & Bosesunma12345No ratings yet

- Gas AbDocument14 pagesGas AbJackielyn EugenioNo ratings yet

- Crystal GeometryDocument17 pagesCrystal GeometryNeel PatelNo ratings yet

- Orifice Sizing PrinciplesDocument12 pagesOrifice Sizing Principlesjlcheefei9258100% (1)

- Principles of Electronic Materials and Devices 4th Edition Kasap Solutions Manual 1Document78 pagesPrinciples of Electronic Materials and Devices 4th Edition Kasap Solutions Manual 1jennifer100% (53)

- Che 415 2018-19 Part 3 PDFDocument66 pagesChe 415 2018-19 Part 3 PDFOsan ThorpeNo ratings yet

- Chemistry Part 2 PDFDocument17 pagesChemistry Part 2 PDFHooi MinNo ratings yet

- Physical Science Quarter 3 LASDocument35 pagesPhysical Science Quarter 3 LASDrama LlamaNo ratings yet

- Problem Set 1Document2 pagesProblem Set 1Marcky Reacher100% (1)

- Notes On Atomic Emission SpecDocument48 pagesNotes On Atomic Emission SpecsanelisofuturemoyoNo ratings yet

- Introduction To Offshore Petroleum Production System: Yutaek SeoDocument39 pagesIntroduction To Offshore Petroleum Production System: Yutaek Seoh0s0No ratings yet

- Q3 Module 1A - Intermolecular Forces of AttractionDocument53 pagesQ3 Module 1A - Intermolecular Forces of AttractionRance Bobadilla100% (2)

- Townsend's Breakdown Mechanism: High Voltage Engineering (18EL) Chapter 1 by DR Suhail KhokharDocument25 pagesTownsend's Breakdown Mechanism: High Voltage Engineering (18EL) Chapter 1 by DR Suhail KhokharIzhar Ahmed NoohpotoNo ratings yet

- Class 12 Set - B: Chemistry - CH 402Document3 pagesClass 12 Set - B: Chemistry - CH 402SonuSharmaNo ratings yet

- Small Scale NGLDocument45 pagesSmall Scale NGLNoirchevalNo ratings yet

- Aib-Fd160 1998-12-01Document16 pagesAib-Fd160 1998-12-01Filipe GuaranyNo ratings yet

- UEE Unit 5 - GKDocument55 pagesUEE Unit 5 - GKRajvir Kaur SidhuNo ratings yet

- Ternario ZN Cu AgDocument11 pagesTernario ZN Cu AgAlicia Jara ChavezNo ratings yet

- Transport Phenomena-Gaskell PDFDocument687 pagesTransport Phenomena-Gaskell PDFmirandaNo ratings yet

- Optimum number of evaporator effects and steam jet ejector designDocument6 pagesOptimum number of evaporator effects and steam jet ejector designfais verianNo ratings yet

- Srivastava DissertationDocument144 pagesSrivastava DissertationleNo ratings yet

- Combination Air Eliminator-Strainer: OVAL CorporationDocument2 pagesCombination Air Eliminator-Strainer: OVAL CorporationChuong DongNo ratings yet

- Centrifugal Pump Sizing, Selection and Design Practices (Hay)Document77 pagesCentrifugal Pump Sizing, Selection and Design Practices (Hay)Scribd_del75% (8)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- One Health: Integrated Approach to 21st Century Challenges to HealthFrom EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)