Professional Documents

Culture Documents

SCM Ans3

SCM Ans3

Uploaded by

SiddharthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCM Ans3

SCM Ans3

Uploaded by

SiddharthCopyright:

Available Formats

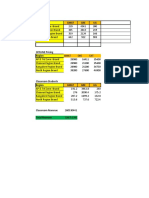

ANS-3

The Third Way Sourcing was designed to be a halfway point between full integration and

traditional outsourcing to make supply chain more efficient by building a true partnership

with VF’s suppliers and integrating VF’s internal technical and supply chain expertise into

external suppliers.

Pros & Cons of VF-

Pros Cons

Better exchange and flow of information at Closing down internal plants despite strong

all stages performance and giving away human

resource to external contractors is a huge

risk

Diversification of risk as each stage has Since contractors & suppliers are getting

different contractors and products were new technology & investment there is a

sourced from different locations. chance that they might open their own

apparel line

Dedicated production lines for VF by Hard to convince existing suppliers as they

suppliers along with timed contracts will lose their existing clients

Product Sourcing Why?

Category

Jeanswear (U.S.) Traditional Since price is the most important

characteristic required along with lower

weightage given to speed and variety.

Jeanswear (Europe) In-House In Europe, jeans are worn as fashion item and

thus would require to give higher weightage

to variety and/designs. Since fashion has a

short life cycle speed is another important

characteristic.

Imagewear Third-Way Here, both price and responsiveness is the

(uniform) driving factor along with the quality. The in-

house technical expertise could be utilized as

a means of knowledge sharing and thus

would be an effective way to reduce the costs

Outdoor and Action In-house This requires high response time, high variety

wear and high quality at the same time. Using In-

house strategy, one can control and monitor

the resources and technical expertise

accordingly.

Sportswear Third-Way Here again since sportswear is price

insensitive while the driving factors are high

quality and response time. Demand

estimation is comparatively easier to

estimate.

You might also like

- StepSmart Fitness ExlDocument9 pagesStepSmart Fitness ExlNishiGogia50% (2)

- Affidavit Sample - Marriage TestimonyDocument2 pagesAffidavit Sample - Marriage Testimonycharles bautista0% (1)

- Printmaking TimelineDocument1 pagePrintmaking Timelineapi-250295080No ratings yet

- Guide On Outcome-Based Security Contracts: Sector LeadDocument45 pagesGuide On Outcome-Based Security Contracts: Sector LeadChris Ang100% (1)

- 2018 Book ContemporaryGothicDrama PDFDocument273 pages2018 Book ContemporaryGothicDrama PDFMiranda Maria100% (1)

- NPV and IRR, Payback Period, ImportantDocument5 pagesNPV and IRR, Payback Period, Important朱潇妤No ratings yet

- Ltopf Individual Application FormDocument1 pageLtopf Individual Application FormCh Gerry BastonNo ratings yet

- VF Brands: Global Supply Chain StrategyDocument4 pagesVF Brands: Global Supply Chain StrategySwarnajit Saha50% (2)

- Big Hair Day by Margaret JohnsonDocument19 pagesBig Hair Day by Margaret JohnsonAmong Sus100% (1)

- IELTSDocument4 pagesIELTSSiddharthNo ratings yet

- Chapter 4 ReportDocument16 pagesChapter 4 ReportShielaMarie MalanoNo ratings yet

- F. Robert Jacobs, Richard B. Chase - Operations and Supply Chain Management (2018, McGraw Hill) - Chapter 7Document6 pagesF. Robert Jacobs, Richard B. Chase - Operations and Supply Chain Management (2018, McGraw Hill) - Chapter 7payalkhndlwlNo ratings yet

- Group 7 - VF BrandsDocument4 pagesGroup 7 - VF BrandsANSHUL SINGH PARIHARNo ratings yet

- Making A Tough Personnel Decision at Nova Waterfront HotelDocument11 pagesMaking A Tough Personnel Decision at Nova Waterfront HotelSiddharthNo ratings yet

- SURVEY On Teachers and Teaching SchoolDocument3 pagesSURVEY On Teachers and Teaching SchoolDivine Grace Samortin100% (1)

- Lectra Fashion Brochure Flex Offer enDocument8 pagesLectra Fashion Brochure Flex Offer enPratama TanadaNo ratings yet

- Assignment - VF BrandsDocument5 pagesAssignment - VF Brandsavnish kumar raviNo ratings yet

- HSC Notes BSTDocument83 pagesHSC Notes BSTkrish k100% (1)

- Driving The Next Generation Purchasing Model: Discussion DocumentDocument35 pagesDriving The Next Generation Purchasing Model: Discussion Documentdivya2882No ratings yet

- Operations Management and TQMDocument6 pagesOperations Management and TQMmartgetaliaNo ratings yet

- Handout For: ClickDocument10 pagesHandout For: ClickNishant SatamkarNo ratings yet

- EHWLC MBA Operations Session 7 - Supply Chain ManagementDocument36 pagesEHWLC MBA Operations Session 7 - Supply Chain ManagementpushkarajgandhiNo ratings yet

- Makalah Management OperationsDocument7 pagesMakalah Management OperationsAry SandiNo ratings yet

- Lecture 4 PDFDocument23 pagesLecture 4 PDFMuhammad AfzalNo ratings yet

- Level 3 - Procurement & Tendering Flashcards by James O'Connor - BrainscapeDocument9 pagesLevel 3 - Procurement & Tendering Flashcards by James O'Connor - Brainscapevinodsj007No ratings yet

- Chapter 8Document17 pagesChapter 8Rachel LozadaNo ratings yet

- Homework 1Document3 pagesHomework 1Oussama BenNo ratings yet

- Supply Chain Management: Who Should Read This Fact Sheet?Document4 pagesSupply Chain Management: Who Should Read This Fact Sheet?Yong Yang YangNo ratings yet

- Managing Strategy Operations and Partnerships 1773803 194477557Document32 pagesManaging Strategy Operations and Partnerships 1773803 194477557Gontla Sai SrijaNo ratings yet

- Opman Ch02 NotesDocument10 pagesOpman Ch02 NotesあいはらめいNo ratings yet

- DC Aerospace-OnlineDocument108 pagesDC Aerospace-OnlineBaskaran NithyanandamNo ratings yet

- Figure 4. Ranking of All Buyer Values Across All Segments, Value Chain Positions and GeographiesDocument6 pagesFigure 4. Ranking of All Buyer Values Across All Segments, Value Chain Positions and GeographiesmittleNo ratings yet

- Opito PurchasingDocument4 pagesOpito PurchasingRosHan AwanNo ratings yet

- Operations StrategiesDocument10 pagesOperations Strategiesfiren1388No ratings yet

- Job in AirtelDocument4 pagesJob in AirtelPriyanka KushwahaNo ratings yet

- Performance Area Importance: Some Typical MeasuresDocument41 pagesPerformance Area Importance: Some Typical MeasuresBhaavyn SutariaNo ratings yet

- Case Study 2 (Supplier Evaluation Using AHP Approach)Document12 pagesCase Study 2 (Supplier Evaluation Using AHP Approach)Lukman AhmadNo ratings yet

- Should-Cost Challenges Demystified: Kumar VaradarajanDocument9 pagesShould-Cost Challenges Demystified: Kumar VaradarajanPramod HegdeNo ratings yet

- Chapter 2 SCMDocument25 pagesChapter 2 SCMKrishna VirdiNo ratings yet

- SUPPLY CHAIN Chapter 3Document5 pagesSUPPLY CHAIN Chapter 3Hamza JavedNo ratings yet

- De Hodaetal 2013 Variety Paper CIRPDocument25 pagesDe Hodaetal 2013 Variety Paper CIRPChester Adriaan HendricksNo ratings yet

- Partnerships in The Supply ChainDocument12 pagesPartnerships in The Supply ChainSri NarendiranNo ratings yet

- Operations Management Chapter 5Document36 pagesOperations Management Chapter 5sandulliNo ratings yet

- Om ReviewerDocument8 pagesOm ReviewerPaulo BernasNo ratings yet

- The Importance of Early Supplier Involvement EbookDocument5 pagesThe Importance of Early Supplier Involvement EbookSamuel LotchouangNo ratings yet

- Powerful Pricing: The Next Frontier in Apparel and Fashion Advanced AnalyticsDocument10 pagesPowerful Pricing: The Next Frontier in Apparel and Fashion Advanced AnalyticsQuang PhanNo ratings yet

- IFMA FMPv3-0 F-B Ch3Document18 pagesIFMA FMPv3-0 F-B Ch3Mohamed IbrahimNo ratings yet

- Costing Large ScaleDocument8 pagesCosting Large Scalekirubakaran janaNo ratings yet

- MaynoothDocument2 pagesMaynoothIchwanto YusroNo ratings yet

- Environmental MarketingDocument6 pagesEnvironmental MarketingJeann MahinayNo ratings yet

- Core Concepts: A New Competitive EnvironmentDocument5 pagesCore Concepts: A New Competitive EnvironmentDing XuanNo ratings yet

- Post PDFDocument11 pagesPost PDFhuseNo ratings yet

- SCM Chapter 4 SOURCING & PRICING IN SUPPLY CHAINDocument75 pagesSCM Chapter 4 SOURCING & PRICING IN SUPPLY CHAINNoha SisayNo ratings yet

- An Approach To Improve Airframe Conceptual Design ProcessDocument10 pagesAn Approach To Improve Airframe Conceptual Design Processst05148No ratings yet

- 05 Introduction To The Bidding UIPE ApprovedDocument33 pages05 Introduction To The Bidding UIPE Approvedjoz lapNo ratings yet

- Integrated Material ManagementDocument24 pagesIntegrated Material ManagementShray TanejaNo ratings yet

- Quality Improvement Incentives and Product Recall Cost Sharing ContractsDocument17 pagesQuality Improvement Incentives and Product Recall Cost Sharing ContractsMisdaNo ratings yet

- LESSON 8: Supplier Partnership and TQMDocument4 pagesLESSON 8: Supplier Partnership and TQMLeshauna CaleighNo ratings yet

- MICHEAL PORTERS Strategic ManagmentDocument31 pagesMICHEAL PORTERS Strategic Managmentganeshpn38No ratings yet

- Project Procurement ManagementDocument9 pagesProject Procurement ManagementIhtasham MalikNo ratings yet

- Unit 1 8Document39 pagesUnit 1 8piyush.foruppoNo ratings yet

- Assignment Mod 2 Product Service DesignDocument8 pagesAssignment Mod 2 Product Service DesignPriyank LashkariNo ratings yet

- Methodology of Developing Product Family ArchitectDocument19 pagesMethodology of Developing Product Family Architectkaff110.aqNo ratings yet

- BEC102 Chapter9SummaryDocument6 pagesBEC102 Chapter9SummaryCarlos Manuel AbalosNo ratings yet

- Buying Beha 123Document31 pagesBuying Beha 123Prakash VadavadagiNo ratings yet

- Determination of Requirements-1-1Document8 pagesDetermination of Requirements-1-1John MutetiNo ratings yet

- Mudassar Bba5 Operational ManagmenrDocument12 pagesMudassar Bba5 Operational ManagmenrAsad mehmoodNo ratings yet

- Maintenance Database: José Caldeira Duarte, Pedro F. Cunha, João T. CraveiroDocument6 pagesMaintenance Database: José Caldeira Duarte, Pedro F. Cunha, João T. Craveiroキラー サミキラーNo ratings yet

- Group01 Logistic ManagementDocument4 pagesGroup01 Logistic ManagementCJ Gaming TVNo ratings yet

- Task A.P. Møller - Group2 PDFDocument12 pagesTask A.P. Møller - Group2 PDFSiddharthNo ratings yet

- BRM Session 7 PDFDocument33 pagesBRM Session 7 PDFSiddharthNo ratings yet

- Slides MilesEversonDocument9 pagesSlides MilesEversonSiddharthNo ratings yet

- Session 8 & 9 - Sales and Operations Planning Faculty - Dr. CP Garg, IIM RohtakDocument31 pagesSession 8 & 9 - Sales and Operations Planning Faculty - Dr. CP Garg, IIM RohtakSiddharthNo ratings yet

- LL Bean Case WorkingDocument2 pagesLL Bean Case WorkingSiddharthNo ratings yet

- How To Build A Talent Pipeline Model: 1. Plan Recruitment According To Business StrategyDocument3 pagesHow To Build A Talent Pipeline Model: 1. Plan Recruitment According To Business StrategySiddharthNo ratings yet

- Talent Pipeline Refers To A Pool of Potential Candidates, Either Company's Employees Who AreDocument3 pagesTalent Pipeline Refers To A Pool of Potential Candidates, Either Company's Employees Who AreSiddharthNo ratings yet

- Cottle-Taylor: Expanding The Oral Care in IndiaDocument9 pagesCottle-Taylor: Expanding The Oral Care in IndiaSiddharthNo ratings yet

- Single Truck 400 Common Ordering Cost 350 Product Specific Cost 50 Product Cost/pound 1 Holding Cost 0.25Document10 pagesSingle Truck 400 Common Ordering Cost 350 Product Specific Cost 50 Product Cost/pound 1 Holding Cost 0.25SiddharthNo ratings yet

- 0.3 Demand Probability 0.1 60 3% 0 0 110 70 6% 0 0 80 13% 0 0 90 18% 0 0 100 20% 0 0 110 15% 0 0 120 16% 0 0 130 6% 0 140 3% 0Document1 page0.3 Demand Probability 0.1 60 3% 0 0 110 70 6% 0 0 80 13% 0 0 90 18% 0 0 100 20% 0 0 110 15% 0 0 120 16% 0 0 130 6% 0 140 3% 0SiddharthNo ratings yet

- Financials WorksheetDocument3 pagesFinancials WorksheetSiddharthNo ratings yet

- SectionD Group15 Larsen&ToubroDocument8 pagesSectionD Group15 Larsen&ToubroSiddharthNo ratings yet

- MoonchemDocument4 pagesMoonchemSiddharthNo ratings yet

- 2Document4 pages2SiddharthNo ratings yet

- Question 5-What Should L. L. Bean Do To Improve Its Forecasting Process?Document1 pageQuestion 5-What Should L. L. Bean Do To Improve Its Forecasting Process?SiddharthNo ratings yet

- 2Document4 pages2SiddharthNo ratings yet

- Region Gmat GRE UGDocument9 pagesRegion Gmat GRE UGSiddharthNo ratings yet

- Sales Force Integration at Fedex: Sales and Distribution ManagementDocument7 pagesSales Force Integration at Fedex: Sales and Distribution ManagementSiddharthNo ratings yet

- Ielts Prep: Edx - Plan1 Edx - Plan2Document14 pagesIelts Prep: Edx - Plan1 Edx - Plan2SiddharthNo ratings yet

- ComparisonDocument10 pagesComparisonSiddharthNo ratings yet

- Ma Excel CLVDocument2 pagesMa Excel CLVSiddharthNo ratings yet

- A Movie Analysis of Jose Rizal Movie (1998)Document7 pagesA Movie Analysis of Jose Rizal Movie (1998)Kate TomaganNo ratings yet

- Yuvan Pidika Acne EtiologyDocument8 pagesYuvan Pidika Acne EtiologyMSKCNo ratings yet

- URC Annual Corporate Governance Report 2016 - FinalDocument74 pagesURC Annual Corporate Governance Report 2016 - FinalDennis DimaanoNo ratings yet

- Complete ReportDocument23 pagesComplete ReportRajeev Kumar100% (1)

- Dissertation On Environmental Law in IndiaDocument8 pagesDissertation On Environmental Law in IndiaWriteMyPaperInApaFormatSingapore100% (1)

- AgroBoga 050923 (2po)Document2 pagesAgroBoga 050923 (2po)AGRO BOGA UTAMANo ratings yet

- SSRN Id2899095Document10 pagesSSRN Id2899095vivek wilsonNo ratings yet

- Mohd - Abrar CVDocument2 pagesMohd - Abrar CVNoufal NazzNo ratings yet

- First Periodical Exam Photo HeaderDocument3 pagesFirst Periodical Exam Photo HeaderJes SaNo ratings yet

- Test Bank For Information Technology For Management On Demand 11th by TurbanDocument28 pagesTest Bank For Information Technology For Management On Demand 11th by Turbanoverlateabutmentptnbf8No ratings yet

- ProjectFinancing ACasestudyonCoimbatoreBypassRoadProjectDocument10 pagesProjectFinancing ACasestudyonCoimbatoreBypassRoadProjectprnishtalaNo ratings yet

- Antofagasta: Scfa - Star 3 Loa 6Document35 pagesAntofagasta: Scfa - Star 3 Loa 6David Alejandro Aguilera RiosNo ratings yet

- Question-02 Human Resource ManagementDocument4 pagesQuestion-02 Human Resource ManagementRiya SinghNo ratings yet

- TravemoreDocument30 pagesTravemoreMawyNo ratings yet

- Mba ZG515 - CP - Course HandoutDocument10 pagesMba ZG515 - CP - Course HandoutudayakumargNo ratings yet

- Physical Facilities and Maintenance Needs Assessment Form: Department of EducationDocument3 pagesPhysical Facilities and Maintenance Needs Assessment Form: Department of EducationNikka Dawn Shallom EstopinNo ratings yet

- Ray A. Abelada: Certificate of RecognitionDocument4 pagesRay A. Abelada: Certificate of RecognitionRemil CastañedaNo ratings yet

- Circular-2019 E7 0Document36 pagesCircular-2019 E7 0Cag ExamsNo ratings yet

- ZOHO ONE Case StudyDocument2 pagesZOHO ONE Case StudySachin PrajapatiNo ratings yet

- Lesson Plan Template About Big and Small 1Document3 pagesLesson Plan Template About Big and Small 1api-294972438100% (1)

- CS1000 Basic Programming: Computing Lab - IIDocument19 pagesCS1000 Basic Programming: Computing Lab - IIPartho BiswasNo ratings yet

- South-Western/Thomson Learning © 2003: SBK - Fin44Document20 pagesSouth-Western/Thomson Learning © 2003: SBK - Fin44Niharika RahmanNo ratings yet