Professional Documents

Culture Documents

Reavell 20-100 HP Water Cooled Reciprocating Compressor PDF

Reavell 20-100 HP Water Cooled Reciprocating Compressor PDF

Uploaded by

MAZENOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reavell 20-100 HP Water Cooled Reciprocating Compressor PDF

Reavell 20-100 HP Water Cooled Reciprocating Compressor PDF

Uploaded by

MAZENCopyright:

Available Formats

20-100 HP | WATER-COOLED MODELS

Reavell Reciprocating Compressors

Compact Design. Application Flexibility.

Minimal Installation Costs.

Reavell water-cooled compressors are manufactured

Reavell compressors from Gardner Denver offer a to withstand some of the harshest compression

compact design which limits installation costs. The and boosting applications across the globe. Typical

compressors feature anti-vibration mounts that applications include leak/pressure testing, gas

eliminate the need for a special base or foundation. recovery, autoclaves, wind tunnels, compressed

The foundation simply needs to be level and able to natural gas (CNG), engine start and electrical power

support the static weight of the compressor. stations. Gas service consists of nitrogen, helium,

hydrogen and methane. Contact Gardner Denver for

a complete listing of approved gases.

Optimal Serviceability.

Enhanced Uptime.

The unrivaled design of Reavell water-cooled

units provide convenient access when it comes to

servicing the units with items such as: liners, valves,

pistons, rings and spin-on oil filters. All maintenance

parts are removable without a major teardown which

equals more uptime.

WATER-COOLED RECIPROCATING COMPRESSORS

MINIMUM PRESSURE MAXIMUM PRESSURE MINIMUM CAPACITY MAXIMUM CAPACITY MOTOR POWER COMPRESSION

MODEL

PSI BAR PSI BAR CFM M³/HR CFM M³/HR HP KW STAGES

5212 145 10 508 35 16 27 34 58 20 15 2

5217 145 10 580 40 38 64 74 126 40 30 2

5236 145 10 580 40 88 150 171 291 100 75 2

5317 580 40 1233 85 20 34 38 65 25 18.5 3

5337 580 40 1233 85 38 65 92 156 60 45 3

5417 2031 140 5000 350 19 32 37 63 40 30 4

5420 2321 160 5000 350 25 43 49 84 50 37 4

5437 2321 160 6000 414 38 65 92 156 75 55 4

Water-Cooled Features

■■ 145 to 6,000 PSIG ■■ Inter and after-stage coolers ■■ Safety valves on all stages

■■ 16 to 171 CFM FAD ■■ Direct

valve access for easy ■■ High temperature cut-out switches

■■ Direct

maintenance and gauges

drive or V-Belt drive,

oil-lubricated two to four-stage ■■ Oil

and moisture separators with ■■ Final delivery air temperature

compressor automatic drainage gauge

■■ Closed loop cooling systems ■■ Forcedlubrication system with oil ■■ Low oil pressure cut-out switch

available pump, filter and relief valve and gauge

■■ Cylinders fully enclosed by water- ■■ Corrosion rod in water-jacket ■■ Pressure gauge on each stage

jacket ■■ Final delivery non-return valve ■■ Controlling air pressure switch

■■ Anti-vibration mounts ■■ Water cooling from closed radiator ■■ Bursting disk in water-jacket

■■ 90°V-configuration for excellent circuit or mains (fresh or sea) ■■ Motor starter and control panel

balance ■■ TEFV electric motor with

■■ Intake

filter silencer with explosion proof options

replaceable element

Gardner Denver, Inc.

1800 Gardner Expressway

Quincy, IL 62305

866-440-6241

www.gardnerdenver.com/gdproducts

©2016 Gardner Denver, Inc. Printed in U.S.A.

GDHPCS-RV-20-100-WC 1st Ed. 12/16

Please recycle after use.

