Professional Documents

Culture Documents

Estimating Tank Service Life Made Perfectly Clear: Information Bulletin

Uploaded by

Francisco Javier Torres AlvaradoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimating Tank Service Life Made Perfectly Clear: Information Bulletin

Uploaded by

Francisco Javier Torres AlvaradoCopyright:

Available Formats

Tanks & Domes

Glass Tanks with a Heart of Steel™

Information Bulletin

Estimating Tank Service Life

Made Perfectly Clear

When conducting a life cycle cost (LCC) analysis for a storage tank, estimating the life expectancy of the tank is very

important. Life expectancy affects the period of evaluation, salvage value and ultimately the total life cycle cost.

There are several different ways of reliably estimating tank life. A recent article by Mr. Bill Neighbors in the July 2010

Water and Wastes Digest titled “Specify Wisely” is one method, purely the opinion of one supplier, that appears to

lack substantiated third-party accreditation.

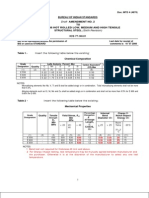

The table below (Figure 1) from the “Specify Wisely” article describes a concept called PDT (Plate Design Thickness)

to estimate tank life, but does not detail how PDT is calculated and does not reference any third-party independent

source that recognizes the PDT methodology. The table implies that several noteworthy standards organizations

estimate tank life using PDT. These organizations do not reference this PDT methodology in the standards noted in

the table.

Figure 1

Design Code Construction Type

LIQ Fusion 7000

Other Coated Tanks

Glass/Vitreous The article implies that one should only use plate

FBE Tanks Enamel Tanks

Service Service Service

thickness as a reliable method for estimating

PDT* PDT* PDT*

Life** Life** Life** tank life. Plate thickness is only one potential

AWWA D102 Bolted 40- 60-80+ 30+ 40+ 30+ 30-40

factor that should be used in an analysis. Plate

AWWA D100 Welded N/A N/A 40+ 60-80+ N/A N/A

FM 4020 Bolted, Welded 40+ 60-80+ 30+ 40+ 30+ 30-40

thickness can have some bearing on the service

FM Principles (not a valid listing) N/A N/A 10+ 10-15+ N/A N/A life of tanks that undergo attack from a failure in

NFPA-22 Bolted, Welded 40+ 60-80+ 30+ 40+ 30+ 30-40 the paint or coating system. It is important to

AISC Bolted, Welded, Hybrid 40+ 60-80+ 20+ 20-30+ 25+ 25-30+ remember that every time a tank is sandblasted

EN 15282 Bolted - Glass Coated N/A N/A N/A N/A 25+ 25-30+

in preparation for repainting, plate thickness can

API 650 Welded N/A N/A 40+ 60-80+ N/A N/A

* PDT: Plate design thickness in years. A function of steel tank design.

be jeopardized.

**Service life in years: A function of periodic maintenence and coatings. Source: Water and Wastes Digest; July 2010

Plate thickness has much less impact on the service life of tanks that utilize field proven coating systems that are

truly fused to the steel plates such as glass-fused-to-steel technology. A properly coated sheet, incorporated into a

professionally engineered tank design, does not rely on the thickness of the plate alone for maximum longevity.

None of the standards listed in the above table reference the term PDT and many of the standards listed do not even

address tank service life. One exception is EN 15282 (also known as ISO 28765), which actually addresses and

defines terms like design life, service life, etc. through direct references to the ISO 15686-1 standard (Building and

Constructed Assets – Service Life Planning – Part 1: General Principals). ISO 15686 is a comprehensive guide to

service life planning and estimating and provides defined methodologies for calculating service life published by a

reputable, well respected, third-party standards organization.

The ISO calculation starts with Reference Service Life (RSL). RSL is the service life that a structure would expect in a

certain, reference set of in-use conditions. Factors relating to the quality of the structure components, the design

level of the structure, the work execution level, the interior operating environment, the exterior environment, the in-use

operating conditions and finally the maintenance levels anticipated are then applied to the RSL.

