Professional Documents

Culture Documents

Method Statement For Cutting

Uploaded by

marckeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Cutting

Uploaded by

marckeCopyright:

Available Formats

QA/QC

METHOD STATEMENT

METHOD STATEMENT FOR CONCRETE SLAB CUTTING

(HALFSLAB AND HOLLOWCORE SLAB)

CLARK INTERNATIONAL AIRPORT PROJECT

PREPARED BY NOTED BY:

NAME Alfred L. Comendador Einstein O. Chiu

TITLE QA/QC M - Precast AVP - Precast

DATE 04 Jan. 2019 04 Jan. 2019

SIGNATURE

MS CODE NO.: MCCMS-5.1-1

REVISION : 00

TABLE OF CONTENTS

1.0 Title

2.0 General Description

3.0 Scope

4.0 Data

5.0 Equipment / Tools

6.0 Repair Materials

7.0 Preparation

8.0 Procedure

9.0 Cutting Sequence

TITLE

METHOD STATEMENT FOR CONCRETE SLAB CUTTING (HOLLOW CORE and Half SLAB)

GENERAL DESCRIPTION

This document outlines the procedure for rectification through cutting of concrete due to the excess length of

hollow core and half slab for Clark International Airport Project. MCC - Precast is the contractor for

manufacturing and delivery of the required precast units and responsible for compliance with this procedure .

SCOPE

This Method Statement directly addresses the non-conformance on the dimension of the hollow core and

half slab due to the revision of framing plan as per MCC-Precast Engineering Department letter dated January

03, 2019. (Subject: Rectification – CIA Hollow Core Slab and Half Slab)

DATA

Below is the list of Hollow core and Half slab need to be cut at site.

At MCC-Precast Factory

Panel Name Cut

D1HC – (307 to 318) 70 mm

D1HC – (341 to 364) 70 mm

D1HC – (387 to 398) 50 mm

D3HC – (101 to 191) 102 mm

D3HC – (194 to 195) 100 mm

D5HC – (226 to 291) 100 mm

A2HC – (91 to 95) 50 mm

A2HC – 97 50 mm

A3HC – (25 to 33) 50 mm

A3HC – (60 to 65) 50 mm

Panel Name Cut

A6HS-14 1890 mm

EQUIPMENT / TOOLS

Diamond Blade (7’’ Diamond Cutter)

Grinding Machine – (Makita)

Chisel (Handy)

REPAIR MATERIALS

Protective Paint for Rebar and PC Strand (epoxy paint)

PREPARATION

An exclusion zone is established around the area to be sawed at CIA Project Site.

The precast slab shall be identified

The slab cutting length shall be identified and mark.

A cut-line is pre-marked on both side of the slab as per specified cutting length

Cutting tools and equipment shall be checked and tested.

Ensure engine is warmed up and the blade is spinning at the correct speed before commencing cutting.

Appropriate PPE should be worn.

PROCEDURE

Work should be done at Project Site and in MCC Precast factory.

Provide a pre-marked at both face of the slab. Be sure that correct layout marked as per specified cutting

length

Cut Straight. Make the first cut about 50-75mm deep from the top of the slab using diamond cutter (See

cutting sequence)

Start the cutting and chipping of concrete from top portion going down at every 50mm-75mm using

diamond cutter and handy chisel

Never leave a running machine unattended

If cutting was done, remove the extra concrete using hand type power chisel or small diameter grinder

Use a handy chisel to chip off loose concrete and diamond cup wheel to get correct dimension of the slab

Protect the exposed cut reinforcement by applying epoxy paint

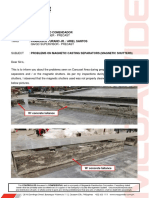

CUTTING SEQUENCE

You might also like

- Work Method Statement For Plain and Reinforced Cement Concrete PCCDocument2 pagesWork Method Statement For Plain and Reinforced Cement Concrete PCCBhargav BbvsNo ratings yet

- Heavy Duty Shoring Installation MethodDocument1 pageHeavy Duty Shoring Installation MethodNizam ShafieNo ratings yet

- Method Statement To Seal The OpeningDocument3 pagesMethod Statement To Seal The OpeningprabhuNo ratings yet

- Method Statement For Columns2Document5 pagesMethod Statement For Columns2Jasmine TsoNo ratings yet

- Method Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneDocument2 pagesMethod Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneParasNo ratings yet