You might also like

- ACLS Test BankDocument13 pagesACLS Test BankSofiaSheikh94% (51)

- 3306 Industrial Spec SheetDocument6 pages3306 Industrial Spec Sheetdanielch123100% (1)

- Marine Generator Set 3304B DINADocument8 pagesMarine Generator Set 3304B DINACarlos AguiarNo ratings yet

- Spec Oem Caterpillar 3306TDocument6 pagesSpec Oem Caterpillar 3306TAminovic MostafaNo ratings yet

- Refrigerated Air Dryer 2016Document8 pagesRefrigerated Air Dryer 2016SAUL OSPINONo ratings yet

- Prince Valves PDFDocument82 pagesPrince Valves PDFMauricio Ariel H. OrellanaNo ratings yet

- Elgi EG 90 160kW 50Hz D I PDFDocument8 pagesElgi EG 90 160kW 50Hz D I PDFMAZENNo ratings yet

- Reavell 4-20 HP Air Cooled Reciprocating CompressorDocument2 pagesReavell 4-20 HP Air Cooled Reciprocating Compressorscrollock0428No ratings yet

- L90RS-L132RS Variable Speed Rotary Screw Compressor BrochureDocument2 pagesL90RS-L132RS Variable Speed Rotary Screw Compressor BrochureSergiSerranoNo ratings yet

- L-Series: Advanced Technology. Inspired Simplicity. First Class ServiceabilityDocument2 pagesL-Series: Advanced Technology. Inspired Simplicity. First Class Serviceabilitywilber fernando nina chambillaNo ratings yet

- Electra-Saver SAV 350-500 HP Cut SheetDocument2 pagesElectra-Saver SAV 350-500 HP Cut SheetEsteban JaramilloNo ratings yet

- Bear Test SeparatorDocument4 pagesBear Test SeparatorJuan P RuizNo ratings yet

- Screw Compressors: Complex Needs - Smarter SolutionsDocument2 pagesScrew Compressors: Complex Needs - Smarter SolutionsMauricioNo ratings yet

- L30-L75 Fixed Speed Rotary Screw Compressor BrochureDocument2 pagesL30-L75 Fixed Speed Rotary Screw Compressor BrochureSpark ElectricNo ratings yet

- Electra Saver II G2 125-200 HP Rotary Screw Compressor Cut SheetDocument2 pagesElectra Saver II G2 125-200 HP Rotary Screw Compressor Cut SheetEsteban JaramilloNo ratings yet

- Vs25 40 Rotary Screw 60 HZ Compressor BrochureDocument2 pagesVs25 40 Rotary Screw 60 HZ Compressor Brochurerobertomb1991No ratings yet

- VS45-70 Rotary Screw 60 HZ Compressor BrochureDocument2 pagesVS45-70 Rotary Screw 60 HZ Compressor BrochureLierton PinheiroNo ratings yet

- Electra Saver II G2 40-60 HP Rotary Screw Compressor Cut SheetDocument2 pagesElectra Saver II G2 40-60 HP Rotary Screw Compressor Cut SheetIliyanPetrovNo ratings yet

- Screw Compressors: Complex Needs - Smarter SolutionsDocument2 pagesScrew Compressors: Complex Needs - Smarter SolutionsMauricioNo ratings yet

- Aircom VST 225 260 - 1st - 2 16Document2 pagesAircom VST 225 260 - 1st - 2 16Rodolfo RamirezNo ratings yet

- Industrial Deionization Systems: Standard FeaturesDocument2 pagesIndustrial Deionization Systems: Standard Featuresashraf-84No ratings yet

- SEHI-T Electric Expansion Valve: R-134a Chillers/Heat PumpsDocument4 pagesSEHI-T Electric Expansion Valve: R-134a Chillers/Heat PumpsMohamed HamadNo ratings yet

- Refrigeration Screw Compressors and Chilling Units PDFDocument8 pagesRefrigeration Screw Compressors and Chilling Units PDFAmandeep singhNo ratings yet

- SSR M200-250: Rotary Screw AirDocument2 pagesSSR M200-250: Rotary Screw AirFIRMANNo ratings yet

- BL HV 100E HV 100G HVH 100E HVH 100G - Iom.Document37 pagesBL HV 100E HV 100G HVH 100E HVH 100G - Iom.Hector Uc ChableNo ratings yet

- Sep Catalog 0212Document30 pagesSep Catalog 0212info2449No ratings yet

- 4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPMDocument5 pages4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPMOrkhan AhadzadeNo ratings yet

- File - 1918 - File0120 (1) .PDF - AeroserviciosDocument2 pagesFile - 1918 - File0120 (1) .PDF - AeroserviciosKazem QarebeiglooNo ratings yet

