Professional Documents

Culture Documents

Ia - Drafting CG

Ia - Drafting CG

Uploaded by

Jhella Ochoa JuacallaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ia - Drafting CG

Ia - Drafting CG

Uploaded by

Jhella Ochoa JuacallaCopyright:

Available Formats

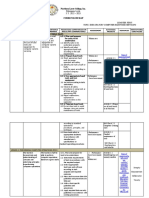

Kto12 BASIC EDUCATION CURRICULUM

TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS- MECHANICAL DRAFTING)

(Exploratory)

Course Description:

This Module is an exploratory and introductory course which leads to Mechanical Drafting, National Certificate Level I (NC I).

It covers five common competencies that a Grade 7/Grade 8 Technology and Livelihood Education (TLE) student ought to possess,

namely: 1) using tools, equipment and paraphernalia; 2) maintaining tools, equipment and paraphernalia 3) performing mensuration

and calculation; 4) interpreting technical drawing and plans mand; 5) practicing Occupational Health and Safety (OHS) procedures.

The preliminaries of this exploratory course include the following: 1) discussion on the relevance of the course; 2) explanation

of key concepts relative to the course and; 3) exploration on career opportunities.

CONTENT CONTENT STANDARD PERFORMANCE STANDARD LEARNING COMPETENCIES

The learner demonstrates The learner independently

One Quarter understanding of concepts and performs simple blueprint

underlying theories and reading based on common

principles in Mechanical Duty competencies as prescribed in

the TESDA Training Regulations.

LESSON 1: PREPARE BASIC TOOLS, MATERIALS AND EQUIPMENT

Basic Drafting tools The learner demonstrates The learner independently LO 1: Prepare tools, materials and

Materials, and understanding of concepts and prepares appropriate drafting instruments in Mechanical Drafting.

Instruments. underlying principles in the tools, materials and instruments 1.1 Classify tools and

preparation of drafting tools, based on job requirements. equipment according to functions.

materials and instruments. 1.2 Prepare tools and

materials based on job

requirement.

CONTENT CONTENT STANDARD PERFORMANCE STANDARD LEARNING COMPETENCIES

Procedure in accomplishing LO 2: Inspect tools and materials received in

forms: Mechanical Drafting.

Job order slips 1.1 Prepare a list of tools and materials to

Tools and materials be requested according to job

requisition slips requirement.

Borrower’s slip 1.2 Request tools and materials according to

Procedures in receiving and prepared list considering the workshop

storing tools and materials procedure.

and equipment 1.3 Inspect the condition of tools, materials

requested.

1.4 Receive and inspect the condition of

tools, materials requested.

1.5 Store tools, materials and equipment.

LESSON 2: USE AND MAINTAIN TOOLS, MATERIALS AND EQUIPMENT

Classification of tools and The learner demonstrates The learner independently LO1: Check condition of tools and

equipment: understanding of concepts and performs proper handling and equipment.

Functional underlying principles in the use maintenance of Drafting tools, 1.1 Classify tools and equipment according

Non-functional and maintenance of Drafting tools materials and instruments. to functions.

Proper handling of: and equipment 1.2 Demonstrate proper handling of drafting

Hand Tools tools, materials and equipment

Materials 1.3 Evaluate the condition of tools and

Equipment equipment.

Segregate functional from non-

functional.

Label each item based on the result of

the evaluation

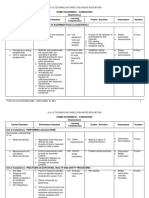

CONTENT CONTENT STANDARD PERFORMANCE STANDARD LEARNING COMPETENCIES

Maintenance of Tools LO2: Perform basic preventive maintenance

and Equipment 2.1 Sharpen dull tools and equipment.

Sharpening 2.2 Perform simple repair of tools and

Oiling equipment.

Repairing 2.3 Use appropriate lubricants for tools and

Cleaning Materials and equipment with moving parts.

procedure 2.4 Clean tool, materials and equipment.

Types of lubricants 2.5 Provide storage for tools, Drafting

Proper Storage of materials and instruments.

Drafting tools, materials

and instrument.