- Method Statement For External Stone Cladding (Marble and Granite)Document7 pagesMethod Statement For External Stone Cladding (Marble and Granite)Muthukumar JayaveerapandianNo ratings yet

- Method Statement For Cement Block Work - Submittal No.165 PDFDocument15 pagesMethod Statement For Cement Block Work - Submittal No.165 PDFThilan SenarathneNo ratings yet

- Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesChecklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- PCC Below Footings ChecklistDocument1 pagePCC Below Footings ChecklistHamidullah TotakhailNo ratings yet

- Method Statement For Repair of Bulged Concrete UsingDocument8 pagesMethod Statement For Repair of Bulged Concrete Usingbureau servicesNo ratings yet

- Jotashield exterior paint work methodDocument2 pagesJotashield exterior paint work methodSetyawanNo ratings yet

- Mos For Hacking RectificationDocument1 pageMos For Hacking Rectificationoj_ordeNo ratings yet

- RCC Pile Works ChecklistDocument1 pageRCC Pile Works ChecklistAyush PuriNo ratings yet

- Method Statement For Construction of An Additional Column To Support The Existing Ground)Document7 pagesMethod Statement For Construction of An Additional Column To Support The Existing Ground)Akash Yadav100% (1)

- Wms - Concrete Repairing Works (Pedestals)Document4 pagesWms - Concrete Repairing Works (Pedestals)krmchari100% (1)

- Method Statement For Demolition of Pile Cap of Existing Dolphin JettyDocument5 pagesMethod Statement For Demolition of Pile Cap of Existing Dolphin JettyPriodeep ChowdhuryNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Method Statement For Marble Flooring and Marble Wall CladdingDocument10 pagesMethod Statement For Marble Flooring and Marble Wall Claddingumit100% (1)

- Method Statement FOR Raft Concrete: 1.0 Scope of Works 2.0 References 3.0 ResponsibilitiesDocument12 pagesMethod Statement FOR Raft Concrete: 1.0 Scope of Works 2.0 References 3.0 ResponsibilitiesJHONALIZANo ratings yet

- Method StatementDocument5 pagesMethod StatementMalith De SilvaNo ratings yet

- Method Statement for Ceramic Tile InstallationDocument4 pagesMethod Statement for Ceramic Tile InstallationAli SaifNo ratings yet

- Method Statement For Wall PuttyDocument5 pagesMethod Statement For Wall PuttySagar ParabNo ratings yet

- DEMOLITION OF WALLS FOR DOOR/WINDOW OPENINGSDocument2 pagesDEMOLITION OF WALLS FOR DOOR/WINDOW OPENINGSDarlyn SagreNo ratings yet

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- Sunken FillingDocument3 pagesSunken FillingASHOKKUMARNo ratings yet

- Method Statement For Conventional Formwork BlogDocument9 pagesMethod Statement For Conventional Formwork BlogMohasin KhanNo ratings yet

- Work Method Statement RCC DismantlingDocument3 pagesWork Method Statement RCC DismantlingCICON Engineers0% (1)

- Method Statement For HoneycombDocument6 pagesMethod Statement For HoneycombCHAR JIN CHEENo ratings yet

- Basic Requirements in Swimming Pool Construction - The ConstructorDocument10 pagesBasic Requirements in Swimming Pool Construction - The ConstructorBunkun15No ratings yet

- Coring Method Statement for Pump Station WallsDocument12 pagesCoring Method Statement for Pump Station WallsjameelNo ratings yet

- The Rise Resort Railing WorksDocument6 pagesThe Rise Resort Railing WorksMin LuoNo ratings yet

- Method Statement Gypsum BoardDocument6 pagesMethod Statement Gypsum Boardsajin100% (1)

- Construction of Dormitory & Housing compounds in NorochcholaiDocument33 pagesConstruction of Dormitory & Housing compounds in Norochcholaisaranga100% (1)

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining Wallibrahim0% (1)

- 2239 - Specification of Brick Work and Plastering WorkDocument12 pages2239 - Specification of Brick Work and Plastering Workvelmurug_bala100% (2)

- Hard Core / Soling Under Floors / Foundations:: Scope of WorkDocument1 pageHard Core / Soling Under Floors / Foundations:: Scope of Worksaurabh dasNo ratings yet

- Pile Build UpDocument6 pagesPile Build UpHimalFernando0% (1)

