Professional Documents

Culture Documents

Himalayan 2 PDF

Himalayan 2 PDF

Uploaded by

Julian GallegoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Himalayan 2 PDF

Himalayan 2 PDF

Uploaded by

Julian GallegoCopyright:

Available Formats

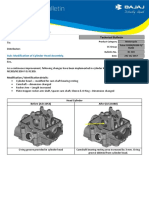

OIL CIRCULATION

LH VIEW RH VIEW

Cam shaft

Main shaft

Counter shaft

Oil Gallery

Oil Strainer screen

Oil Pump Oil Filter

ENGINE-OIL FLOW

20 ROYAL ENFIELD SERVICE MANUAL LS 410

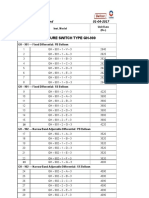

PERIODICAL MAINTENANCE CHART - LS 410

The Periodical maintenance schedule detailed below is based upon average riding conditions and indicates the

Intervals at which regular inspections, adjustments, replacements and lubrications must be carried out to help maintain

your Himalayan motorcycle meticulously

If in case the motorcycle is used frequently in very dusty environment / severe climatic conditions / Poor Roads /

stagnant water etc., the maintenance will need to be done earlier as may be required.

Contact a nearest Royal Enfield Authorised Dealer / Service Center to carry out the periodical maintenance and for

any expert advice.

S. FREE SERVICE PAID SERVICE

DESCRIPTION

No. Whichever is earlier Whichever is earlier

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9 12 15 18 21 24 27 30

R I R I R I R I R I R

1 Engine Oil (Level check / Replace)

Check level at every 1000 Kms or earlier as required

2 Oil Filter Element R R R R R R

3 Engine oil strainer on crankcase LH C C C C C C

4 Inlet / Exhaust Tappet setting I&A I&A I&A I&A I&A I&A I&A I&A I&A I&A I&A

5 Carburetor (C.V. Type) * Clean, Inspect and Tune

6 Rubber hose, Air filter to Carburetor * I I R I R I R I R I R

7 Rubber hose, Inlet manifold * I I R I R I R I R I R

8 Oil cooler inlet & outlet pipes * I I I R I I R I I R I

9 Spark plug C&A C&A C&A R C&A C&A R C&A C&A R C&A

10 Accelerator Cable I I R I R I R I R I R

11 Clutch Plates R R R

12 Cam Chain / Chain Pads / Auto chain Tensioner I I I I I I I I I I I&R

13 Inlet / Exhaust valve seating (compression test) * I I

A : Adjust C : Clean D : De-carbonise I : Inspect L : Lubricate R : Replace

* Refer Service Manual.

# Check every time after vehicle is used for off road riding

For maintenance after 50,000 Kms. , please repeat same frequency specified above, in consultation with a Royal

Enfield Authorised Dealer / Service Center.

ROYAL ENFIELD SERVICE MANUAL LS 410 21

SERVICING / OVERHAULING POSSIBLE

WITHOUT DISMANTLING ENGINE FROM

FRAME

Inlet & Exhaust Tappet adjustments

Auto Chain Tensioner, Cam shaft assembly, Cam

chain, pads

Cylinder Head assembly

Cylinder Barrel, Piston&Rings

Clutch assembly

Oil pump assembly

Gears operating mechanism/ gear shift shaft oil seals

Magneto Stator / Rotor Assembly

Starter Clutch Assembly

Starter Motor replacement

Gear position sensor switch ,

Final Drive sprocket.

SERVICING / OVERHAULING FOR

WHICH ENGINE HAS TO BE REMOVED

FROM FRAME

Crankcases opening

Crank shaft / Balancer Shaft / Main Shaft / Counter

Shaft / Gears / Gear Operator forks / Gear Selector

Drum.

Crank case bearings.

