Professional Documents

Culture Documents

For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair Center

Uploaded by

Amjad AlQasrawiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair Center

Uploaded by

Amjad AlQasrawiCopyright:

Available Formats

BULLETIN NO.

SERVICE PARTS LIST 54-00-2805

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS REVISED BULLETIN DATE

Oct. 2019

M18™ FUEL™ ONE KEY DRIVER-DRILL

WIRING INSTRUCTION

STARTING

CATALOG NO. 2805-20 SERIAL NO. J78A

Service for Milwaukee Tool ONE KEY Products

can only be performed at this

Milwaukee factory Central Repair Center:

MILWAUKEE TOOL Central Repair

1401 Sycamore Avenue l Greenwood, MS 38930-7277

Please send your tool directly to this location for service.

Or

Via e-Service at: www.milwaukeetool.com/e-service

questions, please call 1.800.SAWDUST (1.800.729.3878)

Or

Return it to a MILWAUKEE factory Service Center location, freight prepaid and insured.

A copy of the proof of purchase should be included with the return product.

If you have questions please contact Milwaukee Product Service at:

Product Technical Support via phone at: 262.783.8642

Or

Via email at: METProductSupport@milwaukeetool.com

Disassembly is not recommended and could void the warranty. Drwg. 2

56

REMOVING THE CHUCK SCREW:

Set the Speed Selector Slide (39) to the #1 setting.

With the aid of a small pencil tip torch (or use an air reduction nozzle on a heat gun)

apply heat into the chuck opening, directly to the head of reversing screw just prior to

removing the screw. Place a T40 1/4” torx bit into the head of the reversing screw and

place a 1/4” boxed end wrench over the hex on the T40 bit. It is recommended to use a

12”-18” metal tube or pipe as leverage over the boxed wrench. In a clockwise direction

Speed apply a slow, steady force on the ‘cheater bar’ to break the screw loose.

Selector

46 Slide (39)

REMOVING THE KEYLESS CHUCK:

Tighten a 1/2” or 10mm Allen Key into the jaws of the chuck. Place

the tool into a vise with soft jaws (this will require that you remove

the belt clip from the tool). It is recommended to use a 12”-18” metal

tube or pipe as leverage over the allen key. In a counter-clockwise

direction apply a slow, steady force on the ‘cheater bar’ to break the

chuck loose.

INSTALLING NEW CHUCK AND SCREW:

Torque Chuck to 1095 kg/cm (950.418 in/lbs or 28.93 ft/lbs)

Torque Screw to 461 kg/cm (400.130 in/lbs or 33.34 ft/lbs)

57

48

1

49

26

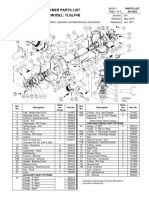

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

52 25

26 1 05-88-0019 M8.0 x 1 LH T-40 Chuck Screw (1)

21 --------------- Coin Cell Board Assembly (1)

25 22 --------------- 3V Coin Cell Battery (CR 2032) (1)

23 31-15-0011 Coin Cell Cover (1)

50 26

43

24

25

05-81-1100

---------------

M2.6 x 6mm ST Phillips Screw

Belt Clip

(2)

(1)

26 06-82-2500 6-32 x 7mm Pan Hd. Slt. T-15 Mach. Screw (2)

39 --------------- Speed Selector Slide (1)

43 --------------- Bit Holder Housing (1)

46 42-55-9005 Blow Molded Carrying Case (1)

59 21

22

48 12-20-0478 Service Namelate (1)

49 10-20-1048 Warning Label (1)

50 43-72-0950 Bit Holder Kit (1)

52 42-70-0950 Belt Clip Kit (1)

26 43 21 56 42-62-1002 Side Handle Assembly (1)

57 42-66-8003 1/2” Keyless Chuck (1)

22 59 14-20-0068 Coin Cell Board Assembly with Battery (1)

23

24

(2x)