Engineered Storage Products Company

345 Harvestore Drive • DeKalb, IL 60155

815-756-1551 • info@engstorage.com

(IB 1002) www.aquastore.com

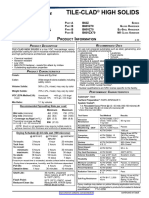

The following table (Figure 2) provides an overview of a typical analysis under ISO 15686 as it relates to AWWA D103, a

widely accepted standard for water storage tanks with glass-fused-to-steel coating technology.

Figure 2

ISO 15686 Methodology for Determination Relevant Conditions

of Estimated Service Life To include: Poor (0.8) Assumed Reference (1.0) Good (1.2) Rankings

Inherent quality A Quality of Components Material type and/or grade Not to AWWA D103 Meets AWWA D103 Exceeds AWWA D103 Glass = 1.0

characteristics Durability features – e.g. Less than AWWA Meets AWWA D103 Exceeds AWWA D103 Glass = 1.2

protection system - coatings D103

B Design Level Details of construction e.g. Less than AWWA Meets AWWA D103 Exceeds AWWA D103 Glass = 1.0

joints, fixings, etc. D103

C Work Execution Level Factory quality systems, Not ISO 9001, No Not ISO 9001 (not ISO 9001; all site Glass = 1.2

site work programs ability to repair site required by AWWA); site changes & damage able

changes or damage changes & damage able to be repaired

to be repaired

Environment D Interior environment Special features – Accelerated effect Moderate effect from Limited or reduced Glass = 1.0

e.g. condensation, immersion, from interior interior environment effect from interior

etc. environment environment

E Exterior environment Special features – e.g. Accelerated effect Moderate effect from Limited or reduced Glass = 1.2

marine, polluted, acid rain, from exterior exterior environment effect from exterior

etc. environment environment

Operation Conditions F In-use conditions Special features, e.g. Difficult to repair Moderate effort to Easy to repair Glass = 1.2

vandalism repair

G Maintenance Level Cyclical, including quality & Frequent, costly Moderate Limited and low cost Glass = 1.2

level required

The formula from ISO 15686 to calculate the Estimated Service Life (ESL) is

ESL = RSL x A x B x C x D x E x F x G

where A, B, C, D, E, F, G refer to the scores from the chart above, and the RSL is based on actual in-use experience or

projected life from testing protocols. A recent survey of glass-fused-to-steel tanks showed that over 95% of the 800+

glass-fused-to-steel tanks that were erected over 20 years ago and over 30 tanks that were erected over

30 years ago are still in service. Based on this data from actual field installations, an RSL of 40 years for glass tanks

is justifiable. The calculation for ESL for a glass-fused-to-steel tank is then

ESL Glass = 40 x 1.0 x 1.2 x 1.0 x 1.2 x 1.0 x 1.2 x 1.2 x 1.2 = 99 years (a 2.488 multiple on RSL)

Using this recognized, third-party process for estimating a tank life of 99 years for a glass-fused-to-steel

provides a dramatically different perspective than the unreferenced method described in the “Specify Wisely”

article. The ISO based approach allows the user to compare different products and derive their own views of relative

merits. The ISO based method is an example of appropriate and published methodology to assist engineers and

operators making important technology decisions for their water storage requirements.

The values used to estimate tank service life should be based on the most accurate and pertinent information

available. The Government even prioritizes the sources of this data(1) with the highest reliability being derived from

actual performance data of the specific product under similar, if not identical, service conditions. Some tank

manufacturers claim to have superior tank service life based on a coating process with less than 5 years of actual

in-service experience. They try to bolster their claims by making references to tanks manufactured by other suppliers

using other coatings. The fact is that the most reliable estimation of tank service life is derived from actual installation

data that truly demonstrates 20-30+ year service life.

When you are analyzing the potential tank service life of multiple coating systems, use a reputable, third-party method

based on actual product performance history to help you make your decision. The results will show that Aquastore’s®

glass-fused-to-steel tanks are clearly the best choice.