22 ROYAL ENFIELD SERVICE MANUAL LS 410

COMPONENTS DISMANTLING SEQUENCE

COMPONENTS DISMANTLING SEQUENCE TO REMOVE ENGINE FROM FRAME

Skid Plate on Frame bottom.(Himalayan models) Rear Chain (Remove from FD sprocket)

Engine oil (Drain when warm. Remove drain plug /

oil strainer cover on crankcase LH & Oil filter on Cover FD sprocket nut (loosen )

RH)

Oil Cooler along with inlet & outlet pipes. Cover RH

Fuel hose & Pulse Air valve connections Oil pump gears / Oil pump

Battery connections Crank shaft Nut (LEFT HAND THREADED)

TPS/Magneto/Gear position/ Side stand switch: Balancer shaft Bolt

couplers dismantle

Starter motor connections Clutch center nut & Clutch assembly

Gear shift shaft assembly (Remove circlip & washer

Spark plug suppressor cap

on shift shaft from LH crankcase side first)

Engine steady bracket Cam shaft covers / Cylinder head cover

Control Cables (Clutch / Accelerator) Automatic chain tensioner

Carburetor Cam shaft gear & cam shaft Assembly

Exhaust pipe & Silencer Cylinder Head Sub Assembly

Gear shift linkage Chain Tensioner Pads

Starter motor Cylinder Barrel Sub Assembly

Cover LH Cradle frame top mountings (with connector)

mounting to frame

Gear position indicator sensor Cradle frame bottom mounting LH& RH on frame

Magneto rotor assembly including Starter clutch Rear top engine mounting on frame (support engine

from bottom suitably)

Starter idler gears with bush & spindles Four mounting studs of Engine to cradle frame

ROYAL ENFIELD SERVICE MANUAL LS 410 23

SPECIAL TOOLS USAGE LIST

Part No. Description Photo Usage purpose

ST-27527-2 Tappet Adjusting Tool To adjust Tappets Clearance

ST-27528-2 Valve Spring Compressor For removal of Inlet/ Exhaust

valves from cylinder head

To support Piston during

ST-27529-2 Piston Support Plate assembly / Dismantling

cylinder barrel & for removal/

installation of circlips in piston

To remove Magneto rotor

ST-27530-2 Magneto Rotor Puller

from Crankshaft

To compress Clutch springs

ST-27531-2 Clutch Locking Plate during dismantling/assembly

of clutch plates

ST-27532-2 Piston Circlip Installer For installing Piston pin circlips

To lock Crankshaft /Clutch gear

ST-27533-2 Crank Gears locking Tool for removing/ tightening

Crankshaft / clutch nut

ST-27534-2 Magneto rotor & FD To lock Magneto rotor/FD

sprocket locking Tool sprocket for removing

tightening nut.

24 ROYAL ENFIELD SERVICE MANUAL LS 410

IMPORTANT NOTES BEFORE DISMANTLING ENGINE FROM FRAME

1. Engine oil should always be drained when the engine is warm and before engine is dismantled from the frame..

2. Ensure oil cooler pipes are dismantled from engine and Oil cooler is removed from the frame.

3. Ensure piston is at TDC on

compression stroke:

Remove inspection bolt on cover LH to

visually check if the timing mark on the

magneto rotor is aligned with the

reference mark on cover LH.

If the marks are not aligned, remove

cover- crankshaft centerfromcover LH

&rotate magneto rotor nut ONLY IN

CLOCKWIS E direction, till the “+”

reference mark on magneto rotor aligns

with the mark on cover LH.

4. Ensure fuel tap is in closed position. Disconnect fuel hose from carburetor end

5. Remove pillion & rider seat

6. Remove fuel tank mounting fasteners at the rear end, Lift up tank slightly and disconnect fuel level sensor

connection coupler to wiring harness.

7. Slide fuel tank towards the rear and gently pull out fuel tank from frame. Take care not to damage fuel tank while

lifting up or while sliding towards the rear.

8. Remove side panel RH, Remove the battery holding strap, Disconnect battery connections.

9. Remove pulse air valve -inlet & outlet pipe connections from inlet manifold and cylinder head.

10. Remove exhaust pipe & silencer.

11. Disconnect all electrical connections& couplers: spark plug suppressor cap, magneto, pulsar coil, E start motor,

throttle position switch, gear position indicator, side stand switch& earth terminals.