- Megnatic Chiller - Product Catalogue 2021Document12 pagesMegnatic Chiller - Product Catalogue 2021Buscat BatuscNo ratings yet

- Hdengcatalog EngDocument26 pagesHdengcatalog EngMùa ThuNo ratings yet

- Technical Manual For Air Cooled Screw Chiller (FCH02-2020,21)Document34 pagesTechnical Manual For Air Cooled Screw Chiller (FCH02-2020,21)yusuf mohd sallehNo ratings yet

- Auto Drain ValveDocument2 pagesAuto Drain ValveRoopa MahtoNo ratings yet

- Utility Vehicles Compressors (Diesel) GommairDocument9 pagesUtility Vehicles Compressors (Diesel) GommairRotair spaNo ratings yet

- Ledeen Actuator General Catalogue - Entire LineDocument24 pagesLedeen Actuator General Catalogue - Entire LineJair LamasNo ratings yet

- Trident CTD - 11 B LeafletDocument2 pagesTrident CTD - 11 B LeafletBOOBALANNo ratings yet

- Brosur HiCOP Air To Water Heat Pump (AW) - 1Document2 pagesBrosur HiCOP Air To Water Heat Pump (AW) - 1fannyNo ratings yet

- Dometic List Price 2017Document136 pagesDometic List Price 2017NerdyNo ratings yet

- Fuel Pro: Product Data SheetDocument2 pagesFuel Pro: Product Data SheetKe HalimunNo ratings yet

- Ledeen Actuator General Catalogue - Entire Line - ENVIADO 20.07.17 PDFDocument24 pagesLedeen Actuator General Catalogue - Entire Line - ENVIADO 20.07.17 PDFDaniele GouveiaNo ratings yet

- Brosur Perkins Marine PDFDocument2 pagesBrosur Perkins Marine PDFhastaNo ratings yet

- 2006 QGB7.5-15 HPDocument4 pages2006 QGB7.5-15 HPjoelmerazNo ratings yet

- Projetting HDMD Diesel High Pressure Units Web CompressedDocument12 pagesProjetting HDMD Diesel High Pressure Units Web CompressedYohanes RezaNo ratings yet

- V DireccionalesDocument70 pagesV DireccionalesFabian CampañaNo ratings yet

- Zamil 5 Ton SectionDocument44 pagesZamil 5 Ton Sectionershad7404No ratings yet

- EHYDF2 Hydraulic Filtration CAT2300-13 OP3Document12 pagesEHYDF2 Hydraulic Filtration CAT2300-13 OP3hariana100% (1)

- Rating Control PanelDocument1 pageRating Control Panelmohammed rinshinNo ratings yet

- FGW2 Weichai Genset WP2.3 Series 60HZ 15 50kwe LTPDocument4 pagesFGW2 Weichai Genset WP2.3 Series 60HZ 15 50kwe LTPMahmoud KokoNo ratings yet

- RS 3.0 - 75.0 KW: RENNER Screw CompressorsDocument5 pagesRS 3.0 - 75.0 KW: RENNER Screw CompressorstitiNo ratings yet

- High-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigDocument4 pagesHigh-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigMateusDinizNo ratings yet

- School Bus Medium Duty Quick Reference Catalog L00100 3-04Document60 pagesSchool Bus Medium Duty Quick Reference Catalog L00100 3-04Wrench97100% (1)

- High-Efficiency Model RC2 Series Screw CompressorDocument8 pagesHigh-Efficiency Model RC2 Series Screw Compressorgyeong gyu moonNo ratings yet

- Introducing The: Gas Pak ProDocument4 pagesIntroducing The: Gas Pak ProSantosh AdadaNo ratings yet

- Weichai Marine Engine - WD12 SeriesDocument3 pagesWeichai Marine Engine - WD12 SeriesAT Solution TechnologyNo ratings yet

- Technical Brochure: Jrd5, Jrd7 and Jrd10 Convertible Jet Pumps, and 1 HP - 60 HZDocument4 pagesTechnical Brochure: Jrd5, Jrd7 and Jrd10 Convertible Jet Pumps, and 1 HP - 60 HZghmp123No ratings yet

- 116 SpecDocument2 pages116 SpecesvwestNo ratings yet

- Datasheet Motor Generador Cummins Onan 30MCGBADocument4 pagesDatasheet Motor Generador Cummins Onan 30MCGBABam BANo ratings yet

