Professional Documents

Culture Documents

Risk Assessment For GIS Preparation For HV Cable Test

Risk Assessment For GIS Preparation For HV Cable Test

Uploaded by

badhur zaman hajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For GIS Preparation For HV Cable Test

Risk Assessment For GIS Preparation For HV Cable Test

Uploaded by

badhur zaman hajaCopyright:

Available Formats

HS.SAF.09.

F12

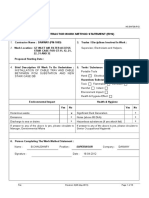

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY E & M ENG’G 3. Trades / Disciplines Involved In Work :

Engineer, Supervisor, Electricians and Helpers.

(TK-4842/ABB)

2. Work Location : GIS Building

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : GIS 5. Tools / Substance

PREPARATION FOR HIGH VOLTAGE TEST

Portable Tools

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Joachim Kuhlmann Position : Joachim Kuhlmann Company : ABB Switzerland

Signature : Date : 30.11.2011

Revision: 0(26-May-2011) Page 1 of 12

HS.SAF.09.F12

7. Approvals

Contractor Site Rep. Name Maan Al-Eshaiker Signature : Date : 30.11.2011

EMAL Contract Admin. Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

• After the Area Owner’s approval the Work Method Statement shall be forwarded to EHS department for

approval

• The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low LP x MS LP x HS

Severity 1 x 1 = 1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

Revision: 0(26-May-2011) Page 2 of 12

HS.SAF.09.F12

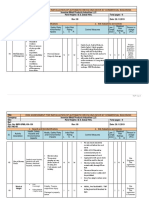

8. Safety Analysis

Identified Persons Precautions and Plan of Severity x

Individual Hazard(s) Exposed actions To Be Taken To Probability =

Activities To Associated With To Hazard Remove / Control Hazards Risk

Complete Work. Activity

List In Sequence Residual Risk

of Activity

(Use Risk

Estimator

Chart)

Emal /

1.PREPARATI Slips, trips SNC Maintain housekeeping

ON. and fall at the rep., around in the working

same level. Engr., area. 1x2=2

Supv.

Elec.

Helpers

Emal /

SNC All workers involve in the

rep., activity must be aware of

Hot

Engr., heat stress, supervisor to 2x2=4

weather.

Supv. ensure drinking cold

Elec water is available.

Helpers.

Emal /

SNC Wear P.P.E.'s at all times

rep., (hard hat, Clear safety

Not using Engr., glass, safety shoes, hand 2x2=4

P.P.E.'s Supv. gloves, dust mask, fire

Elec,Hel retardant long sleeve shirt

pers. / pants).

Electrical Engr., Only qualified employees

shock, fire Supv. will work near or on 3x2=6

and arc flash. Elec,Hel electrical equipment.

pers

Use only proper tools

that have a current colour

coding.

Failure to Engr., Depending on the type of

interact with Supv. activity, the employer

each other Elec,Hel shall ascertain that the

and absence pers employees of other

of a Job employers working 2x2=4

Hazard nearby have been

Assessment. adequately instructed

with regard to the

hazards of each other

tasks and processes to

Revision: 0(26-May-2011) Page 3 of 12

HS.SAF.09.F12

reduce risk.

Ensure that adjacent

work activates and

associated risks are

understood. Stay out of

non-ABB work areas.

Work with Supv. Complete and document

hazardous Elec,Hel hazard communications

substances. pers training for employees.

Follow operation 2x2=4

instruction.

Ensure relevant PPE is

used.

Avoid skin contact and

inhalation potential.

Use of tools Supv. Use proper tools that

Elec,Hel have been inspected

pers Only qualified and trained

employees are allowed to 2x2=4

work.

All tools must be

inspected on a quarterly

basis and prior to use by

the employee.

Work with Emal / Energized parts within

energized SNC working area are

equipment. rep., insulated.