12. Remove carburetor

13. Remove engine steady plate from cylinder head &frame

14. Remove gear shift linkage from gear shaft on frame LH side

15. Remove clutch & accelerator cable connections from engine.

16. Remove rear chain.

17. Remove the bolts & studs mounting cradle frame to main frame at the front, rear & bottom after suitably

supporting the engine at the bottom.

18. Remove the bolts & nuts mounting engine to cradle frame.

ROYAL ENFIELD SERVICE MANUAL LS 410 25

ENGINE DISMANTLING SEQUENCE

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

1. Oil cooler Bolt Union: M17

Socket Spanner:23mm

Remove Inlet & Outlet

Banjo union bolts from NOTE:

LH& RH Crankcase

respectively & allow oil Ensure Oil cooler mounting

to drain. bolts are removed from

frame bracket before

Ensure the 4 washers removing oil cooler.

are removed from the oil

pipes / banjo Union

Remove oil cooler along

with inlet & outlet pipes.

2. Oil drain plug Hex Plug: M14 X 12

Remove hex plug with Socket Spanner: 21 mm

copper washer from oil

strainer housing on CAUTION:

crankcase LH. Dispose drained oil only

through an authorized

recycling agency to prevent

environment pollution.

3. Oil strainer Hex flange bolt: M6 X 20

Remove 2 hex flange Hex Socket: 8 mm

bolts from strainer

cover.

Remove cover with ‘O’

ring.

Pull out the strainer

gently from crankcase

26 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

4. Oil Filter Hex flange bolt: M6 X 70

Hex socket: 8mm

Remove 1 long Hex

flange bolt from the

CAUTION:

bottom of il filter cover.

Remove bolts evently &

slowly since cover is spring

loaded.

Ensure ‘O’ ring is removed

from cover.

Remove 2 Hex flange Hex flange bolts: M6 X 20

bolts from the top of the Hex socket: 8mm

oil filter cover.

Gently pull out of the oil NOTE:

filter element.

The filter element will be

tight in cover RH, due to the

rubber seal on the inside of

the element seating on the

spout.

5. Starter motor Hex flange bolt: M6 X 30

Remove 2 Hex flange Socket spanner: 8mm

bolts from Crankcase RH

side. NOTE:

Ensure Earth terminal is

disconnected from the Hex

flange bolt.

ROYAL ENFIELD SERVICE MANUAL LS 410 27

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

5. Starter motor

Gently pull out starter

motor from the spigot in

crankcase LH& remove.

6. Sprocket cover Hex flange bolt: M6 X 35

Remove 2 hex flange Socket Spanner– 8mm

bolts, holding sprocket

cover to crankcase LH.

Remove cover.

7. Cover crankshaft Hex socket hd. screw:

center M6 X 14

Remove 2 hex socket Allen Key: M5

head screws, from the

cover crankshaft center NOTE:

Remove cover. Remove ‘O’ ring if stuck to

cover LH.

8. Cover LH Hex flange bolt: M6 X 55:

Remove 3 long hex 3 Nos.

Hex flange bolt: M6 X 35:

flange bolts from the 8 Nos.

rear side of cover LH. Socket Spanner– 8mm

NOTE:

Ensure the Magneto & Gear

position sensor wire couplers

are disconnected before

removing cover LH

28 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

8. Cover LH

Remove 8 short hex

flange bolts from the

front & center of cover

LH.

Gently tap on the tabs in

cover LH to release:

- Stator from

magneto rotor.

- From the locating

dowel at the

bottom of

crankcase LH.

Remove gasket.

9. Final drive sprocket

nut:

Straighten locking tab

overhex U nut, using a

suitable chisel.

Locate special tool on FD

Special Tool-

sprocket & remove hex

ST-27534-2, Magneto

“U” nut.

Rotor & FD sprocket

locking Tool

Remove lock washer & Hex “U” Nut: M20

sprocket. Hex Socket: 32mm

ROYAL ENFIELD SERVICE MANUAL LS 410 29

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

10. Gear position Hex flange bolt: M6 X 16

indicator Hex Socket: 8mm

Remove 2 hex flange NOTE:

bolts.

Ensure ‘O’ ring is removed

Gentlyrotate &pull out

along with gear position

from crankcase LH.

indicator.

Remove the pin & spring

from counter shaft.

11. Starter Idle gears

Remove 2 bushes from

idle gear spindles.

Remove idle gear

(middle).

Remove double gear

(top).

30 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

11. Starter Idle gears

Remove the 2 spindles.

12. Magneto Rotor

Special Tool-ST-27534-2,

Locatethe special tool Magneto rotor & FD

on 3 hex socket head sprocket locking Tool

screws inside magneto

rotor to prevent it from

rotating while loosening

Hex nut: M15 X

hex nut.

Hex Socket: 18mm

Remove nut & locate

magneto rotor remov-

ing special tool on the

threaded portion of the

rotor.

Special Tool: ST-27530-2,

Magneto Rotor Puller

Tighten center bolt to NOTE:

remove magneto rotor,

along with starter clutch Ensure special tool is fully

assembly from LH shaft. threaded on the magneto

damage to the rotor.rotor

center, to prevent

NOTE:

Ensure woodruff key is

removed from LH shaft.

ROYAL ENFIELD SERVICE MANUAL LS 410 31

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

13. Starter Clutch

Assembly

Gently rotate outer gear

anticlockwise & remove

from starter clutch.

14. Starter Clutch

Assembly

Remove 6 hex socket

head screws from inside

magneto rotor and

remove outer ring along

with starter clutch.

Remove starter clutch

Hex socket hd screw:

from outer ring.

M6 X 20

Allen Key: M5

15. Cover RH

Hex flange bolt: M6 X 30

Remove 2 Hex flange Hex flange bolt: M6 X 37

bolts holding clutch Hex Socket: 8mm

bracket to cover RH

32 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

15. Cover RH Hex flange bolt: M6 X 20

Remove small Hex flange Hex Socket: 8mm

bolt (fully threaded)

from front of cover RH.

Remove balance 11 Hex

Hex flange bolts: M6 X 37

flange bolts.

Hex Socket: 8mm

Gently tap cover to NOTE:

release the same from

the locating dowels on Ensure the clutch push pad

crankcase RH while does not fall off while

simultaneously removing Cover RH

activating the clutch

lever to remove cover RH

Remove RH cover

gasket.

ROYAL ENFIELD SERVICE MANUAL LS 410 33

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

16. Jet-Crankshaft, Hex socket hd screw:

Cover RH: M6X12

Allen key: M5

Remove hex socket

head screw with retainer

plate.

Remove oil seal& jet from

cover RH.

17. Oil jet in crankcase

RH

Gently pull out the Oil Jet

located in the oil gallery

near the oil pump gear in

Crankcase RH.

18. Balancer shaft bolt

Special Tool- ST-27533-2,

Locate special tool Crank Gears locking Tool

between crankshaft

gear & clutch housing Hex flange bolt: M10 X 20

gear at the bottom to Hex Socket: 14mm

lock crankshaft.

Loosen & remove the

Flanged hex bolt

Remove big & small black

thrust washers.

34 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

19. Crank shaft nut Special Tool: ST-27533-2,

Locate special tool Crank Gears locking Tool

between crankshaft

gear & clutch housing

CAUTION:

gear at the bottom to

lock crankshaft. LH thread nut. Loosen by

rotating

Loosen hex nut by

rotating it “CLOCK-

WISE” & remove. Nut LH thread: M18

Remove small thrust Hex Socket: 24mm

washer.

20. Clutch Nut

Remove clutch bearing

with collar.

Locate special tool

between clutch gear & Special Tool: ST-27533-2,

crank shaft gear at the Crank Gears locking Tool

bottom to lock clutch

housing.

Loosen hex nut.

Hex nut: M20

Hex Socket: 27mm

ROYAL ENFIELD SERVICE MANUAL LS 410 35

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

21. Oil pump sprocket

& chain assembly

Remove circlip on oil

pump shaft.

Remove thrust washer

Remove pump sprocket

along with the small gear

on crankshaft assembly

& chain

22. Oil pump assembly

Hex flange bolts: M6 X 30

Remove 4 hex flange Hex Socket: 8mm

bolts holding oil pump &

remove pump.

