Professional Documents

Culture Documents

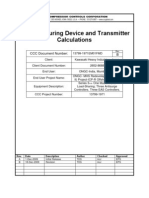

3e Drum Level Control & Compensation

Uploaded by

MI MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3e Drum Level Control & Compensation

Uploaded by

MI MCopyright:

Available Formats

11/12/2019 3E DRUM LEVEL CONTROL & COMPENSATION

HOME POWER PLANT DETAILS EXPERIENCED JOBS LECTURE NEW PROJECTS VIDEOS

POWER NEWS FCA INTERVIEW CONTACT US FREE TRAININGS QUERIES

FRESHERS JOBS

POWER PLANT

INSTRUMENTATION & CONTROL

Recent Posts

Industrial Instrumentation Research Journal

LETS TRY TO READ THE LOGIC BLOCK DIAGRAM OF...

Instrumentation Documents

POWER PLANT VARIOUS CONTROLS

CAPACITANCE TYPE LEVEL SWITCH

3E DRUM LEVEL CONTROL & COMPENSATION

DBR (INST & CONT) - POWER PLANT

HOW TO MAKE HOOP UP DRAWINGS FOR FILED INSTRUMENTS

DCS- ARCHITECTURE

DCS-INTRODUCTION IN BRIEF

3E DRUM LEVEL CONTROL & COMPENSATION

Posted by Debyendu Chakraborty on Tuesday, December 4, 2012 Under: TECHNICAL

3E DRUM LEVEL CONTROL & COMPENSATION

The aim of drum level control is to maintain the drum level at the centre line of the boiler drum.

The 3 element in this loop are the drum level, the steam flow & the feed water flow. The level is measured by two independents DPT.The stream

drum pressure is measured using pressure transmitter PT. The two level signals are corrected for density using the drum pressure signal before the

same is used for indication, control & high, low alarm generation.

The density compensation is done by the formula-

Actual Steam Flow = Indicated steam flow * √ {(P1+1.029)*(T2+273)} / {(P2 +1.029) *(T1+273)} …………….1

Where P1 is measured pressure signal & T1 is measured temp signal, P2 = 89kg/cm2, T2 = 515 Deg C (Designed constant).

For very low trip generation first the constants are generated from individual transmitter & then two out of two is performed on the three density

compensated level signal and the output is used as PV from the drum level controller.

In case 3E the controller LIC output goes to feed forward summation block where the steam flow is added to it & generates the remote set point

flow controller FIC.

Steam flow measured using steam flow transmitter FT-1 & FT-2 , two out of two is performed, whish acts as a feed-forward signals & takes care of

shrink & swell effects. the steam flow transmitter are connected across flow nozzle which is square rooted and then pressure & temperature

compensation done.

This compensation takes care of error arising due to density variation of stream when boiler is operating at conditions different from design

conditions.

For drum level compensation by modifying eqn 1

Hm + DP + h (ra - rs) / (rw - rs)

Hm = corrected drum level, DP = diff pressure measured by level transmitters, ra= wet led density (0.992), rs = saturated steam density(refer steam

table) , rw = saturated water density , H = wet leg height (h=H)

PRESSURE IN KG/CM2 rw rs

45.040 0.7910 0.0217

48.9 0.784 0.0237

…….. ……… ……..

88.644 0.7145 0.04623

www.powerplantinstrumentationcontrol.yolasite.com/power-plant-details/3e-drum-level-control-compensation 1/8

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Cable Sizing CalculationDocument15 pagesCable Sizing CalculationKhairul AshrafNo ratings yet

- Sector Trading StrategiesDocument16 pagesSector Trading Strategiesfernando_zapata_41100% (1)

- Overcurrent ProtectionDocument61 pagesOvercurrent Protectionalimaghami67% (3)

- Testing and Balancing AcsDocument10 pagesTesting and Balancing Acsroshan jaiswalNo ratings yet

- Document and Drawing Numbering Procedure, Rev.0Document10 pagesDocument and Drawing Numbering Procedure, Rev.0dineshnandhu007No ratings yet

- Tce Consulting Engineers Limited Design Guide For Line SizingDocument27 pagesTce Consulting Engineers Limited Design Guide For Line SizingKaliya PerumalNo ratings yet

- ACDB Cable Schedule WEDocument30 pagesACDB Cable Schedule WESaleh El-hawaryNo ratings yet

- Relative and Absolute Dating PDFDocument192 pagesRelative and Absolute Dating PDFPeeyush Kumar0% (1)

- Design Guide FOR Distribution System PlanningDocument19 pagesDesign Guide FOR Distribution System Planningdhairyashil_dspNo ratings yet

- EW - 1 Calculation of Short Circuit Current For Equipment Evaluation EW-1.1 Generating Plant Single Line DiagramDocument11 pagesEW - 1 Calculation of Short Circuit Current For Equipment Evaluation EW-1.1 Generating Plant Single Line DiagramCatrina FedericoNo ratings yet

- Wind Load Calculation For Touatgaz Project - 01Document5 pagesWind Load Calculation For Touatgaz Project - 01Oscar Paredes GarcíaNo ratings yet

- Field of Social WorkDocument16 pagesField of Social WorkJessa CarreonNo ratings yet

- 33kV Cable Sizing CalcDocument9 pages33kV Cable Sizing Calcsrigirisetty208No ratings yet

- Supplier Management Implementation GuideDocument198 pagesSupplier Management Implementation GuideIndra StpNo ratings yet

- Design Guide For Line Sizing of Power Plant PipingDocument27 pagesDesign Guide For Line Sizing of Power Plant Pipingajiths89No ratings yet

- ремонт MWP14 18-1R - 60424511 - 05-03 - GBDocument87 pagesремонт MWP14 18-1R - 60424511 - 05-03 - GBVrshtyr0% (1)

- 0704 MCS System Logic Design Instruction PDFDocument28 pages0704 MCS System Logic Design Instruction PDFrahul100% (1)

- SDTT-De-F4!06!809 - 1 - Stress Analysis Calculation Report ACSDocument45 pagesSDTT-De-F4!06!809 - 1 - Stress Analysis Calculation Report ACSjerrymcflyNo ratings yet

- M0237 01 RBP PD RP 3013Document159 pagesM0237 01 RBP PD RP 3013harishNo ratings yet

- Spec Nalco Trasar 3DTfBoilerDocument16 pagesSpec Nalco Trasar 3DTfBoilercarlos caleroNo ratings yet

- STD 883 MTHD 1000Document208 pagesSTD 883 MTHD 1000jsadachiNo ratings yet

- Incomer Load Calculations For Motor Control CenterDocument2 pagesIncomer Load Calculations For Motor Control CenterChandanSinghNo ratings yet

- 931a ManualDocument161 pages931a ManualaungaungoomanualNo ratings yet

- TI Slva882Document19 pagesTI Slva882alprovieNo ratings yet

- Manual TranstectorDocument6 pagesManual TranstectorHoku's NickNo ratings yet

- The New Tuning ManualDocument55 pagesThe New Tuning ManualnboulegrouneNo ratings yet

- Material List: Produced On 30/03/2021 With Xpress Selection V9.2.0 - Database DIL 16.4.4Document19 pagesMaterial List: Produced On 30/03/2021 With Xpress Selection V9.2.0 - Database DIL 16.4.4Sicologo CimeNo ratings yet

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocument34 pagesLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanNo ratings yet

- Paper 3 - Set B Key: Paper - 3: Energy Efficiency in Electrical UtilitiesDocument17 pagesPaper 3 - Set B Key: Paper - 3: Energy Efficiency in Electrical UtilitiesRAMA RAJU PYDINo ratings yet

- Controlled: Design Manual (SPT, SPD, SPM) : Section 9aDocument32 pagesControlled: Design Manual (SPT, SPD, SPM) : Section 9aAntonio Solís MurilloNo ratings yet

- Département Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual CommissioningDocument71 pagesDépartement Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual Commissioningjrsk638742No ratings yet

- Rockwell Collins Installation Practices Manual 3ed Sept 1998 - 4 Dimming and AnnunciatorsDocument10 pagesRockwell Collins Installation Practices Manual 3ed Sept 1998 - 4 Dimming and AnnunciatorsJoeTheMechNo ratings yet