- 500kVA K600C Rigsafe Diesel Generator Flyer PDFDocument2 pages500kVA K600C Rigsafe Diesel Generator Flyer PDFMd MkNo ratings yet

- ENGINE DATA SHEET 275 KW 6R1600G70SDocument4 pagesENGINE DATA SHEET 275 KW 6R1600G70SAngel RiosNo ratings yet

- Manual Bomba EspumaDocument108 pagesManual Bomba EspumaFrancisco ManriquezNo ratings yet

- HF14Document20 pagesHF14HonoluluNo ratings yet

- Silent Type: Engine Specifica Ons Main Specifica OnsDocument2 pagesSilent Type: Engine Specifica Ons Main Specifica OnsMarketing CTNNo ratings yet

- Robuschi Data Sheet RoboxDocument21 pagesRobuschi Data Sheet RoboxMAZENNo ratings yet

- 009 en Boge Sof Data 20210721 1Document2 pages009 en Boge Sof Data 20210721 1MAZENNo ratings yet

- JL Components Blower LubricationDocument4 pagesJL Components Blower LubricationMAZENNo ratings yet

- Elektronikon MKV PDFDocument2 pagesElektronikon MKV PDFMAZENNo ratings yet

- V Series Boge FilterDocument1 pageV Series Boge FilterMAZENNo ratings yet

- Performance Data D110-10RS: Min. MaxDocument1 pagePerformance Data D110-10RS: Min. MaxMAZENNo ratings yet

- 19 12 18 Tis D110HRS W UkDocument1 page19 12 18 Tis D110HRS W UkMAZENNo ratings yet

- 19 12 18 Tis D37H A UkDocument1 page19 12 18 Tis D37H A UkMAZENNo ratings yet

- Performance Data D75: D75 Technical Information Sheet 50 HZ, Fix Speed, Air Cooled, CE VersionDocument1 pagePerformance Data D75: D75 Technical Information Sheet 50 HZ, Fix Speed, Air Cooled, CE VersionMAZENNo ratings yet

- 19 12 18 Tis D50HRS A UkDocument1 page19 12 18 Tis D50HRS A UkMAZENNo ratings yet

- 3 12 15 Tis L200RS A Ce 2015Document1 page3 12 15 Tis L200RS A Ce 2015MAZENNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- Rotar Rotar Rotar Rotar Rotar Cube SD Cube SD Cube SD Cube SD Cube SDDocument18 pagesRotar Rotar Rotar Rotar Rotar Cube SD Cube SD Cube SD Cube SD Cube SDMAZENNo ratings yet

- Robust and Powerful: Oil-Free Piston CompressorsDocument8 pagesRobust and Powerful: Oil-Free Piston CompressorsMAZENNo ratings yet

- R080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04Document1 pageR080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04MAZENNo ratings yet

- LMF-GP LX45-8 - 10 - 13Document2 pagesLMF-GP LX45-8 - 10 - 13MAZENNo ratings yet

- Frecon HPRDocument4 pagesFrecon HPRMAZENNo ratings yet

- LMF-GP LX37-8 - 10 - 13Document2 pagesLMF-GP LX37-8 - 10 - 13MAZENNo ratings yet

- LMF-GP LX30-8 - 10 - 13Document2 pagesLMF-GP LX30-8 - 10 - 13MAZENNo ratings yet

- LMF-GP LX18-8 - 10 - 13Document2 pagesLMF-GP LX18-8 - 10 - 13MAZENNo ratings yet

- LMF-GP LX11-8 - 10 - 13Document2 pagesLMF-GP LX11-8 - 10 - 13MAZENNo ratings yet

- LMF-GP LX5-8 - 10 - 13Document2 pagesLMF-GP LX5-8 - 10 - 13MAZEN100% (1)

- LMF-GP LX7-8 - 10 - 13Document2 pagesLMF-GP LX7-8 - 10 - 13MAZENNo ratings yet

- Filters FPDocument2 pagesFilters FPMAZENNo ratings yet

- Open-Ended Questions: Chapter 8-1 To 8-5 Test - Honors MATH 7Document5 pagesOpen-Ended Questions: Chapter 8-1 To 8-5 Test - Honors MATH 7ahrianna deitzNo ratings yet

