Professional Documents

Culture Documents

Work Instructions: GAM Installation Gas

Uploaded by

Tareq MollaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instructions: GAM Installation Gas

Uploaded by

Tareq MollaCopyright:

Available Formats

Doc.

Type: Work Instructions

Doc. Title: GAM Installation Gas Area Operations

Scope: This work instruction applies to all power projects within Aggreko International that utilise Aggreko fleet of Gas Generators, QSK60G Doc. No. P06300012

This document describes the steps involved in installing the Generator Ancillary Module (GAM Unit). This work instruction is lead by the power work stream lead and is based around

Purpose: 1 Aggreko Technician and 2-man team of local labour, for clarity each step is broken down to Gen Tech (GT) and local labour. GT & LL must be trained in every step of this work Rev. No. A

instruction.

Related Docs. GAM Unit installation procedure Issue Date: 24/02/2013

Step No. /

Main Steps Detailed Steps Key Points Photos / Comments

(Responsibility)

Tools required for this Install: •

• ½ Inch ratchet set

• Side cutters

• 12 Inch Adjustable

• Cable ties

• Knife

• 6mm Allen key

• 2x 13mm Spanners

• Ladder

• 2x 24mm Spanners

• Battery impact driver

• 24mm ½” drive socket

• 17mm ½” drive socket

• 13mm ½” drive socket

• •

Fitting LTA elbows to Generator • Remove LTA elbows from inside rear of Generator

1

• Remove blank plates from LTA connection point on Generator

(GT)

• Fit LTA elbows to Generator (male at bottom, Female at top) see photos.

• Using battery powered with 17mm socket remove 20xM10 bolts from square cover to expose turbo

Removal of Generator roof covers outlets

2 • Remove left and right hand side circular covers to expose space fans using 13mm socket and ratchet

(LL)

• Re-fit bolts to secure protective metal grill

• Remove 3 fittings situated between radiator fans

Equipment Position: Key Points: Page 1 of 5

CP = Control Panel Safety

LH = Left Side Environmental

RH= Right Side

Step No. /

Main Steps Detailed Steps Key Points Photos / Comments

(Responsibility)

Inspection point: Ensure all covers have been removed and stored in the storage area of

the GAM unit when next step is complete

3 Removal of LP Gas train and other • Remove customs locks from rear door of the GAM unit

(LL) components. • Undo 8xM10 bolts that hold Gas train in position

• Remove box with rain cap etc

• Remove LTA hoses

• Remove long foam for noise cancellation

4 Fitting LTA hoses to GAM • Remove 10xM8 bolts at hose connections for access

(GT) • Remove transit plugs from hoses connections

• Fit shorter of the 2 LTA hoses to the top connection

• Fit Long LTA hose to the bottom connection

• Fit support bracket to GAM unit

• Secure CAM lock rings with cable ties

5 Fitting noise cancellation foam and • Use ladder to access Generator roof

(LL) twist locks • Cut foam to size and fit along appropriate edges

• Fit 4 twist locks at each corner

Equipment Position: Key Points: Page 2 of 5

CP = Control Panel Safety

LH = Left Side Environmental

RH= Right Side

Step No. /

Main Steps Detailed Steps Key Points Photos / Comments

(Responsibility)

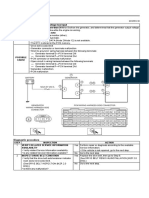

Hold Point: This step is a hold point. Inspection required ensuring that all noise

cancellation foam has been installed and that twist locks are secured in

position of each corner before lifting operation.

6 Lifting GAM into position

(GT&LL) • Use 25 ton spread bar and slings with bottom lift container attachments Refer to: BOP21,22

• Lift GAM over Generator using Tag lines to steady

• Once in position lower GAM unit on top of Generator

• Once in place secure by locking twist locks

• Insert LTA hoses into LTA elbows and lock using CAM locks

• Secure CAM lock rings with cable ties

7 Hose connections inside GAM • Remove 6xM8 bolts from floor plates to expose hose connections and electrical socket

(GT&LL) • Loosen and re-position transit bracket for gate valve

• Loosen hose clamps and fit hose to Inlet on generator roof

• From the 5 hoses coiled inside GAM cross beam fit the red labeled hose to red inlet and blue labeled

hose to blue inlet

• Fit the 3 hoses remaining with no labeling to 3 inlets on generator roof

• Remove floor plate on the RHS of the GAM floor and connect gate valve hose as stated previously

• Connect electrical plug to inlet

• Open Gate valves to allow top fill from expansion tanks

• Re-fit floor plates

• Using the provided green jerry cans, top up LT and HT expansion tanks from the top

Inspection point: Check all hose connections are connected to their corresponding

points and secured

Equipment Position: Key Points: Page 3 of 5

CP = Control Panel Safety

LH = Left Side Environmental

RH= Right Side

Step No. /

Main Steps Detailed Steps Key Points Photos / Comments

(Responsibility)

8 Exhaust silencer and bellows • Remove the bellows and gaskets from the rear of the Generator

(GT&LL) • Turn turbo outlets round so they are facing upwards

• Lift bellows up between turbo outlets and exhaust silencer and fit bellows to underside of silencer with

gaskets and fit loosely

• Using a 6mm Allen key, remove exhaust clamps from turbo outlets

Hold point: Ensure the bellows have been fitted loosely before silencer is lifted from

transit brackets and dropped in place, this will make for easy installation.

9a Dropping of exhaust silencer • On top of GAM remove metal grating surrounding silencer for crane access

(GT&LL) • Once back inside GAM unit and with crane still in position the silencer can be fitted

• Remove the floor plates

• Remove holding bolts fitted to silencer and transit brackets

• Lift exhaust up about 1 inch

• Remove transit brackets

• Lower exhaust and check whilst lowering inside the Generator to ensure the bellows mate with turbo

outlets

• Secure the silencer by fitting the mounting bolts

• Fit remaining bolts to bellows and tighten

• Fit exhaust clamp and tighten using 6mm Allen key

• Tighten band clamps to secure turbo outlets using deep 11mm socket and ratchet

9b Fitting exhaust Lagging • Remove lagging from rear of Generator

(LL) • Use 1 piece each for LH and RH bellows

• Pierce clips through lagging

• Wrap lagging around bellow and secure using wire provided

• Repeat step for remaining bellow

10 Fitting the Rain Cap • Remove rain cap from storage box that was removed from GAM unit

(GT) • Remove long M8 bolt and locking nuts and remove bolts from each side of the rain cap

• Place on top of silencer and line up bolt holes on either side of the cap with the holes on silencer

• Fit bolts, washers and nuts through sides and tighten so that wire rope is secured

• Fit long M8 bolt through front of rain cap to close the bracket

• Re-fit metal grating surrounding rain cap and silencer

Inspection point: Ensure all bolts have been fitted and that rain cap opens freely

Equipment Position: Key Points: Page 4 of 5

CP = Control Panel Safety

LH = Left Side Environmental

RH= Right Side

Step No. /

Main Steps Detailed Steps Key Points Photos / Comments

(Responsibility)

LP regulator Installation • Mount LP regulator on plastic blocks next to fuel inlet on Generator

11 • Remove 8 x M16 bolts from blank plate on site of Generator

(GT)

• Connect 1meter length 3” diameter flexible stainless steel Gas pipe to Generator with Gasket

• Connect open end to fuel output supply on LP Rig with Gasket

• Connect 1 meter length 4” diameter from inlet of LP Rig with Gasket and use stand to support and

cover open end

• Ensure that earth bonding is fitted at each flanged joint

Add Row Delete Row

REVISION HISTORY

Rev. No. Rev. Date Details of Changes Prepared By Reviewed By Approved By

1 11/12/2012 New Document David McLeish

Equipment Position: Key Points: Page 5 of 5

CP = Control Panel Safety

LH = Left Side Environmental

RH= Right Side

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Yamaha YH50 19992006 ENDocument203 pagesYamaha YH50 19992006 ENPassw0rdhotmail75% (4)

- Manual Servicio 310EDocument768 pagesManual Servicio 310ERigoberto Bernal Ramirez80% (5)

- Airbus A319-A320-A321 - Quick Reference HandbookDocument113 pagesAirbus A319-A320-A321 - Quick Reference Handbookrafaelldalpra100% (9)

- 100 Years of Hydrodynamic PDFDocument28 pages100 Years of Hydrodynamic PDFnikodjoleNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Core CuttingDocument21 pagesCore Cuttingsitam_nitj4202No ratings yet

- ACB MaintenanceDocument14 pagesACB MaintenanceTareq Molla100% (1)

- John Deere 1 Family Cab With Heater 1JD1FCA3 Rev. EDocument28 pagesJohn Deere 1 Family Cab With Heater 1JD1FCA3 Rev. EMason100% (1)

- SainSmart Genmitsu CNC Router 3018-User ManualDocument26 pagesSainSmart Genmitsu CNC Router 3018-User ManualFernando MarcanoNo ratings yet

- Indigo Airlines - Final ReportDocument22 pagesIndigo Airlines - Final Reportanand_lihinarNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- S.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Document532 pagesS.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Gianpiero Boccato0% (1)

- Woodburning HandbookDocument16 pagesWoodburning HandbookTareq MollaNo ratings yet

- DQ381 Gearbox Cooler: Golf 7.5 / Audi S3 8VDocument5 pagesDQ381 Gearbox Cooler: Golf 7.5 / Audi S3 8VRogelio MendozaNo ratings yet

- 520L0586 MMF044Document48 pages520L0586 MMF044vendas servicosNo ratings yet

- PLX102 Maintenance ManualDocument8 pagesPLX102 Maintenance ManualJairo Manzaneda100% (4)

- Cabin Mate: Installation, Operation and MaintenanceDocument28 pagesCabin Mate: Installation, Operation and MaintenanceBeltazor HellboyNo ratings yet

- P04300001A - KTA50G3 A Service Planned - EnglishDocument11 pagesP04300001A - KTA50G3 A Service Planned - EnglishCristian VizcainoNo ratings yet

- BmvwinstallDocument16 pagesBmvwinstallAlejandroO.VargasNo ratings yet

- GTR058 Instruction ManualDocument31 pagesGTR058 Instruction ManualElizardo Quispe AlvaradoNo ratings yet

- Presentation 1Document27 pagesPresentation 1sameer kumarNo ratings yet

- S2000 Hard Top Installation & Adjustment InstructionsDocument8 pagesS2000 Hard Top Installation & Adjustment InstructionsNick ArNo ratings yet

- Top Drive HSHCPackingListDocument6 pagesTop Drive HSHCPackingListjokoNo ratings yet

- Toyota 4runner 2020 - Dash CameraDocument24 pagesToyota 4runner 2020 - Dash CamerabelkaidaNo ratings yet

- MZ590803EX - Luz Interior PortonDocument11 pagesMZ590803EX - Luz Interior PortonPepe PerezNo ratings yet

- Installation Instructions High Output 2 Speed Rad Fan AssemblyDocument3 pagesInstallation Instructions High Output 2 Speed Rad Fan Assemblythe enverNo ratings yet

- Maintenance Manual GeaDocument60 pagesMaintenance Manual GeageniusMAHINo ratings yet

- Genmitsu - 4030XLPROVer MANUALv1.01Document39 pagesGenmitsu - 4030XLPROVer MANUALv1.01abunom48No ratings yet

- Heated Grips Install PDFDocument20 pagesHeated Grips Install PDFOscar RibasNo ratings yet

- SSS Square Cat XT Oscillating Floor Machine Series - ManualDocument16 pagesSSS Square Cat XT Oscillating Floor Machine Series - ManualNick KaneNo ratings yet

- (FORD) Diagrama de Cableado Ford FocusDocument29 pages(FORD) Diagrama de Cableado Ford FocusArturoNoCesaNo ratings yet

- Pages From Vol.1 English September 2008 2Document2 pagesPages From Vol.1 English September 2008 2boudardara mohamed amineNo ratings yet

- Como Remover Un Iyector MackDocument6 pagesComo Remover Un Iyector MackHamilton MirandaNo ratings yet

- CordStripper EngDocument18 pagesCordStripper Engcanito73No ratings yet

- Instruction Manual GRBL Controller V1 2Document11 pagesInstruction Manual GRBL Controller V1 2dotu12No ratings yet

- L-2271S MAS CabinMate Stainless Steel MAN-5!23!07Document28 pagesL-2271S MAS CabinMate Stainless Steel MAN-5!23!07PIKO MOBNo ratings yet

- Repair Instruction Repair Instruction Repair Instruction Repair InstructionDocument6 pagesRepair Instruction Repair Instruction Repair Instruction Repair Instructiontsanjuna6623No ratings yet

- Service Manual: Indoor UnitDocument28 pagesService Manual: Indoor UnitEmanuel MarquesNo ratings yet

- Service BulletinDocument8 pagesService Bulletinsuperkid667100% (1)

- Tjmnudgebar Fitting 2Document4 pagesTjmnudgebar Fitting 2Dega VaraždinNo ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- Diagrama de Parachoques DelanteroDocument9 pagesDiagrama de Parachoques DelanteroAbel Mario ArévaloNo ratings yet

- Prusa I3 Rework Rev1.5 - Assembly InstructionsDocument80 pagesPrusa I3 Rework Rev1.5 - Assembly InstructionsGabor LisakNo ratings yet

- Mitsubishi MCFH-GA35-60 Service Manual (OB380)Document24 pagesMitsubishi MCFH-GA35-60 Service Manual (OB380)mmatic123No ratings yet

- BomagDocument52 pagesBomagjonahNo ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- Struktura: Before You Begin Before You BeginDocument11 pagesStruktura: Before You Begin Before You BeginRizki Pradana PutraNo ratings yet

- Rear Axle & Rear Suspension SectionDocument14 pagesRear Axle & Rear Suspension SectionionboloNo ratings yet

- CNC LatheDocument26 pagesCNC LatheAditya Gomte100% (1)

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 pagesSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenNo ratings yet

- Reytec Sr-EnglishDocument40 pagesReytec Sr-EnglishAzre mohd norNo ratings yet

- BISELADORA DE TUBO - MiniMag XM-MATHEY DEARMAN - MANUALDocument16 pagesBISELADORA DE TUBO - MiniMag XM-MATHEY DEARMAN - MANUALMaría Juliana PiedrahitaNo ratings yet

- 5EKD Instalation IntructionsDocument16 pages5EKD Instalation IntructionsMAYINNNo ratings yet

- GEI-M1026 Installation Vertical Non-Reverse-Bolted Coupling PDFDocument9 pagesGEI-M1026 Installation Vertical Non-Reverse-Bolted Coupling PDFEric AndrésNo ratings yet

- Kinetix 5700 Passive Shunt Modules: Installation InstructionsDocument8 pagesKinetix 5700 Passive Shunt Modules: Installation InstructionssenthilNo ratings yet

- Installation InstructionsDocument20 pagesInstallation InstructionsgomeztdiNo ratings yet

- 13-1 Engine Assembly PDFDocument3 pages13-1 Engine Assembly PDFmefisto06cNo ratings yet

- G4000Document24 pagesG4000Syed Rohail AhmedNo ratings yet

- DTC P2503 (MZR 2.0 Disi)Document2 pagesDTC P2503 (MZR 2.0 Disi)Abdul RohmatNo ratings yet

- APHS - 31120 Technıcal DataDocument6 pagesAPHS - 31120 Technıcal DataPraveen Kumar PedapudiNo ratings yet

- Replacing MechatronicsDocument7 pagesReplacing MechatronicsNenad VlašičekNo ratings yet

- Instrument Panel and Console TrimDocument33 pagesInstrument Panel and Console TrimGeo AdmNo ratings yet

- Manual de Servicio Tijera 1932 MedellinDocument93 pagesManual de Servicio Tijera 1932 MedellinARBEY GIRALDONo ratings yet

- CL 060 Wrapsolut Product Sheet GBDocument4 pagesCL 060 Wrapsolut Product Sheet GBapi-473665881No ratings yet

- 315 SJ Rear Axle AssembleDocument25 pages315 SJ Rear Axle Assemblesphiri600No ratings yet

- Work Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveDocument13 pagesWork Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveTareq MollaNo ratings yet

- Module 13 Special ToolsDocument15 pagesModule 13 Special ToolsTareq MollaNo ratings yet

- P06300050 Gas Chromatograph Instalation PDFDocument5 pagesP06300050 Gas Chromatograph Instalation PDFTareq MollaNo ratings yet

- Module 7 Fuel SystemDocument28 pagesModule 7 Fuel SystemAguilar AlexNo ratings yet

- 4.Document192 pages4.Tareq MollaNo ratings yet

- PDFDocument125 pagesPDFharun rashidNo ratings yet

- Mobile Communication Networks: Exercices 4Document2 pagesMobile Communication Networks: Exercices 4Shirley RodriguesNo ratings yet

- Progress Report Week#9 UlubeluDocument6 pagesProgress Report Week#9 UlubelutiantaufikNo ratings yet

- IsdettaDocument2 pagesIsdettaHa Phuoc HoaNo ratings yet

- Med Chem Exam 2Document24 pagesMed Chem Exam 2cNo ratings yet

- Disa Match: A Match You Can Count OnDocument8 pagesDisa Match: A Match You Can Count OngNo ratings yet

- The Ecological Effects of Eucalyptus PDFDocument97 pagesThe Ecological Effects of Eucalyptus PDFgejuinaNo ratings yet

- Afectiuni Si SimptomeDocument22 pagesAfectiuni Si SimptomeIOANA_ROX_DRNo ratings yet

- Mechanics of MaterialsDocument11 pagesMechanics of MaterialsPeter MwangiNo ratings yet

- Lab Centre of Pressure Ecw341Document4 pagesLab Centre of Pressure Ecw341danialNo ratings yet

- Infrastructure Definition:: Economic Infrastructure Includes BroadlyDocument3 pagesInfrastructure Definition:: Economic Infrastructure Includes Broadlyabraha gebruNo ratings yet

- TC AdvisoryDocument1 pageTC AdvisoryJerome DelfinoNo ratings yet

- FENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BDocument388 pagesFENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BQUOC LENo ratings yet

- Wic ReflectionDocument3 pagesWic Reflectionapi-307029735No ratings yet

- Daphne Alpha Cleaner Series: Lubricant Product InformationDocument2 pagesDaphne Alpha Cleaner Series: Lubricant Product InformationChart ChNo ratings yet

- Modular Air Handling Unit (FMA)Document3 pagesModular Air Handling Unit (FMA)Salamet TeguhNo ratings yet

- Daoyin Physical Calisthenics in The Internal Arts by Sifu Bob Robert Downey Lavericia CopelandDocument100 pagesDaoyin Physical Calisthenics in The Internal Arts by Sifu Bob Robert Downey Lavericia CopelandDragonfly HeilungNo ratings yet

- +chapter 6 Binomial CoefficientsDocument34 pages+chapter 6 Binomial CoefficientsArash RastiNo ratings yet

- Art1 2Document24 pagesArt1 2Peter Paul Rebucan PerudaNo ratings yet

- Asyb 2020 2Document295 pagesAsyb 2020 2KhangNo ratings yet

- Technical Methods and Requirements For Gas Meter CalibrationDocument8 pagesTechnical Methods and Requirements For Gas Meter CalibrationIrfan RazaNo ratings yet

- Group Collaborative Activity TaskonomyDocument2 pagesGroup Collaborative Activity TaskonomyTweeky SaureNo ratings yet

- BTL Info CNC ProgrammDocument132 pagesBTL Info CNC ProgrammdieulafaitNo ratings yet

- Chapter 2Document82 pagesChapter 2Kavitha Selvaraj50% (2)

- Thesis 1-15Document15 pagesThesis 1-15hewelirNo ratings yet

- Amc 20-21Document33 pagesAmc 20-21Vasco M C SantosNo ratings yet