Professional Documents

Culture Documents

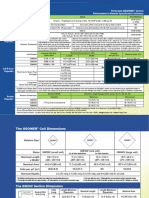

Highways Pavement Specification Limits

Uploaded by

kashifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highways Pavement Specification Limits

Uploaded by

kashifCopyright:

Available Formats

OGL- Original Ground level

Field Compaction (min) 90 % (min)

EMB- Embankment / Borrow Area

Material Classification requirement

Liquid Limit LL / Plasticity Index PI (max) 50 LL and 25 PI

Proctor Density(Min. Value) 1.52 to 1.60 gram/cubic centimeter

7 % min at top 30 cm shall be used with a swell value not more

than 0.3%.

CBR % (min) Whereas a minimum soaked CBR of 5% of embankment material

below the formation of 30 cm

Formation of Embankment as per NHA

Height of Embankment below % of Max. Dry Density as per

sub grade top AASHTO T-180

0-30cm 95

30-75cm 93

Over 75cm 90

Field Compaction

Below the foundation of the

95

structure

At least upper 90 cm (3ft) of the fill should be compacted to obtain

a density in excess of 95% of max.

Modified AASHTO density and the lower portion to 90% of max.

Modified AASHTO density.

Improved Subgrade / Borrow Area

Max compacted thickness of single layer

Nominal size of aggregate

suitable material for sub grade A-1-a, A-1-b, A-2-4, soil classification

liquid limit LL and Plasticity Index PI (Max) LL 40 max and PI 10 max

Proctor Density(Min. Value) Minimum dry density 1.75 g/cc

swelling Test 0.3% max.

CBR % (min) For top 30 cm CBR 8% min at 95%. Dry density (soil swell value

0.5% max)

97 % min depth of one foot and the lower portion to at least 95%

Field Compaction % (Min) of min.

GSB- Granular Sub-base

Granular backfill shall be placed in layer wise, and each layer not

exceeding 20 cm in thickness/fill to 100% of max. Dry density as

per AASHTO T-180(D). In water logged areas the thickness of layer

Max compacted thickness of single layer shall not exceed 50 cm and Common backfill shall be compacted in

layer not exceed 20 cm in depth to the 95% of max. Dry density as

per AASHTO T-180(D).

Nominal size of aggregate

Moisture Content 1-2% Below the OMC

Field Compaction % (min) 98 % min

Nominal size of aggregate

Grading Requirements for Subbase Material as NHA

Sieve Designation Percent Passing by Weight

(mm) (in) Class A Class B

60.6 2.5 100 --

50.0 2 90~100 100

25.0 1 50~80 55~85

9.5 3/8 -- 40~70

4.75 No. 4 35~70 30~60

2.0 No. 10 -- 20~50

0.425 No. 40 -- 10~30

0.075 No. 200 2~8 5~15

suitable material for Granular sub grade A-1-a, A-1-b, A-2-4, according to AASHTO soil classification

LAV - Los Angeles Abrasion Value % (Max) 50

Liquid Limit LL / Plasticity Index PI (Max) LL max 25 and PI max 6

Sand Equivalent (Min) 25% Min

Soundness % (Max):

12

Loss with sodium sulphate-5 cycles

Soundness % (Max):

18

Loss with magnesium sulphate-5 cycles

Water Absorption % (Max) 2

CBR % (min) 50 % at 98% max. Dry density (swell value max %)

Field Compaction % (Min) 98 % min

D15(subbase)/ D85 (Subgrade) <5

ABC - Aggregate Base Course / BASE course (WMM-Wet Mix Macadam)

20 cm (layer should be laying in two layers each layer not more

Maximum thickness of single compacted layer

than 10 cm)

Nominal size of aggregate

Grading Requirements for Base Material

Sieve Designation Percent Passing by Weight

(mm) (in) A B

50.0 2 100 100

25.0 1 70~95 75~95

9.5 3/8 30~65 40~75

4.75 No. 4 25~55 30~60

2.0 No. 10 15~40 20~50

0.425 No. 40 8~20 12~25

0.075 No. 200 2~8 5~10

Aggregate Impact Value – AIV % (Max) 40%. (Max)

Los Angeles Abrasion Value - LAV % (Max) 40%. (Max)

Sand Equivalent (Min) 45%. (Min)

Liquid Limit LL / Plasticity Index PI (Max) LL max 25 and PI max 6

Soundness % (Max):

12% Max (with Sodium Sulphate)

18% Max (with (Magnesium Sulphate)

Water Absorption % (Max) 2

Laminated Material % of Total Volume

15

(Max)

CBR % (Min) 80 % at 100% max. Dry density (swell value max %)

Field Compaction (min) 100% min

After final compaction of WMM course, the bed of WMM shall be allowed to dry for 24 hours.

BBC - Bitumen Base Course / DBM - Dense Bitumen Macadam / Binder Course

GRADING -1

Nominal size of aggregate 37.5 mm

Layer thickness 75-100 mm

Bitumen content % by mass of total mix 4 % Min

GRADING - 2

Nominal size of aggregate =26.5 mm

Layer thickness 50-75 mm

Bitumen content % by mass of total mix should not be less than 4.5%

Temperature ranges of bituminous material for various grades of bitumen

PRIME COAT (MC-30 Medium Curing) Emulsion (SS-1)

Quantity of SS1 grade bitumen Emulsion for various types of Granular surface

Viscosity @ 25 C 20 - 100 Sec.

Water content 20% Max.

Residue by Evaporation 50% Min.

Prime coat Rate of Spray 0.8 – 1.5 Kg/m² (18 - 32 lbs. per 100 sq.ft)

TACK COAT ( RC - 2 Rapid Curing) Emulsion (RS-1)

It should be provided over granular surface (like WMM) treated with prime coat, bituminous surfaces and cement

concrete pavement.

Viscosity @ 50 C 20 - 100 Sec.

Residue by Evaporation 60% Min.

Water content

Bituminous Surface 0.10 - 0.30

Tack coat (kg/Sqm.) @ 65 c to 105 c temp Granular surface 0.25 - 0.30

Cement concrete 0.30 - 3.50

BBC - Bitumen Base Course / BWC - Bitumen Wearing Course

BBC - Bitumen Base

Course / DBM - Dense BWC - Bitumen Wearing Course /

Name of Test

Bitumen Macadam / Binder BC - Bitumen Concrete

Course

Mixing temp. 160◦ C ± 5◦ C

temperature of hot mix asphalt Compacting temp. 145◦ C ± 10◦ C

Nominal size of aggregate 1.5" max 3/4" max

Class A Class B

Compacted Thickness 8cm min & 10cm max

50 -80 mm 35m – 60 mm

Asphalt is normally used in following grades depending on weather

Asphalt Gradings

and traffic condition

Penetration Grade 40/50 60/70, 80/100 and 120/150

Viscosity Grades AC-5, AC-10 and AC-30

Soundness Loss with sodium sulphate-5 cycles 12% max 12% max

Combined FI- flakiness and EI- elongation index 35% Max (should not be more than 35%)

35% Max (should not be 35% Max (should not be more than

AIV - Aggregate Impact Value

more than 35%) 35%)

LAV- Los Angeles Abrasion Value % (Max) 40% Max 40% Max

Sand Equivalent (Min) min 45% min 45%

Clay Lumps & Friable particles 0.25% max 0.25% max

Thin & Elongated particles 8% max 8% max

Liquid Limit LL and Plastic Index PI (Max) 25 LL and 6 PI 25 LL and 6 PI

Coating and stripping 95% min 95% min

Marshall Stability (min) 1000 kg min 1000 kg min

Marshall Flow 0.25 mm (0.01 in) 8 – 14 8 – 14

Voids in Mineral Aggregate (VMA) 12 – 20 % 12 – 20 %

Voids in Total Mix (VIM) 4 – 8% 4–7%

Loss of Stability 25 % (Max.) 20 % (Max.)

Field Compaction Test 92% to 95% 91% to 94%

Requirement of Asphalt / Bitumen

Ductility @ 25 C (After thin film oven test)

Flash and fire point

Softening point

Viscosity @ 50 C

Penetration

Loss on heating

Distillation

Specific gravity of bitumen

5. Bitumen (VG-40)

Absolute Viscosity @60 C Poises 3200 - 4800

Kinematic Viscosity @ 135 C cSt 400 Min.

Penetration @ 135 C 35 Min.

Softening Point 50 Min.

Ductility @ 25 C (After thin film oven test) 25 cm Min.

Flash point 220 C Min.

Solubility test > 99 %

You might also like

- SDBC Design CalculationsDocument30 pagesSDBC Design Calculationsakst1976200095% (19)

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Document2 pagesSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- Norma Astm d3282 Clasificación AashtoDocument6 pagesNorma Astm d3282 Clasificación AashtoEduardo SalgadoNo ratings yet

- فحوص المرور السريع ط 8Document14 pagesفحوص المرور السريع ط 8Abdo AboretaNo ratings yet

- Quality Specifications (As Per Morth 5th Revision)Document16 pagesQuality Specifications (As Per Morth 5th Revision)BSCPLCHDNo ratings yet

- Asphalt Pavement Construction: 1. Improved SubgradeDocument4 pagesAsphalt Pavement Construction: 1. Improved Subgrade143No ratings yet

- QA in Highway Sector-Part-3Document10 pagesQA in Highway Sector-Part-3boomiNo ratings yet

- Basic SpecificationDocument5 pagesBasic SpecificationArunpandiyanNo ratings yet

- Types of MixesDocument68 pagesTypes of MixesVinamraMishraNo ratings yet

- 2 Mrt-ToleranceDocument1 page2 Mrt-TolerancerhouieNo ratings yet

- Construction and Quality Control of Flexible PavementsDocument83 pagesConstruction and Quality Control of Flexible PavementsSayan GharNo ratings yet

- Blue Book SpecsDocument4 pagesBlue Book SpecsNormanBaleanNo ratings yet

- Mix Design For BSM-foam - Feb 2012Document14 pagesMix Design For BSM-foam - Feb 2012Alan FernandezNo ratings yet

- Test Method Description Subbase Material RequirementsDocument1 pageTest Method Description Subbase Material RequirementsTanmay VegadNo ratings yet

- SPECIFICATIONS OF CONSTRUCTION MATERIALS For Matlab Uttar BridgeDocument7 pagesSPECIFICATIONS OF CONSTRUCTION MATERIALS For Matlab Uttar BridgeSreenivasula Reddy KandulaNo ratings yet

- NHA Quality Test & LimitationsDocument18 pagesNHA Quality Test & LimitationsBilal KhanNo ratings yet

- Tcs Q 11302 r0 Earth WorksDocument5 pagesTcs Q 11302 r0 Earth Workschand saigvNo ratings yet

- IGNOU New Exam Time Table Dec 2018 TentativeDocument62 pagesIGNOU New Exam Time Table Dec 2018 Tentativejyothis_joy8315No ratings yet

- Roads 06 Pavements and Shoulders TDO 10mar2022Document11 pagesRoads 06 Pavements and Shoulders TDO 10mar2022FehkalNo ratings yet

- @civilbest, Superpave SummaryDocument60 pages@civilbest, Superpave Summarymehdi zalnezhadNo ratings yet

- Council Construction Specifications Part 264Document1 pageCouncil Construction Specifications Part 264Tanmay VegadNo ratings yet

- VaibhavDocument23 pagesVaibhavnajuka ghodvindeNo ratings yet

- Hand Book On Road PDFDocument56 pagesHand Book On Road PDFrajan sharma100% (1)

- M25 Grade-350 3-8-06Document4 pagesM25 Grade-350 3-8-06Norendro KangjamNo ratings yet

- Specification ForvvDocument3 pagesSpecification ForvvTarunNo ratings yet

- QA in Highway Sector-Part-4Document10 pagesQA in Highway Sector-Part-4boomiNo ratings yet

- Cement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Document7 pagesCement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Praneeth KumarNo ratings yet

- BITUMINOUSDocument1 pageBITUMINOUSJagaran PaulNo ratings yet

- ITEM 200 Latest 2004Document12 pagesITEM 200 Latest 2004Marinella AbellaNo ratings yet

- Construction of Bituminous Layers BBMPDocument84 pagesConstruction of Bituminous Layers BBMPajay chauhanNo ratings yet

- 15sampling & Testing - Minimum Testing. RequirementsDocument157 pages15sampling & Testing - Minimum Testing. Requirementsm0uth_wash1ngNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Marshall Mix Design MethodDocument21 pagesMarshall Mix Design MethodAltaf HossainNo ratings yet

- Saes Q 001 Saes-Q-006Document5 pagesSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Six Lan Rocad ConstructionDocument35 pagesSix Lan Rocad ConstructionDevendra SharmaNo ratings yet

- Orca Share Media1679062815446 7042499883079084480Document12 pagesOrca Share Media1679062815446 7042499883079084480robelyn gayagayNo ratings yet

- IVS Industries M35 50% Crushed Sand GGBSDocument8 pagesIVS Industries M35 50% Crushed Sand GGBSImran KhanNo ratings yet

- Item 200-201 & 310Document19 pagesItem 200-201 & 310KaJong JaclaNo ratings yet

- Attachment For CementingDocument5 pagesAttachment For Cementingzouke2002No ratings yet

- Backfill Engineering Fill Material SpecsDocument4 pagesBackfill Engineering Fill Material SpecsMohamed KhaledNo ratings yet

- WBM (Water Bound Macadam) RoadsDocument13 pagesWBM (Water Bound Macadam) RoadssatishsajjaNo ratings yet

- Flexible Pavement Thickness Design JKR MethodDocument3 pagesFlexible Pavement Thickness Design JKR MethodMohamad Shahrizal AliasNo ratings yet

- Satander Kumar QC Rigid PavementDocument41 pagesSatander Kumar QC Rigid Pavementa dutta100% (1)

- Road Materials & MixesDocument129 pagesRoad Materials & Mixestarunsingh49No ratings yet

- Presto: Property Value Test MethodDocument2 pagesPresto: Property Value Test MethodledagoNo ratings yet

- BFC 31802 Chapter 2b PDFDocument31 pagesBFC 31802 Chapter 2b PDFHawaiiChongNo ratings yet

- Sub-Base, Base and ShouldersDocument10 pagesSub-Base, Base and Shoulderstrilokbist04No ratings yet

- Lec - 8 Mix Design Applications PDFDocument68 pagesLec - 8 Mix Design Applications PDFAZIMERAWNo ratings yet

- My FileDocument2 pagesMy FileSyed Umair RizviNo ratings yet

- Laboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsDocument35 pagesLaboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsMd.imthiyazNo ratings yet

- P 209Document6 pagesP 209Bhanuka SamarakoonNo ratings yet

- Standard Specification For Building MaterialsDocument18 pagesStandard Specification For Building Materialskidi mollaNo ratings yet

- ASTM D2940 Agregates For Base CourseDocument1 pageASTM D2940 Agregates For Base Courseتوفيق عبداللهNo ratings yet

- Desain Layer PadDocument3 pagesDesain Layer Padrachreinaldi49No ratings yet

- 5.04 Sai Singh KhongrymmaiDocument27 pages5.04 Sai Singh Khongrymmaij krishnanNo ratings yet

- Bituminous Mix DesignDocument62 pagesBituminous Mix DesignShaim RehanNo ratings yet

- SRS: Road Surfacing 1.0 Base PreparationDocument5 pagesSRS: Road Surfacing 1.0 Base PreparationAurelius GoraNo ratings yet

- PDE Project OneDocument8 pagesPDE Project OnekashifNo ratings yet

- Normal Distribution AssignmentDocument13 pagesNormal Distribution AssignmentkashifNo ratings yet

- Assignment: Methods of Applied MathematicsDocument2 pagesAssignment: Methods of Applied MathematicskashifNo ratings yet

- AASHTO ASTM CODE NameDocument2 pagesAASHTO ASTM CODE NamekashifNo ratings yet

- MS Proposal ArshadDocument9 pagesMS Proposal ArshadkashifNo ratings yet

- CBR Improvement of Clayey Soil With Geogrid ReinforcementDocument4 pagesCBR Improvement of Clayey Soil With Geogrid Reinforcementbkollarou9632No ratings yet

- Case Studies in Construction MaterialsDocument12 pagesCase Studies in Construction MaterialsArham SheikhNo ratings yet

- Stabilization of Soil Using Bio-Enzyme (Terrazyme) : Gogireddy SomireddyDocument9 pagesStabilization of Soil Using Bio-Enzyme (Terrazyme) : Gogireddy SomireddyFARY MARIYAMNo ratings yet

- Syphon Aqueduct DesignDocument7 pagesSyphon Aqueduct DesignSanjeev Mishra100% (2)

- 1-A-6 Kakrail 13233kV & 3311kV Substation, SS-1A06S-G, Geotechnical Investigation Report 09.02Document225 pages1-A-6 Kakrail 13233kV & 3311kV Substation, SS-1A06S-G, Geotechnical Investigation Report 09.02ibiwumiNo ratings yet

- Index Properties of SoilsDocument26 pagesIndex Properties of SoilsTadesse MegersaNo ratings yet

- RTA Spec. - Soil InvenstigationDocument2 pagesRTA Spec. - Soil InvenstigationSheril Chandrabose100% (1)

- Supplementary Appendix To ARTC Track & Civil Code of Practice Railway Earthworks ETC-08-02Document12 pagesSupplementary Appendix To ARTC Track & Civil Code of Practice Railway Earthworks ETC-08-02roldskiNo ratings yet

- Field Vane Shear Test in Saturated Fine-Grained Soils: Standard Test Method ForDocument8 pagesField Vane Shear Test in Saturated Fine-Grained Soils: Standard Test Method ForAlina GheorgheNo ratings yet

- Classification of Soils For Engineering Purposes (Unified Soil Classification System)Document11 pagesClassification of Soils For Engineering Purposes (Unified Soil Classification System)judithelizabedithNo ratings yet

- SAND AS A SOIL STABILIZERpdfDocument9 pagesSAND AS A SOIL STABILIZERpdfLalit KumarNo ratings yet

- Syllabus Civil Qaqc Course Sdlinc 9600162099Document12 pagesSyllabus Civil Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (1)

- Classification of SOIL V1.00 Sept2010Document16 pagesClassification of SOIL V1.00 Sept2010kameshNo ratings yet

- Stabilization of Expansive Soil Using BaDocument6 pagesStabilization of Expansive Soil Using BaDr-Moamen Abd El Raouf100% (1)

- Soil + GisDocument7 pagesSoil + GisshivachandraNo ratings yet

- Gravel SpecsDocument3 pagesGravel SpecsShe TimbancayaNo ratings yet

- 03 Soil Classification Numerical PDFDocument5 pages03 Soil Classification Numerical PDFabishrantNo ratings yet

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Document13 pagesInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)pavan kumar tNo ratings yet

- Review QuestionsDocument31 pagesReview QuestionsGerby PaaNo ratings yet

- Paper - Solo ColapsivelDocument8 pagesPaper - Solo ColapsivelTen FreireNo ratings yet

- Topic 1 Site Investigation PDFDocument71 pagesTopic 1 Site Investigation PDFgajeel199150% (2)

- PT 2023 Past QuestionDocument7 pagesPT 2023 Past QuestionTSOG MHNo ratings yet

- PROPERTIES of SOIL. Sample ProblemsDocument43 pagesPROPERTIES of SOIL. Sample ProblemsMJ ArboledaNo ratings yet

- TerasoleDocument3 pagesTerasoleNaresh AlaparthiNo ratings yet

- Geotechnical Engineering 1 (Soil Mechanics) Geotechnical Properties of SoilDocument18 pagesGeotechnical Engineering 1 (Soil Mechanics) Geotechnical Properties of SoilErika SemillanoNo ratings yet

- Method Statement For Embankment ConstructionDocument23 pagesMethod Statement For Embankment ConstructionJayaratneNo ratings yet

- MaterialsDocument712 pagesMaterialsRaghavNo ratings yet

- AxialDocument14 pagesAxialarieNo ratings yet

- Book 2018 Encyclopedia of Engineering GeologyDocument292 pagesBook 2018 Encyclopedia of Engineering Geologyscribd_geotecNo ratings yet