References

United States Government Accounting Office “GAO Cost Estimating and Assessment Guide,” GAO-09-3SP, March

(1)

2009

Engineered Storage Products Company

345 Harvestore Drive • DeKalb, IL 60155

815-756-1551 • info@engstorage.com

(IB 1002) www.aquastore.com

You might also like

- Duplex Coatings Over HDG-Researchgate ReportDocument19 pagesDuplex Coatings Over HDG-Researchgate ReportRyanNo ratings yet

- STJLR.50.5041 2009Document9 pagesSTJLR.50.5041 2009Jason-chungNo ratings yet

- 1. Bom - Scissor Lift 2.5 tDocument7 pages1. Bom - Scissor Lift 2.5 tInward QCNo ratings yet

- Ts4040 Double Walled Brazed TubesDocument3 pagesTs4040 Double Walled Brazed TubesFCP PUNEKARNo ratings yet

- An Analysis of Failures in Coiled TubingDocument8 pagesAn Analysis of Failures in Coiled TubingDavid OtálvaroNo ratings yet

- WF6 Potable Water PipeDocument8 pagesWF6 Potable Water PipeBa Thanh DinhNo ratings yet

- Pernos ConexionDocument28 pagesPernos ConexionClaudio Guerrero SanhuezaNo ratings yet

- IBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsDocument10 pagesIBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsMarcelo Varejão CasarinNo ratings yet

- Slyb130 KTT-DesignSummaryDocument8 pagesSlyb130 KTT-DesignSummaryStephan RiahiNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- Standard STD 417-0002: Engine Oil 97487Document7 pagesStandard STD 417-0002: Engine Oil 97487hansiiiNo ratings yet

- Gen PNG STD 001 - 02Document40 pagesGen PNG STD 001 - 02Jose C. MelendezNo ratings yet

- 1-Above Ground Tank LiningDocument9 pages1-Above Ground Tank Liningmehdi abdianNo ratings yet

- Gate Valve Os&yDocument6 pagesGate Valve Os&yJOHN NIKKONo ratings yet

- Resilient-Seated Gate Valves Outside Screw and Yoke General DescriptionDocument6 pagesResilient-Seated Gate Valves Outside Screw and Yoke General DescriptionNikhil JaiswalNo ratings yet

- Inspection LoResDocument16 pagesInspection LoResTukya Nalsra67% (3)

- Victaulic Outlet Coupling Style 72Document5 pagesVictaulic Outlet Coupling Style 72George SobhyNo ratings yet

- Zinc Coating Life Predictor: Derived From TheDocument2 pagesZinc Coating Life Predictor: Derived From ThelakshanNo ratings yet

- WSS M1P94 ADocument9 pagesWSS M1P94 AAleks SenaNo ratings yet

- 2011 Traffic Sign Retroreflective Sheeting Identification GuidDocument2 pages2011 Traffic Sign Retroreflective Sheeting Identification GuidThai Wu TitaniumNo ratings yet

- Properties of Alloys of Multicore Solder WiresDocument3 pagesProperties of Alloys of Multicore Solder Wiresb mNo ratings yet

- MTD4 (4870)Document2 pagesMTD4 (4870)Muthu KumarNo ratings yet

- Max Allowable Pressure of PipesDocument110 pagesMax Allowable Pressure of PipesThammarat PattanarungsanNo ratings yet

- Thermodynamic steam trap performance and specificationsDocument2 pagesThermodynamic steam trap performance and specificationshamid vahedil larijaniNo ratings yet

- Studi Optimasi Offshore Pipeline Indonesie, Balikpapan: Replacement Di Area Bekapai Total E&PDocument40 pagesStudi Optimasi Offshore Pipeline Indonesie, Balikpapan: Replacement Di Area Bekapai Total E&PAbdul AziesNo ratings yet

- JIS C 3202-2014 - Enamelled Winding WiresDocument27 pagesJIS C 3202-2014 - Enamelled Winding WiresMarco PoloNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document106 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- 2011 Heiber PV Int Review Diamond Wire Wafering Technology Meyer BurgerDocument9 pages2011 Heiber PV Int Review Diamond Wire Wafering Technology Meyer BurgerBeyza Nur AKBOLATNo ratings yet

- AN 02.6 Thicker Galvanized Coatings For Specialised ApplicationsDocument10 pagesAN 02.6 Thicker Galvanized Coatings For Specialised Applicationsseii.chenNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Hardox 450 PDFDocument2 pagesHardox 450 PDFAriel Toño Vaquera ZeballosNo ratings yet

- 60 41 Ab SPC 00002Document39 pages60 41 Ab SPC 00002Vineet RungtaNo ratings yet

