Professional Documents

Culture Documents

Fast Clad Er Epoxy: Protective & Marine Coatings

Uploaded by

CarlangasPardoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fast Clad Er Epoxy: Protective & Marine Coatings

Uploaded by

CarlangasPardoCopyright:

Available Formats

®

Protective FASTWITH

CLAD ER EPOXY

OPTI-CHECK OAP TECHNOLOGY

&

Marine PART A

PART A

B62W230

B62L230

WHITE BASE

BLUE OAP

PART A B62RW230 RED OXIDE

Coatings PART B

PART B

B62V230

B62AV230

CLEAR HARDENER

GRAY HARDENER

Revised 9/12 9.50

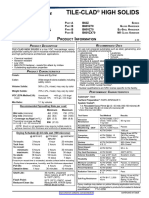

PRODUCT DESCRIPTION RECOMMENDED USES

Fast Clad ER Epoxy is an edge retentive, ultra high solids epoxy For use over prepared steel or masonry surfaces in industrial and

amine coating engineered for immersion service in sea water marine exposures such as:

ballast tanks, fuel/sea water ballast tanks, and petroleum storage • Ballast tank interiors and oil storage tank interiors

tanks. The rapid return to service and high build, edge retentive • Fuel storage tanks and external pipeline coating

properties of this coating provide superior protection compared to • Primary or Secondary containment

conventional epoxies. • Acceptable for use with cathodic protection systems

• One coat protection • Fast return to service • Where rapid return to service and edge protection film build

• Low VOC • Low odor properties are required

• Dry to walk-on within four hours • Meets MIL-PRF-23236 Type VII, Class 5, 7, 5/18, 7/18, 13/18, 17,

• Designed for plural-component application equipment 17/18 Grade C requirements for single and multi-coat seawater,

• Greater than 70% edge build retention fuel, bilges, and CHT tanks

• Low Temperature application and cure capabilities to 35°F (See • Blue OAP contains fluorescent pigment

Application Conditions) • Wind tower gearbox lining and transformer lining up to 284°F

(140°C)

PRODUCT CHARACTERISTICS

Finish: Gloss

PERFORMANCE CHARACTERISTICS

Color: White-Base, Blue OAP, Red Oxide Substrate*: Steel

Surface Preparation*: SSPC-SP10

Volume Solids: 98%, ± 2%, mixed

System Tested*:

Weight Solids: 98%, ± 2%, mixed 1 ct. Fast Clad ER Epoxy @ 18.0-22.0 mils (450-550 microns) dft

*unless otherwise noted below

VOC (EPA method #24): <85 g/L; 0.71 lb/gal, mixed Test Name Test Method Results

Mix Ratio: 1:1 by volume ASTM D4060, CS17

Abrasion wheel, 1000 cycles, 22.4 mg loss

Resistance

Recommended Spreading Rate per coat: 1 kg load

Adhesion ASTM D4541 >2000 psi

Minimum Maximum

Passes 30 days @

Wet mils (microns) 18.0 (450) 22.0 (550) Cathodic 1.5 volts (Cu/CuSO4),

ASTM G8

Dry mils (microns) 18.0 (450) 22.0 (550) Disbondment <10 mm disbondment

radius

~Coverage sq ft/gal (m2/L) 73 (1.8) 89 (2.2)

*Can be applied up to 60.0 mils (1500 microns) dft if required. Rating 10 per ASTM

D610 for Rusting

Theoretical coverage sq ft/gal Corrosion ASTM D5894, 4 (field); Rating 10 per

(m2/L) @ 1 mil / 25 microns dft 1568 (38.4) Weathering cycles, 1134 hours ASTM D714 for

NOTE: Brush or roll application may require multiple coats to Blistering (field)

achieve maximum film thickness and uniformity of appearance. Direct Impact ASTM D2794 15 in-lb

Resistance

Drying Schedule @ 20.0 mils (500 microns): Dry Heat Resistance ASTM D2485 250°F (121°C)

@ 40°F/4.5°C @ 77°F/25°C @ 100°F/38°C Flexibility ASTM D522 7/16" (24-hour cure)

50% RH Passes 6 months at

Immersion Elevated

To touch: 6 hours 1 hour 35 minutes 204°F (96°C) in

Temperature*

To handle: 8-12 hours 3 hours 55 minutes gearbox oil

To recoat: Rating 10 per ASTM

Moisture D610 for Rusting

minimum: 6 hours 1 hour 35 minutes ASTM D4585, 100°F

Condensation (field); Rating 10 per

(38°C), 2000 hours

maximum: 14 days 14 days 14 days Resistance ASTM D714 for

Foot traffic: 8-12 hours 3 hours 1 hour Blistering (field)

Cure to service: 36 hours 24 hours 12 hours Pencil Hardness ASTM D3363 H

Pot Life: 7 minutes *Report No. IM54.1382-09

Sweat-in-Time: None required

Immersion (ambient temperature) for the following:

Shelf Life: 24 months • Ballast tank mix ............................... Recommended

Store indoors at 40°F (4.5°C) to • Crude oil ........................................... Recommended

100°F (38°C) • Fresh water ...................................... Recommended

• Gasoline ........................................... Recommended

Flash Point: 230°F (110°C), PMCC, mixed • Sea water........................................... Recommended

Reducer: Not recommended • Reformulated gasoline .................. Recommended

• Kerosene .......................................... Recommended

Clean Up: MEK (R6K10) or Reducer R7K104 Epoxy coatings may darken or yellow after application and curing.

www.sherwin-williams.com/protective continued on back

®

Protective FASTWITH

CLAD ER EPOXY

OPTI-CHECK OAP TECHNOLOGY

&

Marine PART A

PART A

B62W230

B62L230

WHITE BASE

BLUE OAP

PART A B62RW230 RED OXIDE

Coatings PART B

PART B

B62V230

B62AV230

CLEAR HARDENER

GRAY HARDENER

PRODUCT INFORMATION 9.50

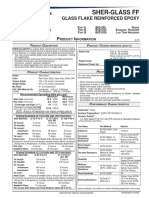

RECOMMENDED SYSTEMS SURFACE PREPARATION

Dry Film Thickness / ct. Surface must be clean, dry, and in sound condition. Remove all oil,

dust, grease, dirt, loose rust, and other foreign material to ensure

Mils (Microns) adequate adhesion.

Steel, immersion:

1 ct. Fast Clad ER Epoxy 18.0 -22.0 (450-550) Refer to product Application Bulletin for detailed surface prepara-

tion information.

Steel, immersion: Minimum recommended surface preparation:

1 ct. Fast Clad Epoxy Primer 4.0 -8.0** (100-200) Iron & Steel:

Atmospheric: SSPC-SP6/NACE 3, 2 mil

1 ct. Fast Clad ER Epoxy 18.0-22.0 (450-550) (50 micron) profile or

SSPC-SP12/NACE No. 5, WJ-3/SC-2

Steel, immersion: Immersion: SSPC-SP10/NACE2, 2-3 mil

(50-75 micron) profile or

2 cts. Fast Clad ER Epoxy 9.0-11.0 (225-275) SSPC- SP12/NACE No. 5,

WJ-2/SC-2

Concrete & Masonry:

Concrete, immersion: Atmospheric: SSPC-SP13/NACE 6, or ICRI

1 ct. Corobond 100 Epoxy Primer/Sealer; apply primer to No. 310.2, CSP2-3

achieve uniform hiding, appearance, and complete Immersion: SSPC-SP13/NACE 6-4.3.1 or 4.3.2,

or ICRI No. 310.2, CSP2-3

wetting of the concrete surface, approximately 4-6 .

Coating will be partially absorbed into the concrete. Surface Preparation Standards

Roll out any pudles. Condition of ISO 8501-1 Swedish Std.

Surface BS7079:A1 SIS055900 SSPC NACE

2 cts. Fast Clad ER Epoxy 9.0 – 11.0 (225-275) White Metal Sa 3 Sa 3 SP 5 1

Near White Metal Sa 2.5 Sa 2.5 SP 10 2

Commercial Blast Sa 2 Sa 2 SP 6 3

Brush-Off Blast Sa 1 Sa 1 SP 7 4

**When using B62L245 Primer containing the OAP fluorescent Hand Tool Cleaning Rusted C St 2 C St 2 SP 2 -

Pitted & Rusted D St 2 D St 2 SP 2 -

pigment, make sure a non-containing OAP fluorescent pigment

Power Tool Cleaning Rusted

Pitted & Rusted

C St 3

D St 3

C St 3

D St 3

SP 3

SP 3

-

-

topcoat is used.

