Professional Documents

Culture Documents

Condensate Line Sizing

Uploaded by

lyly0 ratings0% found this document useful (0 votes)

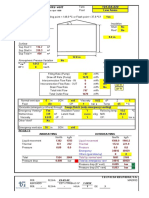

9 views2 pagesThe document provides technical specifications for a 14 inch diameter pipe carrying a condensate-steam mixture, including mass flow rates, pressures, densities, and other parameters. It then calculates the amount of condensate that will flash to steam, the density of the resulting mixture, the pressure drop and velocity in the pipe. It concludes that the specified pipe size is adequate since the calculated velocity is less than 500 feet/minute.

Original Description:

Original Title

condensate_line_sizing

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides technical specifications for a 14 inch diameter pipe carrying a condensate-steam mixture, including mass flow rates, pressures, densities, and other parameters. It then calculates the amount of condensate that will flash to steam, the density of the resulting mixture, the pressure drop and velocity in the pipe. It concludes that the specified pipe size is adequate since the calculated velocity is less than 500 feet/minute.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesCondensate Line Sizing

Uploaded by

lylyThe document provides technical specifications for a 14 inch diameter pipe carrying a condensate-steam mixture, including mass flow rates, pressures, densities, and other parameters. It then calculates the amount of condensate that will flash to steam, the density of the resulting mixture, the pressure drop and velocity in the pipe. It concludes that the specified pipe size is adequate since the calculated velocity is less than 500 feet/minute.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

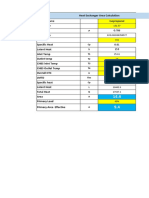

Pipe Diameter 14 Inch

Mass Flow Rate of Condensate 120000 Kg/hr 264552 lb/hr

Condensate Pressure Before Flashing 40 Kg/cm2G 583.143 psia

Flasher Condesate Header Pressure 5 Kg/cm2G 85.338 psia

Constant A 0.198495

Constant X 2.317087

Constant B 0.009815

Weight Fraction of Condensate

flashed to Vapour 0.199555

Flashed Steam Flow Rate 23946.59 Kg/hr 52792.65 lb/hr

Flashed Condensate Liquid Flow 96053.41 Kg/hr 211759.4 lb/hr

Temperature of Flashed Condensate 253.2732 ° C 487.8917 ° F

Flashed Steam Density 3.009158 kg/m3 0.187849 lb/ft3

Flashed Condensate Liquid Density 910.8139 kg/m3 56.85835 lb/ft3

Density of Mixture (Flashed

Condensate/Steam) 14.88213 kg/m3 0.92903 lb/ft3

For Turbulent Flow

Friction Factor 0.012571

Pressure Drop of Flashed Condensate

mixture 0.591644 psi/100ft

Velocity of Flashed Condensate

mixture 4437.05 ft/min

Line Size is adequate

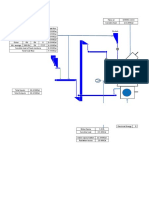

Assumptions:

1. Most of the flow patterns for steam condensate headers fall within the

annular or dispersed region on the baker map. Rarely flow pattern falls in slug

flow region.

2. Flashed steam is less than 30% by weight.

3. Vapour-liquid mixture throughout the condensate line is represented by

mixture conditions near the end of the line.

Method:

1. Amount of condensate flashed is calculated.

2. Further to above the density of the mixture (condensate+flashed steam) is

found out.

3. Using two pressure drop correlations, pressure per 100 ft. is calculated.

4. Also, the velocity of the mixture in the line of specified size is calculated. If

the velocity is lower than 500 Foot/Min., the specified line size is said to be

adequate.

You might also like

- 20 - Condensate Line SizingDocument2 pages20 - Condensate Line SizingJunaid MateenNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- Condensate Line SizingDocument4 pagesCondensate Line SizingMubin Ashraf SheikhNo ratings yet

- Condensate Line SizingDocument3 pagesCondensate Line Sizingadrian sotoNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingrohitkushNo ratings yet

- Condensate Line SizingDocument1 pageCondensate Line SizingShashi RaajNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Steam Condensate in Return LinesDocument13 pagesSteam Condensate in Return LinesAayushi SinhaNo ratings yet

- Calculation of Flow From PinholeDocument6 pagesCalculation of Flow From PinholeSubrata MukherjeeNo ratings yet

- Properties by Correlation For Process SimulationDocument4 pagesProperties by Correlation For Process SimulationSuryakant RanderiNo ratings yet

- Flow Through NozzlesDocument13 pagesFlow Through NozzlesBharat SharmaNo ratings yet