- A Simplified Guide To ISO28765 by United Industries Group IncDocument12 pagesA Simplified Guide To ISO28765 by United Industries Group IncGilberto BarettaNo ratings yet

- Canistered AnodeDocument2 pagesCanistered AnodesubbaraoNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Tank Clad HSDocument4 pagesTank Clad HSvrazhyl linarezNo ratings yet

- Esr 2236Document6 pagesEsr 2236MD MDDNo ratings yet

- Loctite 680Document4 pagesLoctite 680A DamiánNo ratings yet

- Loctite 638™: Technical Data SheetDocument4 pagesLoctite 638™: Technical Data SheetChinmoy BaruahNo ratings yet

- KSH International Continuously Transposed Cables - Conductors (CTC) BrochureDocument4 pagesKSH International Continuously Transposed Cables - Conductors (CTC) Brochurekshintl100% (3)

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- SPUN PILE WikaDocument3 pagesSPUN PILE WikaCalvin SandiNo ratings yet

- Tubing ManDocument30 pagesTubing ManГалинаNo ratings yet

- Durodyne Stuckup Pins InsFasLRDocument12 pagesDurodyne Stuckup Pins InsFasLRSummer KingNo ratings yet

- 05 - Tubing SelectionDocument26 pages05 - Tubing SelectionNisar KhanNo ratings yet

- Parts: Pricing and Reference Guide ForDocument106 pagesParts: Pricing and Reference Guide ForMat MellingeNo ratings yet

- PT RAWLINDO POWER SOLUSI - Reliable Solutions for Industrial Equipment Maintenance and RepairDocument16 pagesPT RAWLINDO POWER SOLUSI - Reliable Solutions for Industrial Equipment Maintenance and RepairHasim AsariNo ratings yet

- Catalogue Seal Oil CoolerDocument28 pagesCatalogue Seal Oil CoolerSharad KokateNo ratings yet

- 110 00 Training Guide Rev 1Document30 pages110 00 Training Guide Rev 1vilegual1No ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- LOCTITE 680 - UpgradeDocument4 pagesLOCTITE 680 - UpgradeChinmoy BaruahNo ratings yet

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsDocument8 pagesMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoNo ratings yet

- KL terminal boxes stainless steelDocument1 pageKL terminal boxes stainless steelMahasweta MitraNo ratings yet

- Castrol Tection 15 W40 Data SheetDocument2 pagesCastrol Tection 15 W40 Data Sheetsava cristianNo ratings yet

- Effect of PWHT Cycles On Fatigue Crack Growth and Toughness of Quenched and Tempered Pressure Vessel Steels bxl97wpjDocument8 pagesEffect of PWHT Cycles On Fatigue Crack Growth and Toughness of Quenched and Tempered Pressure Vessel Steels bxl97wpjZIBA KHADIBINo ratings yet

- Ancon MBT Couplers International Version PDFDocument14 pagesAncon MBT Couplers International Version PDFAhmadHamdyNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesignFrancisco Javier Torres AlvaradoNo ratings yet

- Structural and Crane Load Design CriteriaDocument13 pagesStructural and Crane Load Design CriteriaMontoya SantiagoNo ratings yet

- Behaviour of Cold Formed Lipped Angles in Transmission Line TowersDocument15 pagesBehaviour of Cold Formed Lipped Angles in Transmission Line TowersFrancisco Javier Torres AlvaradoNo ratings yet

- Guid SPCDocument10 pagesGuid SPCAshok SubramaniyanNo ratings yet

- New Fatigue Provisions For The Design of Crane Runway GirdersDocument9 pagesNew Fatigue Provisions For The Design of Crane Runway Girdersdicktracy11No ratings yet

- OpenSees-ManualSensitivity Mar 2010Document63 pagesOpenSees-ManualSensitivity Mar 2010luis BedrinanaNo ratings yet

- Analysis and Testing The Over Head Transmission Steel TowersDocument6 pagesAnalysis and Testing The Over Head Transmission Steel TowersFrancisco Javier Torres AlvaradoNo ratings yet

- Influence of Bolted-Joint Slippage On TH PDFDocument19 pagesInfluence of Bolted-Joint Slippage On TH PDFFrancisco Javier Torres AlvaradoNo ratings yet