Remove pump gasket.

36 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

23. Clutch

Remove splined washer

from clutch main shaft.

Remove clutch assembly

from clutch housing

24. Clutch plates

Hex Screw: M6 X 10

Remove 2 hex screwsat Hex Socket: 10mm

diagonally opposite

ends of the clutch

holding plate. Special tool: ST-27531-2,

Position special tool Clutch locking plate

over clutch holding plate

such that the mounting

holes of the tool is

aligned with the 2 holes

on clutch holding plate.

Assemble 2 long M6

screws over the tool

&tighten till the special

tool rests firmly on the

clutch holding plate.

Loosen & remove the 4

hex screws from the

clutch holding plate.

Loosen the 2 screws

slowly & remove special

tool.

ROYAL ENFIELD SERVICE MANUAL LS 410 37

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

24. Clutch plates

Remove clutch holding

plate and the 6 springs.

Remove clutch hub

along with the clutch

plates.

Remove the clutch

pressure plates, steel

plates, Belleville & steel

washers.

38 ROYAL ENFIELD SERVICE MANUAL LS 410

S. Aggregate to Assemble /

Fastener, Size, Tool Usage, Precautions, Photos

No. Instructions

25. Clutch housing

Remove washer from

main shaft.

Remove clutch housing

with bush from main

shaft.

26. Crank shaft Gear

Remove thrust washer.

Remove splined gear &

bush.

27. Gear Shift Shaft

Outside circlip plier

Remove circlip and

blackened washer from

gear shift shaft on LH CAUTION:

side. Gear shift shaft cannot be

removed if circlip &washer

are not removed from shaft

on LH side.

ROYAL ENFIELD SERVICE MANUAL LS 410 39

You might also like

- RE Himalayan BS IV Vehicle Service Manual Part. 1017122A - Oct. '17Document294 pagesRE Himalayan BS IV Vehicle Service Manual Part. 1017122A - Oct. '17juan camilo gutierrezNo ratings yet

- All New Classic 350 Service Manual Euro VDocument1,213 pagesAll New Classic 350 Service Manual Euro VItalo MarinhoNo ratings yet

- Manual Bajaj Avenger 200 DespieceDocument45 pagesManual Bajaj Avenger 200 DespieceJulio SrKaraokeNo ratings yet

- Form Inspeksi Alat Berat (Compactor)Document1 pageForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYNo ratings yet

- Kubota Flat Rate ScheduleDocument133 pagesKubota Flat Rate ScheduleSteyn Visser0% (1)

- Himalayan 1 PDFDocument20 pagesHimalayan 1 PDFJulian GallegoNo ratings yet

- Himalayan 5 PDFDocument25 pagesHimalayan 5 PDFJulian GallegoNo ratings yet

- Suzuki GSR750 '11 New Model Technical BulletinDocument44 pagesSuzuki GSR750 '11 New Model Technical BulletinNikolas KarrerNo ratings yet

- TVS Apache RTR 180 Service Manual Internal Training Manual Rev1Document28 pagesTVS Apache RTR 180 Service Manual Internal Training Manual Rev1Jhonatan ContrerasNo ratings yet

- Catalogo Partes Rtr-180 2012Document54 pagesCatalogo Partes Rtr-180 2012YeisonNo ratings yet

- Ser Inf - Man / Apache RTR - Revision 3: Downloaded From Manuals Search EngineDocument28 pagesSer Inf - Man / Apache RTR - Revision 3: Downloaded From Manuals Search EngineEduar David Ceballos CabreraNo ratings yet

- Caterpillar D9R 250 Hrs Service No Unit: Date: HM: ShiftDocument12 pagesCaterpillar D9R 250 Hrs Service No Unit: Date: HM: ShiftTLK Channel100% (1)

- Himalayan 5 PDFDocument25 pagesHimalayan 5 PDFJulian GallegoNo ratings yet

- Service Manual-Himalayan Engine - Euro IV - Updated As On 29.01.2018Document131 pagesService Manual-Himalayan Engine - Euro IV - Updated As On 29.01.2018Edgar PinedaNo ratings yet