Engr.,

Supv. Ensure relevant PPE is

used. 3x2=6

Elec

Helpers Prohibit unauthorized

entry.

De energized and ground

when possible.

Revision: 0(26-May-2011) Page 4 of 12

HS.SAF.09.F12

Utilize only qualified and

trained employees.

Follow operation

instruction.

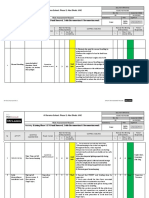

2.INSTALLATI

ON No

specific Supv,El Supervisor to ensure

available ect & approved PTW is 1x3=3

permit. helpers available on site.

Supv,El Check qualifications prior

ect & to allowing employee to

Electrocution 2x2=4

helpers work on electrical

systems.

Unauthorized Supv,El Ensure that approval is

and untrained ect & obtained from site 2x2=4

staff working helpers management prior to

in an unsafe starting work.

manner

Unknown Supv,El Single line must be

aspects of ect & available for review and

circuits can helpers use,updates required

lead to must be reviewed and 3x2=6

electrocution approved.

Continuous interface with

site management and

client.

Encountering Supv,El All work planned for the

energized ect & day must be reviewed

equipment helpers and risks assessed,

thought to be detailed job plan must be 2x2=4

dead. updated daily.

Ensure that site

management and

installation crew interface

daily.

Revision: 0(26-May-2011) Page 5 of 12

HS.SAF.09.F12

Failure to Supv An assessment of

recognize or ,Elect & electrical hazards relative

understand helpers to ongoing work and

risks. adjacent work must be 2x2=4

included in the job hazard

assessment.

Daily tool box talk

conducted before start

the work .

Untested tools Supv Only tools with a current

used ,Elect & certificate of testing will

conducting helpers be used for high voltage

current. work. 2x2=4

Only use tools that are

appropriate for the task

and have a current

certificate of testing.

2.1Staging and Crush, knock, Supv No transport and lift

installing strike, shear, ,Elect & above persons.

equipment etc. helpers

Crane be qualified and a

lift plan current.

All lifting equipment must

have a current annual

inspection and inspected

daily.

2x2=4

Equipment to be secured

against turn over.

Ensure relevant PPE is

used.

Inform personal about

working activity. Follow

operation instruction.

Defect lifting equipment

to be marked and

Revision: 0(26-May-2011) Page 6 of 12

HS.SAF.09.F12

secured against reuse.

Discuss communication

between Crane driver

and rigger before lifting

activity.

2.2 Installation Crush, knock, Supv Only qualified and trained

of GIS strike, shear, ,Elect & employees are allowed to

parts etc. helpers work.

Relevant PPE to be

used.

Use the insulated tools 2x2=4

when working on or near

energized equipment.

Inform personal about

working activity. Follow

operation instruction.

Only use approved tools

and equipment.

2.3Filling Release of Emal / Only qualified and trained

equipment SF6 gas to SNC employees are allowed to

with SF6 the rep., work.

gas Engr.,

environment

Supv. Relevant PPE to be

Elec used.

Helpers Use the correct tools. 3x1=3

Use only closed cycle

system with work SF6

gas.

Use recycling equipment

to capture the SF6 gas

and make sure that all

connections are secure

and leaks do not occur.

Revision: 0(26-May-2011) Page 7 of 12

HS.SAF.09.F12

Displacement Emal / Only qualified and trained

of air by SF6 SNC employees are allowed to

gas rep., work.

Engr.,

Supv. Relevant PPE to be

Elec used.

Helpers Use the correct tools.

Use only closed cycle

system with work SF6

gas.

3x1=3

Generally provide a good

air supply of the work

space.

Ventilate all basement

areas to ensure that a

buildup for SF6 in lower

areas is prevented.

Eating, drinking and

smoking in the work area

are prohibited.

Warn employee by using

warning signs.

Follow operation

instruction.

Prohibit unauthorized

entry.

Exposure to Emal / Only qualified and trained

high pressure SNC employees are allowed to

release rep., work.