Inventory of tools, LO3. Store Tools and Equipment

materials and 3.1 Perform an inventory of tools, materials

equipment and instrument.

Safekeeping and storage 3.2 Inspect the condition of all items before

storing.

3.3 Store tools, materials and equipment

according to the manufacturer’s

specifications.

LESSON.3: PERFORM MENSURATION AND CALCULATION

Measuring The learner demonstrates The learner independently LO1: Select measuring instrument

tools/Instruments understanding of concepts and performs mensuration and 1.1 Select appropriate measuring tool /

underlying principles in measuring calculation activities related to instruments to be used in accordance

and calculating measurements mechanical drafting. with job requirements

and proportion. 1.2 Select the right substitute for

unavailable measuring instruments

CONTENT CONTENT STANDARD PERFORMANCE STANDARD LEARNING COMPETENCIES

LESSON 4: INTERPRET WORKING PLANS AND PRODUCT DESIGNS

Alphabet of lines The learner demonstrates The learner independently reads LO1: Read and interpret work plans and

understanding of concepts and and interprets simple blueprints product designs.

Architectural symbols underlying principles in and product design specifications. 1.1 Classify alphabet of lines

Dimensions interpreting simple blueprints and according to its purpose.

Notations and product designs. 1.2 Differentiate architectural

Specifications symbols

Types of Pictorial 1.3 Read and interpret the

Presentations following:

Blueprints and Product Illustrated product designs.

designs Details of simple work plans.

Simple shop layout

Notations and specifications of

materials used

ESSON 5: PRACTICE OCCUPATIONAL HEALTH AND SAFETY PROCEDURE

Threshold limit values The learner demonstrates The learner independently applies LO1: Control Hazards and risks.

(TLV) understanding of concepts and precautionary measures and 1.1 Observe safe working

Philippine OHS underlying principles of responds to risks and hazards in the habits while at work.

Standards Occupational Health and Safety in workplace 1.2 Read and interpret signage

Hazardous Occupations relation to health and risk hazards in the workplace.

to young workers in the workplace. . 1.3 Use personal protective

Effects of hazards in the equipment while at work.

workplace 1.4 Apply first aid in case of

Ergonomics accidents.

Housekeeping 1.5 Observe proper

housekeeping:

Cleanliness and orderliness in the

workplace

Proper waste disposal

You might also like

- Daily Lesson Log Tle 7-Household ServicesDocument32 pagesDaily Lesson Log Tle 7-Household ServicesArlyn Agustin94% (31)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- Work Procedure For Embedded Plate InstallationDocument10 pagesWork Procedure For Embedded Plate InstallationResearcher100% (1)

- Curriculum Map in Household ServicesDocument6 pagesCurriculum Map in Household ServicesMelcanie91% (11)

- Western Colleges Inc.: Naic, CaviteDocument32 pagesWestern Colleges Inc.: Naic, CaviteJofit DayocNo ratings yet

- Materials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingFrom EverandMaterials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingRating: 4 out of 5 stars4/5 (1)

- 3rd - Periodical - Test Nail CareDocument3 pages3rd - Periodical - Test Nail CareArlyn Agustin100% (1)

- 3rd - Periodical - Test Nail CareDocument3 pages3rd - Periodical - Test Nail CareArlyn Agustin100% (1)

- Script For InvestirureDocument5 pagesScript For InvestirureArlyn Agustin100% (1)

- Ia - Rac CGDocument3 pagesIa - Rac CGArlyn AgustinNo ratings yet

- Ia - Mechanical Drafting CGDocument5 pagesIa - Mechanical Drafting CGAnonymous UeXLzpsr50% (4)

- CG Mechanical DraftingDocument6 pagesCG Mechanical DraftingLENIN BRIONESNo ratings yet

- Curguide NailcareDocument5 pagesCurguide NailcareOlive AsuncionNo ratings yet

- K To 12 CG - Nail Care - v1.0Document5 pagesK To 12 CG - Nail Care - v1.0ROWELYN DIPOSONo ratings yet

- Curriculum Map TLE Computer Hardware 7/8Document6 pagesCurriculum Map TLE Computer Hardware 7/8billy jane ramosNo ratings yet

- Ict - CHS - No PecsDocument4 pagesIct - CHS - No PecsMarvin OrbigoNo ratings yet

- TLE 9 - 2 Grading PeriodDocument3 pagesTLE 9 - 2 Grading PeriodJohn LesterNo ratings yet

- Lesson 1: Use of Hand Tools (Ut) LO 1. Prepare Hand Tools and Equipment in Illustration Tle - Ictil7 /8UT-0a-1Document6 pagesLesson 1: Use of Hand Tools (Ut) LO 1. Prepare Hand Tools and Equipment in Illustration Tle - Ictil7 /8UT-0a-1msdinx100% (2)

- MELC - AFA - Food Processing - G7-8Document4 pagesMELC - AFA - Food Processing - G7-8Edilbert Bonifacio Gayo100% (1)

- EEP Grade 7 8 Technical DraftingDocument4 pagesEEP Grade 7 8 Technical DraftingMark Christopher A. Ibay100% (1)

- Budget of WorkDocument8 pagesBudget of WorkJocelyn Cortes IntanoNo ratings yet

- Daily Lesson Log WEEK 3-4 Sessions1Document3 pagesDaily Lesson Log WEEK 3-4 Sessions1Irene DausNo ratings yet

- Melcs Tle Grade 7&8Document55 pagesMelcs Tle Grade 7&8JANETH MOJICA100% (2)

- TLEDocument84 pagesTLEClifford FloresNo ratings yet

- TLE 7-8 ICT - IllustrationDocument8 pagesTLE 7-8 ICT - IllustrationLady Antoniette M. BonggotNo ratings yet

- CG - Electrical Installation and MaintenanceDocument10 pagesCG - Electrical Installation and MaintenanceEl G. Se ChengNo ratings yet

- MELC IA Carpentry G7-8Document3 pagesMELC IA Carpentry G7-8Edilbert Bonifacio GayoNo ratings yet

- Grades 7 and 8 Technology and Livelihood Education TLE Most Essential Learning Competencies MELCsDocument57 pagesGrades 7 and 8 Technology and Livelihood Education TLE Most Essential Learning Competencies MELCsSophy MeganNo ratings yet

- MELC HE Caregiving G7-8Document2 pagesMELC HE Caregiving G7-8Edilbert Bonifacio GayoNo ratings yet

- Caregiving 7-8 MelcsDocument2 pagesCaregiving 7-8 MelcsEdilbert Bonifacio Gayo0% (1)

- BUDGET of WORK RAC 2020 2021Document8 pagesBUDGET of WORK RAC 2020 2021denica notaNo ratings yet

- High School SyllabusDocument13 pagesHigh School SyllabusJemuel Awid RabagoNo ratings yet

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- Curriculum Guide: K To 12 Basic Education CurriculumDocument8 pagesCurriculum Guide: K To 12 Basic Education Curriculumiriel_31No ratings yet

- Grade 7 & 8 Curriculum MapDocument13 pagesGrade 7 & 8 Curriculum MapRussell SanicoNo ratings yet

- MELCSDocument2 pagesMELCSHyacinth Diane CorderoNo ratings yet

- Learning Outcomes Assessment Criteria Learning Concepts/Content Learning Activities Guide Questions Technology Science Math Eng/CommDocument1 pageLearning Outcomes Assessment Criteria Learning Concepts/Content Learning Activities Guide Questions Technology Science Math Eng/CommEvaNo ratings yet

- Grade 7-12Document84 pagesGrade 7-12Cab VicNo ratings yet

- CLM Common 1 As of 020708am APPLY QUALITY STANDARDSDocument1 pageCLM Common 1 As of 020708am APPLY QUALITY STANDARDSEvaNo ratings yet

- TLE MELCs Grade 7 PDFDocument55 pagesTLE MELCs Grade 7 PDFVincent Emmanuel Salibio40% (5)

- CM 7Document4 pagesCM 7daryl jay BelecarioNo ratings yet

- Workshop Supplying The Critical Content and ActivitiesDocument6 pagesWorkshop Supplying The Critical Content and ActivitiesdomsNo ratings yet

- Bow With ComponentsDocument3 pagesBow With ComponentsRonald CortezanoNo ratings yet

- Illustration MELC 7-10Document7 pagesIllustration MELC 7-10Florino ChinNo ratings yet

- DLL EIM11 1stSem1stQuarter Week1Document4 pagesDLL EIM11 1stSem1stQuarter Week1Gelo Dela TorreNo ratings yet

- Syllabus For Drawing 1 (Mechanical Drafting)Document6 pagesSyllabus For Drawing 1 (Mechanical Drafting)Sangguniang Barangay Malinao IlayaNo ratings yet

- ICT Grade 7 2ndDocument7 pagesICT Grade 7 2ndRhayan Dela Cruz DaquizNo ratings yet

- CLM Common 5 As of 020708am Use Hand ToolsDocument1 pageCLM Common 5 As of 020708am Use Hand ToolsWilma Arenas MontesNo ratings yet

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Document14 pagesK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzNo ratings yet

- Tle Jhs MelcsDocument53 pagesTle Jhs MelcscozimrelNo ratings yet

- Ia - Automotive Servicing CGDocument4 pagesIa - Automotive Servicing CGjayson acunaNo ratings yet

- DLL Cookery-9 Q1 W1Document3 pagesDLL Cookery-9 Q1 W1jefte balitnangNo ratings yet

- CG HorticultureDocument7 pagesCG HorticultureEl G. Se ChengNo ratings yet

- Quarter Exploratory Course Most Essential Learning Competencies (MELC) Learning Competencies No. of Day Taught Q0 Grade 7/8 PlumbingDocument3 pagesQuarter Exploratory Course Most Essential Learning Competencies (MELC) Learning Competencies No. of Day Taught Q0 Grade 7/8 PlumbingMarilyn Lamigo BristolNo ratings yet

- DLL - 8 COMPUTER 3QUARTER - Week1Document8 pagesDLL - 8 COMPUTER 3QUARTER - Week1REBUSORA BTLED IANo ratings yet

- Curriculum Map in Grade 7 TleDocument22 pagesCurriculum Map in Grade 7 TleLeo Niño Gonzales Dulce100% (2)

- Curriculum Map in Tle 7 Subject: Tle Grade Level: Grade 7 TEACHER: Mr. Israel M. MarquezDocument31 pagesCurriculum Map in Tle 7 Subject: Tle Grade Level: Grade 7 TEACHER: Mr. Israel M. MarquezIsrael Marquez0% (1)

- MELC - HE - Nail Care - G7-8Document1 pageMELC - HE - Nail Care - G7-8Edilbert Bonifacio Gayo100% (1)

- K To 12 CG - Agri-Crops - v1.0Document6 pagesK To 12 CG - Agri-Crops - v1.0may tagalogon villacoraNo ratings yet

- CG AutomotiveDocument11 pagesCG AutomotiveJame Paul GalgaoNo ratings yet

- 3rd Quarter Examination Grade 7 Household Services TOSDocument3 pages3rd Quarter Examination Grade 7 Household Services TOSAngellie Arsaga AlaparNo ratings yet

- CURRICULUM MAP in CONSUMER ELECTRONICS SERVICINGDocument5 pagesCURRICULUM MAP in CONSUMER ELECTRONICS SERVICINGMelcanie0% (1)

- 4th-Quarter Week 1.Document9 pages4th-Quarter Week 1.Christan CayananNo ratings yet

- Beauty Care Services-Nail Care (UNPACKED)Document2 pagesBeauty Care Services-Nail Care (UNPACKED)Leahsyl AyubanNo ratings yet

- MELC - HE - Front Office Services - G7-8Document2 pagesMELC - HE - Front Office Services - G7-8Edilbert Bonifacio Gayo100% (2)

- Ia - Smaw CGDocument4 pagesIa - Smaw CGArlyn AgustinNo ratings yet

- Materials - Animal Puzzles, Colors, Number Clip, Etc.Document17 pagesMaterials - Animal Puzzles, Colors, Number Clip, Etc.Arlyn AgustinNo ratings yet

- Rubric PresentationDocument6 pagesRubric PresentationArlyn AgustinNo ratings yet

- Table of Contents Household ServicesDocument2 pagesTable of Contents Household ServicesArlyn AgustinNo ratings yet

- Common DiseasesDocument4 pagesCommon DiseasesArlyn AgustinNo ratings yet

- DLL TLE Grade 8Document6 pagesDLL TLE Grade 8Arlyn Agustin50% (2)

- Handouts EIM SS1. Week 10Document1 pageHandouts EIM SS1. Week 10myco sauraNo ratings yet

- Repairs and Maintenance AppendixDocument27 pagesRepairs and Maintenance AppendixDhurai MuthuNo ratings yet

- 6263-104175.M.Piling Co. LTD - RAMS Monier RD SmallDocument88 pages6263-104175.M.Piling Co. LTD - RAMS Monier RD SmallShumei ZhouNo ratings yet

- Competency - Based Curriculum A. Course Design Bread and Pastry Production NC IiDocument61 pagesCompetency - Based Curriculum A. Course Design Bread and Pastry Production NC IiNeil Andrew Talaro100% (1)

- MSDS EcoPlata VN SDS (English)Document9 pagesMSDS EcoPlata VN SDS (English)viettin02 baobiNo ratings yet

- Information and Communication Technology DeparttmentDocument9 pagesInformation and Communication Technology DeparttmentPradeep ManralNo ratings yet

- Factory Act 1948Document13 pagesFactory Act 1948reetesh88% (8)

- 10.method Statement Piling WorkDocument6 pages10.method Statement Piling Workشاز إياسNo ratings yet

- Sample Risk MGT Policy and ProcedureDocument18 pagesSample Risk MGT Policy and ProcedurebillpaparounisNo ratings yet

- Tm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Document17 pagesTm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Norrodin MangatongNo ratings yet

- 5c SAFETY SIGNSDocument21 pages5c SAFETY SIGNSPark Lin MariNo ratings yet

- GM or Manager Operations - CISSDocument5 pagesGM or Manager Operations - CISSPradeep PanigrahiNo ratings yet

- Leuze KBA 970 Seg Das CélulasDocument45 pagesLeuze KBA 970 Seg Das CélulasJosé BastosNo ratings yet

- SCPX Project Line of Fire Presentation ENGDocument22 pagesSCPX Project Line of Fire Presentation ENGGiorgi KenkebashviliNo ratings yet

- Catedra Ramazzini. Desafios y Oportunidades de La Salud Ocupacional Dr. Yukka Takala PDFDocument41 pagesCatedra Ramazzini. Desafios y Oportunidades de La Salud Ocupacional Dr. Yukka Takala PDFArledis Acevedo GonzálezNo ratings yet

- Earthworks Method StatementDocument23 pagesEarthworks Method Statementukpong aniefiokNo ratings yet

- WHO Informe 2010Document136 pagesWHO Informe 2010julissalopezphdNo ratings yet

- Dahlar Release Bag 500 - MSDSDocument7 pagesDahlar Release Bag 500 - MSDSApol Aguisanda JrNo ratings yet

- ASHCORPDocument16 pagesASHCORPEnrique AlonsoNo ratings yet

- MSDS 269 MultiHanceDocument10 pagesMSDS 269 MultiHanceLukman FirdausNo ratings yet

- Of The: Prevention"Document1 pageOf The: Prevention"Vidya SagarNo ratings yet

- Oxynitrox MsdsDocument4 pagesOxynitrox MsdscapdesuroNo ratings yet

- Chlorine TabletsDocument6 pagesChlorine TabletsNobelion WolfNo ratings yet

- Wa0001.Document3 pagesWa0001.Sarath KumarNo ratings yet

- Details Report ASPL 2018Document45 pagesDetails Report ASPL 2018Biswas LitonNo ratings yet

- Risk Assessment Manual Sliding GateDocument1 pageRisk Assessment Manual Sliding GatePrabhakaran SureshNo ratings yet

- Chemical TrainingDocument68 pagesChemical Traininghi2lathaNo ratings yet

- ATB - PVC Lubricant MSDSDocument11 pagesATB - PVC Lubricant MSDSum erNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument15 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakinglxd.hepNo ratings yet