- Royal Enfield 350 Classic Owners Maintenance ManualDocument71 pagesRoyal Enfield 350 Classic Owners Maintenance Manualtarun100% (1)

- Despiece - APACHE RTR 200 Carburador - InyeccionDocument57 pagesDespiece - APACHE RTR 200 Carburador - InyeccionCarlos BosqueNo ratings yet

- Bullet 350 BS6 ManualDocument72 pagesBullet 350 BS6 ManualAshwin PrakashNo ratings yet

- AK 125 MawiDocument37 pagesAK 125 Mawisergio.carvajal2003No ratings yet

- Owner's Manual Avenger 220ccDocument48 pagesOwner's Manual Avenger 220ccAnkurNo ratings yet

- 1949-1955 350cc + 500cc BulletsDocument102 pages1949-1955 350cc + 500cc Bulletsroyce0% (1)

- DISCOVER DTS I SRR PDFDocument24 pagesDISCOVER DTS I SRR PDFLunatikus EklectikusNo ratings yet

- Eco DeluxeDocument80 pagesEco DeluxeAkshay LalwaniNo ratings yet

- Service Manual Classic 500 & 350 PDFDocument229 pagesService Manual Classic 500 & 350 PDFAvinash Kumar100% (1)

- (TM) Bajaj Manual de Taller Bajaj 200 Ns 2020 en InglesDocument61 pages(TM) Bajaj Manual de Taller Bajaj 200 Ns 2020 en InglesdiegoNo ratings yet

- Copia de Discor SPC Modified1 PartesDocument45 pagesCopia de Discor SPC Modified1 PartesFredy Rodriguez DelgadoNo ratings yet

- Sym Orbit 50 Service ManualDocument178 pagesSym Orbit 50 Service ManualPetrovics AttilaNo ratings yet

- OBD2-Avenger 220 Cruise Street BS VI Rev 10 June 23cda12031Document88 pagesOBD2-Avenger 220 Cruise Street BS VI Rev 10 June 23cda12031BABA MOTORSNo ratings yet

- Jupiter PaintedDocument1 pageJupiter PaintedViKi MuruganNo ratings yet

- CB 160 Manual de Servicio PDFDocument336 pagesCB 160 Manual de Servicio PDFOscar Eduardo Vera Aguirre100% (2)

- TVS Sport User Manual BS6Document69 pagesTVS Sport User Manual BS6tonemetoneNo ratings yet

- Bajaj 220 F Pulsar UG4Document15 pagesBajaj 220 F Pulsar UG4nkj_nbp50% (2)

- BS Iv Himalayan Abs PDFDocument170 pagesBS Iv Himalayan Abs PDFDebaraj BhardwajNo ratings yet

- Dominar 400 BS VI OBD2 Rev 09 April 23db7b11caDocument109 pagesDominar 400 BS VI OBD2 Rev 09 April 23db7b11caBABA MOTORSNo ratings yet

- Boxer BM 150 270415Document72 pagesBoxer BM 150 270415visugue_26100% (1)

- BMW F 650 GS, K72 0218Document880 pagesBMW F 650 GS, K72 0218Alejandro ArroyoNo ratings yet

- Vdocuments - MX - Manual de Taller Honda CBF 150 91 96 en Ingls Informacin Despiece o Catlogo de PDFDocument4 pagesVdocuments - MX - Manual de Taller Honda CBF 150 91 96 en Ingls Informacin Despiece o Catlogo de PDFvisugue_26No ratings yet

- Apache RTR 200 4vDocument260 pagesApache RTR 200 4vJuann Diego Valderamamunozz Stuner100% (2)

- Owner'S Manual: Suzuki Motorcycle India Private LimitedDocument117 pagesOwner'S Manual: Suzuki Motorcycle India Private LimiteddubanjdssfNo ratings yet

- BMW-S1000 RR K67 Service ManualDocument963 pagesBMW-S1000 RR K67 Service ManualcagriadarNo ratings yet

- Tvs Apache RTR 160 4v - Print Spec, Print User ManualDocument2 pagesTvs Apache RTR 160 4v - Print Spec, Print User Manualhitman agent47No ratings yet

- 12 Manual de Servicio Platino y Boxer CT Trainig Notes PDFDocument151 pages12 Manual de Servicio Platino y Boxer CT Trainig Notes PDFJuan Fer JiménezNo ratings yet

- Pulsar 135 Ls SPC 2011Document74 pagesPulsar 135 Ls SPC 2011Maria CruzNo ratings yet

- Benelli TNT 300 AbsDocument2 pagesBenelli TNT 300 AbsWahyudiNo ratings yet

- Manual de Partes Pulsar - NS200 &AS 200 - SPC Abr16 PDFDocument90 pagesManual de Partes Pulsar - NS200 &AS 200 - SPC Abr16 PDFID339101No ratings yet

- DAWN 150 SM Manual de TallerDocument300 pagesDAWN 150 SM Manual de Tallerkamil motorsNo ratings yet

- Spare Parts CatalogDocument75 pagesSpare Parts Catalograhulmahajan_b100% (1)

- Bs IV Himalayan Parts CatalogueDocument3 pagesBs IV Himalayan Parts CatalogueAnonymous O9TX7Yl100% (3)

- 1954-1957 250cc Pre-Unit ClipperDocument81 pages1954-1957 250cc Pre-Unit ClipperroyceNo ratings yet

- TNT25 Engine Intro (HD)Document90 pagesTNT25 Engine Intro (HD)Miguel LemosNo ratings yet

- In Case You Need Any Clarification or Service Assistance, Please Contact Our DealerDocument73 pagesIn Case You Need Any Clarification or Service Assistance, Please Contact Our DealerElmer PereiraNo ratings yet

- IB-303 - NS 200 NS-Fi RS200 - Modification of Cylinder Head AsslyDocument4 pagesIB-303 - NS 200 NS-Fi RS200 - Modification of Cylinder Head AsslyDeibid RVNo ratings yet

- Manual Servico Bajaj Boxer 150Document28 pagesManual Servico Bajaj Boxer 150Lucas TatarenNo ratings yet

- r15.v3 Monstar Indo 2020Document56 pagesr15.v3 Monstar Indo 2020Omar SahadatNo ratings yet

- BMW - G 310 Gs - Taller k02Document629 pagesBMW - G 310 Gs - Taller k02premiermotopsNo ratings yet

- Dominar 400 UG-JAN 19 PDFDocument41 pagesDominar 400 UG-JAN 19 PDFLadLerNo ratings yet

- 43 Manual de Servicios Platino 125 DRL Training NoteDocument116 pages43 Manual de Servicios Platino 125 DRL Training NoteJulian Uribe Herrera67% (3)

- Diesel Compressor Delivery Check ListDocument27 pagesDiesel Compressor Delivery Check ListhaythamNo ratings yet

- Engine RebuildDocument41 pagesEngine RebuildArifin DzulkarnainNo ratings yet

- S4S Engine - DP30NT - Service Manual - 2006-01e1 - CatDocument172 pagesS4S Engine - DP30NT - Service Manual - 2006-01e1 - CatjakagastrusNo ratings yet

- New Cobra 50 使用手冊 88510228-000 - 00Document50 pagesNew Cobra 50 使用手冊 88510228-000 - 00scienceokNo ratings yet

- XP375-HP375-WIR MantenimientoDocument23 pagesXP375-HP375-WIR MantenimientoDanel Gonzalez0% (1)

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDocument3 pagesHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaivaNo ratings yet

- Himalayan 5 PDFDocument25 pagesHimalayan 5 PDFJulian GallegoNo ratings yet

- Himalayan 2 PDFDocument20 pagesHimalayan 2 PDFJulian GallegoNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Gear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Himalayan 5 PDFDocument25 pagesHimalayan 5 PDFJulian GallegoNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Himalayan 1 PDFDocument20 pagesHimalayan 1 PDFJulian Gallego100% (1)

- Gear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Acrich 2 Application NoteDocument16 pagesAcrich 2 Application NoteDavis Cap JuniorNo ratings yet

- AC AC TransformerDocument4 pagesAC AC TransformerKevin GianeNo ratings yet

- I/O-expander Board Installation (SV9000) : Page 1Document15 pagesI/O-expander Board Installation (SV9000) : Page 1Evandro PavesiNo ratings yet

- GH DMDocument8 pagesGH DMer25amitNo ratings yet

- Abb Ovr Range System Prom - 2011 - 1txh000083c0201Document36 pagesAbb Ovr Range System Prom - 2011 - 1txh000083c0201Felix Julio Céspedes SotoNo ratings yet

- 4.0L Cec System: 1988 Jeep CherokeeDocument17 pages4.0L Cec System: 1988 Jeep CherokeefredericdiNo ratings yet

- US433702Document3 pagesUS433702mitza22No ratings yet

- 7XG3123 - ReyArc Catalogue SheetDocument12 pages7XG3123 - ReyArc Catalogue SheetChristian Vasquez MedranoNo ratings yet

- F 2000 EdcDocument86 pagesF 2000 Edcp_janko100% (2)

- Manual Skoda Octavia 1,6 55kW AVMDocument102 pagesManual Skoda Octavia 1,6 55kW AVMCornea Horatiu SebastianNo ratings yet

- Fender Bass Setup GuideDocument4 pagesFender Bass Setup GuideIvan StankovicNo ratings yet

- Comp. Code Comp. Def. Model & Specs Placement Remarks Comp. Code Comp. Def. Model & Specs Placement RemarksDocument3 pagesComp. Code Comp. Def. Model & Specs Placement Remarks Comp. Code Comp. Def. Model & Specs Placement RemarksLuqman HakimNo ratings yet

- Vd412.06.13e GTP 1vyn400990-009Document5 pagesVd412.06.13e GTP 1vyn400990-009Jatupol PongsirisartNo ratings yet

- SM-226x-3Q PI 1303Document2 pagesSM-226x-3Q PI 1303pawerxlNo ratings yet

- Cascade CD101 Auto-Start Controller: Installation and Operations ManualDocument26 pagesCascade CD101 Auto-Start Controller: Installation and Operations ManualJonathan Julián Cantillana DonosoNo ratings yet

- Exp 5 Intro To AC Phase ControlDocument8 pagesExp 5 Intro To AC Phase Controlusmpowerlab67% (3)

- Technical Submittal - LV DBDocument766 pagesTechnical Submittal - LV DBsamirNo ratings yet

- Warehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Document1 pageWarehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Rigor Louise M. LegadaNo ratings yet

- 3 IGCSE Electrical CircuitDocument24 pages3 IGCSE Electrical CircuitNeneng JubaedahNo ratings yet

- Ub1832fx-Pro - Diagrama de BloquesDocument2 pagesUb1832fx-Pro - Diagrama de Bloqueslacc2211No ratings yet

- Residential Electric Service InstallationDocument56 pagesResidential Electric Service InstallationJ Hevesi100% (1)

- User Manual: Screw Air Compressor Controller MAM6090Document43 pagesUser Manual: Screw Air Compressor Controller MAM6090Luis Batlle AguileraNo ratings yet

- Iso KFDocument13 pagesIso KFEnis ĆatićNo ratings yet

- KATALOG2010Document135 pagesKATALOG2010Srdjan CetkovicNo ratings yet

- Detail Construction DrawingsDocument12 pagesDetail Construction DrawingsShafnaFawazNo ratings yet

- Características Motor 75HP, 8900, RL2168Z, DPG - FV-1100499791-20Document3 pagesCaracterísticas Motor 75HP, 8900, RL2168Z, DPG - FV-1100499791-20Guillermo Andres Velasco AlvarezNo ratings yet

- Guntur NBCC SorDocument57 pagesGuntur NBCC SorPrawinkumar RajanNo ratings yet

- STK1R-EN-61-0-A Rev0-1Document98 pagesSTK1R-EN-61-0-A Rev0-1LudovicoNo ratings yet

- 300ma 25Kv High Voltage Diodes: FeaturesDocument1 page300ma 25Kv High Voltage Diodes: FeaturesPhong DoNo ratings yet