Professional Documents

Culture Documents

Shaft Process Planner

Uploaded by

api-538048965Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft Process Planner

Uploaded by

api-538048965Copyright:

Available Formats

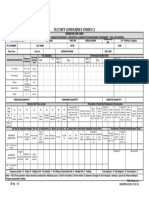

Drawing name or number : Gyrospcope Shaft

CONCORDIA UNIVERSITY MANUFACTURING PROCESSES SHEET

Name of operator: Charles Piper

Date: Sat. Nov 21st 2020 Date: Date: Name of operator2 [assistant/supervisor/etc] :

Time In: Time In: Time In: Name of staff member responsible : Micheal Rembacz

Time Out: Time Out: Time Out: EIR / Process approval : /

Total Expected Duration [min] = 41

Max # of

Name Of Cutting Spindle Machine Expected Actual

Op. # Machine Tool Name Tool Feed Diameter teet D.O.C Risk Comments MRR

Operation Speed, V Speed Feed Duration Duration

Tool/Part h

units [sfm] [inch] [rev/min] [#] [in/min] [inch] [in^3/min] [min] [min]

N/A Cut stock adding at least .125" to

1 Sawing Human Hacksaw N/A N/A N/A N/A N/A N/A N/A 5

desired length

N/A

2 Deburring Human File N/A N/A N/A NA N/A N/A Remove sharp burrs N/A 2

N/A Ensure guards are clean and light

works. Insert workpeice into chuck ,

3 Lathe Setup Lathe N/A N/A N/A N/A NA N/A N/A N/A 4

with end sticking out no more than

2x diameter

Carbide Facing / 2037 Zero z-axis. Remove material to

4 Facing Lathe Turning Tool 200 0.008 0.375 1 16.3 0.015 0.288 3

center

1300

2037

Facing/ Carbide Facing / Repeat for other side. Zero z-axis.

5 Lathe Turning Tool 200 0.008 0.375 1 16.3 0.015 0.288 3

Second Side Remove material to center

1300

N/A Measure width of piece. We will

remove 0.05" per pass so calculate

6 Measure Human Digital Caliper N/A N/A N/A N/A N/A N/A N/A 3

how many passes you will need.

For me: 0.1", so 2 passes of 0.5

Carbide Facing / 2037 Make required number of passes.

7 Facing Lathe Turning Tool 200 0.008 0.375 1 16.3 0.05 0.960 5

For me: 2

1300

2037 Diametral Doc = 0.05. Check for

45 deg. Carbide

8 Chamfering Lathe Turning Tool 200 0.008 0.375 1 16.3 0.025 interference of chuck prior to N/A 3

1300

starting.

Center #3 HSS Center 1375 Go down ~1/2 depth of large

9 Lathe 90 0.006 0.25 1 8.3 0.2 N/A 2

Drilling Drill tapered edge of part of centerdrill.

1300

Carbide Facing / 2037 Diametral Doc = 0.088". Use

10 Tapering Lathe Turning Tool 200 0.008 0.375 1 16.3 0.044 0.845 6

compound rest and set at 10 deg

1300

N/A

11 Deburring Human File N/A N/A N/A NA N/A N/A Remove sharp burrs N/A 5

CON-EDML-019 Process Sheet.08 1 of

You might also like

- Frame Process PlannerDocument5 pagesFrame Process Plannerapi-538048965No ratings yet

- Rotor Process PlannerDocument2 pagesRotor Process Plannerapi-538048965No ratings yet

- Design of Steel ShedDocument164 pagesDesign of Steel ShedKilaru HareeshNo ratings yet

- Ee9al Ee5d Pedro Dalino PDF File 3Document8 pagesEe9al Ee5d Pedro Dalino PDF File 3jenixson tamondongNo ratings yet

- Laporan KerjaDocument1 pageLaporan Kerjagenta abadiNo ratings yet

- Operation Sheet (2) - UprightDocument1 pageOperation Sheet (2) - Uprightalinader20022No ratings yet

- Ewc Atc 3.5.1.16 Tut JR 07 0058Document11 pagesEwc Atc 3.5.1.16 Tut JR 07 0058francisbautistaNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- Internship in Textile Wet Processing/ Garments Etc: (Student's Name Reg. #) (Student's Name Reg. #) Session 2016-20Document17 pagesInternship in Textile Wet Processing/ Garments Etc: (Student's Name Reg. #) (Student's Name Reg. #) Session 2016-20zeshanNo ratings yet

- Project Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateDocument1 pageProject Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateGovendan GopalakrishnanNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- Dpti 002 19Document1 pageDpti 002 19Joshua CooperNo ratings yet

- Dpti 002 14Document1 pageDpti 002 14Joshua CooperNo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- Liner Slot Diffuser - 2 Slots 300lpsDocument1 pageLiner Slot Diffuser - 2 Slots 300lpsSameeh KaddouraNo ratings yet

- RC Piling Method for Elevated Water TankDocument6 pagesRC Piling Method for Elevated Water TankPUI CHEE KHIAN100% (3)