TINTING

Do not tint part A. 5 gallons (18.9L) of clear hardener part B may

The systems listed above are representative of the product's use, be tinted with up to 2.75 ounces of Maxitoner Colorant Phthalo

other systems may be appropriate. Green or Black only.

APPLICATION CONDITIONS

Temperature:

Air & surface: 40°F (4.5°C) minimum*, 110°F (43°C)

maximum

*For application at 35°F (1.7°C) to 40°F (4.5°C), specific guidelines are

required:

SAFETY PRECAUTIONS • Air & Surface temperature conditions must be expected to remain stable

Refer to the MSDS sheet before use. or improve for a period of four hours.

• Environmental controls (dehumidication, heating, forced-air ventilation)

Published technical data and instructions are subject to change are recommended to maintain acceptable application conditions.

without notice. Contact your Sherwin-Williams representative for ad- • Final cure must be confirmed in accordance with ASTM D5402, "Assess-

ditional technical data and instructions. ing the Solvent Resistance of Organic Coatings Using Solvent Rubs".

Test shall consist of 50 double rubs with MEK. Test shall confirm no loss

of DFT, and no coating residue on rubbing cloth.

DISCLAIMER

The material should be 85°F-130°F/29°C-54°C (vary as needed)

The information and recommendations set forth in this Product Data Sheet are at the mixing block for optimal atomization based on tip size and

based upon tests conducted by or on behalf of The Sherwin-Williams Company. pump pressure.. Do not heat above 140°F/60°C.

Such information and recommendations set forth herein are subject to change and

pertain to the product offered at the time of publication. Consult your Sherwin- Relative humidity: 85% maximum

Williams representative to obtain the most recent Product Data Information and

Application Bulletin. Refer to product Application Bulletin for detailed application information.

WARRANTY ORDERING INFORMATION

The Sherwin-Williams Company warrants our products to be free of manufacturing Packaging:

defects in accord with applicable Sherwin-Williams quality control procedures.

Liability for products proven defective, if any, is limited to replacement of the de- Part A: 5 gallon (18.9L) container

fective product or the refund of the purchase price paid for the defective product Part B: 5 gallon (18.9L) container

as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, Weight: 11.71, ± 0.3 lb/gal ; 1.4 Kg/L, mixed

STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

®

Protective FASTWITH

CLAD ER EPOXY

OPTI-CHECK OAP TECHNOLOGY

&

Marine PART A

PART A

B62W230

B62L230

WHITE BASE

BLUE OAP

PART A B62RW230 RED OXIDE

Coatings PART B

PART B

B62V230

B62AV230

CLEAR HARDENER

GRAY HARDENER

Revised 9/12 APPLICATION BULLETIN 9.50

SURFACE PREPARATIONS APPLICATION CONDITIONS

Temperature:

Surface must be clean, dry, and in sound condition. Remove all Air & surface: 40°F (4.5°C) minimum*, 110°F (43°C)

oil, dust, grease, dirt, loose rust, and other foreign material to maximum

ensure adequate adhesion.

*For application at 35°F (1.7°C) to 40°F (4.5°C), specific guidelines are

Iron & Steel (atmospheric service) required:

Minimum surface preparation is Commercial Blast Cleaning per • Air & Surface temperature conditions must be expected to remain stable

SSPC-SP6/NACE 3 or SSPC-SP12/NACE No. 5. For surfaces or improve for a period of four hours.

prepared by SSPC SP6/NACE 3, first remove all oil and grease • Environmental controls (dehumidication, heating, forced-air ventilation)

are recommended to maintain acceptable application conditions.

from surface by Solvent Cleaning per SSPC-SP1. For better per- • Final cure must be confirmed in accordance with ASTM D5402, "Assess-

formance, use Near White Metal Blast Cleaning per SSPC-SP10/ ing the Solvent Resistance of Organic Coatings Using Solvent Rubs".

NACE 2. Blast clean all surfaces using a sharp, angular abrasive Test shall consist of 50 double rubs with MEK. Test shall confirm no loss

for optimum surface profile (2-3 mils / 50-75 microns). For surfaces of DFT, and no coating residue on rubbing cloth.

prepared by SSPC-SP12/NACE No. 5, all surfaces shall be cleaned

in accordance with WJ-3/SC2. Pre-existing profile should be ap- The material should be 85°F-130°F/29°C-54°C (vary as needed)

proximately 2 mils (50 microns). Prime any bare steel the same at the mixing block for optimal atomization based on tip size and

day as it is cleaned or before flash rusting occurs. pump pressure.. Do not heat above 140°F/60°C.

Iron & Steel (immersion service) Relative humidity: 85% maximum

Remove all oil and grease from surface by Solvent Cleaning per

SSPC-SP1. Minimum surface preparation is Near White Metal APPLICATION EQUIPMENT

Blast Cleaning per SSPC-SP10/NACE 2, or SSPC-SP12/NACE

No. 5. For SSPC-SP10/NACE 2, blast clean all surfaces using

a sharp, angular abrasive for optimum surface profile (2-3 mils / The following is a guide. Changes in pressures and tip sizes may

50-75 microns). For SSPC-SP12/NACE No.5, all surfaces to be be needed for proper spray characteristics. Always purge spray

coated shall be cleaned in accordance with WJ-2/SC2 standards. equipment before use with listed reducer. Any reduction must be

Pre-existing profile should be approximately 2 mils (50 microns). compliant with existing VOC regulations and compatible with the

Remove all weld spatter. Prime any bare steel the same day as it

is cleaned or before flash rusting occurs. existing environmental and application conditions.

Concrete and Masonry Reduction ........................Not recommended

For surface preparation, refer to SSPC-SP13/NACE 6, or ICRI

No. 310.2, CSP 2-3. Surfaces should be thoroughly clean and Clean Up ..........................MEK (R6K10) or R7K104

dry. Concrete and mortar must be cured at least 28 days @ 75°F

(24°C). Remove all loose mortar and foreign material. Surface

must be free of laitance, concrete dust, dirt, form release agents, Plural Component Equipment

moisture curing membranes, loose cement and hardeners. Fill Pump..............................WIWA DURO-MIX 1:1, Graco Ex-

bug holes, air pockets and other voids with Steel-Seam FT910. treme Mix, Graco XM, or Graco XP

Primer required. Pressure.........................4000 psi

Follow the standard methods listed below when applicable: Hose...............................3/8" ID

ASTM D4258 Standard Practice for Cleaning Concrete. Tip ...................................021" - .025"

ASTM D4259 Standard Practice for Abrading Concrete. Pump heater setting .......70 - 80

ASTM D4260 Standard Practice for Etching Concrete. Material temperature at

ASTM F1869 Standard Test Method for Measuring Moisture Vapor gun tip .......................85°F-130°F (29°C-54°C)

Emission Rate of Concrete.

SSPC-SP 13/Nace 6 Surface Preparation of Concrete. (vary as needed)

ICRI No. 310.2 Concrete Surface Preparation.

Brush ...............................For stripe coating and repair only

Concrete, Immersion Service: Brush..............................Nylon/Polyester or Natural Bristle

For surface preparation, refer to SSPC-SP13/NACE 6, Section

4.3.1 or 1.3.2 or ICRI No. 310.2, CSP 2-3.

Roller ...............................For stripe coating and repair only

Cover .............................3/8" woven with solvent resistant core

Surface Preparation Standards

Condition of ISO 8501-1 Swedish Std.

Surface BS7079:A1 SIS055900 SSPC NACE If specific application equipment is not listed above, equivalent

White Metal Sa 3 Sa 3 SP 5 1 equipment may be substituted.