You might also like

- For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterDocument2 pagesFor Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterAmjad AlQasrawiNo ratings yet

- IgnitionDocument26 pagesIgnitionRyan ActonNo ratings yet

- Service Parts List: Catalog NoDocument4 pagesService Parts List: Catalog NoJosé Daniel ArenasNo ratings yet

- Model 40D MT Triple Mast: Parts ManualDocument108 pagesModel 40D MT Triple Mast: Parts ManualChristian BedoyaNo ratings yet

- Service Parts List: Catalog NoDocument4 pagesService Parts List: Catalog NoAbdelbagiNo ratings yet

- Mercruiser-3 7LDocument83 pagesMercruiser-3 7LFreakplayer20000No ratings yet

- PT 1728Q Advantage Parts Manual 3 Electronics Cabinet SectionDocument16 pagesPT 1728Q Advantage Parts Manual 3 Electronics Cabinet SectionBrandon CatronNo ratings yet

- M/D Totco:r I: Psi IsDocument6 pagesM/D Totco:r I: Psi IsLuis AlbarracinNo ratings yet

- Vibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Bomba de Vacio Part ListDocument2 pagesBomba de Vacio Part ListNayeli Zarate MNo ratings yet

- Roland JC 40Document31 pagesRoland JC 40boroda2410No ratings yet

- ISO 84 Parts List for 1Document2 pagesISO 84 Parts List for 1Cristian Villagra EscobarNo ratings yet

- WS4500-7500 Parts ManualDocument118 pagesWS4500-7500 Parts ManualtonyNo ratings yet

- 54-47-0480Document2 pages54-47-0480inqwalterNo ratings yet

- Vibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Document2 pagesVibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- MR4AL English ManualDocument46 pagesMR4AL English ManualKalees WaranNo ratings yet

- 8660, 8100 Modification Instructions, Mod 3Document4 pages8660, 8100 Modification Instructions, Mod 3EdilbertoJuarezNo ratings yet

- Alternating RelayDocument4 pagesAlternating RelayAriel DimacaliNo ratings yet

- PM0174EDocument114 pagesPM0174Eapi-2628376675% (4)

- Real Head Kick Pad: Service ManualDocument8 pagesReal Head Kick Pad: Service ManualErikNo ratings yet

- 40 PagesDocument40 pages40 PagesKARTHICKRAJ KANDASAMYNo ratings yet

- Vat 45Document2 pagesVat 45mehralsmenschNo ratings yet

- Service Manual #27Document631 pagesService Manual #27CharlesWhiteNo ratings yet

- V20spareparts Mando HidraulicoDocument108 pagesV20spareparts Mando HidraulicoMiguel Angel Santos PintadoNo ratings yet

- PDocument131 pagesPVictoria CoronaNo ratings yet

- Nema Nomenclature RolesDocument9 pagesNema Nomenclature RolesRicardo LaraNo ratings yet

- Armado de Valvula de Salida Del ConvertidorDocument2 pagesArmado de Valvula de Salida Del ConvertidorKerbin Enrique NuñezNo ratings yet

- Engine Valve Lash - InspectAdjust (UENR4524-24)Document5 pagesEngine Valve Lash - InspectAdjust (UENR4524-24)Guido Emanuel SteinbachNo ratings yet

- Blackmer Parts List Pump Model: Tlglf4BDocument2 pagesBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSNo ratings yet

- Connecting Rod Repair GuideDocument32 pagesConnecting Rod Repair GuideJorge Espinoza100% (1)

- Enerpac Torque Wrench ManualDocument10 pagesEnerpac Torque Wrench ManualM Saad KhanNo ratings yet

- Tlglf4b 09 09 MarkedDocument2 pagesTlglf4b 09 09 MarkedyuanNo ratings yet

- Jupiter 150 PDFDocument73 pagesJupiter 150 PDFRonar TOLITS PajulasNo ratings yet

- Yamaha LCDocument63 pagesYamaha LCjoshuaNo ratings yet

- t-5 Parts CatalogDocument86 pagest-5 Parts CatalogАлексейNo ratings yet

- TFP1421 08 2023Document21 pagesTFP1421 08 2023Vivekanand SonavaneNo ratings yet

- Manual Transmission GuideDocument21 pagesManual Transmission GuideKwun Hok ChongNo ratings yet

- 1F5TL460E1 (AL115C-S) Mio 5TL6-7Document58 pages1F5TL460E1 (AL115C-S) Mio 5TL6-7lyrmp sobrecaryNo ratings yet

- SQ100Document3 pagesSQ100Solrac Nauj Ogaitnas100% (1)

- 1D83 (1C1D8450E2) T105SE Crypton RDocument56 pages1D83 (1C1D8450E2) T105SE Crypton RRenNo ratings yet

- 40C7 (1R40C450E1) AL115C Mio SportyDocument56 pages40C7 (1R40C450E1) AL115C Mio SportyJonard SayodNo ratings yet

- Cessna Cessna Hydro Test Manual SE588 ModelsDocument11 pagesCessna Cessna Hydro Test Manual SE588 ModelsFranco Puga100% (2)

- Manual ING SHJ 7005Document59 pagesManual ING SHJ 7005ricardo assaf marchetiNo ratings yet

- Parts Manual: Automatic ScrubberDocument147 pagesParts Manual: Automatic ScrubberMarco TailleferNo ratings yet

- 580m - Series 2 Loader Backhoe Tier 2 (Na) - Asn N4c303000 (02/04 - 12/08) 07 - Brakes 07-02 - Axle, Rear Drive - Brake, ParkingDocument3 pages580m - Series 2 Loader Backhoe Tier 2 (Na) - Asn N4c303000 (02/04 - 12/08) 07 - Brakes 07-02 - Axle, Rear Drive - Brake, ParkingJESUSNo ratings yet

- Yamaha x1 Parts CatalogDocument66 pagesYamaha x1 Parts CatalogGemson VillarmaNo ratings yet

- Yamaha x1 Parts Catalog PDFDocument66 pagesYamaha x1 Parts Catalog PDFEd TriaNo ratings yet

- Steering System: Service Data and Specifications (SDS) ............ 2Document12 pagesSteering System: Service Data and Specifications (SDS) ............ 2Юра ПетренкоNo ratings yet

- Manual Serviço Hitachi Rak Tem EsquemaDocument72 pagesManual Serviço Hitachi Rak Tem EsquemaFlabio OliveiraNo ratings yet

- 51C2 (1J51C450E1) AT115C Nouvo ZDocument54 pages51C2 (1J51C450E1) AT115C Nouvo ZRenNo ratings yet

- Rectificador Milwaukee Modelo 5192 Part ListDocument1 pageRectificador Milwaukee Modelo 5192 Part ListJesus RamirezNo ratings yet

- BULLETIN NO. 54-26-1701 SERVICE PARTS LIST FOR 1/2Document1 pageBULLETIN NO. 54-26-1701 SERVICE PARTS LIST FOR 1/2chiuchimuNo ratings yet

- Upper Frame and Undercarriage Frame - Connect (RENR8648-32)Document7 pagesUpper Frame and Undercarriage Frame - Connect (RENR8648-32)Anderson Oliveira SilvaNo ratings yet

- Manual de Partes Planta Luminaria DoosanDocument58 pagesManual de Partes Planta Luminaria DoosanRUBERTH ALEXANDER OCHOA0% (1)

- McCulloch Parts and Specs. For Multiple Models TrimmersDocument8 pagesMcCulloch Parts and Specs. For Multiple Models Trimmersdritzz7386% (7)

- 95TI Assembly GuideDocument16 pages95TI Assembly GuideBradley-and Esther ApplemanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ESHT0321Document1 pageESHT0321Amjad AlQasrawiNo ratings yet

- 220-240V Aspirator Blower: EABR4001Document1 page220-240V Aspirator Blower: EABR4001Amjad AlQasrawiNo ratings yet

- 12V Auto Air Compressor: EAAC3501Document1 page12V Auto Air Compressor: EAAC3501Amjad AlQasrawiNo ratings yet

- Service parts list for 3/8 inch drill with spindle lockDocument1 pageService parts list for 3/8 inch drill with spindle lockAmjad AlQasrawiNo ratings yet

- Nitrile Gloves XL for Oil EnvironmentsDocument1 pageNitrile Gloves XL for Oil EnvironmentsAmjad AlQasrawiNo ratings yet

- Service Parts List: Bulletin NoDocument3 pagesService Parts List: Bulletin NoAmjad AlQasrawiNo ratings yet

- ESGG0101Document1 pageESGG0101Amjad AlQasrawiNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List: 54-06-2903 3/8" Pistol Grip Drill With Spindle Lock 069DDocument3 pagesService Parts List: 54-06-2903 3/8" Pistol Grip Drill With Spindle Lock 069DAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterDocument1 pageFor Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List: Bulletin NoDocument1 pageService Parts List: Bulletin NoAmjad AlQasrawiNo ratings yet

- For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterDocument2 pagesFor Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ FUEL™ Multi-Head DrillDocument2 pagesService Parts List: M12™ FUEL™ Multi-Head DrillAmjad AlQasrawiNo ratings yet

- For Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterDocument1 pageFor Milwaukee Tool ONE KEY Products: Service Can Only Be Performed at This Milwaukee Factory Central Repair CenterAmjad AlQasrawiNo ratings yet

- Service Parts List: M12™ FUEL™ Multi-Head DrillDocument2 pagesService Parts List: M12™ FUEL™ Multi-Head DrillAmjad AlQasrawiNo ratings yet

- Service Parts List: M18™ Fuel™ Power Unit 2825-21 K49A 54-49-2810Document7 pagesService Parts List: M18™ Fuel™ Power Unit 2825-21 K49A 54-49-2810Amjad AlQasrawiNo ratings yet

- Service Parts List: M18™ FUEL™ Brushless Drill-DriverDocument2 pagesService Parts List: M18™ FUEL™ Brushless Drill-DriverAmjad AlQasrawiNo ratings yet

- Service Parts List: M18™ FUEL™ Brushless Drill-DriverDocument2 pagesService Parts List: M18™ FUEL™ Brushless Drill-DriverAmjad AlQasrawiNo ratings yet

- DUT 230 MM - 1 PCDocument1 pageDUT 230 MM - 1 PCAmjad AlQasrawiNo ratings yet

- BULLETIN NO. 54-00-2723 SERVICE PARTS LISTDocument5 pagesBULLETIN NO. 54-00-2723 SERVICE PARTS LISTAmjad AlQasrawiNo ratings yet

- Service Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42ADocument2 pagesService Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42AAmjad AlQasrawi100% (1)

- M18 Oneslsp-0: - M18™ ONE-KEY™ LED Compact Site LightDocument1 pageM18 Oneslsp-0: - M18™ ONE-KEY™ LED Compact Site LightAmjad AlQasrawiNo ratings yet

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument24 pagesOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorAmjad AlQasrawiNo ratings yet

- SetupWizard logs document changes during initial device configurationDocument10 pagesSetupWizard logs document changes during initial device configurationAhmed ZeharaNo ratings yet

- Daily Stoic Amor Fati Excerpt From The Obstacle Is The WayDocument7 pagesDaily Stoic Amor Fati Excerpt From The Obstacle Is The WaySirLouen100% (9)

- Echotrac Mkiii: Model DFDocument2 pagesEchotrac Mkiii: Model DFjonathansolverNo ratings yet

- DNA Microarrays: DR Divya GuptaDocument33 pagesDNA Microarrays: DR Divya GuptaRuchi SharmaNo ratings yet

- MBenz E320 W211 CDI OM648 Specifications1Document31 pagesMBenz E320 W211 CDI OM648 Specifications1rodolfodiazNo ratings yet

- User Manual Servo Driver SZGH-302: (One Driver To Control Two Motors Simultaneously)Document23 pagesUser Manual Servo Driver SZGH-302: (One Driver To Control Two Motors Simultaneously)Zdeněk HromadaNo ratings yet

- Experiment No. 2 Introduction To Combinational Circuits: Group Name: Group 7 Group Leader: JOSE DOROSAN Group MemberDocument11 pagesExperiment No. 2 Introduction To Combinational Circuits: Group Name: Group 7 Group Leader: JOSE DOROSAN Group MemberJoy PeconcilloNo ratings yet

- MINI R56 N12 Valve Stem Seal ReplacementDocument9 pagesMINI R56 N12 Valve Stem Seal ReplacementJohn DoeNo ratings yet

- Differential ManometersDocument3 pagesDifferential ManometersAnonymous QM0NLqZO100% (1)

- Modulus of FunctionsDocument14 pagesModulus of FunctionsVajan SelvaratnamNo ratings yet

- Chapter 1-Introduction To Green BuildingsDocument40 pagesChapter 1-Introduction To Green Buildingsniti860No ratings yet

- Natural Lighting at The Kimbell Museum: Gifford Pierce of IdahoDocument5 pagesNatural Lighting at The Kimbell Museum: Gifford Pierce of IdahoPriscilia ElisabethNo ratings yet

- MCT001 InstructionsDocument2 pagesMCT001 Instructionspatterl2No ratings yet

- Science: Locating Places On Earth Using Coordinate SystemDocument29 pagesScience: Locating Places On Earth Using Coordinate Systemlawrence maputolNo ratings yet

- Chinese Character Writing Exercise SheetsDocument47 pagesChinese Character Writing Exercise Sheetsapi-3700050100% (1)

- Questionnaire DesignDocument16 pagesQuestionnaire DesignCriss James AnsunNo ratings yet

- CNC USB Controller API: User ManualDocument29 pagesCNC USB Controller API: User ManualVisajientoNo ratings yet

- Concrete Mix Design Report for M20 GradeDocument5 pagesConcrete Mix Design Report for M20 GradesatishNo ratings yet

- INGLES TECNICO IV (En Ambas Caras)Document45 pagesINGLES TECNICO IV (En Ambas Caras)ESGUAR INSTRUCTORESNo ratings yet

- Modelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsDocument9 pagesModelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsShailendra YadavNo ratings yet

- Lithium Carbonate Tablets USPDocument4 pagesLithium Carbonate Tablets USPCesar Alejandro Olguin MarquezNo ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- Graderroadmotori 019931 MBPDocument97 pagesGraderroadmotori 019931 MBPblarkins1No ratings yet

- Treadmill Error Code GuideDocument19 pagesTreadmill Error Code GuideŞener MutluNo ratings yet

- Mahmadali Shakilahmad Mulla: Register No.: AB32045Document2 pagesMahmadali Shakilahmad Mulla: Register No.: AB32045BaakdNo ratings yet

- Hydraulic ConductivityDocument8 pagesHydraulic ConductivityJill AndersonNo ratings yet

- Of For of or Or: The Professional School of Psychology San Francisco, CaliforniaDocument9 pagesOf For of or Or: The Professional School of Psychology San Francisco, CaliforniaSamiMolinaNo ratings yet

- PN Junction Diode OperationDocument8 pagesPN Junction Diode OperationAyush NinaweNo ratings yet

- Alice Through The Looking Glass Movie Review (Great Books)Document2 pagesAlice Through The Looking Glass Movie Review (Great Books)Maria Kara Alexir CalambaNo ratings yet

- Fabric in ArchitectureDocument28 pagesFabric in ArchitecturesubalakshmiNo ratings yet