Professional Documents

Culture Documents

United States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)

Uploaded by

AGUAVIVANJ0 ratings0% found this document useful (0 votes)

12 views7 pagesPlanos

Original Title

US7866757

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPlanos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views7 pagesUnited States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)

Uploaded by

AGUAVIVANJPlanos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

US007866757B2

(12) United States Patent (10) Patent No.: US 7.866,757 B2

Boucherie (45) Date of Patent: Jan. 11, 2011

(54) BRUSH STUFFING MACHINE (56) References Cited

U.S. PATENT DOCUMENTS

(75) Inventor: Bart Gerard Boucherie, Izegem (BE)

3,059.972 A * 10/1962 Herbert ......................... 300.5

(73) Assignee: Firma G.B. Boucherie N.V., Izegem 5,518,301 A * 5/1996 Boucherie .................... 300/21

(BE) 6,016,757 A * 1/2000 Boucherie ...... ... 112,80.01

6,905,176 B2* 6/2005 Boucherie .................... 300/21

*) Not

Ot1Ce: Subj

ubject to anyy d1Sclaimer,

disclai h term off thi

the this 7,594,704 B2* 9/2009 Boucherie ...................... 300.5

patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS

U.S.C. 154(b) by 993 days.

DE 1016O220 6, 2003

(21) Appl. No.: 11/645,486 EP O3O4110 * 8/1989

EP 1493 355 1, 2005

(22) Filed: Dec. 26, 2006 EP 1 535534 6, 2005

(65) Prior Publication Data * cited by examiner

US 2007/O145812 A1 Jun. 28, 2007 Primary Examiner Laura C Guidotti

(74) Attorney, Agent, or Firm Stuart J. Friedman

(30) Foreign Application Priority Data (57) ABSTRACT

Dec. 27, 2005 (DE) ................... 2O 2005 O2O 231 U.

A brush stuffing machine comprising a bristle magazine and

(51) Int. Cl. a stuffing tool which is movable between abundle take-over

A46D 3/04 (2006.01) position and a stuffing position, the stuffing tool is pivotally

(52) U.S. Cl. .................................... 300/5: 300/7; 300/8 mounted about an axis for movement on a circular arc

(58) Field of Classification Search ..................... 300/5, between the take-over position and the stuffing position.

300/7, 8, 21

See application file for complete search history. 11 Claims, 4 Drawing Sheets

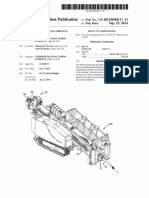

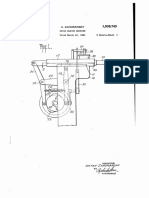

U.S. Patent Jan. 11, 2011 Sheet 1 of 4 US 7.866,757 B2

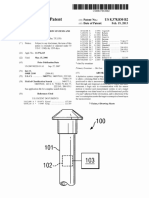

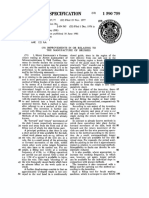

U.S. Patent Jan. 11, 2011 Sheet 2 of 4 US 7.866,757 B2

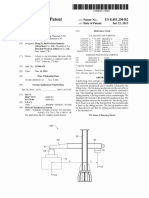

U.S. Patent Jan. 11, 2011 Sheet 3 of 4 US 7.866,757 B2

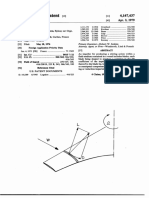

U.S. Patent Jan. 11, 2011 Sheet 4 of 4 US 7.866,757 B2

US 7,866,757 B2

1. 2

BRUSH STUFFING MACHINE Preferably, it is provided that a tongue is associated to the

stuffing tool, which is pivotally driven about the same axis.

BACKGROUND OF THE INVENTION The tongue pushes the bundles of bristles and the wire

anchors through the tool tip into the brush body. The mount

1. Field of the Invention ing of the tongue is effected in the same way as in the case of

This invention relates to a brush stuffing machine compris the stuffing tool at a distance from the brush body holder and

ing a bristle magazine and a stuffing tool which is movable from the bristle magazine.

between abundle take-over position and a stuffing position. Advantageous aspects of the invention can be taken from

2. Description of Related Art the Sub-claims.

10

In the prior art, the stuffing tool is translationally movable BRIEF DESCRIPTION OF THE DRAWINGS

between the bundle take-over position and the stuffing posi

tion. In the bundle take-over position, a bundle of bristles is The invention will subsequently be described with refer

transferred to the stuffing tool, which upon arrival of the ence to an embodiment which is illustrated in the accompa

stuffing tool at the stuffing position is inserted into a brush 15 nying drawings, in which:

body disposed in a brush body holder. FIG. 1 is a perspective view of a brush stuffing machine;

A disadvantage of known stuffing tools is the fact that a FIG. 2 shows part of the brush stuffing machine of FIG. 1

comparatively complex guideway requiring much space is on an enlarged scale, wherein the stuffing tool is in a starting

necessary for the stuffing tool, which in addition must be position;

arranged in a region where little space is available. Further FIG. 3 is a view corresponding to the one of FIG. 2,

more, it is disadvantageous that at high clock rates the guide wherein the stuffing tool is disposed between a bundle take

way for the stuffing tool comes up against the limits of its over position and a stuffing position; and

mechanical capacity. FIG. 4 is a view corresponding to the one of FIG. 2,

BRIEF SUMMARY OF THE INVENTION

wherein the stuffing tool is in the stuffing position.

25

DETAILED DESCRIPTION OF THE INVENTION

Thus, it is the object of the invention to create a brush

stuffing machine which offers more possibilities with regard FIG. 1 shows a brush stuffing machine to which a brush

to the space conditions in the vicinity of the brush magazine body holder 10 is associated, in which there is held a tooth

and in front of the brush body holder and with regard to the 30 brush 12 to be provided with bristles. The brush stuffing

admissible clock rates. machine of the invention can of course also be used for fitting

For the solution of this object, it is provided in accordance other brushes with bristles.

with the invention that the stuffing tool is pivotally mounted The brush stuffing machine includes a stuffing tool 29,

about an axis, so that it moves on a circular arc between the which at its front end has a tool tip 28 with two tool jaws and

take-over position and the stuffing position. The invention is 35 at its rear end anchor cutting and anchor guiding plates 17.

based on the knowledge that it is not necessary to insert the The stuffing tool 29 is curved in the shape of a circular arc and

bundles of bristles into the brush bodies by means of an mounted on a swivel arm 20. The swivel arm 20 is pivotally

exactly linear movement. When the swivel radius of the stuff mounted about a bearing axis 18 which here is indicated only

ing tool is large enough, the deviations of the actual (curved) schematically. For mounting the swivel arm 20, low-friction

path of movement of the stuffing tool during insertion of the 40 ball bearings are used. Inside the stuffing tool 29, anarcuately

bundle of bristles into the brush body from the ideal (linear) curved guiding groove is provided for a tongue 14, which can

path of movement are so Small that they can be ignored. On be swivelled relative to the stuffing tool 29. The tongue is

the other hand, a few practical advantages are obtained: When guided by the guiding groove during all of its movement.

using a rotary movement for the stuffing tool instead of a The tongue 14 is mounted on a swivel arm 16 which is

translational movement, the main bearing of the stuffing tool 45 pivotally mounted about the same bearing axis 18 as the

can be arranged far away from the region in front of the brush Swivel arm 20. As a result, the tongue 14 can perform a

body holder. Thus, the stuffing tool is swivelled “from the movement on a circular arc in the same way as the stuffing

outside towards the brush body holder, without a complex tool 29, the center of this circular arc lying on the bearing axis

bearing being necessary directly in front of the brush body 18.

holder and the bristle magazine. With regard to the mechani 50 There is provided a bundle pick-up 22, which is pivotally

cal loads, a Swivel bearing is very much more advantageous mounted about an axis which is parallel to axis 18 of stuffing

than a translationally movable sliding bearing, as the relative tool 29 and in a manner known per se can take a bundle of

Velocity between stationary and moving parts is very much bristles from a bristle magazine 24.

Smaller in the case of a Swivel bearing than in the case of a Furthermore, a wire cutter 26 is provided, which can cut a

sliding bearing. In the case of a sliding guideway, the relative 55 piece of a certain length from a continuously supplied wire,

Velocity between the stationary and the moving parts is equal which together with the bundle of bristles can be inserted into

to the maximum speed of movement of the stuffing tool, the brush 12 as a wire anchor.

whereas in the case of a swivel bearing, the relative velocity is The brush stuffing machine described above operates as

geared down in proportion to the radii of the stuffing tool and follows: Starting in the starting position as shown in FIGS. 1

of the bearing Surface. 60 and 2, the stuffing tool 29 is swivelled in the direction of arrow

In a manner known perse, the stuffing tool has a so-called P on a circular arc towards the brush body holder 10. The

tool tip at its front, by means of which the bristles are double tongue which moves inside the stuffing tool 29 takes a wire

folded, before they are inserted into the brush body, and anchor from the wire cutter 26 and abundle of bristles from

further to the rear so-called anchor cutting and anchor guiding the bundle pick-up 22. Loaded with the bundle of bristles and

plates, which together with the wire cutter form the wire 65 the wire anchor, the tip of the stuffing tool 29 gets quite close

anchors, which together with the bundles of bristles are to the brush body (see FIG.3, where the bundle of bristles and

inserted into the brush body. the wire anchor have been omitted for the sake of clarity).

US 7,866,757 B2

3 4

Approximately at this time, the front end of the tongue 14 4. The brush stuffing machine as claimed in claim 3,

passes through the tool tip 28 and thereby inserts the bundle of wherein the movements of the stuffing tool and the tongue are

bristles together with the wire anchor into the brush body held synchronized with each other when the same are swivelled

in the brush body holder 10 (see FIG. 4). For driving and from the bundle take-over position into the stuffing position.

synchronizing the two swivel movements of the stuffing tool 5. The brush stuffing machine as claimed in claim 2, further

29 and the tongue 14, a cam and/or eccentric mechanism is including a bundle pick-up for cooperating with a bristle

used, for instance. magazine in order to transferabundle of bristles to the stuff

Synchronized with the movement of the stuffing tool 29 ing tool in the bundle take-over position, the bundle pick-up

and the tongue 14, the bundle pick-up is swivelled such that its being pivotally mounted about an axis which is parallel to the

bundle pick-up notch 23 is swivelled towards the bristle 10 axis of the stuffing tool.

magazine 24, as soon as the stuffing tool 29 has taken the 6. The brush stuffing machine as claimed in claim 2, further

corresponding bundle of bristles from the bundle pick-up including a wire cutter for cooperating with the stuffing tool

notch 23. While the stuffing tool 29 is swivelled from the in order to transfer a wire anchor to the stuffing tool.

stuffing position shown in FIG. 4 back into the starting posi 7. A brush stuffing machine comprising a bristle magazine

tion shown in FIG. 2, the bundle pick-up 22 likewise returns 15 and a stuffing tool which moves in a plane between abundle

to the position shown in FIG. 2, in which a new bundle of take-over position and a stuffing position, said stuffing tool

bristles is presented to the stuffing tool 29. being pivotally mounted about a pivot axis for tracing a cir

The invention claimed is: cular arc within said plane, said pivot axis being perpendicu

1. A brush stuffing machine comprising a bristle magazine lar to the plane of stuffing tool movement between the take

and a stuffing tool which is movable between abundle take over position and the stuffing position.