- New Fatigue Provisions For The Design of Crane Runway GirdersDocument9 pagesNew Fatigue Provisions For The Design of Crane Runway Girdersdicktracy11No ratings yet

- Transmission Tower DesignDocument11 pagesTransmission Tower DesignPn EkanayakaNo ratings yet

- Influence of Bolted-Joint Slippage On TH PDFDocument19 pagesInfluence of Bolted-Joint Slippage On TH PDFFrancisco Javier Torres AlvaradoNo ratings yet

- Failure Analysis of Lattice Tower Like StructuresDocument9 pagesFailure Analysis of Lattice Tower Like StructuresFrancisco Javier Torres AlvaradoNo ratings yet

- Review On Analysis and Design of Lattice Steel Structure of Overhead Transmission TowerDocument9 pagesReview On Analysis and Design of Lattice Steel Structure of Overhead Transmission TowerFrancisco Javier Torres AlvaradoNo ratings yet

- IMPROVED MENEGOTTO-PINTO MODELDocument10 pagesIMPROVED MENEGOTTO-PINTO MODELSebastian Pozo OcampoNo ratings yet

- Wind Load Design in JapanDocument12 pagesWind Load Design in JapanSkyZero Wen BinnNo ratings yet

- Peyrot WindDocument25 pagesPeyrot WindMuhannad AbdulRaoufNo ratings yet

- IMPROVED MENEGOTTO-PINTO MODELDocument10 pagesIMPROVED MENEGOTTO-PINTO MODELSebastian Pozo OcampoNo ratings yet

- Panel zone design influences seismic demandsDocument7 pagesPanel zone design influences seismic demandsFrancisco Javier Torres AlvaradoNo ratings yet

- Review of Transmission Tower Testing Stations Around The WorldDocument11 pagesReview of Transmission Tower Testing Stations Around The WorldFrancisco Javier Torres AlvaradoNo ratings yet

- Transmission Tower DesignDocument11 pagesTransmission Tower DesignPn EkanayakaNo ratings yet

- Failure Analysis of Lattice Tower Like StructuresDocument9 pagesFailure Analysis of Lattice Tower Like StructuresFrancisco Javier Torres AlvaradoNo ratings yet

- 220kV Transmission Line Tower Analysis and DesignDocument10 pages220kV Transmission Line Tower Analysis and DesignPiyushNo ratings yet

- Overhead Transmission TowerDocument8 pagesOverhead Transmission TowerJorge Pinto RochaNo ratings yet

- Remote SensingDocument19 pagesRemote SensingLucas MartinsNo ratings yet

- AJCE - Volume 3 - Issue 1 - Pages 61-74 PDFDocument14 pagesAJCE - Volume 3 - Issue 1 - Pages 61-74 PDFFrancisco Javier Torres AlvaradoNo ratings yet

- 0014 Geometrydesignandstructuralanalysisofsteelsingle Layergeodesicdomes PDFDocument2 pages0014 Geometrydesignandstructuralanalysisofsteelsingle Layergeodesicdomes PDFFrancisco Javier Torres AlvaradoNo ratings yet

- Wind Reliability of Transmission Line Models Using Kriging-Based MethodsDocument8 pagesWind Reliability of Transmission Line Models Using Kriging-Based MethodsFrancisco Javier Torres AlvaradoNo ratings yet

- Case Studies in Engineering Failure Analysis: Soheil Dadras Eslamlou, Behrouz AsgarianDocument10 pagesCase Studies in Engineering Failure Analysis: Soheil Dadras Eslamlou, Behrouz AsgarianFrancisco Javier Torres AlvaradoNo ratings yet

- Analysis of Diagrid Structural System Using Push Over AnalysisDocument3 pagesAnalysis of Diagrid Structural System Using Push Over AnalysisFrancisco Javier Torres AlvaradoNo ratings yet

- Collapse Analysis of A Transmission Tower Under Wind ExcitationDocument7 pagesCollapse Analysis of A Transmission Tower Under Wind ExcitationRm1262100% (1)

- Assessment Review - Corporate Finance Institute-21-40Document27 pagesAssessment Review - Corporate Finance Institute-21-40刘宝英No ratings yet

- Grade 8 Term 1 NotesDocument26 pagesGrade 8 Term 1 NotesShadow WalkerNo ratings yet