- Control Valves Data Sheet: K9 S.P.A. - ItalyDocument11 pagesControl Valves Data Sheet: K9 S.P.A. - ItalyAhmadNo ratings yet

- Load CalculationsDocument12 pagesLoad CalculationsAmer AlmansoryNo ratings yet

- Davis Standard-Hes SLC 500 Melt Pump Control System Setup and Operational ManualDocument17 pagesDavis Standard-Hes SLC 500 Melt Pump Control System Setup and Operational ManualManutenção Industrial MicroserviceNo ratings yet

- Ch. No Chapter Name Page NoDocument27 pagesCh. No Chapter Name Page NoSruthi ReddyNo ratings yet

- TMGT DRP E3 Cs 001 - Lighting Illumination Level Cal - Rev 0Document16 pagesTMGT DRP E3 Cs 001 - Lighting Illumination Level Cal - Rev 0Bally JanNo ratings yet

- Multiple RPM-Based PWM Fan Controller For Three Fans: Product FeaturesDocument52 pagesMultiple RPM-Based PWM Fan Controller For Three Fans: Product FeaturesЕвгений ИвановNo ratings yet

- ST Micro - An4076Document14 pagesST Micro - An4076smhbNo ratings yet

- Position Paper: Stake Holder Consultation Process Offshore Grid NLDocument16 pagesPosition Paper: Stake Holder Consultation Process Offshore Grid NLAnonymous tj7dWBvUuxNo ratings yet

- M-05-15030-Centrifugal Axial Flow Pump Sets-Version 2.0Document4 pagesM-05-15030-Centrifugal Axial Flow Pump Sets-Version 2.0Reza SalimiNo ratings yet

- ML Prd01 Ceg Ccal 0082 Rev 0Document74 pagesML Prd01 Ceg Ccal 0082 Rev 0Tedi SNo ratings yet

- How The Switching Frequency Affects The Performance of A Buck ConverterDocument8 pagesHow The Switching Frequency Affects The Performance of A Buck ConverterJitbro PrajapatiNo ratings yet

- Dning DBRDocument10 pagesDning DBRD.SathyanarayananNo ratings yet

- Sizing LV CableDocument7 pagesSizing LV CableGireeshNo ratings yet

- Closed DrainDocument7 pagesClosed DrainMohammad MohseniNo ratings yet

- TG-NET-ENG-500 Asset Numbering and Nomenclature of Transmission Equipment Guide (Rev1.00Document28 pagesTG-NET-ENG-500 Asset Numbering and Nomenclature of Transmission Equipment Guide (Rev1.00selva raja100% (1)

- TM 9 4935 601 14 3&PDocument137 pagesTM 9 4935 601 14 3&Pkhaerul jannahNo ratings yet

- Brand Worcester Digistat Optimiser 87161144620 ENDocument36 pagesBrand Worcester Digistat Optimiser 87161144620 ENJohn WalesNo ratings yet

- Catalogue MEGA HISSOTTO MAROCDocument37 pagesCatalogue MEGA HISSOTTO MAROCKatcherr CherrNo ratings yet

- Instrumentation Technicians-Enginneers Interview Questions-1Document87 pagesInstrumentation Technicians-Enginneers Interview Questions-1tusmanstoreNo ratings yet

- LT Cable Sizing-FormulaesDocument17 pagesLT Cable Sizing-FormulaesMamoon MohdNo ratings yet

- CAT MAK SystemDocument15 pagesCAT MAK SystemQaiser Iqbal100% (1)

- Installation Calculation Report: TR1 FullDocument37 pagesInstallation Calculation Report: TR1 FullZeyad EltobgyNo ratings yet

- Current Rating For SemiconductorsDocument8 pagesCurrent Rating For SemiconductorsAnonymous akwRljJvYNo ratings yet

- 1971em01fmdDocument24 pages1971em01fmdArnab DeNo ratings yet

- Tac 07 CsaDocument36 pagesTac 07 CsaWalter TaipeNo ratings yet

- KS Pulp Creator Final Quotation Air CompressorDocument4 pagesKS Pulp Creator Final Quotation Air Compressoratul guptaNo ratings yet

- Selection and Ordering Data: Motion ControlDocument46 pagesSelection and Ordering Data: Motion ControlMiguel RomeroNo ratings yet

