0% found this document useful (0 votes)

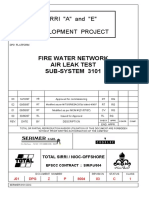

263 views7 pagesAir Leak Test Procedure: SIRRI A

This document describes an air leak test procedure for the closed drain subsystem 2301 of the SIRRI "A" and "E" DPG development project. The test will pressurize partial closed drain systems to 2.5 barg using oil-free air supplied at 7 barg. Temporary hoses will be installed at various points to pressurize sections and monitor pressure. The test is estimated to take 3 days with a 4-person team and will check for leaks using soap solution. Safety precautions like signage and horns will be followed.

Uploaded by

Mohammad MohseniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

263 views7 pagesAir Leak Test Procedure: SIRRI A

This document describes an air leak test procedure for the closed drain subsystem 2301 of the SIRRI "A" and "E" DPG development project. The test will pressurize partial closed drain systems to 2.5 barg using oil-free air supplied at 7 barg. Temporary hoses will be installed at various points to pressurize sections and monitor pressure. The test is estimated to take 3 days with a 4-person team and will check for leaks using soap solution. Safety precautions like signage and horns will be followed.

Uploaded by

Mohammad MohseniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

- Cover Page: Title page detailing the air leak test procedure for closed drains in subsystem 2301, including document control details.

- Revision Record: Lists revisions made to the document, specifying the purpose and sections updated.

- Test Summary: Summarizes the air leak test procedure, including scope, methodology, and precautions.

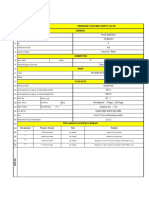

- Planning and Manpower: Covers the required planning and manpower estimates for conducting the test.

- Test Requirements: Details the duration, precommissioning achievements, and logistic support necessary for the test.

- Test Equipment and Tools: Specifies the equipment and consumables list required for the air leak test.

- Procedure: Outlines detailed step-by-step procedures, including mechanical preparations and testing tasks.

- Leak Test Procedures: Describes procedures for conducting leak tests, including final checks and post-test conditions.