Professional Documents

Culture Documents

JSA File-Jerin Sam Kurian

JSA File-Jerin Sam Kurian

Uploaded by

jerin sam kurianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA File-Jerin Sam Kurian

JSA File-Jerin Sam Kurian

Uploaded by

jerin sam kurianCopyright:

Available Formats

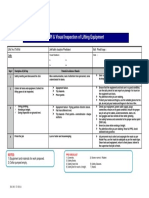

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Deck Activities

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Storing gas • Bottles of different gases • Explosion • Ensure safe distance kept between different types of gases

stored together • Always turn bottles off

• Insecure bottles falling over • Ensure bottles labelled

• Keep bottles in storage rack where possible

• Tie bottles and hoses securely

• Anti-snag device fitted

• 1, 2, 3, 4, 5, 8, 9, 11, 12

Working at height • Person falling • Personnel injury • Wear correct PPE, including safety harness

• Dropped objects • Remove loose items

• Place restricted access barrier as appropriate

• For container use ladder to access slings

• Access only when in stowed position

• 1, 2, 3, 4, 5, 8, 9, 11, 12

Sea fastenings • Insecure load • Personnel injury • Ensure sea fastenings are correct and carried out by a competent person

• Damage to equipment • Inspect all welding

• Use certified rigging which has been visually checked

• 1, 3, 4, 9, 12

Rigging and slinging • Rigging failure • Damage to equipment and • Wear correct PPE

• Dropped loads injury to personnel • Use certified rigging

• Dropped objects • Perform visual inspection of rigging

• Remove all loose objects

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Be extra vigilant

• 1, 3, 4, 5, 9, 12

Static rigging • Mechanical failure in • Damage to equipment • Wear correct PPE

- chain hoists appliance • Injury to personnel • Use certified rigging

- lever hoists • Perform visual inspection

• Use safety pins in all shackles

• 1, 3, 4, 5, 9, 12

Storing steel • Insecure and unstable steel • Trapped arms or legs • Store steel in proper rack

storage • Small items to be placed in boxes or containers

• 1, 3, 4, 5, 9, 12

Sweeping • Airborne particles of dirt or • Eye injury • Sweep upwind if possible

dust • Wear PPE including safety glasses

• 1, 3, 4, 5, 9, 12

General lifting and moving • Straining • Back injury • General awareness regarding correct lifting techniques

equipment by hand • Access around deck • Pulled muscles • Request assistance if required

• Trip hazards • Foot or leg injuries • Keep walkways clear

• Dropped loads • General awareness on deck

• 1, 3, 4, 5, 9, 12

Washing down using fire main • Volume of water • Eye damage • Minimum personnel on deck

• Air borne particles • Man overboard • Hose management

• 1, 5, 12

JERIN SAM KURIAN

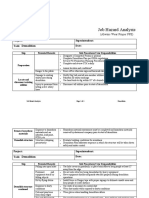

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Surface Maintenance

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Chipping rust • Excessive noise • Ear damage • Use ear protection

• Flying particles • Eye injury • Use safety glasses

• Dust • Poisoning • Use respiratory protection

• Damage to electric cables • Breathing problems • Avoid chipping on cables

• Electric shock • COSHH

• Malfunction of equipment • 1, 5, 12

Paintwork outside - brush and • Exposure to solvents in air • Poisoning by inhalation • Use natural ventilation to carry fumes away

rollers • Exposure to solvents on skin • Poisoning by skin penetration • Avoid skin contact

• Spillage • Pollution • Secure paint tins

• Residual paint is restricted garbage

• COSHH

• 1, 5, 12

Paintwork outside - high • Exposure to solvents in air, • Respiratory poisoning • Complete respiratory and body protection

pressure paint spraying • fumes and particles • Skin/eye contamination • Secure working area

Malfunction, leakage of • Escaping of pressurised paint • Proper maintenance and checks on equipment

equipment • COSHH

• 1, 5, 12

Paintwork inside • Exposure to solvents in air, • Explosion • Ventilation

fumes and particles • Suffocation • Limited work periods

• Exposure to solvents on skin • Check gas concentration

• Spillage • Respiratory protection

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Accumulating combustible • COSHH

• gasses • 1, 3, 5, 12

Lack of oxygen

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Lifting & Moving Equipment

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Lifting and moving equipment • Falling down • Head injury • Safe lifting equipment

with gantry hoist and by hand • Swinging loads • Hand injury • Secure the load

• Excessive loads being lifted • Foot injury • Not lifting in rough sea

• by hand • Back injury • Not lifting excessive load by hand

Awkward Heavy loads • Damaged equipment • Correct lifting procedure

• Wear safety equipment

• Follow man handling procedures

• Use correct stance

• 1, 3, 4, 5, 9, 12

Lifting / moving objects at sea • Shifting loads • Impact • Only certified lifting equipment

with gantry hoist and by hand • Objects falling off lifts • Equipment damage • Check equipment before use

• Exceeding load limits • Experienced personnel

• Good communication

• Secure the area

• Use tag lines on large lifts

• Confirm status of cargo to be lifted

• Ensure alarm limits are set

• 1, 3, 4, 5, 9, 12

Moving equipment / stores • Uncontrolled movement • Crushing injuries • Only use in stable conditions

with pallet trolley • 1, 9, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Load Testing Winch

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Run wires • Trapped fingers • Personnel • PPE – Safety Harness

• Wire falling • Equipment • Trained rigging crew

• Working at heights • Toolbox talk

• 1, 2, 3, 4, 5, 8, 9, 11, 12

Load rigging • Dropped equipment • Personnel • Good communication between crane/ banksman

Crane/pipe contact • Equipment • Tag lines

• 1, 2, 3, 4, 5, 8, 9, 11, 12

Connect load cell and shackle • Trapped fingers • Personnel • Use air tuggers to support shackles

• Personnel Falling • Equipment • PPE – Safety Harness

• Toolbox talk

• 1, 2, 3, 4, 5, 8, 9, 11, 12

De-rig equipment • Trapped fingers • Personnel • Use air tuggers to support shackles

• Personnel Falling • Equipment • PPE – Safety Harness

• Toolbox talk

• 1, 2, 3, 4, 5, 8, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Chain Hoists

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Lifting and lowering loads using • Uncontrolled load • Personnel injury • Use qualified operators only

chain hoists • Damage to beams, hoist or • Ensure rigging is certified and tested