- Course Code Course Name Lecturer Assignment TitleDocument11 pagesCourse Code Course Name Lecturer Assignment TitleMuhd ArifNo ratings yet

- Semi Formal ExamplesDocument3 pagesSemi Formal ExamplesDjshh oiNo ratings yet

- Módulo 22: Pasivos y Patrimonio: Fundación IFRS: Material de Formación Sobre LaDocument64 pagesMódulo 22: Pasivos y Patrimonio: Fundación IFRS: Material de Formación Sobre LaDAYANA ANDREA DAMS MOLINANo ratings yet

- Commentary: Ophthalmic Increasing Operations ofDocument2 pagesCommentary: Ophthalmic Increasing Operations ofDurval SantosNo ratings yet

- Claim Form GMCDocument7 pagesClaim Form GMCBhaskar RawatNo ratings yet

- Response To Child Support Modification and Retroactive Pay.Document7 pagesResponse To Child Support Modification and Retroactive Pay.Lindsay OlahNo ratings yet

- Class 7 - Spring 2021 - TopostDocument24 pagesClass 7 - Spring 2021 - TopostMahin AliNo ratings yet

- Questionnaire SummaryDocument7 pagesQuestionnaire Summaryinfo -ADDMASNo ratings yet

- Lorelle CarenderiaDocument22 pagesLorelle CarenderiaShiela may AdlawonNo ratings yet

- Landmark Guide Real Estate Valuation PrinciplesDocument8 pagesLandmark Guide Real Estate Valuation PrinciplesChristopher Gutierrez CalamiongNo ratings yet

- Complaint (Final)Document31 pagesComplaint (Final)Kirk Yngwie EnriquezNo ratings yet

- Journal Homepage: - : IntroductionDocument9 pagesJournal Homepage: - : IntroductionNikhita KrishnaiahNo ratings yet

- Annual Income Statement Report Name: Laporan Laba Rugi / Nama / Ery Abd Nasir PelupessyDocument2 pagesAnnual Income Statement Report Name: Laporan Laba Rugi / Nama / Ery Abd Nasir PelupessyErry Abdul Nasir PelupessyNo ratings yet

- Tosun Lang 2017 - Policy IntegrationDocument19 pagesTosun Lang 2017 - Policy IntegrationEdward T MaiaNo ratings yet

- Contractor's taxable gross receipts include salaries, SSS contributionsDocument3 pagesContractor's taxable gross receipts include salaries, SSS contributionsSuzanne Pagaduan CruzNo ratings yet

- PLDT Inc - 17a 2019Document381 pagesPLDT Inc - 17a 2019Kylie Luigi Leynes BagonNo ratings yet

- Contract Law - Premium ChocolatesDocument9 pagesContract Law - Premium Chocolatesprathmesh agrawalNo ratings yet

- FX Factsheet Leveraged Forward enDocument2 pagesFX Factsheet Leveraged Forward enPiyushKumarNo ratings yet

- Final Propsal 3Document63 pagesFinal Propsal 3hinsene begna100% (1)

- Marketing CommunicationsDocument19 pagesMarketing CommunicationsGracezel Evangelista GarciaNo ratings yet

- Department of Labor checklist for construction safety evaluationDocument1 pageDepartment of Labor checklist for construction safety evaluationKevin BasaNo ratings yet

- MRP FormatDocument39 pagesMRP Formatgyan ganga higher secondary school rampur baghelanNo ratings yet

- Solution Time Value of Money 5 Loan Amortization Schedule and PV of Perpetual Annuity and PV Growing Annuity 3PVyvICyHiDocument5 pagesSolution Time Value of Money 5 Loan Amortization Schedule and PV of Perpetual Annuity and PV Growing Annuity 3PVyvICyHiShareshth JainNo ratings yet

- OST Report - Christ UniversityDocument44 pagesOST Report - Christ UniversityRNo ratings yet

- E ChoupalDocument8 pagesE ChoupalRakesh NandanNo ratings yet

- Book 1Document3 pagesBook 1nauraluna.nevetari.sriyono-2021No ratings yet

- Girish KSDocument3 pagesGirish KSSudha PrintersNo ratings yet

- ARBURG Customer Service Contact List 2021Document2 pagesARBURG Customer Service Contact List 2021Moises GeberNo ratings yet