Professional Documents

Culture Documents

Description: M0300 Strap-On Saddle Flow Meter

Uploaded by

Jamesh BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Description: M0300 Strap-On Saddle Flow Meter

Uploaded by

Jamesh BabuCopyright:

Available Formats

Specification Sheet

M0300 Strap-on Saddle Flow Meter

DESCRIPTION

All Mc Propeller flow meters are manufactured

to comply with applicable provisions of AWWA

Standard No. C704-02 for propeller-type flow

meters.

FEATURES

Saddle

• The fabricated stainless steel saddle

eliminates the fatigue-related breakage

common to cast iron and aluminum saddles

and provides unsurpassed corrosion

protection.

• Fabricated stainless steel construction offers

the additional advantage of being flexible

enough to conform to out-of-true pipe.

Impellers

• Impellers are manufactured of high-impact

plastic, capable of retaining their shape and Typical Applications

accuracy over the life of the meter.

• Each impeller is individually calibrated at • Center pivot systems

the factory to accommodate the use of any • Sprinkler irrigation systems

standard McCrometer register, and since no • Drip irrigation systems

change gears are used, the M0300 can be

field-serviced without the need for factory • Golf course and park water management

recalibration. • Gravity turnouts from underground pipelines

Bearings • Commercial nurseries

• Factory lubricated, stainless steel bearings • Water and wastewater management

are used to support the impeller shaft.

• The shielded bearing design limits the entry

of materials and fluids into the bearing

chamber providing maximum bearing

protection. • The register housing protects both the register

and cable drive system from moisture while

Register

allowing clear reading of the flowrate indicator

• The instantaneous flowrate indicator is and totalizer.

standard and available in gallons per minute,

cubic feet per second, liters per second and

other units.

• The register is driven by a flexible steel cable

with a magnetically coupled drive, encased

within a protective vinyl liner.

24517-00 Rev. 2.3 | 23MAR2020

Specification Sheet

M0300 Strap-on Saddle Flow Meter

SPECIFICATIONS

Performance

• ±2% of reading guaranteed throughout full range

Accuracy /

• ±1% over reduced range

Repeatability

• Repeatability 0.25% or better

Range 4” to 16”

Maximum

(Standard Construction) 160°F constant

Temperature

Pressure Rating 150 psi. Consult factory for higher rated version.

Materials

Saddle 304 stainless steel construction

Bearing Assembly Impeller shaft is 316 stainless steel. Ball bearings are 440C stainless steel

Magnets (Permanent type) Alnico

Bearing Housing For models 4” to 16”: 304 stainless steel standard, 316 stainless steel optional

Register An instantaneous flowrate indicator and six-digit straight-reading totalizer are

standard. The register is hermetically sealed within a die cast aluminum case.

This protective housing includes a domed acrylic lens and hinged lens cover with

locking hasp.

Impeller Impellers are manufactured of high-impact plastic, retaining their shape and

accuracy over the life of the meter.

Options

• Extended warranty

• Register extensions

• High temperature construction, 180°F max

• Marathon bearing assembly for higher than normal flowrates 4” and larger

• Digital register available in all sizes of this model

• A complete line of flow recording / control instrumentation

• Canopy boot

• Saddle can be constructed to fit any outside diameter pipe dimensions, including

metric sizes.

• Blank repair saddle

• Can be used on a variety of pipe materials such as steel, plastic, cast iron, cement or

asbestos cement

• Straightening vanes

Page 2 24517-00 Rev. 2.3 | 23MAR2020

Specification Sheet

M0300 Strap-on Saddle Flow Meter

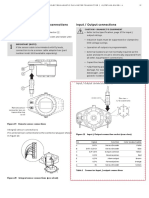

DIMENSIONS

FLOW

M0300 DIMENSIONS

Meter and Nominal Pipe Size 4 6 8 10 12 14 16

OD up to (inches) 5.5 7.5 9.5 11.5 13.5 15.5 17.5

Minimum Flow U.S. GPM 50 90 100 125 150 250 275

Maximum Flow U.S. GPM 600 1200 1500 1800 2500 3000 4000

Max. Flow w/Marathon Bearing 900 1800 2250 2700 3750 4500 6000

Approx. Head Loss in Inches at Max. Flow 23.00 17.00 6.75 3.75 2.75 2.00 1.75

1000/ 1800/ 2500/ 3K/ 4K/ 6K/ 8K/

Standard Dial Face (GPM/Gal) * 100 100 100 1000 1000 1000 1000

A (inches) 7 5/8 15 15 15 15 15 15

B (inches) 8 1/4 10 3/4 10 3/4 10 3/4 11 3/4 13 3/4 13 3/4

C (inches) 7 8 8 9 1/2 9 1/2 9 1/2 9 1/2

D (inches) 4** 5 1/8** 6** 7** 7 1/4 7 1/4 7 1/4

E (inches) 10 3/4 14 15 17 19 20 5/8 21 5/8

Approx. Shipping Weight-lbs. 12 17 21 24 28 28 30

*Indicates the dial face range and multiplier

**Standard pipe only. For other than standard pipe, consult factory for cutout dimensions.

For larger sizes see Model M1400.

McCrometer reserves the right to change design or specification without notice.

Please specify the inside diameter of the pipe when ordering.

Page 3 24517-00 Rev. 2.3 | 23MAR2020

SADDLE Specification Sheet

M0300 Strap-on Saddle Flow Meter

INSTALLATION

Standard installation is horizontal mount. If the meter is to be mounted in the vertical position, please advise

the factory.

PIPE RUN REQUIREMENTS

Configuration A B

Without straightening vanes 10 1

With straightening vanes 5 1

With FS100 Flow Straightener 1.5 1

w B

Flo

15”

Measure 15” from center of

ell to determine average

location of the propeller tip.

Elbow shown - Other piping components can be

pumps, valves and expansions or reductions

STRAIGHTENING VANES

Special attention should be given to systems using two elbows “out of plane” or devices such as a centrifugal

sand separator. These cause swirling flow in the line that affect propeller meters. Well developed swirls can

travel up to 100 diameters downstream if unobstructed. Since most installations have less than 100 diameters

to work with, straightening vanes become necessary to alleviate the problem. Straightening vanes will break

up most swirls and ensure more accurate measurement. McCrometer actively encourages installing vanes just

ahead of the meter. Straightening vanes are available in weld-in, bolt-in, and the FS100 Flow Straightener.

Elbows out of plane Bolt-in straightening vanes FS100 Flow Straightener

Page 4 24517-00 Rev. 2.3 | 23MAR2020

Specification Sheet

M0300 Strap-on Saddle Flow Meter

TOTALIZERS

Typical face plates

2500 2500

2000 3000 2000 3000

1500 3500 1500 3500

1000 4000 1000 4000

500 4500 500 4500

0 9 2 5 4 5 0 9 2 5 4 5 7

0 5000 0 5000

Standard register Optional 7-wheel totalizer FlowCom register

Mechanical Totalizer

The instantaneous flowrate indicator is standard and available in gallons per

minute, cubic feet per second, liters per second and other units. The register is

driven by a flexible steel cable encased within a protective vinyl liner. The register

housing protects both the register and cable drive system from moisture while

allowing clear reading of the flowrate indicator and totalizer.

Digital Totalizer

The optional FlowCom register displays a flowmeter’s flowrate and volumetric

total. Available are optional outputs: scaled pulse and/or industry standard

4-20mA signal. The FlowCom can be fitted to any new or existing McCrometer

propeller flowmeter.

Wireless Telemetry

The optional FlowConnect is designed specifically for wireless telemetry via either

satellite or cellular data service. Manual meter reading is never required. It uses

either the mechanical register or the digital register (both shown above).

You can determine how often readings are made and transmitted to the cloud

database, which you can view on a PC or on a cell phone. The viewing utility

provides data tools that can analyze flow rate, consumption, and possible

anomalies in an irrigation system.

Copyright © 2001-2019 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published pricing,

technical data, and instructions are subject to change without notice. Contact your McCrometer representative for current pricing, technical data, and instructions.

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078

www.mccrometer.com

Page 5 24517-00 Rev. 2.3 | 23MAR2020

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Specification Sheet Bolt-On Saddle Flow Meter Model: DescriptionDocument2 pagesSpecification Sheet Bolt-On Saddle Flow Meter Model: Descriptioncontrol1y1segu-65318No ratings yet

- Merilnik Pretoka S Turbino 1500 BalancedDocument4 pagesMerilnik Pretoka S Turbino 1500 BalancedIvan MatijevićNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Nuflo Ez-InDocument8 pagesNuflo Ez-InAnonymous Wu6FDjbNo ratings yet

- Turbine Meter NufloDocument8 pagesTurbine Meter NufloJaime SeguraNo ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Meters b042 Bro GB Rev2Document12 pagesMeters b042 Bro GB Rev2onizuka-t2263No ratings yet

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- FLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFDocument6 pagesFLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFOctavio CharryNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNo ratings yet

- NuFlo Liquid Turbine FlowmetersDocument6 pagesNuFlo Liquid Turbine FlowmetersphostyNo ratings yet

- Barton 7000 PDFDocument8 pagesBarton 7000 PDFmbloexNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- SATAM-zc17-12 24 48 80 150 250 330Document2 pagesSATAM-zc17-12 24 48 80 150 250 330Mr. AlferditomaNo ratings yet

- Section 21 - Liquid Turbine MeterDocument9 pagesSection 21 - Liquid Turbine MeterhammamiNo ratings yet

- Flowmeter For Boiler Vzo 25Document16 pagesFlowmeter For Boiler Vzo 25jebisiNo ratings yet

- DB Turbine Sa SeriesDocument4 pagesDB Turbine Sa Seriespenelopezeus39No ratings yet

- Ge Dresser HPC Meter Spec SheetDocument4 pagesGe Dresser HPC Meter Spec SheetfharishputraNo ratings yet

- MAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetDocument4 pagesMAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetPhilippe jean-louisNo ratings yet

- Pompa EbaraDocument24 pagesPompa Ebaraahsan sunartoNo ratings yet

- Cold Water: Rubin Meistream, Meistream PlusDocument12 pagesCold Water: Rubin Meistream, Meistream PlusAgus SuwardonoNo ratings yet

- Datasheet Hi Cart Meter SpecDocument4 pagesDatasheet Hi Cart Meter SpeccartarNo ratings yet

- Sbin 001Document24 pagesSbin 001Julián CamargoNo ratings yet

- SMS ColdPilgerMillsDocument8 pagesSMS ColdPilgerMillsSUNILNo ratings yet

- Technical Brochure: Multi-Stage Centrifugal PumpDocument4 pagesTechnical Brochure: Multi-Stage Centrifugal PumpcurlyjockeyNo ratings yet

- ValvesDocument8 pagesValvespravin_2011No ratings yet

- General Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentDocument18 pagesGeneral Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentLoki C GowdaNo ratings yet

- Barton 7000Document8 pagesBarton 7000Abrakain69No ratings yet

- Torque Systems Ms400 SpecsheetDocument2 pagesTorque Systems Ms400 SpecsheetElectromateNo ratings yet

- Hdl5530Thb6365E: Boom Pump-63MDocument2 pagesHdl5530Thb6365E: Boom Pump-63MAkhmad SebehNo ratings yet

- Optiflux 1000Document8 pagesOptiflux 1000Sudipto MajumderNo ratings yet

- Visual Flow Indicator Guide from Flow-MonDocument12 pagesVisual Flow Indicator Guide from Flow-Mondhanu_aquaNo ratings yet

- FC81081Document2 pagesFC81081Khalid ZaeemNo ratings yet

- Pre StressingDocument48 pagesPre StressingRameshNo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- 1c Elster Kent Optima 100 Water Meter Brochure PDFDocument4 pages1c Elster Kent Optima 100 Water Meter Brochure PDFRoy.markunNo ratings yet

- "A" Series: Gas MetersDocument4 pages"A" Series: Gas Meterszeeshan tanveerNo ratings yet

- Hdl5410Thb5254E: Boom Pump-52MDocument2 pagesHdl5410Thb5254E: Boom Pump-52MAkhmad SebehNo ratings yet

- BB3 Catalogue 2015Document8 pagesBB3 Catalogue 2015nima hasanzadehNo ratings yet

- M Orbitales A PDFDocument20 pagesM Orbitales A PDFAcu TomeiNo ratings yet

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersDocument7 pages2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraNo ratings yet

- CopperalloybrakeDocument4 pagesCopperalloybrakeReinaldo Side JuniorNo ratings yet

- ABAC Air Receiver Leaflet English LRDocument6 pagesABAC Air Receiver Leaflet English LRmogwai71No ratings yet

- Tur-Flwmtr Nf00152 0912fDocument2 pagesTur-Flwmtr Nf00152 0912fAntonio ImperiNo ratings yet

- KOLLER Product Catalogue Rev12Document100 pagesKOLLER Product Catalogue Rev12maxim27100% (1)

- Brochure - SPM 2002 Iron Products - 3-25-21Document20 pagesBrochure - SPM 2002 Iron Products - 3-25-21walter moreno vegaNo ratings yet

- BmaDocument6 pagesBmaraouf youssefNo ratings yet

- Brochure Liquid Flow MeterDocument12 pagesBrochure Liquid Flow MeterErick Perez MoralesNo ratings yet

- Blancett b133-300Document4 pagesBlancett b133-300frankurt1No ratings yet

- Technical Brochure: Submersible 4" Non-Clog Sewage PumpDocument4 pagesTechnical Brochure: Submersible 4" Non-Clog Sewage PumpLisandro Torrealba MedranoNo ratings yet

- RacorVMT AquaPro Pumps BulletinDocument2 pagesRacorVMT AquaPro Pumps BulletinAzril DahariNo ratings yet

- ABAC Air Receiver LeafletDocument6 pagesABAC Air Receiver LeafletRakesh ReddyNo ratings yet

- Longitudinal SeamDocument8 pagesLongitudinal SeamKauane FeliniNo ratings yet

- Halliburton Liquid Turbine Meters Data SheetDocument6 pagesHalliburton Liquid Turbine Meters Data SheetPaul Alejandro CampoverdeNo ratings yet

- Lorentz Water-Meter Manual en PDFDocument4 pagesLorentz Water-Meter Manual en PDFLuis RolaNo ratings yet

- Am ItDocument27 pagesAm Itakalbhor90No ratings yet

- Satam Zc17-B037-Bro-Gb-Rev3Document2 pagesSatam Zc17-B037-Bro-Gb-Rev3warung1bensinNo ratings yet

- 10-3 Primary Elements PDFDocument10 pages10-3 Primary Elements PDFAbderrahmaneTemhachetNo ratings yet

- ABB Ability Verification For Measurement Devices: SRV500 EnhancedDocument42 pagesABB Ability Verification For Measurement Devices: SRV500 EnhancedJamesh BabuNo ratings yet

- Description: Dura Mag Flow Meter With Procomm ConverterDocument6 pagesDescription: Dura Mag Flow Meter With Procomm ConverterJamesh BabuNo ratings yet

- Ci Fex300 Fex500-En HDocument76 pagesCi Fex300 Fex500-En HJamesh BabuNo ratings yet

- ABB Aquamaster3&4 Terminal ConnectionDocument2 pagesABB Aquamaster3&4 Terminal ConnectionJamesh BabuNo ratings yet

- MA WATERFLUX3070 V3 en 200520 4004999702 R02Document96 pagesMA WATERFLUX3070 V3 en 200520 4004999702 R02Jamesh BabuNo ratings yet

- MC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationDocument4 pagesMC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationJamesh BabuNo ratings yet

- Flow Tool Siemens MAG 8000Document18 pagesFlow Tool Siemens MAG 8000Jamesh BabuNo ratings yet

- Mag 8000 Oi en En-UsDocument165 pagesMag 8000 Oi en En-UsJamesh BabuNo ratings yet

- Ultrasonic, level, flow meters, switches proposalDocument5 pagesUltrasonic, level, flow meters, switches proposalJamesh BabuNo ratings yet

- Waagner Biro Model Code Clarification 2Document1 pageWaagner Biro Model Code Clarification 2Jamesh BabuNo ratings yet

- 43 PDFDocument10 pages43 PDFJamesh BabuNo ratings yet

- Fpi Mag Flow Meter With Procomm ConverterDocument10 pagesFpi Mag Flow Meter With Procomm ConverterJamesh Babu0% (1)

- My InvitationDocument1 pageMy InvitationJamesh BabuNo ratings yet

- Getting Started with HTML - An IntroductionDocument14 pagesGetting Started with HTML - An IntroductionJamesh BabuNo ratings yet

- WP Flwins 1Document1 pageWP Flwins 1Jamesh BabuNo ratings yet

- Getting Started with HTML - An IntroductionDocument14 pagesGetting Started with HTML - An IntroductionJamesh BabuNo ratings yet

- Gas Density MeasurementDocument31 pagesGas Density MeasurementJamesh BabuNo ratings yet

- FET 200 Aquamaster TransmiterDocument48 pagesFET 200 Aquamaster TransmiterJamesh BabuNo ratings yet

- Transmitter SpecsDocument40 pagesTransmitter SpecsJamesh BabuNo ratings yet

- DS Wm-En XDocument20 pagesDS Wm-En XJamesh BabuNo ratings yet

- Republic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Document14 pagesRepublic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Juvy BustamanteNo ratings yet

- DBMS Notes For BCADocument9 pagesDBMS Notes For BCAarndm8967% (6)

- Structural Knowledge LEEERRR PDFDocument22 pagesStructural Knowledge LEEERRR PDFMaría Paula BaqueroNo ratings yet

- Preschool ADHD QuestionnaireDocument2 pagesPreschool ADHD QuestionnaireAnnaNo ratings yet

- MC61ADocument5 pagesMC61AAlison Foster100% (1)

- Haven, Quantum Social ScienceDocument306 pagesHaven, Quantum Social ScienceMichael H. HejaziNo ratings yet

- Class9-NTSE MATH WORKSHEETDocument4 pagesClass9-NTSE MATH WORKSHEETJeetu RaoNo ratings yet

- R V Akeemly Grant & Andre WilliamsDocument5 pagesR V Akeemly Grant & Andre WilliamsKerry-Ann WilsonNo ratings yet

- Happy Shopping PDFDocument21 pagesHappy Shopping PDFVinutha NayakNo ratings yet

- Cardio Fitt Pin PostersDocument5 pagesCardio Fitt Pin Postersapi-385952225No ratings yet

- Abstract & Concrete NounsDocument2 pagesAbstract & Concrete NounsSitifatimah92No ratings yet

- POMR Satiti Acute CholangitisDocument30 pagesPOMR Satiti Acute CholangitisIka AyuNo ratings yet

- Aspen Separation Unit-OpsDocument25 pagesAspen Separation Unit-Opsedwin dableoNo ratings yet

- Mac 2009Document60 pagesMac 2009Ridwan Pramudya100% (1)

- Kma 252 Exam 18 NewstyleDocument19 pagesKma 252 Exam 18 NewstyleSebin GeorgeNo ratings yet

- PreciControl CMV IgG Avidity - Ms - 05942322190.V4.EnDocument2 pagesPreciControl CMV IgG Avidity - Ms - 05942322190.V4.EnARIF AHAMMED PNo ratings yet

- Maximizing Emissions Control with Compact Fume ExtractionDocument9 pagesMaximizing Emissions Control with Compact Fume ExtractionS Ray Chaudhury100% (1)

- Hotel Training ReportDocument14 pagesHotel Training ReportButchick Concepcion Malasa100% (1)

- Farmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptDocument87 pagesFarmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptYemima MNo ratings yet

- Business Ethics Q3 Mod2 Foundations of The Principles of Business1Document5 pagesBusiness Ethics Q3 Mod2 Foundations of The Principles of Business1Julie CabusaoNo ratings yet

- Personal SWOT AnalysisDocument8 pagesPersonal SWOT AnalysisNamNo ratings yet

- Hsslive Xii History All in One Notes 2023 by SujithDocument72 pagesHsslive Xii History All in One Notes 2023 by SujithKanupriya AgnihotriNo ratings yet

- Mystic Mystique Face Reading-IIDocument10 pagesMystic Mystique Face Reading-IIVijay KumarNo ratings yet

- Philippine School Action Plan for Scouting ProgramDocument1 pagePhilippine School Action Plan for Scouting ProgramLaira Joy Salvador - ViernesNo ratings yet

- ASTM G 38 - 73 r95Document7 pagesASTM G 38 - 73 r95Samuel EduardoNo ratings yet

- Itm Guia Rapida Tds 600 Tipo4 Ed1 EspDocument148 pagesItm Guia Rapida Tds 600 Tipo4 Ed1 Espcamel2003No ratings yet

- Example For Chapter - 2Document16 pagesExample For Chapter - 2sahle mamoNo ratings yet

- Compare and Contrast History EssayDocument9 pagesCompare and Contrast History EssayGiselle PosadaNo ratings yet

- Downfall of Ayub Khan and Rise of Zulfikar Ali BhuttoDocument9 pagesDownfall of Ayub Khan and Rise of Zulfikar Ali Bhuttoabdullah sheikhNo ratings yet

- 3rd Simposium On SCCDocument11 pages3rd Simposium On SCCNuno FerreiraNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet