Professional Documents

Culture Documents

Air Separation Unit: Distilling Carl Von Linde

Uploaded by

Yuri YamirnovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Separation Unit: Distilling Carl Von Linde

Uploaded by

Yuri YamirnovCopyright:

Available Formats

Air Separation Unit

Pure gases can be separated from air by first cooling it until it liquefies, then

selectively distilling the components at their various boiling temperatures. The process can

produce high purity gases but is energy-intensive. This process was pioneered by Carl von

Linde in the early 20th century and is still used today to produce high purity gases. He developed

it in the year 1895; the process remained purely academic for seven years before it was used in

industrial applications for the first time (1902). [2]

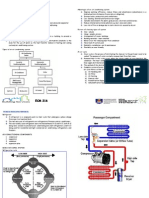

The cryogenic separation process[3][4][5] requires a very tight integration of heat exchangers and

separation columns to obtain a good efficiency and all the energy for refrigeration is provided by

the compression of the air at the inlet of the unit.

To achieve the low distillation temperatures an air separation unit requires a refrigeration

cycle that operates by means of the Joule–Thomson effect, and the cold equipment has to be

kept within an insulated enclosure (commonly called a "cold box"). The cooling of the gases

requires a large amount of energy to make this refrigeration cycle work and is delivered by an

air compressor. Modern ASUs use expansion turbines for cooling; the output of the expander

helps drive the air compressor, for improved efficiency. The process consists of the following

main steps:[citation needed]

1. Before compression the air is pre-filtered of dust.

2. Air is compressed where the final delivery pressure is determined by recoveries and

the fluid state (gas or liquid) of the products. Typical pressures range between 5 and 10

bar gauge. The air stream may also be compressed to different pressures to enhance the

efficiency of the ASU. During compression water is condensed out in inter-stage coolers.

3. The process air is generally passed through a molecular sieve bed, which removes any

remaining water vapour, as well as carbon dioxide, which would freeze and plug the

cryogenic equipment. Molecular sieves are often designed to remove any

gaseous hydrocarbons from the air, since these can be a problem in the subsequent air

distillation that could lead to explosions. [6] The molecular sieves bed must be

regenerated. This is done by installing multiple units operating in alternating mode and

using the dry co-produced waste gas to desorb the water.

4. Process air is passed through an integrated heat exchanger (usually a plate fin heat

exchanger) and cooled against product (and waste) cryogenic streams. Part of the air

liquefies to form a liquid that is enriched in oxygen. The remaining gas is richer in

nitrogen and is distilled to almost pure nitrogen (typically < 1ppm) in a high pressure (HP)

distillation column. The condenser of this column requires refrigeration which is obtained

from expanding the more oxygen rich stream further across a valve or through

an Expander, (a reverse compressor).

5. Alternatively the condenser may be cooled by interchanging heat with a reboiler in a low

pressure (LP) distillation column (operating at 1.2-1.3 bar abs.) when the ASU is

producing pure oxygen. To minimize the compression cost the combined

condenser/reboiler of the HP/LP columns must operate with a temperature difference of

only 1-2 K, requiring plate fin brazed aluminium heat exchangers. Typical oxygen purities

range in from 97.5% to 99.5% and influences the maximum recovery of oxygen. The

refrigeration required for producing liquid products is obtained using the Joule–Thomson

effect in an expander which feeds compressed air directly to the low pressure column.

Hence, a certain part of the air is not to be separated and must leave the low pressure

column as a waste stream from its upper section.

6. Because the boiling point of argon (87.3 K at standard conditions) lies between that of

oxygen (90.2 K) and nitrogen (77.4 K), argon builds up in the lower section of the low

pressure column. When argon is produced, a vapor side draw is taken from the low

pressure column where the argon concentration is highest. It is sent to another column

rectifying the argon to the desired purity from which liquid is returned to the same location

in the LP column. Use of modern structured packings which have very low pressure

drops enable argon with less than 1 ppm impurities. Though argon is present in less to

1% of the incoming, the air argon column requires a significant amount of energy due to

the high reflux ratio required (about 30) in the argon column. Cooling of the argon column

can be supplied from cold expanded rich liquid or by liquid nitrogen.

7. Finally the products produced in gas form are warmed against the incoming air to ambient

temperatures. This requires a carefully crafted heat integration that must allow for

robustness against disturbances (due to switch over of the molecular sieve beds [7]). It

may also require additional external refrigeration during start-up.

The separated products are sometimes supplied by pipeline to large industrial users near the

production plant. Long distance transportation of products is by shipping liquid product for large

quantities or as dewar flasks or gas cylinders for small quantities.

You might also like

- An Air Separation Plant Separates Atmospheric Air Into Its Primary ComponentsDocument4 pagesAn Air Separation Plant Separates Atmospheric Air Into Its Primary ComponentsAbhinav AjmaniNo ratings yet

- Air Composition DryDocument11 pagesAir Composition DryrahulNo ratings yet

- Manufact Liquid OxygenDocument2 pagesManufact Liquid Oxygenz leeNo ratings yet

- Refrigeration ME 201Document13 pagesRefrigeration ME 201pathan_440No ratings yet

- FridgeDocument6 pagesFridgeshashlearnNo ratings yet

- The Definitive Guide To Cryogenic EngineeringDocument21 pagesThe Definitive Guide To Cryogenic EngineeringSamanthaPereraNo ratings yet

- Unit-V: Refrigeration & Air-ConditioningDocument25 pagesUnit-V: Refrigeration & Air-ConditioningNalliah PrabakaranNo ratings yet

- Cryogenic Air Separation Unit Maintenance TipsDocument14 pagesCryogenic Air Separation Unit Maintenance Tipsokoro matthewNo ratings yet

- Vapor Compression Refrigeration Cycle ExplainedDocument16 pagesVapor Compression Refrigeration Cycle ExplainedDiether RigorNo ratings yet

- Absorption Refrigerator - WikipediaDocument5 pagesAbsorption Refrigerator - Wikipediaaravind grandhiNo ratings yet

- Meat Technology Update: Refrigeration PrinciplesDocument4 pagesMeat Technology Update: Refrigeration PrinciplesDebasis Dasgupta100% (1)

- Cooling Towers Are Heat Removal Devices Used To Transfer Process Waste Heat To The AtmosphereDocument26 pagesCooling Towers Are Heat Removal Devices Used To Transfer Process Waste Heat To The AtmosphereAIYODOT DOTNo ratings yet

- Cryogenic Separation Plants PDFDocument20 pagesCryogenic Separation Plants PDFHemanth Kumar Sarosh KiranNo ratings yet

- Absorption Refrigerator Uses Heat Source for Cooling Without CompressorDocument5 pagesAbsorption Refrigerator Uses Heat Source for Cooling Without CompressorThanveer Ahmed SNo ratings yet

- Industrial Visit To Centralized Air Conditioning SystemDocument9 pagesIndustrial Visit To Centralized Air Conditioning SystemsoumikNo ratings yet

- Cryogenic Systems Introduction - Joule-Thomson CryocoolerDocument9 pagesCryogenic Systems Introduction - Joule-Thomson CryocoolerGanesh ThoratNo ratings yet

- Oxygen Plant ManualDocument54 pagesOxygen Plant Manualmahaveen89% (18)

- Oxygen PlantDocument10 pagesOxygen Plantshoaib705No ratings yet

- Cpe 601 Mini ProjectDocument9 pagesCpe 601 Mini ProjectSchaieraNo ratings yet

- Development of two highly efficient adsorption heat pump systemsDocument6 pagesDevelopment of two highly efficient adsorption heat pump systemsBalaji RajNo ratings yet

- 351 Chap1 Refrigeration Intro 2014Document24 pages351 Chap1 Refrigeration Intro 2014Faiz AmeeriNo ratings yet

- Process DescriptionDocument5 pagesProcess DescriptionGurunath EpiliNo ratings yet

- Performance (COP) Analysis of A Vapour Compression Refrigeration System Component With Nano CoatingDocument4 pagesPerformance (COP) Analysis of A Vapour Compression Refrigeration System Component With Nano CoatingantonytechnoNo ratings yet

- ECM 216 BUILDING SERVICES Bab 2.3 Ahu, Chiller and Cooling TowerDocument3 pagesECM 216 BUILDING SERVICES Bab 2.3 Ahu, Chiller and Cooling TowerAZUAN BIN AHMAD FAUZI100% (1)

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Pollution Control: Woods Practical Guide To Fan EngineeringDocument13 pagesPollution Control: Woods Practical Guide To Fan EngineeringprokjongNo ratings yet

- Evaporative Cooling Technology TodayDocument10 pagesEvaporative Cooling Technology TodayWinwin07No ratings yet

- Air ConditioningDocument11 pagesAir ConditioningBrilliantJohnMalandacRubiaNo ratings yet

- Chapter 11: Cryogenic Vacuum Pumps: The Effect of Temperature On The Vapor Pressure of GasesDocument18 pagesChapter 11: Cryogenic Vacuum Pumps: The Effect of Temperature On The Vapor Pressure of GasesRicky Ocktavi RizkyNo ratings yet

- 11 AirconditioningDocument19 pages11 AirconditioningRohit AgrawalNo ratings yet

- Mine ClimateDocument16 pagesMine ClimateRehal JandialNo ratings yet

- Functioning of ChillersDocument22 pagesFunctioning of ChillersAnonymous b9fcR5No ratings yet

- Hvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6Document11 pagesHvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6AliNo ratings yet

- Cryopump: Vacuum Pump Gases VapoursDocument2 pagesCryopump: Vacuum Pump Gases VapoursEmil Florin TutaNo ratings yet

- Chapter - 5Document19 pagesChapter - 5Getasew TesfaNo ratings yet

- VIP06 Heat RecoveryDocument12 pagesVIP06 Heat RecoveryAdbhut KumarNo ratings yet

- 1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledDocument500 pages1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledChristopher Lennon Dela CruzNo ratings yet

- Refrigeration Air ConditioningDocument7 pagesRefrigeration Air Conditioningkonduri chaitanyaNo ratings yet

- Oxygen, Nitrogen, Propane Methane CondenseDocument7 pagesOxygen, Nitrogen, Propane Methane Condensekonduri chaitanyaNo ratings yet

- Vapor-Compression Refrigeration - WikipediaDocument11 pagesVapor-Compression Refrigeration - Wikipediaaravind grandhiNo ratings yet

- Ullmann's Encyclopedia of Industrial Chemistry: Cryogenic TechnologyDocument6 pagesUllmann's Encyclopedia of Industrial Chemistry: Cryogenic TechnologyJulio GomezNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Thermal WheelDocument32 pagesThermal Wheelzaldy1985No ratings yet

- Nonconventional Methods of Gas LiquefactionDocument45 pagesNonconventional Methods of Gas LiquefactionImtisal E NoorNo ratings yet

- Performance and Efficiency Test of Refrigeration PlantDocument52 pagesPerformance and Efficiency Test of Refrigeration PlantIvy Joy UbinaNo ratings yet

- Adsorption RefrigerationDocument22 pagesAdsorption RefrigerationVijay Krishnan100% (1)

- Experiment 11-Hvac For Small HouseDocument9 pagesExperiment 11-Hvac For Small Houseengrjayasis20No ratings yet

- How Surface Condensers WorkDocument12 pagesHow Surface Condensers WorkPrabir Kumar Pati100% (1)

- Refrigeration System DiagramDocument7 pagesRefrigeration System DiagramNama Saya ZulNo ratings yet

- ECM216 BUILDING SERVICES Bab 2.2 Air ConditioningDocument8 pagesECM216 BUILDING SERVICES Bab 2.2 Air ConditioningAZUAN BIN AHMAD FAUZI100% (3)

- 1 Chapter Eight INERT GAS PLANT 8.1 DesignDocument15 pages1 Chapter Eight INERT GAS PLANT 8.1 DesignsugumarNo ratings yet

- Production and Generation of Sulfonated ProductsDocument15 pagesProduction and Generation of Sulfonated ProductsAbraham wisdomNo ratings yet

- Process Description Nitric Acid ProductionDocument2 pagesProcess Description Nitric Acid ProductionLaman AlipashayevaNo ratings yet

- HVAC & Refrigeration SystemDocument22 pagesHVAC & Refrigeration SystemSivakumar NadarajaNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- HydrodesulfurizationDocument6 pagesHydrodesulfurizationYuri YamirnovNo ratings yet

- Disproportionation: DiethylbenzenesDocument3 pagesDisproportionation: DiethylbenzenesYuri YamirnovNo ratings yet

- Acetaldehyde Organic Compound with Wide OccurrenceDocument9 pagesAcetaldehyde Organic Compound with Wide OccurrenceYuri YamirnovNo ratings yet

- Ethylene OxideDocument25 pagesEthylene OxideYuri YamirnovNo ratings yet

- History: Catalytic Reforming Is A Chemical Process Used To ConvertDocument7 pagesHistory: Catalytic Reforming Is A Chemical Process Used To ConvertYuri YamirnovNo ratings yet

- Benzene Ring Model: Aromatic Compounds Are ThoseDocument7 pagesBenzene Ring Model: Aromatic Compounds Are ThoseYuri YamirnovNo ratings yet

- Elemental GaseseditDocument3 pagesElemental GaseseditYuri YamirnovNo ratings yet

- What Defines An Industrial GasDocument2 pagesWhat Defines An Industrial GasYuri YamirnovNo ratings yet

- Air Separation Unit: Membrane Nitrogen GeneratorDocument1 pageAir Separation Unit: Membrane Nitrogen GeneratorYuri YamirnovNo ratings yet

- Industrial gases used in many industriesDocument1 pageIndustrial gases used in many industriesYuri YamirnovNo ratings yet

- Distribution of a Solute Between Immiscible SolventsDocument6 pagesDistribution of a Solute Between Immiscible SolventsKuo Sarong67% (6)

- Heating, Ventilation and Air Conditioning (HVAC) System Validation Process - Pharmaceutical GuidelinesDocument2 pagesHeating, Ventilation and Air Conditioning (HVAC) System Validation Process - Pharmaceutical GuidelinesShoaib BiradarNo ratings yet

- Doha Extraco, Po Box.41253,: Client Design ConsultantDocument144 pagesDoha Extraco, Po Box.41253,: Client Design ConsultantAli JaberNo ratings yet

- Manual EL FLOW SelectDocument55 pagesManual EL FLOW SelectZoran ConstantinescuNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Wa0036.Document2 pagesWa0036.GMHSS VehariNo ratings yet

- Fluid Loss Additives For Oilwell CementingDocument6 pagesFluid Loss Additives For Oilwell CementingCarlos RochaNo ratings yet

- Rock Forming Minerals 2Document39 pagesRock Forming Minerals 2Jun Louise Putis DagandanNo ratings yet

- Yardim2016 Shear Strengthening of Unreinforced Masonry Wall With Different Fiber Reinforced Mortar JacketsDocument6 pagesYardim2016 Shear Strengthening of Unreinforced Masonry Wall With Different Fiber Reinforced Mortar JacketsAbdulkhaliq AbdulyimahNo ratings yet

- Properties of MineralsDocument31 pagesProperties of MineralsJenzen fe PalmaNo ratings yet

- Flanges: KPC CorporationDocument6 pagesFlanges: KPC Corporationdj22500No ratings yet

- O Level Bio - Chapter 1 - CellsDocument10 pagesO Level Bio - Chapter 1 - CellsTakudzwa ZvidzaNo ratings yet

- Student Exploration: Balancing Chemical EquationsDocument4 pagesStudent Exploration: Balancing Chemical EquationsMichael Benson0% (1)

- WAC Guide PDFDocument4 pagesWAC Guide PDFNeo AieNo ratings yet

- Chemical Reactions and StoichiometryDocument9 pagesChemical Reactions and StoichiometryNathaniel Jay Rogador SumalinogNo ratings yet

- Reaction Rates and EquilibriumDocument71 pagesReaction Rates and EquilibriumDiepNo ratings yet

- Chemistry For Engineers: Chem 11Document8 pagesChemistry For Engineers: Chem 11Rhea Mae ApinNo ratings yet

- Calculate ChemSheet ModelDocument3 pagesCalculate ChemSheet ModelBùi Hắc HảiNo ratings yet

- 1.nitrogen Fertilizer. Nitrogen Fertilizer Fertilizers Nitrogen N Fertilizer NitrogenDocument4 pages1.nitrogen Fertilizer. Nitrogen Fertilizer Fertilizers Nitrogen N Fertilizer NitrogenAngeel MalicseNo ratings yet

- Carryover in BoilerDocument2 pagesCarryover in Boilershan877No ratings yet

- 7740 8330 KG-33 Corning Schott Kimble Kavalier Pyrex Duran Kimax SimaxDocument5 pages7740 8330 KG-33 Corning Schott Kimble Kavalier Pyrex Duran Kimax SimaxPrimaria PuhaceniNo ratings yet

- Experiment9 A011Document35 pagesExperiment9 A011Manas GaikwadNo ratings yet

- Model No 20501Document5 pagesModel No 20501Achmad HambaliNo ratings yet

- DuraclearDocument2 pagesDuraclearRupesh ParaswarNo ratings yet

- CH 05 ThermodynamicsDocument18 pagesCH 05 ThermodynamicsJhonnBeikerAnccasiLachoNo ratings yet

- Different Types of Cement and Their Uses - We Civil EngineersDocument10 pagesDifferent Types of Cement and Their Uses - We Civil EngineersMuhammad YaseenNo ratings yet

- Density and Specific Gravity (Relative Density) of Plastics by DisplacementDocument6 pagesDensity and Specific Gravity (Relative Density) of Plastics by DisplacementGabriel Herrera GonzalezNo ratings yet

- Savant Brochrue NewDocument12 pagesSavant Brochrue Newrajarao001No ratings yet

- An Experimental and Theoretical Approach On Kinetics and Mechanism For Formation of A Four Membered (S, S) Chelated PT (II) ComplexDocument13 pagesAn Experimental and Theoretical Approach On Kinetics and Mechanism For Formation of A Four Membered (S, S) Chelated PT (II) Complexyousif husseinNo ratings yet

- #Tutorial 3 - Fossil Fule Steam Generators TroubleshootingDocument5 pages#Tutorial 3 - Fossil Fule Steam Generators Troubleshootingmohamed EldesokyNo ratings yet