Near White Metal Sa 2.5 Sa 2.5 SP 10 2

Commercial Blast Sa 2 Sa 2 SP 6 3

Brush-Off Blast Sa 1 Sa 1 SP 7 4

Hand Tool Cleaning Rusted

Pitted & Rusted

C St 2

D St 2

C St 2

D St 2

SP 2

SP 2

-

-

Power Tool Cleaning Rusted

Pitted & Rusted

C St 3

D St 3

C St 3

D St 3

SP 3

SP 3

-

-

www.sherwin-williams.com/protective continued on back

®

Protective FASTWITH

CLAD ER EPOXY

OPTI-CHECK OAP TECHNOLOGY

&

Marine PART A

PART A

B62W230

B62L230

WHITE BASE

BLUE OAP

PART A B62RW230 RED OXIDE

Coatings PART B

PART B

B62V230

B62AV230

CLEAR HARDENER

GRAY HARDENER

APPLICATION BULLETIN 9.50

APPLICATION PROCEDURES PERFORMANCE TIPS

Repair of Pitted Tank Bottoms

Surface preparation must be completed as indicated. Extensive, deep pitting:

Options:

Option 1 ..Apply a full wet coat, by spray application, of Fast

Mixing Instructions: Mix contents of each component thoroughly Clad Epoxy Primer. Follow with rubber squeegee to

using low speed power agitation. Make certain no pigment remains work material into and fill the pitted areas. After recom-

on the bottom or the sides of the can. Then combine one part by mended drying time, apply a full coat of Fast Clad ER

at recommended film thickness.

volume of Part A with one part by volume of Part B. Thoroughly Option 2 ..Apply Dura-Plate UHS Clear Laminant Resin with 1½

agitate the mixture with power agitation. oz fiberglass mat over the pitted areas. After recom-

To ensure that no unmixed material remains on the sides or bottom mended drying time, apply a full coat of Fast Clad ER

at recommended film thickness.

of the cans after mixing, visually observe the container by pouring Option 3 ..Weld new steel plates, or use puddle welds, as required

the material into a separate container. to repair pitted areas. Coat areas as recommended.

Shallow pitting, isolated areas:

Apply paint at the recommended film thickness and spreading Options:

rate as indicated below: Option 1 ..Same as number 1 above.

Option 2 ..Apply Steel Seam FT910 as required to fill the pitted

Recommended Spreading Rate per coat: areas. Coat areas as recommended.

Minimum Maximum When using spray application, use a 50% overlap with each pass

of the gun to avoid holidays, bare areas, and pinholes. If necessary,

Wet mils (microns) 18.0 (450) 22.0 (550) cross-coat spray at a right angle.

Dry mils (microns) 18.0 (450) 22.0 (550)

~Coverage sq ft/gal (m2/L) 73 (1.8) 89 (2.2) Spreading rates are calculated on volume solids and do not include

an application loss factor due to surface profile, roughness or po-

*Can be applied up to 60.0 mils (1500 microns) dft if required. rosity of the surface, skill and technique of the applicator, method

Theoretical coverage sq ft/gal

1568 (38.4) of application, various surface irregularities, material lost during

(m2/L) @ 1 mil / 25 microns dft mixing, spillage, overthinning, climatic conditions, and excessive

NOTE: Brush or roll application may require multiple coats to film build.

achieve maximum film thickness and uniformity of appearance. No reduction of material is recommended as this can affect film

build, appearance, and adhesion.

Drying Schedule @ 20.0 mils (500 microns): Stripe coat all crevices, welds, and sharp angles to prevent early

@ 40°F/4.5°C @ 77°F/25°C @ 100°F/38°C

failure in these areas.

50% RH Do not mix previously catalyzed material with new.

To touch: 6 hours 1 hour 35 minutes

Do not apply the material beyond recommended pot life.

To handle: 8-12 hours 3 hours 55 minutes

To recoat: Remove and solvent clean tip housing every 20-30 minutes.

minimum: 6 hours 1 hour 35 minutes

For Immersion Service: (if required) Holiday test in accordance

maximum: 14 days 14 days 14 days with ASTM D5162 for steel, or ASTM D4787 for concrete.

Foot traffic: 8-12 hours 3 hours 1 hour

Cure to service: 36 hours 24 hours 12 hours When using an OAP fluorescent pigment system, use the Fast

Clad Epoxy Primer, with a non-OAP containing Fast Clad ER

Pot Life: 7 minutes topcoat color.