- Almacen Sunarp - B - GCM - 01Document17 pagesAlmacen Sunarp - B - GCM - 01Sicologo CimeNo ratings yet

- H-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - BDocument16 pagesH-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - Bnguyen rinNo ratings yet

- 01 8768 Fe 61021Document1 page01 8768 Fe 61021mohammadtm90No ratings yet

- Self Inflating TyresDocument12 pagesSelf Inflating TyresRishabh DeedwaniyaNo ratings yet

- SSRBM Jeevan Bhima Nagar Handbook 2023-24 - 0 - 1Document9 pagesSSRBM Jeevan Bhima Nagar Handbook 2023-24 - 0 - 1Kiran Kidiyappa ShivakumarNo ratings yet

- Gao2007 PDFDocument5 pagesGao2007 PDFAnonymous cYpEVvoNo ratings yet

- Campus Placement DataDocument28 pagesCampus Placement DatakoolestniteshNo ratings yet

- Mystic Light Software Development Kit - 1.0.0.8Document10 pagesMystic Light Software Development Kit - 1.0.0.8Saifi HidayatullahNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDocument82 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) Finalsamarrana1234679No ratings yet

- Heathwood - Desire-Fufillment-TheoryDocument7 pagesHeathwood - Desire-Fufillment-TheorydanolmoNo ratings yet

- The Incoherence of The PhilosophersDocument7 pagesThe Incoherence of The PhilosophersArisha AsifNo ratings yet

- Utilities FUNDAMENTALS OF LIGHTINGDocument25 pagesUtilities FUNDAMENTALS OF LIGHTINGSidisGarciaNo ratings yet

- Manual16 Hayward PoolDocument1 pageManual16 Hayward PoolAhmed FaroukNo ratings yet

- Beginner Typing Lesson 1 - LEARN TYPINGDocument5 pagesBeginner Typing Lesson 1 - LEARN TYPINGThiyagu0% (1)

- The Word Stress Has Its Origin in The Latin WordsDocument2 pagesThe Word Stress Has Its Origin in The Latin Wordssayooj tvNo ratings yet

- F.T. Valvula Mariposa - XD381X - UL FMDocument4 pagesF.T. Valvula Mariposa - XD381X - UL FMMiguel RondinelNo ratings yet

- RVG Simplified PDFDocument1 pageRVG Simplified PDFzardarwaseemNo ratings yet

- Urdu NotesDocument2 pagesUrdu NotesEleazer NomanNo ratings yet

- Behaviour Change For Sustainable Development: October 2018Document11 pagesBehaviour Change For Sustainable Development: October 2018Febrian Bagus SetiawanNo ratings yet

- BATCH 8 MajorDocument52 pagesBATCH 8 MajorHemsundar ArepallyNo ratings yet

- Salesforce - CRT 600.v2021 03 30 PDFDocument21 pagesSalesforce - CRT 600.v2021 03 30 PDFJonathan Alejandro ZambranoNo ratings yet

- Tructured Uery Anguage: 1 ©stefan Stanczyk P00482 - 2005Document71 pagesTructured Uery Anguage: 1 ©stefan Stanczyk P00482 - 2005Sky ShetuNo ratings yet

- 9.write The Short Notes On Laser ScanningDocument4 pages9.write The Short Notes On Laser Scanningمحمد تانزيم ابراهيمNo ratings yet

- Log Cat 1700663779292Document144 pagesLog Cat 1700663779292Enry GomezNo ratings yet

- K N Rao - Char Dasha Example of LadyDocument47 pagesK N Rao - Char Dasha Example of LadyAnonymous KpVxNXsNo ratings yet

- Research Paper For McaDocument8 pagesResearch Paper For Mcagw1qjeww100% (1)

- Service (Repair) Manual For Panasonic SA-BT100PDocument174 pagesService (Repair) Manual For Panasonic SA-BT100PDan Guertin50% (2)

- Nay Aung CV - FormDocument3 pagesNay Aung CV - FormTECHNO ProductionNo ratings yet

- Wastewater DN80 To DN600 PDFDocument36 pagesWastewater DN80 To DN600 PDFMR seaNo ratings yet