- Feed Drum/ Vessel General Design Considerations Basis or AssumptionsDocument9 pagesFeed Drum/ Vessel General Design Considerations Basis or AssumptionsLouie GresulaNo ratings yet

- Consequence AnalyserDocument23 pagesConsequence AnalyserGlacier RamkissoonNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- Heat Balance GrindingDocument13 pagesHeat Balance GrindingAbhijeet JhankalNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Pneumatic Conveyor Sizing CalculationsDocument3 pagesPneumatic Conveyor Sizing Calculationsm_nassifNo ratings yet

- IPA PreheaterDocument9 pagesIPA PreheaterNitin KurupNo ratings yet

- Scrubbing Tower DesignDocument10 pagesScrubbing Tower DesignPrathmesh GujaratiNo ratings yet

- Two Phase Beggs BrillDocument4 pagesTwo Phase Beggs BrillOsmund MwangupiliNo ratings yet

- Steam Leak CalculationDocument3 pagesSteam Leak CalculationJunaid MateenNo ratings yet

- Steam Leak CalculationDocument3 pagesSteam Leak CalculationJunaid MateenNo ratings yet

- Two Phase Flow - Beggs & Brill Method: Line Number P-10001 Description Feed Pipe Date 30-Aug-15 by CheguideDocument2 pagesTwo Phase Flow - Beggs & Brill Method: Line Number P-10001 Description Feed Pipe Date 30-Aug-15 by CheguidewaelNo ratings yet

- Mid Evaluation Amine Gas Treating Unit PresentationDocument39 pagesMid Evaluation Amine Gas Treating Unit PresentationAsad PatelNo ratings yet

- Line III Heat BalanceDocument65 pagesLine III Heat Balancehmaza shakeelNo ratings yet

- ProjectDocument26 pagesProjectsiddharthkharat123No ratings yet

- Combustion CalcsDocument8 pagesCombustion Calcs31331311313No ratings yet

- Combustion CalcsDocument8 pagesCombustion CalcsZhaqir HusseinNo ratings yet

- Fan Flow - CementDocument5 pagesFan Flow - CementharikrushnaNo ratings yet

- Pneumatic Conveying System Design Calculation: Input Parameters Unit ValueDocument6 pagesPneumatic Conveying System Design Calculation: Input Parameters Unit ValueTECHCONS Consulting and Engineering Pvt Ltd0% (1)

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Pressur Drop Calculation For DS Unit Vessels With F ProductsDocument9 pagesPressur Drop Calculation For DS Unit Vessels With F ProductsMaryam vafaee.nNo ratings yet

- Steam Nozzles and TurbinesDocument49 pagesSteam Nozzles and TurbinesN. VasanthNo ratings yet

- BF6M 1013ec - 9997264Document2 pagesBF6M 1013ec - 9997264Yader SanchezNo ratings yet

- IPA HeaterDocument14 pagesIPA HeaterNitin KurupNo ratings yet

- Ideal Gas Flowrate Volume-Nvolume-Mass Converter - Rev6Document2 pagesIdeal Gas Flowrate Volume-Nvolume-Mass Converter - Rev6OilGasRosettaStoneNo ratings yet

- Calculated Primary Air Flow and MomentumDocument4 pagesCalculated Primary Air Flow and MomentummadhuNo ratings yet

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- Fuel Gas Flow ConvDocument3 pagesFuel Gas Flow ConvmgkvprNo ratings yet

- Double Effect EvapDocument32 pagesDouble Effect EvapJubell MogoteNo ratings yet

- Experiment - 7: Aim: Sizing of Pressure VesselDocument5 pagesExperiment - 7: Aim: Sizing of Pressure VesselHomesick TutorsNo ratings yet

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- Gas DensityDocument4 pagesGas DensityjollyNo ratings yet

- 1 - Calcuquick D.Ginsky 6.6.2005 EnglishDocument82 pages1 - Calcuquick D.Ginsky 6.6.2005 EnglishRahul ChandrawarNo ratings yet

- Boilers and Steam Systems ..BoeDocument151 pagesBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (1)

- Venteo API 2000 (Amine)Document8 pagesVenteo API 2000 (Amine)Produccion VegetalNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Fire Tube Boiler DesignDocument3 pagesFire Tube Boiler DesignRajendraNo ratings yet

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- 2 Phase Flow Pressure Drop Calc Suresh1Document6 pages2 Phase Flow Pressure Drop Calc Suresh1NKNo ratings yet

- Evaporator: Main Function EvaporatorsDocument6 pagesEvaporator: Main Function EvaporatorsJames VincentNo ratings yet

- Liquid Nitrogen VolumeDocument2 pagesLiquid Nitrogen VolumeIndrajit BorikarNo ratings yet

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringFrom EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet