Professional Documents

Culture Documents

4.a Brainstorm Ideas: Template For Brainstorm and 5 Whys

Uploaded by

KavinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.a Brainstorm Ideas: Template For Brainstorm and 5 Whys

Uploaded by

KavinCopyright:

Available Formats

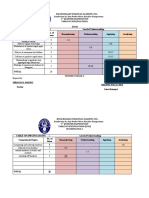

Template for Brainstorm and 5 Whys

Extract of SQF-QA-82-00079 (Rev.B)

4.a Brainstorm Ideas

MAN METHOD MATERIAL

Inadequate CATIA knowledge Wrong 3D ply definition Unexpected material

of new designers (interns) shrinkage

Wrong 2D ply definition

Unskilled operators not meeting

lay-up tolerance requirements

Effect

Flange

thickness

variation

out of

Wrong Lectra cut or program Mix-up between EEOP and No probable causes

tolerance

MEOP

Unanticipated functionality

change due to CATIA Version

upgrade

Grit strip location

LM tool surface

MACHINE MEASUREMENT ENVIRONMENT

Use the above Ishikawa (fish bone) diagram 4a to brainstorm the problem. Use consensus voting to select the three

most probable causes to transfer into table 4 and conduct the 5 Why’s analysis to determine root cause.

The standard categories of HUMAN, MACHINE, METHOD and MATERIAL may be used or any others that are relevant

to the problem.

We select the following reasons to be most significant:

Wrong 2D ply definition in CATIA for Lectra ply cutter resulted in too short plies at the critical

locations.

Inadequate CATIA knowledge of new designers (interns)

STRATA MANUFACTURING PJSC– PO BOX 86519, AL AIN – UNITED ARAB EMIRATES

Template for Brainstorm and 5 Whys

Extract of SQF-QA-82-00079 (Rev.B)

4.b Diagnostics

Why does the problem exist? – Ask Why?

Select the most prominent/probable causes, ask why each occurs and record the answer in the box below. For the

answer you have just recorded ask why again and put the answer in the box below. Continue to do this until you have

exhausted the question why. Some may not require all 5 Y’s, but ensure that the 5 Y’s have been exhausted before

moving to section 5. To the contrary some causes may take more than 5 Y’s, use as many Y’s as required to get down

to the root cause (if more than 5 Y’s are required insert more rows into this document).

When this task is complete, it gives you the root cause/causes. Use table 5 to implement corrective actions to prevent

the failure from occurring again.

Brief description Probable Cause 1 Probable Cause 2 Probable Cause 3

of cause

Why 1 Wrong 2D ply definition in Inadequate CATIA

CATIA for Lectra ply cutter knowledge of new designers

(interns)

Why 2 No verification of the No formal procedure exists

flattened geometry is for training of new personnel

performed against the in the Design Team.

required 3D-boundaries.

Why 3 Inadequate process of

ply flat pattern creation

from the 3D-model

Why 4 Current process of 2D

ply definition has been

based on a presentation

without formal QMS

procedure

Why 5

Action:

1. Create an SQI for design engineers to be guided by when working on 2D ply

definition (flattening). The instruction shall include a verification process, which will

ensure alignment between the original 3D and the outcome 2D ply boundaries.

2. Conduct an internal training for the current design team staff when the new procedure

is released.

STRATA MANUFACTURING PJSC– PO BOX 86519, AL AIN – UNITED ARAB EMIRATES

You might also like

- What Is E-Library?Document5 pagesWhat Is E-Library?Mehedi HasanNo ratings yet

- Psychiatric Rehab PrimerDocument49 pagesPsychiatric Rehab PrimergavinbuzzNo ratings yet

- Lesson - 5.2 - Root Cause Analysis - Improve - PhaseDocument29 pagesLesson - 5.2 - Root Cause Analysis - Improve - Phaseطلال المطيريNo ratings yet

- School Management and Daily Operations: Dr. Dinah F. Mindo Former Director Deped, Region IiiDocument192 pagesSchool Management and Daily Operations: Dr. Dinah F. Mindo Former Director Deped, Region IiiPetRe Biong PamaNo ratings yet

- Effects of Visual Aids in Enhancing The Learning Performance of Students at Elementary Level in District Peshawar (Bushra Khan)Document43 pagesEffects of Visual Aids in Enhancing The Learning Performance of Students at Elementary Level in District Peshawar (Bushra Khan)Muhammad Nawaz Khan Abbasi95% (43)