over position and a stuffing position, said stuffing tool being 8. The brush stuffing machine as claimed in claim 7, further

pivotally mounted about an axis for movement on a circular including a tongue associated to the stuffing tool, said tongue

arc between the take-over position and the stuffing position, being movable on a circular arc whose centerlies on the same

and abundle pick-up for cooperating with a bristle magazine axis as the pivot axis of the stuffing tool.

in order to transfer a bundle of bristles to the stuffing tool in 25 9. The brush stuffing machine as claimed in claim 8.

the bundle take-over position, the bundle pick-up being piv wherein the movements of the stuffing tool and the tongue are

otally mounted about an axis which is parallel to the axis of synchronized with each other when the same are swivelled

the stuffing tool. from the bundle take-over position into the stuffing position.

2. A brush stuffing machine comprising a bristle magazine 10. The brush stuffing machine as claimed in claim 7.

and a stuffing tool which is movable between abundle take

30 further including a bundle pick-up for cooperating with a

over position and a stuffing position, the stuffing tool being bristle magazine in order to transferabundle of bristles to the

pivotally mounted on a Swivel arm for Swiveling movement stuffing tool in the bundle take-over position, the bundle

about a pivotaxis from the take-over position towards a brush pick-up being pivotally mounted about an axis which is par

holder. allel to the axis of the stuffing tool.

3. The brush stuffing machine as claimed in claim 2, further

35 11. The brush stuffing machine as claimed in claim 7.

including a tongue associated to the stuffing tool, said tongue further including a wire cutter for cooperating with the stuff

being movable on a circular arc whose centerlies on the same ing tool in order to transfer a wire anchor to the stuffing tool.

axis as the pivot axis of the stuffing tool. k k k k k

You might also like

- United States Patent (10) Patent No.: US 8,002,692 B2Document15 pagesUnited States Patent (10) Patent No.: US 8,002,692 B2avalosheNo ratings yet

- United States Patent (10) Patent No.: US 8.403,825 B2Document13 pagesUnited States Patent (10) Patent No.: US 8.403,825 B2avalosheNo ratings yet

- United States Patent (191: Fujimoto (11) 4,190,411Document7 pagesUnited States Patent (191: Fujimoto (11) 4,190,411Vansala GanesanNo ratings yet

- United States Patent: Walter Patent No.: Date Patent: DecDocument11 pagesUnited States Patent: Walter Patent No.: Date Patent: Decmohamedabbas_us3813No ratings yet

- Meccanismo 2Document8 pagesMeccanismo 2Marco Raneo PezzanoNo ratings yet

- EP1208038B1Document6 pagesEP1208038B1Keyur B ShrimaliNo ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet

- United States Patent (10) Patent No.: US 7,594,704 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,594,704 B2AGUAVIVANJNo ratings yet

- United States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentDocument10 pagesUnited States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentClaudinei MayerNo ratings yet

- United States Patent: Sanford (45) Date of Patent: Apr. 25, 2006Document8 pagesUnited States Patent: Sanford (45) Date of Patent: Apr. 25, 2006samNo ratings yet

- Vehicle Shock Tower Design PatentDocument13 pagesVehicle Shock Tower Design Patentjohnmaxin1114No ratings yet

- Pipe Supporting Apparatus for Trench BackfillingDocument6 pagesPipe Supporting Apparatus for Trench BackfillingPato Patiño MuñozNo ratings yet

- US7698836Document31 pagesUS7698836zoyaNo ratings yet

- Archery Bow Vibration Dampener Device Reduces ShockDocument10 pagesArchery Bow Vibration Dampener Device Reduces Shockemnm30No ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument10 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentPriyankaNo ratings yet

- US6443044Document10 pagesUS6443044Sadia MoinNo ratings yet

- United States Patent: Lapauw Et Al. (45) Date of Patent: May 21, 2013Document15 pagesUnited States Patent: Lapauw Et Al. (45) Date of Patent: May 21, 2013Mary HullNo ratings yet

- Us8371532 PDFDocument12 pagesUs8371532 PDF雷黎明No ratings yet

- Soft Landing Assembly for ParachutesDocument7 pagesSoft Landing Assembly for ParachutesPENANTNo ratings yet

- Us9976567 (B2)Document10 pagesUs9976567 (B2)Gabriel PhilippiNo ratings yet

- United States Patent (10) Patent No.: US 6,755,365 B1: Meredith (45) Date of Patent: Jun. 29, 2004Document17 pagesUnited States Patent (10) Patent No.: US 6,755,365 B1: Meredith (45) Date of Patent: Jun. 29, 2004MekaTronNo ratings yet

- 2014 - Us20140284111 - Horizontal Directional Drilling SystemDocument16 pages2014 - Us20140284111 - Horizontal Directional Drilling SystemCường Nguyễn QuốcNo ratings yet

- Cutting Blade Assembly Boosts Shredder EfficiencyDocument17 pagesCutting Blade Assembly Boosts Shredder Efficiencyjozsef laszloNo ratings yet

- US8012197Document13 pagesUS8012197Pardeep SharmaNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,450,269 B1Document8 pagesUnited States Patent: (12) (10) Patent N0.: US 6,450,269 B1Cường Nguyễn QuốcNo ratings yet

- US8846977Document8 pagesUS8846977Muhammad Taufik MahadikaNo ratings yet

- Us 8029605Document10 pagesUs 8029605ELMER DELOSSANTOSNo ratings yet

- Patent Application for a Directional Drilling Machine ViseDocument11 pagesPatent Application for a Directional Drilling Machine ViseCường Nguyễn QuốcNo ratings yet

- Brevet Filetare VartejDocument12 pagesBrevet Filetare Vartejirina100% (1)

- United States Patent (10) Patent No.: US 8,157,658 B2Document6 pagesUnited States Patent (10) Patent No.: US 8,157,658 B2maulik_20_8No ratings yet

- United States Patent (10) Patent No.: US 8,590,068 B2Document10 pagesUnited States Patent (10) Patent No.: US 8,590,068 B2Alex KattamisNo ratings yet

- United States Patent (10) Patent No.: US 8,749,240 B1Document9 pagesUnited States Patent (10) Patent No.: US 8,749,240 B1Javad NooriNo ratings yet

- United States Patent (10) Patent No.: US 8,919,272 B2Document10 pagesUnited States Patent (10) Patent No.: US 8,919,272 B263No ratings yet

- US7383809B2 失效Document8 pagesUS7383809B2 失效Steven CHENNo ratings yet

- Us6843149 PDFDocument10 pagesUs6843149 PDFDana CucuNo ratings yet

- United States Patent (19) 11 Patent Number: 5,616,142: Yuan Et Al. (45) Date of Patent: Apr. 1, 1997Document7 pagesUnited States Patent (19) 11 Patent Number: 5,616,142: Yuan Et Al. (45) Date of Patent: Apr. 1, 1997Ca Nd RaNo ratings yet

- EP0616965B1Document10 pagesEP0616965B1Shankar PediredlaNo ratings yet

- Convertible tiltrotor aircraft increases forward speed without jet engineDocument17 pagesConvertible tiltrotor aircraft increases forward speed without jet enginegorgiNo ratings yet

- Device Machines Crankshaft Pins In-EngineDocument9 pagesDevice Machines Crankshaft Pins In-EngineMahnooshNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- Segmented Bearing BushingDocument12 pagesSegmented Bearing BushingAnonymous 2k25WMLY0No ratings yet

- United States Patent (10) Patent No.: US 8,646,487 B2Document9 pagesUnited States Patent (10) Patent No.: US 8,646,487 B2hernidasari hasibuanNo ratings yet