- Methodology of CHBDocument15 pagesMethodology of CHBLevy Jane DobleNo ratings yet

- Method Statement Tiling WorksDocument8 pagesMethod Statement Tiling WorksNara Kong100% (2)

- Method Statement For Aac BlockworkDocument10 pagesMethod Statement For Aac BlockworkobieNo ratings yet

- Work Method Statement - POP PUNNINGDocument3 pagesWork Method Statement - POP PUNNINGSathish Gowda100% (1)

- L'WZAAR FISH MARKET & RESTAURANT DEMOLITION CHECKLISTDocument2 pagesL'WZAAR FISH MARKET & RESTAURANT DEMOLITION CHECKLISTMohammed Javid100% (1)

- Method Statement For Metal Roof and Wall Cladding WorkDocument14 pagesMethod Statement For Metal Roof and Wall Cladding WorkAnantha PadmanabhanNo ratings yet

- Method Statement - Ground Floor SlabDocument8 pagesMethod Statement - Ground Floor SlabHannaFouadNo ratings yet

- Method Statement For False Ceiling WorkDocument5 pagesMethod Statement For False Ceiling Worktrija_mrNo ratings yet

- Daily labour report for Ansal Town siteDocument2 pagesDaily labour report for Ansal Town siteKapil SharmaNo ratings yet

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Raft - MSDocument10 pagesRaft - MSabson pongNo ratings yet

- Method Statement and SpecificationDocument17 pagesMethod Statement and SpecificationApai MfarNo ratings yet

- RCC Jacketing Method StatementDocument5 pagesRCC Jacketing Method Statementrobin7No ratings yet

- MOS Civil EngineeringDocument19 pagesMOS Civil EngineeringSahar GulNo ratings yet

- Method Statements For Plain Cement ConcreteDocument5 pagesMethod Statements For Plain Cement ConcreteKrm Chari75% (4)

- INFOSYS MULTI LEVEL CAR PARKDocument159 pagesINFOSYS MULTI LEVEL CAR PARKG Ravi Kumar Reddy50% (2)

- Method Statement For Cuplock Shuttering WorkDocument7 pagesMethod Statement For Cuplock Shuttering WorkAkash YadavNo ratings yet

- Quality Systems Manual Method Statement: Tiling Work (Floors and Walls)Document8 pagesQuality Systems Manual Method Statement: Tiling Work (Floors and Walls)Lloyd MariNo ratings yet

- Method Statement For Screed Concreting Aerator TWTDocument4 pagesMethod Statement For Screed Concreting Aerator TWTChamara Nilantha KarunarathnaNo ratings yet

- Mivan Component CodesDocument9 pagesMivan Component Codeskishor150688100% (1)

- Method Statement For Casting of Cement Based ScreedDocument8 pagesMethod Statement For Casting of Cement Based Screedmd_rehan_2100% (1)

- Welding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFDocument5 pagesWelding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFRakesh RanjanNo ratings yet

- Faculty of Engineering and TechnologyDocument1 pageFaculty of Engineering and TechnologyaeropaschalNo ratings yet

- WWP Lifting Anchor Breakage PDFDocument5 pagesWWP Lifting Anchor Breakage PDFmarckeNo ratings yet

- Poultry Egg Production Business Plan and Management Guide: Deep Litter Housing and Battery Cage System ManagementDocument13 pagesPoultry Egg Production Business Plan and Management Guide: Deep Litter Housing and Battery Cage System ManagementCervancia Lianco Marc Raven50% (2)

- WWP Lifting Anchor Breakage PDFDocument5 pagesWWP Lifting Anchor Breakage PDFmarckeNo ratings yet

- Report On Magnetic Shutter and Other Forms PDFDocument6 pagesReport On Magnetic Shutter and Other Forms PDFmarckeNo ratings yet

- NCR BulacanDocument11 pagesNCR BulacanmarckeNo ratings yet

- Travel Request FormDocument2 pagesTravel Request FormmarckeNo ratings yet

- Report On Cement For Precast ConcreteDocument4 pagesReport On Cement For Precast ConcretemarckeNo ratings yet

- Hotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1Document2 pagesHotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1marckeNo ratings yet

- CPD Certificate - 10Document1 pageCPD Certificate - 10marckeNo ratings yet

- MS For Grouting ApplicationDocument20 pagesMS For Grouting ApplicationmarckeNo ratings yet

- Reynaldo Mamacos BPO SupervisorDocument3 pagesReynaldo Mamacos BPO SupervisormarckeNo ratings yet

- HCS OpeningDocument3 pagesHCS OpeningmarckeNo ratings yet

- Erection Method Statement Royal Comision (Hollow Core)Document17 pagesErection Method Statement Royal Comision (Hollow Core)marcke0% (1)

- Forbo Acoustic Vinyl Environmental Datasheet Aug 2015 UKDocument2 pagesForbo Acoustic Vinyl Environmental Datasheet Aug 2015 UKIvan PopovicNo ratings yet

- FlyweelDocument6 pagesFlyweelTalebNo ratings yet

- Comviva - PF - Bulk Messaging GatewayDocument2 pagesComviva - PF - Bulk Messaging Gatewayraednoor20No ratings yet

- Tadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Document4 pagesTadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Sandya KaranamNo ratings yet

- Goz - Study of The Numerical Instabilities in Lagrangian Tracking of Bubbles and Particles in Two Phase FlowDocument7 pagesGoz - Study of The Numerical Instabilities in Lagrangian Tracking of Bubbles and Particles in Two Phase FlowguilhermehsssNo ratings yet

- Sap Fi Accounts ReceivableDocument66 pagesSap Fi Accounts ReceivableNikola100% (1)

- BX2750Document18 pagesBX2750Mike BurdNo ratings yet

- Inter Standard Roaming: GSM SponsorDocument21 pagesInter Standard Roaming: GSM SponsorKamaldeep Singh DhanotaNo ratings yet

- Molecular Self-AssemblyDocument11 pagesMolecular Self-AssemblyAnonymous dBVpivgaBNo ratings yet

- 22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Document52 pages22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Kiran VeesamNo ratings yet

- FilterPRO MBF and Sallen Key Low-Pass Filter Design ProgramDocument16 pagesFilterPRO MBF and Sallen Key Low-Pass Filter Design ProgramDaniel LeivaNo ratings yet

- Functions of Production VersionDocument5 pagesFunctions of Production VersiongvlaxmipathiNo ratings yet

- Consumer Reports Buying Guide 2013: Home AppliancesDocument66 pagesConsumer Reports Buying Guide 2013: Home Appliancesdesijnk100% (1)

- Government of Odisha Rural Development Department Odisha, BhubaneswarDocument179 pagesGovernment of Odisha Rural Development Department Odisha, BhubaneswarPradeepta PatraNo ratings yet

- Cambridge English Logo Regulations for Preparation CentresDocument2 pagesCambridge English Logo Regulations for Preparation CentresdarshanNo ratings yet

- ACP Solution Training SlidesDocument21 pagesACP Solution Training Slidesmausam_panchal2013No ratings yet

- Basics of Indoor Pool Air DistributionDocument4 pagesBasics of Indoor Pool Air DistributionNebojsa GolubovicNo ratings yet

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019Document2 pagesBe - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019loharjay772No ratings yet

- Operations and Performance Management Long VersionDocument19 pagesOperations and Performance Management Long VersionSodhi S SohalNo ratings yet

- Medical and Inclement Weather PlanDocument3 pagesMedical and Inclement Weather PlanUs Cosplay SpecialistNo ratings yet

- Method Statement For Storage Tank Jack LiftingDocument18 pagesMethod Statement For Storage Tank Jack LiftingSyafiq100% (3)

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- 9852 2934 01 HCS 3715 Manual - en - Spare Parts ListDocument75 pages9852 2934 01 HCS 3715 Manual - en - Spare Parts Listgugi100% (1)

- RQD After 20 Years Deere 1989Document101 pagesRQD After 20 Years Deere 1989Johan Van Staveren100% (1)

- Distributed File SystemsDocument42 pagesDistributed File SystemsGaurav ManurNo ratings yet

- GatesDocument2 pagesGatesAnca ZibityNo ratings yet

- Smart Key System - KhaphamKJGUDocument41 pagesSmart Key System - KhaphamKJGUthu vuNo ratings yet

- 1 SECTION 16425 Switchboards (600 V and Below)Document4 pages1 SECTION 16425 Switchboards (600 V and Below)Ahmed AliNo ratings yet

- Building Construction Metric Volume 1 by W.BDocument180 pagesBuilding Construction Metric Volume 1 by W.BHenra Halim100% (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet