Professional Documents

Culture Documents

Regeneration of Softener Standard Procedure

Uploaded by

Mdrahaman Mithu100%(1)100% found this document useful (1 vote)

284 views2 pagesfor boiler plant room & other

Original Title

Regeneration of softener Standard Procedure

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document100%(1)100% found this document useful (1 vote)

284 views2 pagesRegeneration of Softener Standard Procedure

Uploaded by

Mdrahaman MithuYou are on page 1of 2

Regeneration of softener Standard Procedure

SOP Number: Hotel Engineering SOP – 03/ Training

Department: Engineering and Maintenance

Date Issued: 14–Feb-2019

Time to Train: 30 Minutes

Stages of regeneration of softener:

1) Back-wash:

Backwash is reverse flow in the softener bed by closing normal flow inlet and outlet valve and

opening the backwash inlet and outlet valve.

The dirty water is drained out during the backwash process.

This process is done to clean the resin bed and also obtain free flow during normal process.

The backwash time depends upon the watercolor or dirt accumulated.

When clear water is draining backwash system is closed, and the salt or brain charging starts.

2) Salt charge or Brine charge:

It is done by introducing common salt solutions of 1.8 specific gravity, by the ejecting system.

Salt solution is kept prepared in salt tank where ejector suction pipe is placed.

During salt charging the entire solution in the tanks is emptied, then close the drain valve of the

softener and also close the salt charging inlet valve.

Keep the softener bed for 10 - 20 minutes by the brine solution in order for recharging the resins

inside the bed, and then start rinsing process.

The quantity of salt used in one regeneration is 200 - 300 Kgs. (depending upon the filter size.)

3) Rinsing of the softener:

Open the normal flow inlet valve, close the normal outlet valve and then open the drain valve.

Start raw water pump to drain the water till the taste of the water is sweet.

Once you feel the water is sweet, test the water with the reagents for measuring the hardness of

the soft water.

When the sample of soft water is 10ppm as CaCo3 it indicates that the water is ready to be put

into the process/consumption.

Procedure for hardness test:

1. Take 50 ml of water to be tested in a beaker.

2. Add one inch of reagent "A", after adding the sample water color turns pink/ red.

3. Add reagent "B", 10 to 15 drops.

4. Now start adding reagent "S" drop by drop and stir the solution simultaneously count the number

of drops.

5. When the sample color turns pink to blue count the no. of reagent "S" and multiply by 2.

6. Hardness is no. of reagent drops x 2 = hardness of water in ppm as CaCo3

7. 10 drop x 2 = 20 ppm(e.g.)

Training Summary questions:

Q1. Explain the procedure for water hardness test?

Q2. What are the main stages of regeneration process?

Q3. What is the quantity of salt used in one regeneration?

Q4. How long the softener bed to be kept on brine solution?

Q5. What are the steps in rinsing the softener?

You might also like

- Quality Assuarance - Sop For Cleaning of Sparkler FilterDocument5 pagesQuality Assuarance - Sop For Cleaning of Sparkler FilterKrishna PalNo ratings yet

- GMP Cleanroom RequirementsDocument4 pagesGMP Cleanroom Requirementswaludde conradNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Operate and Report On A Water Treatment PlantDocument3 pagesOperate and Report On A Water Treatment PlantMziyanda Boet-Bhayi ShumîNo ratings yet

- Analytical Methods for Drinking Water: Advances in Sampling and AnalysisFrom EverandAnalytical Methods for Drinking Water: Advances in Sampling and AnalysisNo ratings yet

- Sustainable Production: Effluent Treatment PlantDocument12 pagesSustainable Production: Effluent Treatment PlantKush SharmaNo ratings yet

- Operation Manual for ETPDocument67 pagesOperation Manual for ETPFaisal Sr. ExecutiveNo ratings yet

- RO Water System SpecificationDocument16 pagesRO Water System SpecificationZachi UkiNo ratings yet

- Effluent & Sewage Treatment Plant 110 KLD: Operation ManualDocument10 pagesEffluent & Sewage Treatment Plant 110 KLD: Operation ManualBinod DavisNo ratings yet

- Membrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021Document14 pagesMembrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021fera meilasariNo ratings yet

- SOP For Operation and Maintenance of Water Purification SystemDocument2 pagesSOP For Operation and Maintenance of Water Purification SystemSan ThisaNo ratings yet

- Treatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryDocument19 pagesTreatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryReshab SahooNo ratings yet

- Proposed Wastewater Treatment for Sugar IndustriesDocument27 pagesProposed Wastewater Treatment for Sugar IndustriesChali HaineNo ratings yet

- Ultra Filtration SystemDocument5 pagesUltra Filtration SystemAbdul SamadNo ratings yet

- Wastewater Characteristics and Appropriate MethodDocument8 pagesWastewater Characteristics and Appropriate MethodFarag Hussein AlhassiNo ratings yet

- ETP UpgradationDocument7 pagesETP UpgradationYogesh DhekaleNo ratings yet

- SOP For Operation of Effulent Treatment PlantDocument3 pagesSOP For Operation of Effulent Treatment PlantRakesh RauniyarNo ratings yet

- User Manual ETPDocument26 pagesUser Manual ETPclaoker100% (1)

- Central Water Standard Operating Procedure Coagulant Jar TestDocument7 pagesCentral Water Standard Operating Procedure Coagulant Jar Testعراقي iraqiNo ratings yet

- MSDS - ACUTHERM 3221 Boiler AntiscalantDocument4 pagesMSDS - ACUTHERM 3221 Boiler AntiscalantBopanna BolliandaNo ratings yet

- Cooling Tower RO SystemDocument7 pagesCooling Tower RO SystemAbdul SamadNo ratings yet

- Sri Balaji Pharma Limited Quality PolicyDocument1 pageSri Balaji Pharma Limited Quality PolicyChilaNo ratings yet

- MSDS - Polyelectrolyte, CleartechDocument7 pagesMSDS - Polyelectrolyte, CleartechBazil BoliaNo ratings yet

- Sewage Treatement PlantDocument42 pagesSewage Treatement PlantSunil A. Bakoliya100% (2)

- Sop For Cleaning of FiltersDocument1 pageSop For Cleaning of FiltersChandra SekharNo ratings yet

- MBR InfoDocument10 pagesMBR InfoJulie MahadiNo ratings yet

- 16012019FV4Q6RWBAnnexure documentofEIAEMP PDFDocument400 pages16012019FV4Q6RWBAnnexure documentofEIAEMP PDFJainam Shah100% (1)

- Determination of Biochemical Oxygen Demand (BOD) : WaterDocument14 pagesDetermination of Biochemical Oxygen Demand (BOD) : WaterHimu DasNo ratings yet

- Removal of Chromium From Tannery Solid WasteDocument7 pagesRemoval of Chromium From Tannery Solid WasteLuis Paz Soldán G100% (1)

- Effluent Traetment Plant SopDocument45 pagesEffluent Traetment Plant SopFahad Maqsood100% (2)

- Equipments Raw MaterialsDocument5 pagesEquipments Raw MaterialsDivya KMNo ratings yet

- Join Taloja CETP SocietyDocument4 pagesJoin Taloja CETP Society555angel100% (1)

- Waste ManagementDocument1 pageWaste ManagementShukra Daasa100% (1)

- Filter PressDocument5 pagesFilter PressMinol JayakodyNo ratings yet

- Handover Document - Yaden KatunayakeDocument39 pagesHandover Document - Yaden KatunayakeUTY ENGNo ratings yet

- Sparkle FilterklDocument5 pagesSparkle FilterklArvind ChaudharyNo ratings yet

- Sop For Dosing CalculationDocument3 pagesSop For Dosing CalculationShyam QCNo ratings yet

- 500 LPH Ro SystemDocument9 pages500 LPH Ro SystemAbdul SamadNo ratings yet

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- LPG Centrifugal Spray Dryer Operation InstructionDocument9 pagesLPG Centrifugal Spray Dryer Operation InstructionM BJNo ratings yet

- SAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTDocument5 pagesSAFETY DATA SHEET FOR HYDRO-X BOILER TREATMENTZoran ObradovicNo ratings yet

- Wastewater TrainDocument3 pagesWastewater TrainLester Mercado100% (1)

- WEDECO LBXSeriesDocument8 pagesWEDECO LBXSeriesÁrpád VassNo ratings yet

- LaMotte 3670-01 DC1200-CL Chlorine Colorimeter Tablet DPD Kit InstructionsDocument4 pagesLaMotte 3670-01 DC1200-CL Chlorine Colorimeter Tablet DPD Kit InstructionsPromagEnviro.comNo ratings yet

- OPERATION & MAINTENANCE MANUAL HIGHLIGHTSDocument49 pagesOPERATION & MAINTENANCE MANUAL HIGHLIGHTSsudhakarrajam2002100% (1)

- Choosing an Effluent Treatment Plant for Textile IndustriesDocument34 pagesChoosing an Effluent Treatment Plant for Textile Industriesravikpandey100% (2)

- Bioreactor DesignDocument4 pagesBioreactor DesignMahendra Varma BoopathyNo ratings yet

- Performance Qualification Protocol For Blister Packing MachineDocument9 pagesPerformance Qualification Protocol For Blister Packing Machinemehrdarou.qaNo ratings yet

- Stream Water Quality AnalysisDocument12 pagesStream Water Quality AnalysisRahul DekaNo ratings yet

- Foulants and Cleaning Procedures of RO MembraneDocument7 pagesFoulants and Cleaning Procedures of RO MembranesushantNo ratings yet

- CIP Design BasisDocument3 pagesCIP Design Basiskemas biruNo ratings yet

- Ultra Pure Water Treatment For Pharmaceutical IndustryDocument4 pagesUltra Pure Water Treatment For Pharmaceutical Industryraju1559405100% (1)

- Reverse Osmosis System FaridDocument30 pagesReverse Osmosis System FaridAchFaridWadjdiNo ratings yet

- Water Sample SopDocument1 pageWater Sample SopmubashirNo ratings yet

- Design of Control System For Cover Washing Machine PDFDocument7 pagesDesign of Control System For Cover Washing Machine PDFYeron GelayeNo ratings yet

- Water Treatment PlantDocument5 pagesWater Treatment PlantbinukirubaNo ratings yet

- V3i4 Ijertv3is040786 PDFDocument5 pagesV3i4 Ijertv3is040786 PDFsarikagNo ratings yet

- Sudharsanam VidyaashramDocument11 pagesSudharsanam VidyaashrammanojNo ratings yet

- PPM Check List: Floor: Wing: Room No: DateDocument3 pagesPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuNo ratings yet

- Standard Operating Procedure For Baking Oven MaintenanceDocument2 pagesStandard Operating Procedure For Baking Oven MaintenanceMdrahaman MithuNo ratings yet

- Stewarding SOP For Cleaning Deep FreezerDocument7 pagesStewarding SOP For Cleaning Deep FreezerMdrahaman Mithu100% (1)

- Daily Works Report File Civil & CarpentryDocument2 pagesDaily Works Report File Civil & CarpentryMdrahaman MithuNo ratings yet

- Diesel Generator (DG) Operation Standard ProcedureDocument2 pagesDiesel Generator (DG) Operation Standard ProcedureMdrahaman MithuNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyMdrahaman MithuNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyMdrahaman Mithu100% (2)

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Cooling Tower Asset Code Frequency MonthlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Cooling Tower Asset Code Frequency MonthlyMdrahaman MithuNo ratings yet

- Royal Tulip Engg Sop Mithu 74Document151 pagesRoyal Tulip Engg Sop Mithu 74Mdrahaman MithuNo ratings yet

- Standard Operating Procedure For Baking Oven MaintenanceDocument2 pagesStandard Operating Procedure For Baking Oven MaintenanceMdrahaman MithuNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyMdrahaman MithuNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyMdrahaman Mithu100% (2)

- Standard Operating Procedure For Double Door Cooling Cabinet ChecklistDocument3 pagesStandard Operating Procedure For Double Door Cooling Cabinet ChecklistMdrahaman MithuNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Cooling Tower Asset Code Frequency MonthlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Cooling Tower Asset Code Frequency MonthlyMdrahaman MithuNo ratings yet

- Water Treatment Plant SOPDocument3 pagesWater Treatment Plant SOPMdrahaman MithuNo ratings yet

- Stewarding SOP For Cleaning Deep FreezerDocument7 pagesStewarding SOP For Cleaning Deep FreezerMdrahaman Mithu100% (1)

- Standard Operating Procedure For Engineering 01Document1 pageStandard Operating Procedure For Engineering 01Mdrahaman MithuNo ratings yet

- Engineering Breakdown Maintenance SOPDocument2 pagesEngineering Breakdown Maintenance SOPMdrahaman Mithu100% (1)

- Water Treatment Plant SOPDocument3 pagesWater Treatment Plant SOPMdrahaman MithuNo ratings yet

- RCE-592ACPA: Vent-Free Gas Convection Heater With Plasmacluster +hepa Air Cleaning Technology FC-420 HEPADocument32 pagesRCE-592ACPA: Vent-Free Gas Convection Heater With Plasmacluster +hepa Air Cleaning Technology FC-420 HEPASalam HaddadNo ratings yet

- MAN 515 - Servo Hydraulic Valves: Types and Working PrinciplesDocument6 pagesMAN 515 - Servo Hydraulic Valves: Types and Working PrinciplesAli EhabNo ratings yet

- Far GT-2 - 2Document19 pagesFar GT-2 - 2Adnan AhmadNo ratings yet

- Technical Offer Rev 0 - OptDocument47 pagesTechnical Offer Rev 0 - OptRafeek AliNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual CODocument46 pages2003 Nissan Altima 2.5 Serivce Manual COAndy Dellinger100% (1)

- MBE4000 EGR Connector Pipe InstallationDocument6 pagesMBE4000 EGR Connector Pipe InstallationАндрейNo ratings yet

- Hr-Hs Manual enDocument54 pagesHr-Hs Manual enGerChuLu C.D.No ratings yet

- Autoclave All American PDFDocument24 pagesAutoclave All American PDFVÍCTOR castro100% (1)

- Shock Repair Repair Guide GuideDocument11 pagesShock Repair Repair Guide Guidebigblock3142No ratings yet

- Aeronox Service ManualDocument103 pagesAeronox Service ManualDerrickNo ratings yet

- Fire Pro Pricelist PDFDocument26 pagesFire Pro Pricelist PDFBernardNo ratings yet

- Warrior 250H14HR-H01Document84 pagesWarrior 250H14HR-H01Alex RamirezNo ratings yet

- Verderair Va 25 Repair PartsDocument36 pagesVerderair Va 25 Repair PartsMalik MussaddiqueNo ratings yet

- Travel Motor: Systems OperationDocument5 pagesTravel Motor: Systems OperationAllan LariosaNo ratings yet

- Spirax SarcoDocument3 pagesSpirax SarcotienNo ratings yet

- Manual For Multipump - TSM Viking PumpsDocument116 pagesManual For Multipump - TSM Viking PumpsMarcosNo ratings yet

- 2 VBN - Guia de SeleccionDocument12 pages2 VBN - Guia de SeleccionPaola Andrea Osorio GNo ratings yet

- List of German Companies in PuneDocument27 pagesList of German Companies in PuneMandar Joshi80% (5)

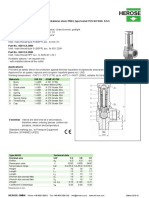

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed RaafatNo ratings yet

- Instrucciones Cambio de FusiblesDocument8 pagesInstrucciones Cambio de FusiblesalecsfcNo ratings yet

- PINCH VALVES: THE NEXT GENERATION V5Document9 pagesPINCH VALVES: THE NEXT GENERATION V5Raymond BalladNo ratings yet

- HydroMinder 511Document2 pagesHydroMinder 511razaq athabNo ratings yet

- Slip Form PaverDocument183 pagesSlip Form PaverAlejandro PeowichNo ratings yet

- Oil Service Parts CatalogDocument44 pagesOil Service Parts CatalogUbanAirlanggaNo ratings yet

- Data Sheet For Shut Down ValveDocument3 pagesData Sheet For Shut Down ValveSilpa Asti Nura100% (2)

- Rescue BoatsDocument11 pagesRescue BoatsElmer SullonNo ratings yet

- Install and maintain your hydropneumatic booster setDocument5 pagesInstall and maintain your hydropneumatic booster setdonchakdeNo ratings yet

- Types of Actuators Used in IoT DevicesDocument7 pagesTypes of Actuators Used in IoT DevicesnananananaNo ratings yet

- 415Q5 Plunger Pump Operation ManualDocument147 pages415Q5 Plunger Pump Operation ManualCESAR MORANo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)