Engr., 2x2=4

Supv. Relevant PPE to be

Elec used.

Helpers Use the correct tools.

For filling of equipment

follow operation

instruction and gas

layout.

Warn workplace by

caution label.

Inform personal about

Revision: 0(26-May-2011) Page 8 of 12

HS.SAF.09.F12

working activity.

Check the quality of the

pressure hoses.

2.4Evacuate Release to Emal / Only qualified and trained

SF6 gas. the SNC employees are allowed to

environment rep., work.

Engr.,

Supv. Relevant PPE to be

used. 2x2=4

Elec

Helpers Use the correct tools.

Use recycling equipment

to recycle SF6 and

ensure that charging

operations stop when any

leak of SF6 is observed.

Follow operation

instruction.

Inform personal about

working activity.

Eliminate air Emal / Only qualified and trained

by SF6 gas SNC employees are allowed to

rep., work.

Engr., 3x1=3

Supv. Relevant PPE to be

Elec used.

Helpers Use the correct tools.

Use only closed cycle

system with work SF6

gas.

Ensure that supply

ventilation is used in the

work area.

Ventilate cavities and

more deeply lying areas.

Eating, drinking and

smoking in the work area

are prohibited.

Revision: 0(26-May-2011) Page 9 of 12

HS.SAF.09.F12

Warning Workplace by

caution label.

Contaminated objects

with SF6 gas to be

separately disposed.

Consider operating

instruction.

Follow operation

instruction.

Prohibit unauthorized

entry.

High pressure Emal / Only qualified and trained

SNC employees are allowed to

rep., work.

Engr.,

Supv. Relevant PPE to be

used. 3x1=3

Elec

Helpers Use the correct tools

Warn workplace by

caution label.

Inform personal about

working activity.

Check the quality of the

pressure hoses.

2.5Installation Crush, knock, Emal / Only qualified and trained

of strike, shear, SNC employees are allowed to

secondary etc. rep., work.

equipment Engr.,

Supv. Relevant PPE to be

used. 2x2=4

Elec

Helpers Inform personal about

working activity

Follow operation

instruction.

Only use approved tools

and equipment.

Revision: 0(26-May-2011) Page 10 of 12

HS.SAF.09.F12

Electrical Emal / Only qualified and trained

shock. SNC employees are allowed to

rep., work.

Engr., 2x2=4

Supv. Relevant PPE to be

Elec used.

Helpers Use the correct tools.

Follow operation

instruction.

2.6Installation Crush, knock, Supv. Only qualified and trained

of parts strike, shear, Elec employees are allowed to

etc. Helpers work.

Relevant PPE to be

used. 2x2=4

Use the correct tools.

Follow operation

instruction.

Inform personal about

working activity.

Electrical Supv. Only qualified and trained

shock. Elec employees are allowed to

Helpers work.

Relevant PPE to be

used. 2x2=4

Use the correct tools.

Follow operation

instruction.

Inform personal about

working activity.

This sheet must be properly completed detailing all of the steps required to complete the job along

with the sequence of events and each of the hazards arising. Failure to properly complete the form

will result in non-approval.

Revision: 0(26-May-2011) Page 11 of 12

HS.SAF.09.F12

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

…………

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to

properly complete the form will result in non-approval.

Revision: 0(26-May-2011) Page 12 of 12

You might also like

- Electrical Installation Risk AssesmentDocument6 pagesElectrical Installation Risk AssesmentSumit KumarNo ratings yet

- 5. job-safety Equipment and electrical panels设备服务和电箱工作安全分析Document5 pages5. job-safety Equipment and electrical panels设备服务和电箱工作安全分析ADEN LIUNo ratings yet

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- 1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15Document8 pages1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15NirmalKumarSelvarajNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Cable PullingDocument4 pagesCable Pullingmykelrenz92% (12)