- US8283551 PatentDocument9 pagesUS8283551 PatentdanNo ratings yet

- Us8128008 - B2 LVMHDocument8 pagesUs8128008 - B2 LVMHsakthivel ArumugamNo ratings yet

- 2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryDocument17 pages2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- United States Patent (10) Patent No.: US 8.414,195 B2Document6 pagesUnited States Patent (10) Patent No.: US 8.414,195 B2Anshumaan Pratap BhagatNo ratings yet

- US5304036Document24 pagesUS5304036wen longNo ratings yet

- Us 7748384Document28 pagesUs 7748384himanshi413No ratings yet

- Us8378830 PDFDocument12 pagesUs8378830 PDFAndy AbieNo ratings yet

- TEPZZ 5649 8B - T: European Patent SpecificationDocument13 pagesTEPZZ 5649 8B - T: European Patent SpecificationneusonNo ratings yet

- European Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftDocument23 pagesEuropean Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftgorgiNo ratings yet

- US7743601Document4 pagesUS7743601Alien GmpNo ratings yet

- US3889885Document7 pagesUS3889885Claudinei MayerNo ratings yet

- Us8758606 - B2 LVMHDocument6 pagesUs8758606 - B2 LVMHsakthivel ArumugamNo ratings yet

- Single Screw Extruder Screw Sections Improve Low Viscosity ProcessingDocument19 pagesSingle Screw Extruder Screw Sections Improve Low Viscosity ProcessingXuan Phuong HuynhNo ratings yet

- Us 8784647Document15 pagesUs 8784647peymanNo ratings yet

- Balancing Mechanism for Palletizing RobotDocument10 pagesBalancing Mechanism for Palletizing RobotRoyLoraGallardoNo ratings yet

- US8453712Document9 pagesUS8453712Ashkan AsefiNo ratings yet

- Diseño de Impulsores para Mezcla de SuspensionesDocument9 pagesDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNo ratings yet

- Applications: Cutting Edge Solutions For FoodDocument2 pagesApplications: Cutting Edge Solutions For FoodAGUAVIVANJNo ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- Assus - Sa-E-: Be LiaDocument16 pagesAssus - Sa-E-: Be LiaAGUAVIVANJNo ratings yet

- United States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)Document7 pagesUnited States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)AGUAVIVANJNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- United States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)Document7 pagesUnited States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)AGUAVIVANJNo ratings yet

- United States Patent: SchofieldDocument14 pagesUnited States Patent: SchofieldAGUAVIVANJNo ratings yet

- Machine Forms Bristle Knots for Brush Making Based on Pressure SensingDocument5 pagesMachine Forms Bristle Knots for Brush Making Based on Pressure SensingAGUAVIVANJNo ratings yet

- Ley Aeland A Ghapman,: Fig. FIG. 2Document3 pagesLey Aeland A Ghapman,: Fig. FIG. 2AGUAVIVANJNo ratings yet

- Alimentador de CerdasDocument7 pagesAlimentador de CerdasAGUAVIVANJNo ratings yet

- Universal Brush Machine Patent from 1928Document14 pagesUniversal Brush Machine Patent from 1928AGUAVIVANJNo ratings yet

- United States Patent (10) Patent No.: US 7,594,704 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,594,704 B2AGUAVIVANJNo ratings yet

- QU-BD Printer Assembly InstructionsDocument67 pagesQU-BD Printer Assembly InstructionsNeilNo ratings yet

- GB 1590759 ADocument12 pagesGB 1590759 AAGUAVIVANJNo ratings yet

- European Patent Application A46D 3/06Document21 pagesEuropean Patent Application A46D 3/06AGUAVIVANJNo ratings yet

- European Patent Application A46D 3/06Document21 pagesEuropean Patent Application A46D 3/06AGUAVIVANJNo ratings yet

- 福建马尾MMC887PSV完工图 PDFDocument48 pages福建马尾MMC887PSV完工图 PDFcarlos100% (1)

- Dorma HWDocument196 pagesDorma HWmohammad alsayyidNo ratings yet

- 16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPDocument50 pages16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPHASNA JILANNo ratings yet

- McCormick C-L Mondial Tier 2 (2007-) - RT30 - C85L Tractor Service Repair Manual PDFDocument29 pagesMcCormick C-L Mondial Tier 2 (2007-) - RT30 - C85L Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- Weil Mclain Parts Catalog CD Version 2010Document298 pagesWeil Mclain Parts Catalog CD Version 2010123anthonyNo ratings yet

- St. Francis School, Mount Poinsur, Borivali (W), Mumbai Preliminary Examination 2 - Semester 2 2021-22 Class:X Date: 29/03/2022Document5 pagesSt. Francis School, Mount Poinsur, Borivali (W), Mumbai Preliminary Examination 2 - Semester 2 2021-22 Class:X Date: 29/03/2022yuvraj keswaniNo ratings yet

- 04ionic Equilibrium Set Test Final EDocument5 pages04ionic Equilibrium Set Test Final EBad boy boyNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- Technical Bulletin 3Document17 pagesTechnical Bulletin 3RANAIVOARIMANANANo ratings yet

- Parts Catalog: 0CW10-M70600ENDocument14 pagesParts Catalog: 0CW10-M70600ENCarlos PariNo ratings yet

- Lecture 4 5 Workholding PrinciplesDocument99 pagesLecture 4 5 Workholding PrinciplesSolidworks Mania100% (1)

- Force Distributions in Lathe PartsDocument23 pagesForce Distributions in Lathe Partskarthick rajNo ratings yet

- Hybrid Top Drive ltr2 PDFDocument4 pagesHybrid Top Drive ltr2 PDFHunterNo ratings yet

- Dr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, ChennaiDocument12 pagesDr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, Chennaim sriNo ratings yet

- Lintel and Sunshade DesignDocument17 pagesLintel and Sunshade DesignNikhilNo ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- PM Tyler Screen PDFDocument1 pagePM Tyler Screen PDFMohammad Rezza PachruraziNo ratings yet

- B.Tech 5th Sem MechanicalDocument10 pagesB.Tech 5th Sem MechanicalRahul KumarNo ratings yet

- Fastener Torque Charts: Phone: 1-800-558-2808 Fax: 1-800-553-8769Document2 pagesFastener Torque Charts: Phone: 1-800-558-2808 Fax: 1-800-553-8769KOMATSU SHOVELNo ratings yet

- Maintain Circular Sawing Machine Safely and EffectivelyDocument6 pagesMaintain Circular Sawing Machine Safely and EffectivelyMichał JabłońskiNo ratings yet

- Daikin RXYHQ12-36P (8) SpecificationsDocument78 pagesDaikin RXYHQ12-36P (8) SpecificationsserbanicNo ratings yet

- Precontraint 502S2 & 702S2Document1 pagePrecontraint 502S2 & 702S2Muhammad Najam AbbasNo ratings yet

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 pagesCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineNo ratings yet

- Silva Et Al.-2013Document6 pagesSilva Et Al.-2013Tuğçe KabakcıNo ratings yet

- ITC One Colombo (Sri Lanka) : Project InformationDocument1 pageITC One Colombo (Sri Lanka) : Project InformationMohammed SajidNo ratings yet

- B. Concrete Having 25MP Compressive StrengthDocument4 pagesB. Concrete Having 25MP Compressive StrengthBiruk AberaNo ratings yet

- Vishnu Internship Report 1Document27 pagesVishnu Internship Report 1Vishnu ChitragarNo ratings yet

- 010 - Denison Control Valve 3-EN2400-ADocument15 pages010 - Denison Control Valve 3-EN2400-Agustavo aguilarNo ratings yet