Professional Documents

Culture Documents

Holding DCM Cleaning With Tool

Holding DCM Cleaning With Tool

Uploaded by

ravindra kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holding DCM Cleaning With Tool

Holding DCM Cleaning With Tool

Uploaded by

ravindra kumarCopyright:

Available Formats

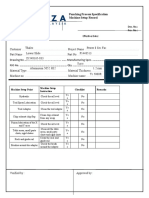

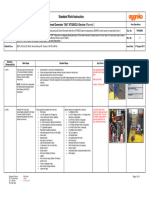

Approved By Checked By Issued By

Part Name :- All

Operation Name : Oil Chip cleaning OPERATION STANDARD Dpt. : - DC Issue Date :- 28/08/08 Control No. :- Q-09-0111-DC-20

MR. N. TAKAO MR.R. KUMAR A BLOWRIA

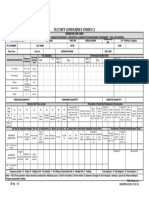

Schematic diagram № Operation Procedure Characteristics Frequency Operation Point Tool Used Reaction Plan Safety point

Cleaning Chip

Put the chip trolly in proper location. Use only chip trolly

1

Every shift

Use marked trolly for each machine

Chip

chip trolly &

Put chip trolly(450*400*600)mm

in trolly 2 Use Proper tool for cleaning of chip Chip romoving Chip Use proper tool length

bar(1500*200)mm Every shiftDrop only oil chips in trollyromoving

bar

During cleaning

3 Put All the chip in chip trolly Every shift insure that tool not

touch in machine

Clean Properly pannel

Empty chip trolly Use proper tool Put chip

Trolly Movement Producer

Move the trolly Roll chip trolly

1 Full chip trolly move from DCM to melting zone In 1 st shift carefully ,not drop chip carefully

in shop flore

Chip

trolly &

fork lift

2 Full chip trolly put near chip contener In 1 st shift Trolly should be

straight

Push the trolly

Unloading Chip trolly

During lifting trolly

1 Full chip trolly lift by fork lifter In 1 st shift insure that the fork

Lift the trolly in proper hight proper go in slot

Chip

trolly,

chip Should be insure that

2 Full chip trolly Empty in Chip contener In 1 st shift contener chip not flow in

Tilt the chip trolly slowly & fork outside

lift

3 Empty chip trolly put in near DCM machine In 1 st shift

Tilt the trolly above chip

contener

№ Date Revision article Approved By Incharge № Date Revision article Approved By Incharge

Date

p

r

o Operator

Confirmation

t

Sign

e safety glass Safety shoes Earplug

c Helmet gloves

You might also like

- Fire Control Pocket With A DRODocument7 pagesFire Control Pocket With A DROterrencebelles100% (1)

- Die Trial BlankDocument2 pagesDie Trial Blankravindra kumar100% (1)

- Operating Instructions For Colliding ToolDocument2 pagesOperating Instructions For Colliding Toolirtaza324197100% (1)

- FM200 - System ComponentsDocument36 pagesFM200 - System Componentsnastyn-1100% (3)

- I Ma 3010.71 1320 622 Huy 067 - A - ComDocument140 pagesI Ma 3010.71 1320 622 Huy 067 - A - ComValério de Oliveira Santos100% (1)

- Uffy Liquid Level Controls With Electric Switches: Installation and Operating ManualDocument12 pagesUffy Liquid Level Controls With Electric Switches: Installation and Operating ManualSaeed VuNo ratings yet

- Reverse Camera Installation Guide: Tools and Supplies NeededDocument9 pagesReverse Camera Installation Guide: Tools and Supplies Neededaxell AxelzonNo ratings yet

- Dpti 002 15Document1 pageDpti 002 15Joshua CooperNo ratings yet

- Reversing Camera Installation GuideDocument5 pagesReversing Camera Installation GuideMuhammad ZamanNo ratings yet

- Dpti 002 13Document1 pageDpti 002 13Joshua CooperNo ratings yet

- Win Flex TurnDocument2 pagesWin Flex Turnsezgin bayramNo ratings yet

- Dpti 002 19Document1 pageDpti 002 19Joshua CooperNo ratings yet

- Creality CR 10S Pro V2 3D Printer User Manual OptimizedDocument16 pagesCreality CR 10S Pro V2 3D Printer User Manual OptimizedalexandreutilisNo ratings yet

- Turbomachine PDFDocument93 pagesTurbomachine PDFVarun PathakNo ratings yet

- Installation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Document8 pagesInstallation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Luis AguirreNo ratings yet

- 18ME54 TurbomachineDocument102 pages18ME54 TurbomachineBandaiah GNNo ratings yet

- Fujifilm FCR Prima T2 Brochure With Logo Ver. Dec. 2017Document2 pagesFujifilm FCR Prima T2 Brochure With Logo Ver. Dec. 2017luilorna27No ratings yet

- Self Maintenance ChecklistDocument19 pagesSelf Maintenance Checklistgrapher05No ratings yet

- CR-10 Max 3D Printer User ManualDocument16 pagesCR-10 Max 3D Printer User ManualDbz BoleroNo ratings yet

- Machine Setup Check List CNC003Document2 pagesMachine Setup Check List CNC003zulfahmyNo ratings yet

- Technical Report: Sharp CorporationDocument2 pagesTechnical Report: Sharp Corporationphu polyfaxNo ratings yet

- Td10523 Mill Leveling 1019aDocument7 pagesTd10523 Mill Leveling 1019akasper35No ratings yet

- Calibration Tool - WZ58enDocument14 pagesCalibration Tool - WZ58enLepa PekarkaNo ratings yet

- Grafadora HidraulicaDocument29 pagesGrafadora HidraulicaArleyTrujillo1224No ratings yet

- Machining Expt 3&4Document4 pagesMachining Expt 3&4HrishikeshNo ratings yet

- Zavitove FrezyDocument136 pagesZavitove FrezyPrajwal VarunNo ratings yet

- Checking Valve Clearance: ON KX250FDocument1 pageChecking Valve Clearance: ON KX250FRafael Perez GiraldoNo ratings yet

- FSN34100LM2 Flyer HorizontalDocument1 pageFSN34100LM2 Flyer Horizontaljoel borlandNo ratings yet

- Machine ShopDocument1 pageMachine ShopPankaj GolchhaNo ratings yet

- BK91 1310 CPF Pip PT 0032Document1 pageBK91 1310 CPF Pip PT 0032Panneer SelvamNo ratings yet

- Operation Sheet (2) - UprightDocument1 pageOperation Sheet (2) - Uprightalinader20022No ratings yet

- 43: Transmission, Automatic, B8444S, TF-80SC AWD Transmission Fluid, ChangingDocument7 pages43: Transmission, Automatic, B8444S, TF-80SC AWD Transmission Fluid, ChangingVinrue AmpereNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- Tohnichi - Katalog 2009 ENDocument56 pagesTohnichi - Katalog 2009 END.T.No ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Agitador de Tamices Dura Tap Vibratory Sieve ManualDocument45 pagesAgitador de Tamices Dura Tap Vibratory Sieve ManualLuis RodriguezNo ratings yet

- Cash MemoDocument2 pagesCash MemoLALRINCHHANA HRAHSELNo ratings yet

- Kubota Models DM1017 DM1022 DM1024 Dimensions and WeightDocument1 pageKubota Models DM1017 DM1022 DM1024 Dimensions and Weightgioconda122No ratings yet

- User Manual DTrite Version 4Document45 pagesUser Manual DTrite Version 4Edgardo BonillaNo ratings yet

- DDL 8000 ADocument2 pagesDDL 8000 AYM Tsai100% (1)

- Lz2290asr Ip100d Sc916 eDocument33 pagesLz2290asr Ip100d Sc916 eMuhammad IrfanNo ratings yet

- Dpti 002 37Document1 pageDpti 002 37Joshua CooperNo ratings yet

- Preventive For Control ArmDocument4 pagesPreventive For Control ArmsselhbbplNo ratings yet

- Hid - PCH Coal Crusher EngliDocument8 pagesHid - PCH Coal Crusher EngliabdulfetahNo ratings yet

- SIUIDocument93 pagesSIUIjesus cesar tiburcio pelaezNo ratings yet

- CNC Milling Labsheet - DJJ40142Document8 pagesCNC Milling Labsheet - DJJ40142tonik 66No ratings yet

- Dpti 004 13Document1 pageDpti 004 13Joshua CooperNo ratings yet

- Piccola Data SheetDocument2 pagesPiccola Data SheetDaniel ZabalaNo ratings yet

- Dpti 002 18Document1 pageDpti 002 18Joshua CooperNo ratings yet

- P04300001A - KTA50G3 A Service Planned - EnglishDocument11 pagesP04300001A - KTA50G3 A Service Planned - EnglishCristian VizcainoNo ratings yet

- Site Acceptance/Change Form: Classification: Mobily INTERNAL USEDocument1 pageSite Acceptance/Change Form: Classification: Mobily INTERNAL USEqaisersiddiNo ratings yet

- Standard WorkDocument1 pageStandard WorkeduardoNo ratings yet

- Toyota 4runner 2020 - Dash CameraDocument24 pagesToyota 4runner 2020 - Dash CamerabelkaidaNo ratings yet

- Pro CrimperDocument6 pagesPro CrimperDon SlavenNo ratings yet

- FCR Prima t2 BrochureDocument2 pagesFCR Prima t2 BrochureBagoes PrasetyoNo ratings yet

- Singer Sewing Motors SpecificationDocument4 pagesSinger Sewing Motors SpecificationScott LawlessNo ratings yet

- E95 002 PDFDocument14 pagesE95 002 PDFMIGUELNo ratings yet

- Design Analysis and Manufacturing SystemsDocument20 pagesDesign Analysis and Manufacturing SystemsAjay MsdNo ratings yet

- PBG Mangan Kelompok 6 Kelas ADocument1 pagePBG Mangan Kelompok 6 Kelas AChristian BudimanNo ratings yet

- J Drum SectionDocument22 pagesJ Drum SectionRheana DomingoNo ratings yet

- Shaft Process PlannerDocument1 pageShaft Process Plannerapi-538048965No ratings yet

- Dpti 002 14Document1 pageDpti 002 14Joshua CooperNo ratings yet

- Fieldpiece Dual Temperature ProbeDocument2 pagesFieldpiece Dual Temperature Probemarkamcfarlane17No ratings yet

- Repair of DuctDocument1 pageRepair of Ductravindra kumarNo ratings yet

- Red Hot Area at The Shell of Furnace in Between Burner No. 1 & 2Document1 pageRed Hot Area at The Shell of Furnace in Between Burner No. 1 & 2ravindra kumarNo ratings yet

- Preheating of Crucible - InstallationDocument1 pagePreheating of Crucible - Installationravindra kumarNo ratings yet

- Normal Abnormal Condition Check SheetDocument3 pagesNormal Abnormal Condition Check Sheetravindra kumarNo ratings yet

- 20 Basic Quality RulesDocument23 pages20 Basic Quality Rulesravindra kumarNo ratings yet

- TROUBLE SHOOTING (Ravindra)Document4 pagesTROUBLE SHOOTING (Ravindra)ravindra kumarNo ratings yet

- FP400 Installation EN v2-3Document28 pagesFP400 Installation EN v2-3Jose Manuel CarvalhoNo ratings yet

- Sbae Ndb-Rwy-35 Iac 20210812Document1 pageSbae Ndb-Rwy-35 Iac 20210812Cassiano CapellassiNo ratings yet

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocument14 pagesEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituNo ratings yet

- Armadura Deflection IFL D PDFDocument4 pagesArmadura Deflection IFL D PDFleonardoNo ratings yet

- TKD Tokyo Ko-On Denpa Volume Control Main PageDocument1 pageTKD Tokyo Ko-On Denpa Volume Control Main PageninniNo ratings yet

- LGH 25RVX e - 60Document5 pagesLGH 25RVX e - 60Qui documNo ratings yet

- Schema Cuptor Microunde SamsungDocument34 pagesSchema Cuptor Microunde SamsungLucian BuradelNo ratings yet

- QM - CW - EG2 - DR - 11 Eglobe G2 Technical Drawings 2020 Q170 Rev01Document35 pagesQM - CW - EG2 - DR - 11 Eglobe G2 Technical Drawings 2020 Q170 Rev01vodoley634No ratings yet

- 03.QSP-QC-003-Transmitter Calibration Procedure With RTD & TCDocument2 pages03.QSP-QC-003-Transmitter Calibration Procedure With RTD & TCMangesh MohiteNo ratings yet

- AMC-AASD15A WiringDocument1 pageAMC-AASD15A Wiringnelu petNo ratings yet

- Awid XP-3620 ReaderDocument2 pagesAwid XP-3620 Readergroovey9040No ratings yet

- Iron Steel RailingsDocument102 pagesIron Steel Railingsaroubi inphoNo ratings yet

- Promerix Maintenance Manual DO1085-3-3.en-55-58Document4 pagesPromerix Maintenance Manual DO1085-3-3.en-55-58hüseyin vururNo ratings yet

- Instruction For Use INDESITDocument6 pagesInstruction For Use INDESITkosi79No ratings yet

- Erin-B6fm8d R0 enDocument4 pagesErin-B6fm8d R0 enMoises ReznikNo ratings yet

- v007 User Manual ALFA 53-Grasso Thermo-Master Compressor Unit With PCB For Sensor InputsDocument16 pagesv007 User Manual ALFA 53-Grasso Thermo-Master Compressor Unit With PCB For Sensor InputsToni kityanNo ratings yet

- EL Wire Standard Version1Document11 pagesEL Wire Standard Version1Nathan BlythNo ratings yet

- XB700 Operation ManualDocument13 pagesXB700 Operation ManualElvis Javier Gómez MonterreyNo ratings yet

- Shutdown Maintenance Activites at Mechanical Clinker (Line-1)Document4 pagesShutdown Maintenance Activites at Mechanical Clinker (Line-1)salman saleemNo ratings yet

- SWA Multipolares Clase 2Document4 pagesSWA Multipolares Clase 2Juan AdrianzenNo ratings yet

- PEC Meter Wiring SpecsDocument11 pagesPEC Meter Wiring Specsdentron2No ratings yet

- Touchswitch Sensor de DesalinhamentoDocument2 pagesTouchswitch Sensor de DesalinhamentoadilsonrodriguesNo ratings yet

- Diode Laser Kit: Assembly InstructionsDocument16 pagesDiode Laser Kit: Assembly InstructionsJoshua SvnNo ratings yet

- Usulan Standar Satuan Harga Tahun 2022 - 2025Document18 pagesUsulan Standar Satuan Harga Tahun 2022 - 2025MUHSINNo ratings yet

- Rosalina Dulce Complete Plan E2Document1 pageRosalina Dulce Complete Plan E2BenssshNo ratings yet

- 1 - Gate ValveDocument16 pages1 - Gate Valveyasser hegazyNo ratings yet

- LPG Chapter 09-18Document12 pagesLPG Chapter 09-18DINESH SIVANo ratings yet