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Electrical Risk AssessmentDocument6 pagesElectrical Risk AssessmentEman Fawzy100% (1)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- 6-Transformer Installation PDFDocument3 pages6-Transformer Installation PDFAhmed ZaiNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 pagesRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuNo ratings yet

- Jha For - TransformerDocument7 pagesJha For - Transformermujahid1137No ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- TRA-Street Light Foundation Installation WorkDocument5 pagesTRA-Street Light Foundation Installation WorkbinunalukandamNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment - T&C For Medium Voltage SwitchgearDocument8 pagesRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad IrfanNo ratings yet

- Risk Assessment - PlantingDocument5 pagesRisk Assessment - PlantingJunaid Mir100% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Cable PullingDocument10 pagesCable PullingnsadnanNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocument16 pagesRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNo ratings yet

- Cable PullingDocument4 pagesCable Pullingtrndem0% (1)

- Transformer Oil Regeneration Issue Based Risk AssessmentDocument2 pagesTransformer Oil Regeneration Issue Based Risk AssessmentMoses Muchakaviri100% (5)

- Lock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Document2 pagesLock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Ionian TribeNo ratings yet

- Electrical Loto ProcedureDocument2 pagesElectrical Loto ProcedureRitesh Dev MaityNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Risk Assessment For Trial Pit Excavation-RevDocument15 pagesRisk Assessment For Trial Pit Excavation-RevRawoofuddin Chand100% (1)

- HIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)Document8 pagesHIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)DEBASISH KHADANGA50% (2)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Risk Assesment For Lighting Protection SystemDocument2 pagesRisk Assesment For Lighting Protection SystemAsfand AyazNo ratings yet

- Electrical Risk Assessment FormDocument1 pageElectrical Risk Assessment FormGyogi MitsutaNo ratings yet

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 pagesRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanNo ratings yet

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- 002 11KV Switchgear JHA Work SheetDocument4 pages002 11KV Switchgear JHA Work SheetWaseem Ahmad100% (1)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead Cranensadnan100% (1)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead Cranensadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- JSA Cable Glanding & Wiring Termination Works 112Document5 pagesJSA Cable Glanding & Wiring Termination Works 112Francis Enriquez Tan83% (6)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- Important Risk Assessment of Wind FarmDocument3 pagesImportant Risk Assessment of Wind FarmRaza Muhammad SoomroNo ratings yet

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Jsa - Cable Termination PDFDocument4 pagesJsa - Cable Termination PDFD FiransyahNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- RA Switchgear and TransformerDocument16 pagesRA Switchgear and Transformeramal100% (1)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- HIRADC - 001 - Installation of Earthing SystemDocument3 pagesHIRADC - 001 - Installation of Earthing SystemZhafri SyazwiNo ratings yet

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- Development of Job Recommender For Alumni Information SystemDocument6 pagesDevelopment of Job Recommender For Alumni Information SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 pagesRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanNo ratings yet

- 6 QualitiesDocument5 pages6 Qualitiesrahmaa04No ratings yet

- Tool Box Talk 2-07 Excavation Egress - OSHADocument3 pagesTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24No ratings yet

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan75% (8)

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- EHS Risk Assessment - 5. DTR ErectionDocument2 pagesEHS Risk Assessment - 5. DTR Erectionshamshu123No ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Operation: Electrical Installation Risk Assessment Assessor: DateDocument4 pagesOperation: Electrical Installation Risk Assessment Assessor: Dateم.عبدالرحيم سلمان100% (1)

- JSA-002-Safety WatchDocument2 pagesJSA-002-Safety WatchNishad MuhammedNo ratings yet

- Contractor Work Method Statement-GIS Parts, Equipmentand ToolsDocument10 pagesContractor Work Method Statement-GIS Parts, Equipmentand ToolsnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanNo ratings yet

- D02 MS Ra Pov PDFDocument35 pagesD02 MS Ra Pov PDFnsadnanNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Midsummer Nights Dream CourseworkDocument6 pagesMidsummer Nights Dream Courseworkafjwdxrctmsmwf100% (2)

- Excretion RevisionDocument7 pagesExcretion RevisionmuskanNo ratings yet

- Barthel Index - English 1Document1 pageBarthel Index - English 1JU WSDNo ratings yet

- Bread of Salt Reader-Response CriticismDocument4 pagesBread of Salt Reader-Response CriticismSrJocelyn L. BetacheNo ratings yet

- Grand Mutondo Viva PresentationDocument25 pagesGrand Mutondo Viva PresentationMwanakomana MberimachenaNo ratings yet

- Triacs and Diac1Document4 pagesTriacs and Diac1Shamsul Haq NtcNo ratings yet

- Clinical Immunology Nima Rezaei Full ChapterDocument51 pagesClinical Immunology Nima Rezaei Full Chaptertim.morrison630100% (15)

- BGP Neighbor Adjacency StatesDocument3 pagesBGP Neighbor Adjacency StatesSon Tran Hong NamNo ratings yet

- Medtronic Company OverviewDocument35 pagesMedtronic Company OverviewIhsan DisiniNo ratings yet

- Special Instruction Heat ExchangerDocument26 pagesSpecial Instruction Heat ExchangerDhiyo MulyadiNo ratings yet

- Mysteries of The Holy RosaryDocument3 pagesMysteries of The Holy RosaryTimothy Justin FranciscoNo ratings yet

- Percentage Boq: Total Amount Without Taxes in Total Amount in WordsDocument4 pagesPercentage Boq: Total Amount Without Taxes in Total Amount in WordsUmesh MishraNo ratings yet

- SAND2022 16425 HyRAMplus 5.0 Technical Reference ManualDocument64 pagesSAND2022 16425 HyRAMplus 5.0 Technical Reference ManualFatima Zahra JirraneNo ratings yet

- Chapter 5 Economic AnalysisDocument15 pagesChapter 5 Economic Analysisabera assefaNo ratings yet

- Jabra Talk 65 Tech Sheet ENDocument2 pagesJabra Talk 65 Tech Sheet ENTaj BurryNo ratings yet

- Frick: Frick® HD Unity Compressor Control PanelDocument10 pagesFrick: Frick® HD Unity Compressor Control PanelGustavo GutierrezNo ratings yet

- MIT18 S096F13 Lecnote14Document34 pagesMIT18 S096F13 Lecnote14eni100% (1)

- Design IconDocument29 pagesDesign Iconคณกฎ ปิยะวงศ์สมบูรณ์No ratings yet

- Tally WorkshopDocument16 pagesTally WorkshopSourashtra tally academyNo ratings yet

- CBSE Class 8 Maths Activity 6Document2 pagesCBSE Class 8 Maths Activity 6vinoth814No ratings yet

- Neoflo 1-68i (IO)Document3 pagesNeoflo 1-68i (IO)Kinni ShenoldNo ratings yet

- Sketching Piecewise Clothoid CurvesDocument8 pagesSketching Piecewise Clothoid Curvesidrissi_toronNo ratings yet

- Satsuma RebellionDocument12 pagesSatsuma RebellionRuh Javier AlontoNo ratings yet

- Measuring Soil Salinity: Viti-Note SummaryDocument2 pagesMeasuring Soil Salinity: Viti-Note SummaryAli Abu ShhiwaNo ratings yet

- Right To Education - Lesson PlanDocument3 pagesRight To Education - Lesson PlanVin Lagasca100% (2)

- MSDS Colateric ZF-50Document3 pagesMSDS Colateric ZF-50mndmattNo ratings yet

- GaussDocument5 pagesGaussJohn Wanyoike MakauNo ratings yet

- Arduino Uno: Arduino Uno R3 Front Arduino Uno R3 BackDocument4 pagesArduino Uno: Arduino Uno R3 Front Arduino Uno R3 Backjuan diegoNo ratings yet