- Educ 1 Module-Edited Wendell PagonDocument133 pagesEduc 1 Module-Edited Wendell PagonMaureen Betonio100% (2)

- Here: Miller Harley Zoology 8th Edition PDFDocument2 pagesHere: Miller Harley Zoology 8th Edition PDFImam Hamda21% (14)

- LNG The Next Big ThingDocument23 pagesLNG The Next Big Thingyasuni1000No ratings yet

- Kaizen Idea Sheet: CountermeasureDocument1 pageKaizen Idea Sheet: CountermeasurerahulNo ratings yet

- Abaqus CAE Geometry Import and MeshingDocument14 pagesAbaqus CAE Geometry Import and MeshingRam Kumar KesharwaniNo ratings yet

- TQM LeadershipDocument16 pagesTQM LeadershipVikram Vaidyanathan100% (1)

- Modeling Fracture and Failure With AbaqusDocument24 pagesModeling Fracture and Failure With AbaqusFaizan Rashid100% (1)

- Face Mask Detection ProjectDocument57 pagesFace Mask Detection Projectakhil rebelsNo ratings yet

- Six Sigma Green Belt 2. MEASURE (IASSC)Document125 pagesSix Sigma Green Belt 2. MEASURE (IASSC)kachkach zak100% (1)

- The Importance of Continuous Professional Development For EducatorsDocument5 pagesThe Importance of Continuous Professional Development For Educatorsmarian fae Mallari100% (1)

- 8D-2019-109 - Fishbone FixtureDocument2 pages8D-2019-109 - Fishbone FixtureKavinNo ratings yet

- Mca Ass Semester IVDocument12 pagesMca Ass Semester IVvikram vikramNo ratings yet

- EN CMLE Syllabus V2.0Document8 pagesEN CMLE Syllabus V2.0yassinebouazziNo ratings yet

- Software Project Management: Spring Semester, 2020 Time Allowed: 2 HrsDocument3 pagesSoftware Project Management: Spring Semester, 2020 Time Allowed: 2 HrsRitaNo ratings yet

- PPTDocument33 pagesPPTSam SamNo ratings yet

- ATENA-Science-GiD Tutorial FRCDocument50 pagesATENA-Science-GiD Tutorial FRCChris LumyNo ratings yet

- Apparel CAD Evaluation Format Appendix Vii: Section ADocument11 pagesApparel CAD Evaluation Format Appendix Vii: Section APriyanshi GuptaNo ratings yet

- 15ecsc704 576 Kle54-Ecsc704Document5 pages15ecsc704 576 Kle54-Ecsc704Aniket AmbekarNo ratings yet

- Apparel CAD Evaluation Format Appendix Vii: Section ADocument9 pagesApparel CAD Evaluation Format Appendix Vii: Section AVishwanath KrNo ratings yet

- Report Mukul & AbhayDocument76 pagesReport Mukul & AbhayMusic HouseNo ratings yet

- Lab Manual of Advanced Dbms Etcs 457 IndDocument172 pagesLab Manual of Advanced Dbms Etcs 457 IndKulu MollaNo ratings yet

- Tools TRG Module ACT Advance ClusterDocument80 pagesTools TRG Module ACT Advance ClusterSANKUSINo ratings yet

- Dissertation Cad CamDocument7 pagesDissertation Cad CamHelpWithWritingPaperSiouxFalls100% (1)

- Major Project Documentation Final 2Document62 pagesMajor Project Documentation Final 2puppalasai2001No ratings yet

- Lab6a 2-Out-Of-5 To BCD Code Converter and Display CircuitDocument11 pagesLab6a 2-Out-Of-5 To BCD Code Converter and Display CircuitMustafaAsimNo ratings yet

- khảo sát các lỹ thuật tính toán gần đúngDocument33 pageskhảo sát các lỹ thuật tính toán gần đúnghuynhtrongtuan1998No ratings yet

- Test Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeDocument6 pagesTest Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeshaguftaNo ratings yet

- Master of Computer Applications (MCA) : Mca/Assign/Semester-IvDocument12 pagesMaster of Computer Applications (MCA) : Mca/Assign/Semester-IvAnuj JainNo ratings yet

- Master of Computer Applications (MCA) : Mca/Assign/Semester-IvDocument12 pagesMaster of Computer Applications (MCA) : Mca/Assign/Semester-IvShardaNo ratings yet

- Assignment 5 T221Document3 pagesAssignment 5 T221Kedd ZoNo ratings yet

- LabReport 2Document4 pagesLabReport 2durantNo ratings yet

- Parametric Process Optimization To Improve The Accuracy of Rapid Prototyped Stereolithography PartsDocument23 pagesParametric Process Optimization To Improve The Accuracy of Rapid Prototyped Stereolithography Partsasdada1428No ratings yet

- Risk Management Plan On U SATA Hard Drive SSD Interface For Laptops Submitted ToDocument5 pagesRisk Management Plan On U SATA Hard Drive SSD Interface For Laptops Submitted ToRRNo ratings yet

- MSC SimDesigner™ 2010.2 Workbench Edition For CATIA® V5 R19 Release GuideDocument54 pagesMSC SimDesigner™ 2010.2 Workbench Edition For CATIA® V5 R19 Release GuideMSC.Software100% (1)

- Fundamentals of Additive Manufacturing Technologies - Unit 6 - Week 4 - Liquid Additive ManufacturingDocument2 pagesFundamentals of Additive Manufacturing Technologies - Unit 6 - Week 4 - Liquid Additive ManufacturingSaurav KumarNo ratings yet

- Dynamic and Progressive Filter Pruning For Compressing Convolutional Neural Networks From ScratchDocument9 pagesDynamic and Progressive Filter Pruning For Compressing Convolutional Neural Networks From ScratchisharkNo ratings yet

- 23MEE115 - Manufacturing Practice - WorksheetDocument40 pages23MEE115 - Manufacturing Practice - WorksheetvasanthjeeaspirantNo ratings yet

- Predicting and Preventing WarpageDocument21 pagesPredicting and Preventing WarpageChen Zhi shenNo ratings yet

- 10 Ways To Fix SETUP and HOLD Violation: Static Timing Analysis (STA) Basic (Part-8) - VLSI ConceptsDocument6 pages10 Ways To Fix SETUP and HOLD Violation: Static Timing Analysis (STA) Basic (Part-8) - VLSI ConceptsAbhi AggarwalNo ratings yet

- ISCC20 Project Documentation TemplateDocument12 pagesISCC20 Project Documentation TemplateChristian DemavivasNo ratings yet

- RAK Clarity3DLayout Cut-and-Stitch FlowDocument36 pagesRAK Clarity3DLayout Cut-and-Stitch FlowLê ChíNo ratings yet

- Semester-IV: Computer Networking Course Code: 4340703Document10 pagesSemester-IV: Computer Networking Course Code: 4340703Zaidali BurmawalaNo ratings yet

- Thesis On Machine VisionDocument7 pagesThesis On Machine Visionannjohnsoncincinnati100% (2)

- KPMG VI New Raw Data Update FinalDocument3,697 pagesKPMG VI New Raw Data Update FinalhkNo ratings yet

- Acsse Ifm03b3 2020 Sa1-1 ST1-1-QPDocument6 pagesAcsse Ifm03b3 2020 Sa1-1 ST1-1-QPTreciouh MNo ratings yet

- Ain Shams University Faculty of EngineeringDocument3 pagesAin Shams University Faculty of EngineeringRitaNo ratings yet

- EE038-3-2-ESA APU2F2302ENG Assignment QPDocument9 pagesEE038-3-2-ESA APU2F2302ENG Assignment QPRegarian TaringNo ratings yet

- University of Mauritius: November/December 2013Document9 pagesUniversity of Mauritius: November/December 2013my pcNo ratings yet

- FEMAP Solid Modeling Workflow: A Seminar For FEMAP and NX Nastran UsersDocument26 pagesFEMAP Solid Modeling Workflow: A Seminar For FEMAP and NX Nastran Users127blablaprNo ratings yet

- VCAS 2022 Paper 632Document9 pagesVCAS 2022 Paper 632Prashant PrashantNo ratings yet

- Master of Computer Applications (MCA) : Mca/Assign/Semester-IvDocument12 pagesMaster of Computer Applications (MCA) : Mca/Assign/Semester-IvRakhi GuptaNo ratings yet

- PBK CPP File FormatDocument9 pagesPBK CPP File FormatSneha Khule -51No ratings yet

- Mini Project Report FormatDocument16 pagesMini Project Report Formatdhdw kwhdhwNo ratings yet

- 2010 03 09 Dmbok and CDMPDocument31 pages2010 03 09 Dmbok and CDMPKicrut KerenNo ratings yet

- Project Doc Part 1Document19 pagesProject Doc Part 1Abdulaziz ShaikhNo ratings yet

- Coppa IN - AssignmentDocument8 pagesCoppa IN - AssignmentjasperNo ratings yet

- 1.LAB REPORT EVALUATION FORM MEM564 (SESSION 3 & 4) Rev1.1Document3 pages1.LAB REPORT EVALUATION FORM MEM564 (SESSION 3 & 4) Rev1.1Izzam HarithNo ratings yet

- Automatic Visual Inspection of Printed Circuit Board For Defect Detection and ClassificationDocument6 pagesAutomatic Visual Inspection of Printed Circuit Board For Defect Detection and ClassificationAldemir SilvaNo ratings yet

- B.Tech Mini Project Document TemplateDocument38 pagesB.Tech Mini Project Document TemplateKeerthana RaoNo ratings yet

- 2019-TAX4438-Tutor Marked Assignments PDFDocument8 pages2019-TAX4438-Tutor Marked Assignments PDFHasun MalingaNo ratings yet

- Effect of Shrinkage On The Design and Manufacture of Plastic PartDocument87 pagesEffect of Shrinkage On The Design and Manufacture of Plastic PartAbhinav MishraNo ratings yet

- ParabolaDocument73 pagesParabolaGlaieza Claire SajulgaNo ratings yet

- Detailed-Lesson-Plan-Literalandfigurativespeech-Newest (1) (AutoRecovered)Document5 pagesDetailed-Lesson-Plan-Literalandfigurativespeech-Newest (1) (AutoRecovered)Natanohj BuezaNo ratings yet

- Homework PolicyDocument4 pagesHomework Policyapi-284668628No ratings yet

- Lesson Plan The Greenhouse EffectDocument3 pagesLesson Plan The Greenhouse Effectapi-263275919No ratings yet

- Lesson Plan 3rd Grade OldenburgDocument4 pagesLesson Plan 3rd Grade Oldenburgapi-243788225100% (1)

- IISTE May 30th Edition Peer Reviewed ArtDocument6 pagesIISTE May 30th Edition Peer Reviewed ArtSaiNo ratings yet

- Physical Education in Schools: A Global Perspective: Ken HardmanDocument24 pagesPhysical Education in Schools: A Global Perspective: Ken HardmanLianne Grace De VeraNo ratings yet

- Wenz's ResumeDocument1 pageWenz's ResumeWenz XingNo ratings yet

- French Weekend Worksheet - 2Document2 pagesFrench Weekend Worksheet - 2jivayNo ratings yet

- 3 - The McKinsey 7SDocument6 pages3 - The McKinsey 7SAlex SimmonsNo ratings yet

- Ten Ways To Make Lectures More DynamicDocument3 pagesTen Ways To Make Lectures More DynamicindahmuliasariNo ratings yet

- 2 - Entrepreneurial Thinking and Decision Making ProcessDocument18 pages2 - Entrepreneurial Thinking and Decision Making ProcessTu TranNo ratings yet

- What To Say To Candidates in An ExamDocument9 pagesWhat To Say To Candidates in An ExamNalin SureshNo ratings yet

- Tos PeriodicalDocument14 pagesTos Periodicalynid wageNo ratings yet

- Iitm Spoc Wkshop PPT 01Document33 pagesIitm Spoc Wkshop PPT 01Balaji VenkataramanNo ratings yet

- I Will Not Let An Exam Result Decide My FateDocument3 pagesI Will Not Let An Exam Result Decide My FateAbdul KadirNo ratings yet

- LTFH Digital Sakhi Empowering Women Through Digital FinanceDocument7 pagesLTFH Digital Sakhi Empowering Women Through Digital Financesunnykumar.m2325No ratings yet

- Test AmeeshDocument7 pagesTest AmeeshUdit DravidNo ratings yet

- Bachelor of Science in Office AdministrationDocument2 pagesBachelor of Science in Office AdministrationRuel NezortadoNo ratings yet

- Các công thức viết lại câu hay gặpDocument13 pagesCác công thức viết lại câu hay gặpHà ThủyNo ratings yet

- BA in Management Program Spring 2021 FIN301 Financial ManagementDocument7 pagesBA in Management Program Spring 2021 FIN301 Financial Managementgeorge fireproofNo ratings yet

- Britannia CVDocument3 pagesBritannia CVJay jayNo ratings yet