Professional Documents

Culture Documents

Assignment 3 MOM

Uploaded by

Talha Mughal0 ratings0% found this document useful (0 votes)

9 views1 pageThis assignment involves designing a flywheel for a punching press machine. The flywheel is used as an energy storage and delivery mechanism between the power source and the machine. The student must design the flywheel within the given constraints: [1] The punching machine must make 30 holes per minute in 18mm thick steel plates. [2] The flywheel diameter cannot exceed 1000mm due to space limitations. [3] The design must not exceed a coefficient of fluctuation of speed of 0.11. [4] The mean flywheel speed must be less than or equal to 275 rpm. [5] The flywheel mass cannot exceed 255kg. [6] The flywheel material is gray cast iron with a density

Original Description:

Original Title

Assignment 3 MOM .doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis assignment involves designing a flywheel for a punching press machine. The flywheel is used as an energy storage and delivery mechanism between the power source and the machine. The student must design the flywheel within the given constraints: [1] The punching machine must make 30 holes per minute in 18mm thick steel plates. [2] The flywheel diameter cannot exceed 1000mm due to space limitations. [3] The design must not exceed a coefficient of fluctuation of speed of 0.11. [4] The mean flywheel speed must be less than or equal to 275 rpm. [5] The flywheel mass cannot exceed 255kg. [6] The flywheel material is gray cast iron with a density

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageAssignment 3 MOM

Uploaded by

Talha MughalThis assignment involves designing a flywheel for a punching press machine. The flywheel is used as an energy storage and delivery mechanism between the power source and the machine. The student must design the flywheel within the given constraints: [1] The punching machine must make 30 holes per minute in 18mm thick steel plates. [2] The flywheel diameter cannot exceed 1000mm due to space limitations. [3] The design must not exceed a coefficient of fluctuation of speed of 0.11. [4] The mean flywheel speed must be less than or equal to 275 rpm. [5] The flywheel mass cannot exceed 255kg. [6] The flywheel material is gray cast iron with a density

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

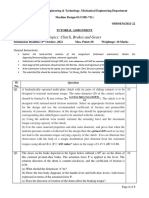

University of Management and Technology

Sialkot Campus

Mechanics of Machines

ASSIGNMENT#03

Course Code : ME 222 Max Time : 10 days

Program : BSME (Batch 5) Section :A

Resource Person: Engr. Zia Ullah Arif Total Marks : 10

Submission date: 15-June-2020

Flywheel’s design for punching press operation

Note: You can assume the data (design variables) while designing flywheel (as design is all about correct

assumption so that one can design objects within the given range of objective variables). Furthermore, compile

a comprehensive report with proper introduction, methodology, calculations and conclusions (pdf or doc

format). Results can be different based on your design assumption. Hence, avoid copying as it will result in

deduction of marks.

1. A flywheel is the bulky rotating mass that is placed between the driven machine and the power source to act

as an energy reservoir. It acts as an energy storage element when the demand for energy is less and delivers

it when the demand for energy is high. The current problem’s objective is to design (analytical) of arm type

of flywheel which is used for punching press operation as shown in figure below. With regard to the design

of flywheel, it is required to decide the mean diameter of the flywheel rim which depends upon two factors

such as the limiting value of the peripheral velocity of the flywheel and availability of space. However, the

design problem is to be formulated for a punching machine that has to make holes of 30 holes/minute in a

steel plate of 18mm thickness with space limitation that is the diameter of the flywheel should not exceed

1000mm.

a) The design should not exceed the coefficient of fluctuation of speed from 0.11.

b) The mean speed of flywheel (N) should be less than or equal to 275 rpm.

c) Mass of flywheel should not exceed 255 kg.

d) The material of flywheel has to be grey cast iron with a density of 7100 kg/m3.

Page 1 of 1

You might also like

- Optimization of CNC MachiningDocument3 pagesOptimization of CNC MachiningVIVA-TECH IJRINo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Reverse Engineering of Pump Casing and ImpellerDocument12 pagesReverse Engineering of Pump Casing and ImpellerEmad BadrNo ratings yet

- Project: Design and Analysis of Shock AbsorberDocument18 pagesProject: Design and Analysis of Shock AbsorberKunal KureelNo ratings yet

- Analysis of The Vertical Moving Table Type Broaching MachineDocument11 pagesAnalysis of The Vertical Moving Table Type Broaching MachineRijalul KhoiriNo ratings yet

- Comparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingDocument10 pagesComparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingIJRASETPublicationsNo ratings yet

- EM305 CAD Course WorkDocument2 pagesEM305 CAD Course WorkAlan DavenportNo ratings yet

- 2008-Manufacturing Complexity Evaluation For Additive andDocument12 pages2008-Manufacturing Complexity Evaluation For Additive andsachinkashidNo ratings yet

- Project 4-Last OneDocument10 pagesProject 4-Last Oneengineer.mohammedtahhanNo ratings yet

- Design and Fabrication of 3-Axes Mini CNC Milling MachineDocument15 pagesDesign and Fabrication of 3-Axes Mini CNC Milling MachinePavaniNo ratings yet

- Me 5 PT 2021Document3 pagesMe 5 PT 2021SameerNo ratings yet

- INME 4011 Term Project Guideline: D&T OnlineDocument9 pagesINME 4011 Term Project Guideline: D&T OnlineAnkur MenonNo ratings yet

- High Precision Linear Slide. Part I: Design and ConstructionDocument13 pagesHigh Precision Linear Slide. Part I: Design and ConstructionhamidrezamohamadzadeNo ratings yet

- Design and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingDocument12 pagesDesign and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingMido MoussaNo ratings yet

- Comparative Study of Casting Simulation Packages Used in FoundriesDocument4 pagesComparative Study of Casting Simulation Packages Used in FoundriesPrasad AnandNo ratings yet

- 20180204-Test01 (Chap01 Automats in Chap02) - With AnswersDocument10 pages20180204-Test01 (Chap01 Automats in Chap02) - With AnswersdeepakNo ratings yet

- Design Through Engineering Integration of Connecting ROD: AbstractDocument4 pagesDesign Through Engineering Integration of Connecting ROD: Abstractketthegr8No ratings yet

- EML2322L Wheel Hub DesignDocument5 pagesEML2322L Wheel Hub DesignVincentius NikimNo ratings yet

- Selected Aspects of Modular Fixtures Design For Car Body ProductionDocument10 pagesSelected Aspects of Modular Fixtures Design For Car Body Productionjames bondNo ratings yet

- Topics: Clutch, Brakes and GearsDocument3 pagesTopics: Clutch, Brakes and GearsVEER SINGHNo ratings yet

- Low Cost Automation For CNC Machining Center PDFDocument11 pagesLow Cost Automation For CNC Machining Center PDFgsudhanta1604No ratings yet

- Irjet V8i4487Document13 pagesIrjet V8i4487Saravanan SolutionsNo ratings yet

- Axial Flow Turbine Aerodynamic Shape DesignoptimizationDocument11 pagesAxial Flow Turbine Aerodynamic Shape Designoptimizationntik 23No ratings yet

- BaierDocument7 pagesBaierJackson PhinniNo ratings yet

- Design and Fabrication of Portable Drilling and Boring MachineDocument4 pagesDesign and Fabrication of Portable Drilling and Boring MachineVIVA-TECH IJRINo ratings yet

- 1 s2.0 S2212827119303142 MainDocument6 pages1 s2.0 S2212827119303142 Maindigvijaybhingare1243No ratings yet

- KLE Technological University Hubballi: A Minor Project Report OnDocument18 pagesKLE Technological University Hubballi: A Minor Project Report Onchannaveer kalaseNo ratings yet

- Micro-Machines For 3D Micro-PartsDocument8 pagesMicro-Machines For 3D Micro-PartsVictor VargasNo ratings yet

- Modelling and Analysis of CNC Milling Machine Bed With UHM CFRP Composite MaterialDocument11 pagesModelling and Analysis of CNC Milling Machine Bed With UHM CFRP Composite MaterialIJRASETPublicationsNo ratings yet

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDocument7 pagesTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesseventhsensegroupNo ratings yet

- Analysis of Flywheel: Akshay P. Punde, G.K.GattaniDocument3 pagesAnalysis of Flywheel: Akshay P. Punde, G.K.GattaniKelsey RyanNo ratings yet

- Ali 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Document14 pagesAli 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Yashvant SinghNo ratings yet

- 2014 MFE2201 Advanced Manufacturing SystemsDocument5 pages2014 MFE2201 Advanced Manufacturing SystemsBernice JohnsonNo ratings yet

- Robot Arm Without Using Robot Language and Its Application To Machining ProcessDocument5 pagesRobot Arm Without Using Robot Language and Its Application To Machining ProcessJulio Vega AngelesNo ratings yet

- ME465 - Major Course Project - Fall 2019Document2 pagesME465 - Major Course Project - Fall 2019Abdul BariNo ratings yet

- Design of Machine Members-I: Lecture NotesDocument74 pagesDesign of Machine Members-I: Lecture NotesChandan SinghNo ratings yet

- Automated Pressing MachineDocument7 pagesAutomated Pressing MachineIJRASETPublicationsNo ratings yet

- 156-Article Text-693-1-10-20211125Document6 pages156-Article Text-693-1-10-20211125oussama elhjoujiNo ratings yet

- Mekelle University Ethiopian Institute of Technology-Mekelle Mechanical Engineering DepartmentDocument3 pagesMekelle University Ethiopian Institute of Technology-Mekelle Mechanical Engineering Departmentgerea994047No ratings yet

- Multi Operation Machine Using Scotch Yoke MechanismDocument65 pagesMulti Operation Machine Using Scotch Yoke MechanismCrispNo ratings yet

- Manual de Uso de Chute MavenDocument33 pagesManual de Uso de Chute MavenMiguel FarahNo ratings yet

- Use of PLC Module To Control A Rotary TaDocument9 pagesUse of PLC Module To Control A Rotary TaΠερικλής ΖυγούραςNo ratings yet

- Gearless TransmissionDocument37 pagesGearless TransmissionTanvi KhuranaNo ratings yet

- Semi - Outer Thread Cutting MachineDocument4 pagesSemi - Outer Thread Cutting MachineTechnico TechnocratsNo ratings yet

- AFDEX Simulation of Connecting RodDocument7 pagesAFDEX Simulation of Connecting RodKumar SatyamNo ratings yet

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Document8 pagesDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNo ratings yet

- F-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoDocument5 pagesF-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoSumit MalikNo ratings yet

- MOMII - Project Fall 2023Document5 pagesMOMII - Project Fall 2023hameezaqeel713No ratings yet

- Mcsullog,+10 21791IJEMS 2020 2 35Document15 pagesMcsullog,+10 21791IJEMS 2020 2 35Yasar KhanNo ratings yet

- Numerical Hull Series For Calm WaterDocument15 pagesNumerical Hull Series For Calm WaterSarath Babu SNo ratings yet

- Material Selection For Spur Gear Design Using Ashby Chart: Prathamesh Surnis, Dr. Pravin KulkarniDocument11 pagesMaterial Selection For Spur Gear Design Using Ashby Chart: Prathamesh Surnis, Dr. Pravin KulkarniDumithJayathilakaNo ratings yet

- Design, Development, Motion Simulation and Analysis of Heavy Coil Wrapping MachineDocument4 pagesDesign, Development, Motion Simulation and Analysis of Heavy Coil Wrapping Machinekarthik bodangadaNo ratings yet

- Design For Manufacturing Applied To Turbomachine Components: Original ArticleDocument11 pagesDesign For Manufacturing Applied To Turbomachine Components: Original ArticleVignesh KumaranNo ratings yet

- Sheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesDocument23 pagesSheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesManolo GipielaNo ratings yet

- DMS All Assignment & Exeracises (2019-2020)Document6 pagesDMS All Assignment & Exeracises (2019-2020)Nikhil BhosaleNo ratings yet

- Btme 505 Cad Cam Cim Lab Mannual NewDocument35 pagesBtme 505 Cad Cam Cim Lab Mannual NewWube HabshaNo ratings yet

- About I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018Document8 pagesAbout I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018npatil_10No ratings yet

- Reverse Engineering of B-Pillar With 3D Optical Scanning For Manufacturing of Non-Uniform Thickness PartDocument10 pagesReverse Engineering of B-Pillar With 3D Optical Scanning For Manufacturing of Non-Uniform Thickness PartalirezaNo ratings yet

- Machining of Steam Turbine Blade On 5-Axis CNC Machine: SciencedirectDocument7 pagesMachining of Steam Turbine Blade On 5-Axis CNC Machine: SciencedirectMido MoussaNo ratings yet

- Cloud Service and Deployment Models 15052023 054248pmDocument41 pagesCloud Service and Deployment Models 15052023 054248pmTalha MughalNo ratings yet

- AWS Azure Google Cloud 22052023 053615pmDocument26 pagesAWS Azure Google Cloud 22052023 053615pmTalha MughalNo ratings yet

- Minutes of Meeting-4-3-2024Document4 pagesMinutes of Meeting-4-3-2024Talha MughalNo ratings yet

- What Is Child PsychologyDocument16 pagesWhat Is Child PsychologyTalha MughalNo ratings yet

- Basic Electrical Engineering Lab Group Members: - Fatima - Ur-Rehman (015) - URWADocument2 pagesBasic Electrical Engineering Lab Group Members: - Fatima - Ur-Rehman (015) - URWATalha MughalNo ratings yet

- TQM Intro 097,081,063,045Document2 pagesTQM Intro 097,081,063,045Talha MughalNo ratings yet