• rigging • Wear correct PPE

Damage to equipment • Operators to be extra vigilant

• Routine maintenance

• 1, 3, 9, 10, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Crane Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Lifting / moving objects in port • Falling/ swinging loads • Impact • Only certified lifting equipment

• Shifting loads • Equipment damage • Check equipment before use

• Objects falling off lifts • Exceeding load limits • Experienced personnel

• Limit switches malfunction • Falling load • Good communication

• Secure the area

• Use tag lines on all lifts

• Confirm status of cargo to be lifted

• Ensure alarm limits are set

• 1, 3, 4, 5, 8, 9, 10, 11, 12

Lifting / moving objects at sea • Falling/ swinging loads • Impact • Only certified lifting equipment

• Shifting loads • Equipment damage • Check equipment before use

• Objects falling off lifts • Falling load • Experienced personnel

• Limit switches malfunction • Exceeding load limits • Good communication

• Injury to person • Secure the area

• Conflict with deck operations • Use tag lines on all lifts

• Consider sea and wind state

• Consider vessel movements

• Confirm status of cargo to be lifted

• Ensure alarm limits are set

• Extra care on lifts from seabed

• 1, 3, 4, 5, 8, 9, 10, 11, 12

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Lifting/over boarding loads • Poor visibility • Impact • Only certified lifting equipment

from main deck • Poor communications • Equipment damage • Check equipment before use

• Command/response delay • Falling objects • Experienced personnel

• Incorrect crane movement • Exceeding load limits • Good communication

• Swinging load • Conflict with deck operations • Secure the area

• Injury to personnel • Use tag lines on all lifts

• Consider sea and wind state

• Consider vessel movements

• Confirm status of cargo to be lifted

• Ensure alarm limits are set

• Extra care on lifts from seabed

• 1, 3, 4, 5, 8, 9, 10, 11, 12

Lifting/moving objects at sea • Shifting loads • Impact • Only certified lifting equipment

utilising platform cranes • Objects falling off loads • Equipment damage • Experienced personnel

• Dropped loads • Exceeding load limits • Good communication between platform and vessel

• Swinging loads • Injury to personnel • Minimum personnel on deck

• Malfunction of limit switches • Damage to platform crane • Weather state

• Damage to ’A’ frame wire • Use tag lines on all lifts

• Crane becoming entangled • Confirm status of cargo to be lifted

• Set alarm limits

• Ensure loads and slings cannot become trapped

• 1, 3, 4, 5, 8, 9, 10, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Crane Testing

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Operation crane on emergency • Dropped object • Injury to personnel • All non-essential personnel to keep clear of deck.

power • Burst hoses • Damage to crane • Crane driver to be fully briefed.

• Damage to deck structure Hydraulic Tech to be in attendance

• Deck crew • Locate suitable test weight within crane parameters

• Crane driver • Barrier off deck

• Operational delay • Protect deck

• Pollution • Test and inspect hoses

• Identify procedure for future hook-up of emergency power pack

• 1, 3, 4, 5, 8, 9, 10, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Operating Air & Hydraulic Deck Winches

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Operating hydraulic winches • Moving parts • Trapped limbs • Follow set up and running procedures

• Wires under tension • Personnel injury • Ensure good communications

• Material damage • Wear correct PPE

• 1, 3, 5, 9, 10, 11, 12

• Wire parts • Whiplash injury to • Wire must have in date certificates

• personnel • Move vessel to safe position during lifting ops.

Damage to subsea • 1, 3, 5, 9, 10, 11, 12

structure

• Brakes fail • Free fall of wire • Routine maintenance

• Damage to Subsea • Check brakes before use

structure • 1, 3, 5, 9, 10, 11, 12

• HP / LP Fluids • Personnel • Eye protection

• 1, 3, 5, 9, 12

Operating air winches • Moving parts • Trapped limbs • Follow set up and running procedures

• Wires under tension • Personnel injury • Ensure good communications

• Material damage • Wear correct PPE

• 1, 3, 5, 9, 10, 11, 12

• Wire parts • Whiplash injury to • Wire must have in date certificates

personnel • Move vessel to safe position during lifting ops.

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Damage to subsea • 1, 3, 5, 9, 10, 11, 12

structure

• Brakes fail • Free fall of wire • Routine maintenance

• Damage to Subsea • Check brakes before use

structure • 1, 3, 5, 9, 10, 11, 12

• HP / LP Fluids • Personnel • Eye protection

• 1, 3, 5, 9, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Deck Welding Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Changing oxygen • Contamination by oil • Explosion • Ensure cleanliness

• Sparks or naked flames • Isolate bottles

• Ensure no hot work in vicinity

• 1, 3, 4, 5, 12, 13

Changing acetylene • Sparks or naked flames • Explosion • Ensure no hot work in vicinity

• Isolate bottles

• 1, 3, 4, 5, 12, 13

Burning • Flash back • Explosion • Permit to work in place

• Naked flame • Burns • Ensure flash back arrestors fitted to gauges

• Eye injury • Wear correct PPE, including gloves and burning visor

• 1, 3, 4, 5, 12, 13

Welding • Welding arc • Burns • Permit to work in place

• Flammable material • Eye injury • Wear correct PPE, including gloves and welding visor

• Fumes • Fire • Utilise a fire watcher and have fire blankets to hand

• Electric Cable • Lung damage • Use extractors and dust mask

• Electric shock • Ensure cables insulated

• 1, 3, 4, 5, 12, 13

Arc air gouging • High pressure air hose bursts • Burst hose whips around • Permit to work in place

• Welding arc • Burns, eye injury • Wear correct PPE

• Flammable materials • Fire • Ensure hose safety straps used on connections

• Electric Cable • Electric shock • Fire watcher to be utilised

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Fire blankets in vicinity

• Ensure cables insulated

• 1, 3, 4, 5, 12, 13

Grinding • Sparks • Fire • Permit to work in place

• Electrical Cables • Electric shock • Wear correct PPE

• Grinding or cutting wheel • Personnel injury • Ensure cables insulated

• shatters • Eye injury • Qualified personnel only to change wheels

Noise • Ear damage • Fire watcher to be utilised

• Fire blankets in vicinity

• Ear protection

• Ensure correct voltage

• 1, 3, 4, 5, 12, 13

Welding slag removal • Hot slag • Burns • Eye protection, gloves, overalls

• Eye damage • 1, 3, 4, 5, 12, 13

Repair burning leads • High pressure leak in lead • Personnel injury • Wear correct PPE

• Ensure leads are correctly stored

• Check frequently

• 1, 3, 4, 5, 12, 13

Repair welding leads • Exposed electrical cable due • Electric shock • Wear correct PPE

to split lead • Ensure leads are correctly stored

• Check frequently

• Isolate before repair

• 1, 3, 4, 5, 12, 13

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working with Oils

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Storage • Leakage • Pollution • Lockable/secure store

• Fire • Explosion • Wear correct PPE

• Temperature control • Spontaneous combustion • Use smoke/heat sensors

• Slipping • Have available extinguishing media, CO2/deluge system/dry power/ foam

• 1, 3, 6, 11, 12

Transportation • Leakage • Pollution • Specialised handling equipment and transportation systems

• Fire • Explosion • Specialised absorbents

• Temperature changes • Spontaneous combustion • Foam/COs/dry power extinguishers available

• Personnel injury • Temperature monitoring devices

• 1, 3, 9, 11, 12

Handling • Spillage • Pollution/fire • Specialised absorbents

• Handling heavy drums • Personnel injury • Wear correct PPE

• Contact with skin • Slip hazard • Medical facilities available

• Fittings blow off • Injury to personnel • Foam/CO2/dry powder extinguishers to be available

• Fittings are properly tightened

• 1, 3, 9, 11, 12

Operational use • Equipment malfunction • Pollution • Wear correct PPE

• Leakage • Fire/explosion • Specialised absorbents

• Overheating • Personnel injury • Medical facilities available

• Foam/CO2/dry powder extinguishers to be available

• 1, 3, 6, 9, 11, 12

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Disposal • Offloading/ craneage • Pollution • Wear correct PPE

• Container leakage • Fire • Medical facilities available

• Personnel injury • Foam/CO2/dry powder extinguishers to be available

• Specialised absorbents

• COSHH

• 1, 3, 6, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working with Chemicals

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Working with chemicals • Leaking • Eye injury • Using the correct equipment

• pollution • Hand injury • Having cleaning material around

Gases • Breathing problems • Having eye wash available

• Working in ventilated area

• 1, 2, 3, 4, 5, 8, 9, 11, 12

• Wrong chemicals for job • Potential explosion • COSHH assessment sheets available

Lifting chemicals • Falling loads • Injury to personnel • Correct slinging to be employed

• Chemical spillage • Damage to environment • Absorbents to be ready

• 1, 2, 3, 4, 5, 8, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working at Heights

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Painting/cleaning • Working at heights • Fall injury • Second person to watch vicinity

• Dropped objects • Skin/eye injury • Secure objects

• Solvent/ chemical exposure • Long term solvent injury • Respiratory protection

• Hit by radar antenna • Ensure adequate work platform

• Do not overstretch from safe area

• Signs and barriers in place

• 1, 3, 4, 5, 12

Working up mast • Working at heights • Fall injury • Second person

• Dropped objects • Injury to persons below • Secure objects

• Fall arrestor

• 1, 3, 4, 5, 9, 12

Routine maintenance • Falling • Injury to maintenance crew/ • Experienced personnel only

• Dropped objects deck personnel • Ensure adequate work platform

• Do not over stretch from safe area

• 1, 3, 5, 6, 7, 8, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working Overboard

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Painting/ cleaning • Fall overboard into water • Drowning • Secure equipment - guard quay area

• Fall overboard onto quay • Impact injury • Respiratory protection to be used

• Falling objects onto quay • Eye injury • Second person to watch

exposure to solvents and • Chemical burns • Adequate work platform

chemicals • Solvent damage • Do not over stretch

• Harness and fall arrestor

• 1, 3, 5, 9, 12

Launching workboat • Fall overboard • Drowning • Enter boat before lifting from deck

• Rigging failure • Impact injury • Any more than two personnel to enter boat at pilot ladder

• Harness and fall arrestor

• 1, 3, 5, 9, 12

Rigging • Fall overboard • Drowning • Wear life vest/safety harness

• Rigging failure • Impact injury • Permit

• Dropped tools and equipment • Correct PPE

Burning, welding • Fall overboard • Drowning • Fire extinguisher on hand

• Rigging failure • Impact injury • See risk assessment burning/welding

• Dropped tools and equipment • Burns • Fall arrestor

• Burns • 1, 3, 4, 5, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Tank entry

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Inspection/ works • Lack of oxygen • Suffocation • Ventilation, oxygen test

• Slippery surface and poor • Fall from height • Two personnel present

• lighting • ‘Epidemic’ diseases • Ensure sufficient lighting

Pollution • Wear good/clean footwear

• Being shut in tank • Walk on dry areas only

• Remove all loose material (rags, paint, etc.)

• 1, 2, 3, 4, 5, 8, 9, 11, 12

• Slip/fall • Injury • Have adequate lighting

• Injured person in • 1, 2, 3, 4, 5, 8, 9, 11, 12

inaccessible area

• Wrong tank • Personnel enter wrong tank • Study ships plan before starting works

• 1, 2, 3, 4, 5, 8, 9, 11, 12

• Maintenance • Leave undesirable items in • Blockage of pipework etc. • Remove all items after completion

tank • 1, 2, 3, 4, 5, 8, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Starting Electrical/Hydraulic Power Units

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Starting any electric/hydraulic • HP oil • Damage to equipment • Ensure start/stop procedure is followed

power unit • Destruction of moving parts • Ensure all valves, gauges, etc. are clearly marked/tagged

• Lost time • Ensure equipment is maintained

• Injury to personnel • Ensure safety procedures are in place

• 1, 3, 5, 7, 12

• Fire • Damage to equipment • Ensure start/stop procedure is followed

• Destruction of moving parts • Ensure all valves, gauges, etc. are clearly marked/tagged

• Lost time • Ensure equipment is maintained

• Injury to personnel • Ensure safety procedures are in place

• 1, 3, 5, 7, 12

• Pollution • Injury to personnel • Ensure start/stop procedure is followed

• Ensure all valves, gauges, etc. are clearly marked/tagged

• Ensure equipment is maintained

• Ensure safety procedures are in place

• 1, 3, 5, 7, 12

Starting any electric/hydraulic • Moving parts • Injury to personnel • Ensure stop / start procedure is followed

power unit • 1, 3, 5, 7, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working on Electrical Equipment

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Working on electrical • Electrical shock • Heart attack • Switch off main power

equipment • Hand injury • Place notice on switch and fuses

• Burns • Work in pairs

• Eye injury • 1, 3, 4, 5, 7, 9, 12

• Moving parts • Heart attack • Switch off main power

• Hand injury • Place notice on switch and fuses

• Burns • Work in pairs

• Eye injury • 1, 3, 4, 5, 7, 9, 12

• Short circuit • Heart attack • Switch off main power

• Hand injury • Place notice on switch and fuses

• Burns • Work in pairs

• Eye injury • 1, 3, 4, 5, 7, 9, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working with Power Tools

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Working with high pressure • Noise • Injury to personnel • Ear protection

and high revolution tools • Equipment must have ‘safe to use’ tags

• 1, 3, 4, 6, 12

• Dust • Respiratory problems • Clean and good working area

• Injury to personnel • Equipment must have ‘safe to use’ tags

• Inspect tool before use

• 1, 3, 4, 6, 12

• Leaking • Injury to personnel • Clean and good working area

• Safe equipment

• Equipment must have ‘safe to use’ tags

• Inspect tool before use

• 1, 3, 4, 6, 12

• Tools slipping • Injury to personnel • Safe equipment

• Equipment must have ‘safe to use’ tags

• Inspect tool before use

• 1, 3, 4, 6, 12

Working with high pressure • Electrical shock • Injury to personnel • Correct voltage

and high revolution tools • Equipment must have ‘safe to use’ tags.

• Inspect tool before use.

• 1, 3, 4, 6, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Diving Procedures

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

At depth connect and test Malfunctioning equipment Abort dive Bell checks to be done properly

standby divers hat for gas 1, 2, 3, 9, 12

Diver leaves bell Hot water malfunctions Diver gets cold (hypothermia) Hot water temp. is checked before start of bell run

Set alarms

1, 2, 3, 9, 12

Loss of gas to diver Diver goes on to bailout / Pre-lock out checks done properly

onboard gas Gas pressures recorded before dive start

Comms to diver stop working No comms to diver Flash hat light, give four pulls

Follow procedure

Diver descending from bell to Diver cannot clear his ears Burst ear drum Diver to be lowered slowly if ears are sticky

seabed Diver can become disoriented

Diver has a tooth cavity problem Extreme pain for diver Diver to stop descent when pain onsets

Diver working in water 2 Diver gets headache, disoriented, When working hard, flush mask through

Build up of CO

etc. 1, 2, 3, 9, 12

Umbilical is fouled Diver becomes trapped Diver regularly checks umbilical back to bell

Umbilical management

Diver working in water (cont) Bad gas to diver Diver becomes unconscious Pre-dive checks

Liase with gasman

Set alarms / analysers

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Too much divers umbilical paid Entrapment / thruster danger Bellman / divers / supervisors are familiar with umbilical markings

out of bell Umbilical management

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Diving Check Lists

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Wrong gas mix • Reduced emergency • Divers pass out • Gas man records pressures and mix and gives copy to shift supervisor

Wrong gas pressure in O/B • breathing time • Wrong mix • Analyse gas before going online

bottles Bailout U/S • Reduced time 1, 2, 3, 9, 12

Bailouts • Wrong pressure

Bell external checks • Miss out valves/ • No gas to divers • Laminated check sheet to be used

equipment • Equipment malfunction • 1, 2, 3, 9, 12

Valve checks • Trip/Fall/bang head on • Injury to diver doing • Harness to be worn if needed

bell handling structure checks • Care to be taken

• 1, 2, 3, 9, 12

Valve checks • Sudden vent. • Injury to diver doing • Dive supervisor to co-ordinate between divers and surface

• Off of gas checks • 1, 2, 3, 9, 12

Valve checks • Working on - near • Injury to diver doing • Care to be taken at all times

pressure vessels checks • 1, 2, 3, 9, 12

Re-tooling work basket • Diver can slip/fall into • Drowning • Wear a harness - life jacket

moonpool • Work in pairs where possible

• 1, 3, 9, 12

Equipment checks on bell • Port on bell smashed • Injury/death to divers • No lifting of heavy/awkward equipment near bell

external inside & outside bell • 1, 2, 3, 9, 12

Bell internal checks • Accidentally opening a • Divers inside - • Divers to be fully familiarised with bell internals

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

valve that vents to • personnel outside • Personnel outside

surface Rapid decompression • Pressure vessels

• 1, 2, 3, 9, 12

2

Bell internal checks • Oxygen-enriched gas in • Oxygen toxicity to diver • O analysers to be kept on and calibrated at all times

bell • inside • 1, 2, 3, 9, 12

Fire hazard

2 2

Bell internal checks • Oxygen-deficient gas in • Lack of O to sustain • O analysers etc.

bell life/ consciousness • Hull stops to be kept closed where appl.

• 1, 2, 3, 9, 12

Bell internal checks • Cut fingers • Wound becomes • Take care when opening/closing awkward placed valves using knives

• Grazed knuckles infected • 1, 2, 3, 9, 12

Bell internal checks • Bang head • Unconsciousness • Always store equipment properly - tie down, etc.

• Diver trapped in bell • 1, 2, 3, 9, 12

Bell internal checks • Bell internal too • Diver cannot • Try and keep bell at constant temperature comfortable for divers

hot/cold concentrate on checks • 1, 2, 3, 9, 12

Operation of pneumos • Incorrect depth of • Divers - wrong storage • Gauges should have calibration certificates visible

divers • depth selected • 1, 2, 3, 9, 12

Wrong decompression

schedule selected

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Bell Handling Procedures

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Personnel movements under • Depth changes • Decompression sickness • Adhere to correct working procedures

pressure • Environmental changes • Extremes of temperature • 3, 9, 12

• O2 parameter changes • Asphyxia

• Door/hatch opening or • O2 toxicity

closing • Personnel injury

• Entrapment

• Chamber occupants

Climbing ladder to transfer • Falling/slipping • Fall/injury • Adhere to correct working procedures Secure any loose objects or equipment

• Objects dropped • Chamber occupants • 3, 9, 12

Establishing a seal • No seal • Prolonged exposure to risk • Ensure clean seals

• ‘O’ ring seal not • Unable to transfer • Adhere to correct operating/working procedures

• seated/damaged • Unable to pressurise trunk • Adhere to maintenance procedures

Vent valve left open • Delay in operations • Good communications

• Decompression sickness • 3, 9, 12

• Chamber occupants

Clamp removal • Interlock malfunction • Pressure retention • Adhere to maintenance schedules

• Pressure still in trunk • Pressure release • Adhere to correct working procedures

• Poor communications • Injury • Good communication procedure

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Vent line blocked • Decompression sickness • 1, 2, 3, 4, 9, 12

• Gauge inoperative • Mechanical and material

damage

• Bell occupants and people in

vicinity

Starting hydraulic machinery • Electric’s • Electric shock • Follow correct working and maintenance schedules

• Operator and people in • Display local warning signs and good ships husbandry

vicinity • Good communication procedure

• 1, 2, 3, 9, 12

• Mechanical • Entrapment • Follow correct working and maintenance schedules

• Personal injury • Display local warning signs and good ships husbandry

• Operator and people in • Good communication procedure

vicinity • 1, 2, 3, 9, 12

• Remote start • Entrapment • Follow correct working and maintenance schedules

• Personal injury • Display local warning signs and good ships husbandry

• Operator and people in • Good communication procedure

vicinity • 1, 2, 3, 9, 12

• Release of high pressure • Injection of fluids into the • Follow correct working and maintenance schedules

hydraulic fluids • body • Display local warning signs and good ships husbandry

Personal injury • Good communication procedure

• Contamination of • 1, 2, 3, 9, 12

environment

• People in vicinity

Bell deployment • Moving of bell and ancillary • Entrapment • Follow correct working and maintenance schedules

equipment • Personal injury • Display local warning signs and good ships husbandry

• Mechanical and material • Good communication procedure

damage • 1, 2, 3, 9, 12

• Bell occupants and people in

vicinity

Operating clump weight • Entrapment in moving wires • Injury • Follow correct working and maintenance schedules

• Severed umbilical • Inform divers of movements

• Bell occupants and bell • Display local warning signs and good ships husbandry

handling crew • 1, 2, 3, 9, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Hot Water System

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Starting hot water machine • Electricity • Electric shock • Certified equipment

• Operator • 1, 2, 3, 10, 12

Starting pumps • Dead heading • Mechanical damage • Follow correct starting procedures

• Operator and people in • 1, 2, 3, 10, 12

vicinity

• Electricity • Electric shock • Certified equipment

• Operator • 1, 2, 3, 10, 12

Operational activity • Fluctuating temperature • Hot water burns • Adequate monitoring and early warning sensors

• Cooling divers in water • 1, 2, 3, 10, 12

• Diving operations stopped

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Bell Emergency Procedures

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Use of emergency procedures • Inability to assess the • Inappropriate response to • Thorough assessment of situation

emergency situation the emergency • Practice emergency procedures

• 2, 3, 9, 11, 12

• Misunderstanding of • Confusion among personnel • Routine practice drills

procedures • 2, 3, 9, 11, 12

Personnel movements under • Depth changes • Decompression sickness • Adhere to correct working procedures

pressure • Chamber occupants • 2, 3, 9, 11, 12

• Door/hatch opening or • Back injury • Adhere to correct working procedures

closing • Entrapment • 2, 3, 9, 11, 12

• Chamber occupants

Establishing a seal • No seal • Prolonged exposure to risk • Ensure clean seals

• ‘O’ ring seal not • Unable to transfer • Adhere to correct operating/working procedures

• seated/damaged • Unable to pressurise trunk • Adhere to maintenance procedures

Vent valve left open • Delay in operations • 2, 3, 9, 12

• Decompression sickness

• Chamber occupants

Starting hydraulic machinery • Electric’s • Electric shock • Follow correct working and maintenance schedules

• Operator and people in • Display local warning signs and good ships husbandry

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

vicinity • 1, 2, 3, 6, 9, 10, 12

• Mechanical • Entrapment • Follow correct working and maintenance schedules

• Personal injury • Display local warning signs and good ships husbandry

• Operator and people in • 1, 2, 3, 4, 7, 10, 12

vicinity

• Remote start • Entrapment • Follow correct working and maintenance schedules

• Personal injury • Display local warning signs and good ships husbandry

• Operator and people in • 1, 2, 3, 9, 10, 11, 12

vicinity

• Release of high pressure • Injection of fluids into the • Follow correct working and maintenance schedules

hydraulic fluids • body • Display local warning signs and good ships husbandry

Personal injury • 1, 2, 3, 9, 10, 11, 12

• Contamination of

environment

• People in vicinity

Operating clump weight • Entrapment in moving wires • Injury • Follow correct working and maintenance schedules

• Severed umbilical • Display local warning signs and good ships husbandry

• Bell occupants and bell • Good communication practices

handling crew • 1, 2, 3, 9, 10, 11, 12

Operating valves in Hydraulic • Operate wrong valves • Winches will not operate or • Emergency lighting installed

room to emergency position because of no emergency be rendered inoperable • Torches to be used in meantime

lighting • 1, 2, 3, 9, 10, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

ROV/Diver Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

ROV/diver working in close Electric shock to diver Death/injury to diver Test of earth circuit leakage breaker every 24 hrs. min.

proximity ROV hits diver Crush injury to diver ROV maintains a safe distance from diver

ROV umbilical gets tangled in Diver gets dragged off job/to ROV maintains safe distance

divers umbilical surface Good tether management

ROV hits bell Possible injury to bellman divers ROV is equipped with sonar etc. in poor visibility

ROV looses power Entanglement/ knocks diver ROV keeps down stream of diver in tides

ROV thrusters Damage to Divers umbilical Make sure suitable guards are fitted over all thrusters

Trapped fingers Dive Supv has monitor with ROV pilot vision

Diver entrapment Open comms Dive / ROV control

3, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Shallow Water Diving

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Shallow water diving • Ship’s Thrusters. • Diver Injury. • Umbilical secured in bell at maximum permissible length.

operations. • Umbilical entrapment. • Bellman to inform Supervisor of umbilical length deployed from

• Diver entrapment. bell/basket.

• Barotrauma.

• Exceeding diver’s • Reduced DP reference • Monitor diver’s depth and PPO2.

• excursion limits. • system. • Cross reference structure/worksite.

Tidal rise and fall. Diver • Bellman/divers/supervisors are familiar with umbilical markings

• Excessive subsea current. • Operational limits. • Good management of diver umbilical.

• Reduced visibility. • Loss of HPR signal. • Constant tending

• DP reference system • Diver • Ensure umbilicals are negatively buoyant.

limitations. • Hull interference to Taut • Ensure bailouts are charged to capacity

Wire.

• Diver

• Degradation of DP status.

Shallow water diving • Confused communications • Possible unplanned vessel • Generate accurate tidal graph.

operations • Erratic vessel move. • movement. • Monitor current speed and rise and fall.

• Close proximity of DP Injury to diver. • Diver only to lock in/out during periods when current speed is

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

reference systems to the • Increased power workable.

worksite. consumption. • Work within limits of HPR & Taut Wire.

• Excessive thruster wash. • Pre- plan location of HPR transponders and taut wires.

• Increased subsea noise.

• Interference to divers.

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Diving Operations Alongside a Platform

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Diving operations utilising • DP reference system conflict. • Damage to vessel. • Obtain permission to enter 500-metre zone.

dynamic positioning alongside • Loss of DP. • Taut wire weight hits diver. • Identify platform based external activities.

a Platform or Structure • Loss of HPR signal. • Taut wire weight parts. • Use full system redundancy.

• Confused communications. • Degradation of DP status. • Monitor all vessel moves.

• Dropped objects. • Damaged or broken crane • Regular checks of taut wire rigging.

• Dumping of mud/cuttings. • wire or hook. • DPO must not deploy, reposition or recover taut wire without informing Dive

• Simultaneous operations. Collision. Supv.

• Strong surface currents. • possible unplanned vessel • Work within limits of reference systems.

• Platform based emissions. • movement. • Monitor DGPS system.

• Foreign objects entangling Bell collides with structure. • Identify vessel escape routes.

with thrusters • Reduced visibility. • Confirmation of HPR transponders in use and taut wire locations.

• Injury to diver. • maintain good clear communications.

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Diving in the Vicinity of a Subsea Structure

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Diving operations in the • Erratic vessel movement. • Loss of ship’s position. • Use full system redundancy.

vicinity of a fixed subsea • DP reference system • Damage to equipment • Monitor weather.

structure. • conflict. • being installed. • Confirm all vessel moves.

Trapped, snagged crane Bell collides with • Regular checks of taut wire rigging.

• wire. • structure. • DPO must not deploy, recover or reposition taut wire without

Loss of HPR signal. Injury to diver. informing the Dive Supv.

• Taut wire weight

entanglement.

Diving operations in the • Confused • Degradation of DP status. • Work within limits of the HPR.

vicinity of a fixed subsea • communications. • Damaged or broken crane • Monitor DGPS system.

structure (cont) Deployment of subsea • hook. • Identify vessel escape routes.

equipment. Dropped objects. • Confirmation of HPR transponders in use and taut wire locations.

• Collision • Locate bell and clump weight above the structure.

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Dynamically Positioned Diving Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Diving Operations Utilising • DP reference system • Reduced DP reference system • Operate vessel in accordance with regulatory and statutory requirements.

Dynamic positioning. • limitations. • operational limits. • Utilise available system redundancy and maintain lookout.

Confused communications. Loss of HPR signal. • Maintain good radar watch.

• Erratic vessel move. • Hull interference to Taut • Confirm all vessel moves.

• Third party shipping. • Wire. • D.P.O. must not deploy reposition or recover Taut Wire without informing

• Rapid change in current, Degradation of DP status. Dive Supv.

speed and direction. • Collision. • Work within limits of HPR & Taut Wires.

• Rapid change/deterioration • Possible unplanned vessel • Monitor fishing and third party vessel activity.

in environmental conditions. movement.

• Close proximity of DP • Injury to diver.

reference system to the • Increased power.

worksite. • Excessive thruster wash.

• Increased subsea noise.

• Interference to divers.

Relocation of ship whilst diving • Failure of ships equipment. • Loss of Ship’s position. • Ensure sufficient independent reference systems are on line one of which

bell is deployed. • Loss of power. • DP reference system should be a surface reference system.

• Loss of reference system. exceeding operational limits. • DP Officers on watch to be extra vigilant.

• Diver entrapment. • Good clear concise communications.

• Inform Dive Supv. of all vessel movements ie. heading and position.

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

BIBS Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Breathing on BIBS • Incorrect mix • Asphyxia • Analysation

• O2 toxicity • Correct routing

• Chamber occupants • Isolation

• Incorrect valve operation • No gas • Correct valve labelling

• Injury • Adhere to correct procedures

• Pressure release

• Chamber occupants

• Inadequate hygiene • Cross infection • Adhere to hygiene procedures when cleaning masks

• Chamber occupants

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Fire Fighting Equipment

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Firefighting equipment • Inappropriate/ • Inability to extinguish fire • Correct maintenance and operating procedures

inadequate equipment • Injury • Safe working practices

• Mechanical/

material damage

• All crew

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Life Support Package (LSP) Procedures

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Connecting service umbilical • Incompatible connection • Inability to connect LSP. to • Ensure pre-mobilisation checks are carried out

HRL • Familiarisation of operating procedures and equipment

• Unserviceability of equipment • Explosion - fire • Ensure pre-mobilisation checks are carried out

• Injury • Familiarisation of operating procedures and equipment

• Inability to use equipment

Supplying services • Unprotected umbilical (LSP) • Decompression sickness • Ensure pre-mobilisation checks are carried out

• Pressure release • Familiarisation of operating procedures and equipment

• Explosion - fire

• Mechanical and material

damage

• HRL occupants and people in

vicinity

Operation of LSP. • Limited resources • Fatigue • Ensure pre-mobilisation checks are carried out

• Depletion of supplies and gas • Familiarisation of operating procedures and equipment

• stocks • Periodic checks by LSS at LSP location

HRL occupants

JERIN SAM KURIAN

ACTIVITY: DATE : Reviewed by: PROJECT : Vessel Generic

Dry Docking Vessel with Personnel in Saturation

LOCATION : REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Entering the dry dock • Collision • Damage to vessel. • Fendering.

• Flooding at chamber • Cross-winds.

level. • Weather forecast.

• Adequate crew on deck to man ropes.

Setting down on blocks • Distortion of chamber • Loss of pressure. • During docking process all internal doors to remain closed

complex • Leakage. • Check stability of vessel

Changing from ships • Continuity of services • Loss of environmental • Situation to be stressed at pre docking meeting.

services to shore services control

Day to day problems • Additional fire hazard • Hot work round gas • Permit to work system enforced.

quads / risk of fire • Restrictions on hot work permit on adjacent compartments to living

area and around O2 storage.

• Permanent fire watch

Day to day problems • Loss of services • As above (continuity of • Clarification of primary power to be used (safe, reliable power supply)

services). with ship’s generator as secondary supply (back-up).

• Loss of water • Two independent water supplies and discussions to be held with local

fire brigade

Hyperbaric Evacuation • Inability to deploy HRL • Divers exposed to • Pre-rigging of fire hoses for boundary cooling of HRL.

uncontrolled dangers. • Designated crane with designated transportation trolley.

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Fire. • Shoreside LSP with gas supplies (check compatibility of LSP with

• Explosion. system).

• Pre-rig boat for crane deployment.

• Adequate Life Support personnel for evacuation

Additional dock yard works • Falling loads. • Loss of pressure to HRL. • Restrict overhead movement of loads above HRL and gas quads.

• Damage to equipment. • O2 explosion / fire. • Ensure all lifting rigging is certified.

Security • Sabotage. • Danger to personnel in • Gangway watch / position camera on gangway

chamber

• Loss of equipment

Power requirements for • Inability to supply • Unable to maintain life • Upgrade shore supply connection box to accept 630 amp supply.

diving system in addition to sufficient power to support to divers in • Ensure immediate availability and serviceability of onboard emergency

vessel requirements 150 maintain life support saturation. generator.

kW through shore power • Shore side power requirements would be additional and above normal

connections dockyard supplies require rental of portable generator 60Hz, 500KW.

Unfamiliar activity of • Unintentional hazardous • Interruption with the • Dockyard personnel to cover Risk Assessment of this activity during

decompression of divers activities by dockyard. LSP and / or danger of their pre-works induction meeting.

whilst in dockyard hands. fire in life support

machinery

compartments.

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Working with High Pressure Gases

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Working with high pressure • Leaking • Cold/hot burns • Good ventilation

gasses • Explosion • Breathing problems • Clean working area

• Fire • Eye injury • Checking for leakage

• No open fire

Lifting helium gas quads • Lifting strops • Impact injury • Check lay of strops before lifting

• Caught round pillar valve • Rapid gas discharge

Lifting O2 gas quads • Lifting strops • Impact injury • Check lay of strops before lifting

• Caught round pillar valve • Rapid gas discharge

• Explosion

Lifting gas quads with incorrect • Slings parting • Falling load • Never remove slings from quads

slings

Lifting quads • Damage to manifold • Render quad unusable • Take care when lifting

pipework • Release of gas • Use tag lines

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Gas Management Procedures

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Working with high pressure gas • Massive gas release • Over pressurisation of an • Storage area suitable for use

storage • Massive gas release (high O2 area causing structural • Adherence to routine maintenance schedules of all safety analytical

content) • damage equipment and machinery

• Massive gas release (low O2 Explosion - fire • Safe working practices

content) • Asphyxia

• Operator and people in

vicinity

Gas transferring • Unsuitable whips and fitting • Injury • Correct usage of materials and equipment

• Mis-routing of gas mixes • Damage • Identification and awareness of gas routes

• Damage to unprotected • Explosion - fire • Local area warning signs

• whips, pipes, flasks • Asphyxia • Protection of vulnerable gas lines and equipment

Lack of maintenance and • Contamination • Always secure gas whips using wire tie backs

• cleanliness of equipment • Operator and people in • Adherence to recommended maintenance schedules

Personnel unaware of gas vicinity • Restricted access

• transferring operations • Inform relevant personnel

Unauthorised operations • Familiarisation and training

• Unauthorised • Adequate illumination

operator/ • Wear ear/eye protection

personnel in area of gas • Note: Competent personnel only to use gas transferring equipment.

transferring

• Inadequate lighting

• Noise

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Gas Storage and Distribution

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Opening high pressure gas • High pressure gas loss • Injury • Visual and mechanical inspection of valves and fittings

flasks • Mechanical damage

• Operator and people in vicinity

Distribution of gas to required • High pressure gas in transit • Injury • Vigilance/awareness

destination • Mechanical damage

• Operator and people in vicinity

• Incorrect routing • Injury/death • Correct labelling and valve positioning

• Explosion - fire

• Operator and people in vicinity

Below decks gas storage • Over pressurisation of whips, • Injury/death • Correct relief valve and sensor setting on compressor and gas bag

pipes, flasks and gas bag • Explosion - fire

• Operator and people in vicinity

• Inadequate lighting • Injury • Adequate illumination

• Poor access for leak detection • Incorrect mechanical • Ensure all pipe work fittings are accessible

on pipe work runs operations

• Gas loss

• Operator and people in vicinity

• Noise • Injury • Wear ear/eye protection

• Operator and people in vicinity

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Tow Operations

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Deploy Tow • Swinging Loads • Personnel injury • Secure the area

using the stern • Dropped objects • Personnel falling • Use tag lines

A-frame and towcable winch • Overside work • overboard • Use Life vests

Simultaneously Damage to Tow • Consider Vessel movements

• Consider sea and wind state

• Experienced personnel

• 1, 2, 3, 4, 5, 8, 9, 11, 12, 13

A-Frame deployed to outer • Moving parts • Trapped limbs • Secure the area

position • Experienced personnel

• 1, 3, 4, 5, 9, 12

Remote operation of towcable • Moving machinery • Moving machinery • Secure area by red/white plastic chain

winch • Towcable under tension • Towcable under • Ensure that sign “Danger Remote”

tension • 1, 3, 4, 5, 9, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Mooring

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Arrival / departure • Caught in bights • Leg injury • Keep rope coils tidy

• Hit by slipping lines • Body/head injury • Watch moving lines

• Hit by parting lines • Watch load on the lines

• Tripping over lines / material • Stay in correct positions

• Lifting • Back strain • Correct stance/lifting techniques

• Handling mooring ropes • Sufficient deck lights

• 1, 11, 12

Working capstan • Trapped fingers • Correct hold on ropes

• Riding turn, rope jams on • Keep safe distance from capstan

capstan • Feed rope properly onto capstan

• Rope jumps off or parts • Work area tidy and accessible

• Mooring lines fit for purpose

• 1, 3, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Anchoring, Hanging off Anchor and Running Anchor

Wires

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Anchoring operations • Hit underwater structures • Damage to structures • Use safety glasses

• Flying rust and dirt particles • Eye injury • Confirm anchor position

• Crew member gets caught • Time wasting • Do not let anchor go until Master has given order to do so

between chain and winch • Injury to crew • Keep clear of operating winches

• Inadvertent letting go of • Visual check of chain locker before operations

anchor • Minimum 2 persons required for hoisting anchor

• Sufficient lights on deck and in chain locker

Hanging off anchor • Fall overboard • Drowning • PPE – Safety Harness, life jackets

• Falling objects • Loss of equipment • Raise permit to work

• Rigging failure • Impact • Clear non essential personnel from location

• Personnel injuries • Establish good communication

Running anchor wires • Fall overboard from workboat • Drowning • PPE – lifejackets

• Falling objects • Loss of equipment • Establish good communication

• Wire and ropes in tension • Personnel injuries • Ensure correct positioning of wires/ropes

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Ballasting

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Step 1Task/Activity Description Who or What

Hazard Exposed Recommended Corrective Actions /

Control Measures

Ballasting load/ discharge • Loss of stability • Unstable ship • Consult responsible stability officer before starting ballast operation

• flooding • Damage to equipment • Check manhole records

Ballasting to port/stb. • Ballast pumps malfunction • Unstable ship delays • Regular maintenance function tests

• Equipment breaks loose • Crew to be aware of ballasting

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Bunkering at Sea

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Navigation at worksite. • Grounding • Damage to vessel • Favourable conditions

• Collision • Personal injury • Double check positions at regular intervals

• Heavy weather • Off course • Ensure who is in command

• Fog • Late arrival • Keep sharp lookout and take action well before situation gets critical

• Instruments malfunction • Difficult for other vessel to • Use “seaman’s eye”

• Navigation lights identify • Have adequate systems on line

malfunction • Need to celestial navigate • Plan actions in good time

• Total instrument failure • Loose night vision • Use back up instruments

• Normal lights on bridge • Miss mayday or pan signal • Check calibration of instruments

whilst steaming • Delay to Project • 1, 2, 3, 4, 5, 6, 7, 8, 9, 11, 12

• V.H.F. on wrong channel

Navigation at worksite • Permission to enter zones • Regular check of lights

• Mobile installations • Nav. instruments

• Fix installations • Back up nav. Instruments

• Restricted manoeuvring • Red light status to be maintained at all times

• Drifting • V.H.F. checks to be done prior to departure

• In Field Rules

Mooring ship alongside • Pollution Both ships • Fenders to be placed alongside.

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• Leaking • All personnel • Captains to evaluate conditions.

• Pipe rupture • Delay to Project • Approach of second ship to be in a slow controlled manner.

• Explosion • Only Captains to give final approval to proceed.

• Collision of ships • Marine checklist to be completed.

• Connecting fuel hose • Briefing to be held prior.

• Prevailing condition • Task plan to be produced

• Offshore Installation

• Ships • Task Briefing / Toolbox Talk.

• All Personnel • Comms. Check to be completed with all stations.

• Delay to project • Single Point Control

• 1, 4, 10, 12

• Ships • None essential personnel to remain clear.

• All Personnel • MOB to be made ready.

• Delay to project • All personnel to wear Life Jackets.

• Single point control.

• 1, 4, 10, 12

• Ships equipment • Both ships to ensure lines in good condition.

• Delay to Project • Good seamanship.

Transfer fuel/bunkering • Pollution • Environment • Watch keeping

• Leaking • Eye injury • Close monitoring

• Pipe rupture • Injury from falling • Establish max pumping pressure

• Explosion • Fire • Stop welding and burning whilst bunkering

• Collision of ships • Pipework • Display fuelling notices

• Connecting fuel hose • Fall overboard • Pollution equipment standing by

• Structural damage • Good communications

• Back strain • No smoking

• Grated fingers • Good lookouts

• Use of fenders

• Correct lifting techniques

• 1, 2, 3, 4, 5, 8, 9, 11, 12

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Ship to Ship Transfer of Materials

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

Mooring ship alongside • Weather conditions • Both ships • Fenders to be placed alongside

• All personnel • Captains to evaluate conditions

• Delay to project • Approach of second ship to be in a slow controlled manner

• Only Captains to give final approval to proceed

• Marine checklist to be completed

• Briefing to be held prior

• Task Plan to be produced

• 1, 3, 9, 11, 12

• Loss of DP • See section 3.8 Ships • See section 3.8 Ships Generic Risk Assessment

Generic Risk Assessment

• Communication failure • Ships • Task briefing/toolbox talk

• Incorrect instructions • All personnel • Comms. Check to be completed with all stations

• Misheard instructions • Delay to project • Single point control

• 1, 3, 9, 11, 12

Mooring ship alongside • Impact damage • Ships • None essential personnel to remain clear

JERIN SAM KURIAN

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures

• MOV • All personnel • MOB to be made ready

• Delay to project • All personnel to wear life jackets

• Single point control

• 1, 3, 9, 11, 12

• Fouled mooring lines • Ships equipment • Both ships to ensure lines in good condition

• Delay to project • Good seamanship

Crane transfer of deck cargo • Vessel stability • Both ships • Tag lines

• Man overboard • Captains to evaluate

• Collision damage • Only Captains to allow work to proceed

• MOB ready

• Toolbox talk

• Single point control

• 1, 3, 9, 11, 12

• Swinging load • Ships • Monitor weather

• Ships equipment • Vessel stability

• Personnel • Tag lines

• Load • Good comms

• Delay to project • A. Independence crane, speed, performance to be checked

• 1, 3, 9, 11, 12

• Impact with superstructure • Ships • Monitor weather

and deck equipment • Ships equipment • Vessel stability

• Personnel • Tag lines

• Load • Good comms.

• Delay to project • A. Independence crane, speed, performance to be checked

• 1, 3, 9, 11, 12

Landing Loads • Swinging Load • Ships • Monitor load movement.

• Ships equipment • Use Tag Lines

• Personnel • Clear escape route

• Load • 1, 3, 9, 11, 12

• Delay to Project

JERIN SAM KURIAN

ACTIVITY: DATE: Reviewed by: PROJECT: Vessel Generic

Lifeboat Drills

LOCATION: REF PROCEDURES:

Basic/ General Safety Requirements

1. APPROPRIATE PPE 5. PERMIT TO WORK 9. SUPERVISION

2. TASK SPECIFIC PROCEDURE 6. MECHANICAL ISOLATION 10. CERTIFICATION

3. SPECIFIC TRAINING 7. ELECTRICAL ISOLATION 11. TOOL BOX TALKS

4. RESTRICT WORK AREA ACCESS 8. POST BARRIERS / SIGNS 12. COMPETENT PERSON

Task/Activity Description Hazard Who or What Recommended Corrective Actions /

Exposed Control Measures