- Dpti 002 18Document1 pageDpti 002 18Joshua CooperNo ratings yet

- Certificado de Tanque de GLPDocument2 pagesCertificado de Tanque de GLPMirian Mamani ChNo ratings yet

- Dpti 002 37Document1 pageDpti 002 37Joshua CooperNo ratings yet

- DDR 10-Feb 2024Document20 pagesDDR 10-Feb 2024lehibyardNo ratings yet

- Sawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDocument33 pagesSawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDIPAK VINAYAK SHIRBHATENo ratings yet

- Báo Cáo Test DaikouDocument1 pageBáo Cáo Test Daikoutuananhngo19096No ratings yet

- Air Cooled Heat Exchanger: General InformationDocument2 pagesAir Cooled Heat Exchanger: General Informationcorey jacobsNo ratings yet

- 300 Cutting Data Manual Smart Focus 300+FC-300+PerCut4000Document36 pages300 Cutting Data Manual Smart Focus 300+FC-300+PerCut4000peswanipgNo ratings yet

- Water Tank Structural Analysis ReportDocument7 pagesWater Tank Structural Analysis Report31 Gunjal AniketNo ratings yet

- HCC F 085 17 091, R 00 - 1 of 3 - Cyclic Vertical Plate Load Test On RockDocument1 pageHCC F 085 17 091, R 00 - 1 of 3 - Cyclic Vertical Plate Load Test On RockAshwin JadhavNo ratings yet

- FormP-005 - Pile Load TestDocument1 pageFormP-005 - Pile Load Testkrishna KumarNo ratings yet

- Operator's Manual: CP7731/CP7732 Series 3/8 & 1/2 Impact WrenchDocument32 pagesOperator's Manual: CP7731/CP7732 Series 3/8 & 1/2 Impact WrenchGabriela de Jesús Ruíz OrantesNo ratings yet

- Reference List ACHE PDFDocument8 pagesReference List ACHE PDFMarakanaMaheshNo ratings yet

- 1.RFI COVER-combinedDocument3 pages1.RFI COVER-combinednatamas systemsNo ratings yet

- Head 4-In Standard Rev2010Document3 pagesHead 4-In Standard Rev2010densrxNo ratings yet

- Daily Report CoatingDocument2 pagesDaily Report CoatingjhdmssNo ratings yet

- (Name and Address of Manufacturer) : Body Flanges On ShellsDocument3 pages(Name and Address of Manufacturer) : Body Flanges On Shellsjoseph alcantara perezNo ratings yet

- Side FacingDocument1 pageSide FacingChiller PartyNo ratings yet

- Thermowells Threaded TRC 0320Document2 pagesThermowells Threaded TRC 0320Fernando ChavezNo ratings yet

- Add Work RappDocument4 pagesAdd Work Rappsumantri NCNo ratings yet

- SJ71-00055D (08Q) Cylinder CAN Process Inspection Check Sheet (SE)Document6 pagesSJ71-00055D (08Q) Cylinder CAN Process Inspection Check Sheet (SE)segar PalanisamyNo ratings yet

- Master Plan For FS Activities 2019Document2 pagesMaster Plan For FS Activities 2019Ardiansyah ILmanNo ratings yet

- Certificado Tatsa TK-500 (H2301476-H2301491)Document3 pagesCertificado Tatsa TK-500 (H2301476-H2301491)Carlos Alonso SintiNo ratings yet

- Dpti 004 14Document1 pageDpti 004 14Joshua CooperNo ratings yet

- 130cutting Data Manual Smart Focus 130+FC-300+PerCut2000 2016-01-15Document28 pages130cutting Data Manual Smart Focus 130+FC-300+PerCut2000 2016-01-15peswanipgNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- Cougar Shock Tool Product Technical SheetDocument2 pagesCougar Shock Tool Product Technical SheetJulio Alejandro Rojas BarbaNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- T BEAM Rectangular Beam 3sections FinalDocument24 pagesT BEAM Rectangular Beam 3sections FinalDipanjan MitraNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Asme U1Document1 pageAsme U1arif99pakNo ratings yet

- Casefbwrg JKDocument29 pagesCasefbwrg JKSmileNo ratings yet

- FlipCUT Brochure 06-24-16 PDFDocument16 pagesFlipCUT Brochure 06-24-16 PDFAlexandre SouzaNo ratings yet

- Quality Report N2 Receiver 3.3 J1363 U1A - N2 ReceiverDocument2 pagesQuality Report N2 Receiver 3.3 J1363 U1A - N2 Receiverjuan aguilarNo ratings yet

- WNMG 080408 (Sprocket) TitanDocument1 pageWNMG 080408 (Sprocket) TitanLiliana YuniantoNo ratings yet

- Reverse Camera Installation Guide: Tools and Supplies NeededDocument9 pagesReverse Camera Installation Guide: Tools and Supplies Neededaxell AxelzonNo ratings yet

- BPVC Viii 1 U-1a-2021Document5 pagesBPVC Viii 1 U-1a-2021SivaramkumarNo ratings yet

- DDR FB8 14-Feb 2024Document22 pagesDDR FB8 14-Feb 2024lehibyardNo ratings yet

- (Name and Address of Manufacturer) : Body Flanges On ShellsDocument3 pages(Name and Address of Manufacturer) : Body Flanges On ShellsNancy FloresNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- Dfa AnalyseDocument8 pagesDfa Analyseapi-350519371No ratings yet

- Mv-22 Details 02Document1 pageMv-22 Details 02riyazNo ratings yet

- 282 Group PaperDocument15 pages282 Group Paperapi-538048965No ratings yet

- Mech313 Final Design Project Na Charles Piper 40080356Document25 pagesMech313 Final Design Project Na Charles Piper 40080356api-538048965No ratings yet

- 380 Final PaperDocument46 pages380 Final Paperapi-538048965No ratings yet

- Assembly ProcedureDocument3 pagesAssembly Procedureapi-538048965No ratings yet

- Shoe Rack-2Document42 pagesShoe Rack-2api-538048965No ratings yet

- SEMI Detailed Lesson Plan in Tle DressmakingDocument15 pagesSEMI Detailed Lesson Plan in Tle DressmakingRenie Federico92% (115)

- Module 1Document21 pagesModule 1AzizNo ratings yet

- Baby Go To Leggings PatternDocument12 pagesBaby Go To Leggings Patterncamby1No ratings yet

- Unimat MUNIMAT MACHINE TOOL 3RD EDITIONachine Tool 3rd EditionDocument37 pagesUnimat MUNIMAT MACHINE TOOL 3RD EDITIONachine Tool 3rd Editionjojora100% (5)

- Japanese Shoji Cabinet Inspired BookcaseDocument17 pagesJapanese Shoji Cabinet Inspired BookcaseRicardo Salcido67% (15)

- Tolerance Standard Table For Engineering DrawingsDocument12 pagesTolerance Standard Table For Engineering Drawingsவிவேக் குருசாமிNo ratings yet

- M.CAROL (Set B) - Lana Lui MadeDocument18 pagesM.CAROL (Set B) - Lana Lui MadeAnaPalaciosGutierrez100% (1)

- Crochet Firefly Amigurumi PDF Free PatternDocument7 pagesCrochet Firefly Amigurumi PDF Free PatternSandraNo ratings yet

- Pattern Making PDFDocument360 pagesPattern Making PDFloosenut100% (2)

- Cutting ToolsDocument2 pagesCutting ToolsVivialyn YumulNo ratings yet

- Modern Garden Cardigan 2013Document5 pagesModern Garden Cardigan 2013JWilhNo ratings yet

- China Pottery AnalysisDocument10 pagesChina Pottery AnalysisNikhil ToshniwalNo ratings yet

- Kenmore 158.1240 Sewing Machine Instruction ManualDocument47 pagesKenmore 158.1240 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Make A Plaid Cutting Board: InstructablesDocument8 pagesMake A Plaid Cutting Board: InstructablesRod Hyatt100% (1)

- Zodiac Dragon Baby - Crochet Amigurumi Doll Pattern PDFDocument14 pagesZodiac Dragon Baby - Crochet Amigurumi Doll Pattern PDFMaika Pardo100% (1)

- All Summer Long Classes: Closed Thursday July 4thDocument9 pagesAll Summer Long Classes: Closed Thursday July 4thKristina RostNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineHermilih SiregarNo ratings yet

- The Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsDocument211 pagesThe Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsAmmad Ahmad100% (2)

- 2nd Sem Question PDFDocument36 pages2nd Sem Question PDFjankimchandraNo ratings yet

- Forgotten Local Materials and Techniques - CPARDocument3 pagesForgotten Local Materials and Techniques - CPARacorbashleyNo ratings yet

- Turning Parameters for ASTM A1045 SteelDocument3 pagesTurning Parameters for ASTM A1045 SteelElang KevinNo ratings yet

- Crochet Parrot Toy DIY InstructionsDocument18 pagesCrochet Parrot Toy DIY Instructionsmalu diaz100% (4)

- Courses Offerd-1 KTDMCDocument31 pagesCourses Offerd-1 KTDMCusamaumerNo ratings yet

- Circus Lion Free Crochet Pattern by Elisa's CrochetDocument6 pagesCircus Lion Free Crochet Pattern by Elisa's CrochetCristiane Serra100% (1)

- Pec Ifica Tion .PW: Surface Vehicle InformationDocument11 pagesPec Ifica Tion .PW: Surface Vehicle InformationCelso100% (1)

- Sears Kenmore Model 52 / Model 158.523Document36 pagesSears Kenmore Model 52 / Model 158.523Christopher Orrell67% (3)

- Project Report FinalDocument87 pagesProject Report FinalarunNo ratings yet

- Wonderable Catalogue 2013 LRDocument57 pagesWonderable Catalogue 2013 LRPatrick NellestijnNo ratings yet

- Welding Technology GuideDocument25 pagesWelding Technology GuideApras TyoNo ratings yet

- Caswell ScarfDocument1 pageCaswell ScarfArashi KenseiNo ratings yet