- Lease Telecom Sprint MD3147 CityCollegeDocument23 pagesLease Telecom Sprint MD3147 CityCollegeParents' Coalition of Montgomery County, Maryland100% (1)

- Rotational Equilibrium and Rotational DynamicsDocument8 pagesRotational Equilibrium and Rotational DynamicsNathalie SerafinNo ratings yet

- Forklift Safety: Osha TrainingDocument89 pagesForklift Safety: Osha Trainingreda mesbahNo ratings yet

- Is JIT Manufacturing The Right PrescriptionDocument1 pageIs JIT Manufacturing The Right PrescriptionjoannakamNo ratings yet

- Irish LyricsDocument18 pagesIrish Lyricsmattgood0% (1)

- 2013 Outsourcing Trip-Invitation Letter-CEO ClubDocument12 pages2013 Outsourcing Trip-Invitation Letter-CEO ClubCEOclubNo ratings yet

- Manuskrip RiniDocument11 pagesManuskrip RiniRiniWagisanRkwtNo ratings yet

- Hot Topic 02 Good Light Magazine 56smDocument24 pagesHot Topic 02 Good Light Magazine 56smForos IscNo ratings yet

- Sample Specification of FansDocument5 pagesSample Specification of Fanscashlover100% (1)

- Motorcycle Classics 03.04 2020 PDFDocument100 pagesMotorcycle Classics 03.04 2020 PDFAnonymous 7Je2SSU100% (2)

- Gas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Document43 pagesGas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Mario HuasasquicheNo ratings yet

- Get Job Id 73594Document5 pagesGet Job Id 73594محمد عليNo ratings yet

- GMP Behavior RequirementsDocument5 pagesGMP Behavior RequirementsFrankMartinezNo ratings yet

- Emko Genset CatalogueDocument46 pagesEmko Genset Cataloguedarius perezNo ratings yet

- CONSTRUCTION COMMUNICATIONS PLAN FinVer4Document18 pagesCONSTRUCTION COMMUNICATIONS PLAN FinVer4Mohammed MuzakkirNo ratings yet

- Ansys Aqwa WaveDocument26 pagesAnsys Aqwa Wavepackya7191100% (1)

- A Shoe Story: Look at Manny's Shoes. Where Do You Think They Have Been?Document8 pagesA Shoe Story: Look at Manny's Shoes. Where Do You Think They Have Been?Renier John BambaNo ratings yet

- NON EV FGD QuestionsDocument1 pageNON EV FGD QuestionsVideep ViratNo ratings yet

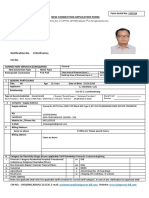

- New Connection Application FormDocument5 pagesNew Connection Application FormsiamitonsingNo ratings yet

- Non Destructive Testing (NDT) : by Mr. H.P.VaradeDocument42 pagesNon Destructive Testing (NDT) : by Mr. H.P.Varaderaj6062No ratings yet

- Solid Mensuration Module 1Document9 pagesSolid Mensuration Module 1Azha Clarice Villanueva100% (2)

- MRP Lot For LotDocument43 pagesMRP Lot For LotAmin ShafanezhadNo ratings yet

- The Properties of Gases and LiquidsDocument11 pagesThe Properties of Gases and LiquidsfarizkadimasNo ratings yet

- Carroll - The Philosophy of Motion Pictures PDFDocument250 pagesCarroll - The Philosophy of Motion Pictures PDFMaria Fernanda UgazNo ratings yet

- QPT 200 500 Pan Tilt Positioners SPSDocument4 pagesQPT 200 500 Pan Tilt Positioners SPSStanley Ochieng' OumaNo ratings yet

- Kenya Standard: ©KEBS 2010 . Edition 2010Document10 pagesKenya Standard: ©KEBS 2010 . Edition 2010Ahmed IsmailNo ratings yet

- General Specification: Welding - MaterialsDocument14 pagesGeneral Specification: Welding - MaterialsGil-Alain EgnakouNo ratings yet

- Energies: Building Applications, Opportunities and Challenges of Active Shading Systems: A State-Of-The-Art ReviewDocument32 pagesEnergies: Building Applications, Opportunities and Challenges of Active Shading Systems: A State-Of-The-Art ReviewNupur BhadraNo ratings yet