Sweat-in-Time: None required

Guidance on techniques and required equipment to inspect a

Application of coating above maximum or below minimum coating system incorporating Opti-Check OAP Technology can be

recommended spreading rate may adversely affect coating found in SSPC-TU 11.

performance. Refer to Product Information sheet for additional performance

characteristics and properties.

CLEAN UP INSTRUCTIONS SAFETY PRECAUTIONS

Refer to the MSDS sheet before use.

Clean spills and spatters immediately with MEK, R6K10. Clean

Published technical data and instructions are subject to change without notice.

tools immediately after use with MEK, R6K10. Follow manufac- Contact your Sherwin-Williams representative for additional technical data and

turer's safety recommendations when using any solvent. instructions.

WARRANTY

DISCLAIMER The Sherwin-Williams Company warrants our products to be free of manufacturing

The information and recommendations set forth in this Product Data Sheet are defects in accord with applicable Sherwin-Williams quality control procedures.

based upon tests conducted by or on behalf of The Sherwin-Williams Company. Liability for products proven defective, if any, is limited to replacement of the de-

Such information and recommendations set forth herein are subject to change and fective product or the refund of the purchase price paid for the defective product

pertain to the product offered at the time of publication. Consult your Sherwin- as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED,

Williams representative to obtain the most recent Product Data Information and STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MER-

Application Bulletin. CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

You might also like

- Targaurd Apcs 3 BLACKDocument4 pagesTargaurd Apcs 3 BLACKNoman AhmedNo ratings yet

- Cor Cote HTDocument4 pagesCor Cote HTlovaldes62No ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Macropoxy 646 PW 2021Document4 pagesMacropoxy 646 PW 2021Jeisson BravoNo ratings yet

- Eutalloy 1202Document2 pagesEutalloy 1202Siddharth DasNo ratings yet

- Dura-Plate Uhs Primer NSF: Protective & Marine CoatingsDocument4 pagesDura-Plate Uhs Primer NSF: Protective & Marine CoatingscerorideNo ratings yet

- Macropoxy 646 PW: Protective & Marine CoatingsDocument4 pagesMacropoxy 646 PW: Protective & Marine CoatingsAnn HewsonNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Polylon HP PDSDocument4 pagesPolylon HP PDSJose MachadoNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- JCB HP HYDRAULIC FLUID 46 - enDocument2 pagesJCB HP HYDRAULIC FLUID 46 - enMiguel MacedoNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- LOCTITE ABLESTIK 2600BT en - GLDocument2 pagesLOCTITE ABLESTIK 2600BT en - GLJess OrtonNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationDocument8 pagesZinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationThennarasu VelloreNo ratings yet

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozNo ratings yet

- 3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Document2 pages3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Massimiliano VolaNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- B62W80_PDS_English_Document4 pagesB62W80_PDS_English_juanNo ratings yet

- Alpha Om-353 Solder Paste en 08nov19 TBDocument7 pagesAlpha Om-353 Solder Paste en 08nov19 TBShamsur RahmanNo ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Intergard 269 PDFDocument4 pagesIntergard 269 PDFAdi SeptiNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- 406-2012 New-EnDocument3 pages406-2012 New-EnNishant SenapatiNo ratings yet

- Lubri-Bond 220: Technical Data (Spec Qualified)Document2 pagesLubri-Bond 220: Technical Data (Spec Qualified)Santaj TechnologiesNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Technical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantDocument3 pagesTechnical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantSantaj TechnologiesNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- TDS Gadus S5 V220 2Document2 pagesTDS Gadus S5 V220 2Nokiabhre WijayaNo ratings yet

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- Technical Data Sheet for Baltoflake CoatingDocument6 pagesTechnical Data Sheet for Baltoflake CoatingSaul AntayhuaNo ratings yet

- Duraplate 301K - Sherwin WilliamsDocument4 pagesDuraplate 301K - Sherwin WilliamsJardenson CésarNo ratings yet

- Premium Insulating Oil Meets Industry StandardsDocument3 pagesPremium Insulating Oil Meets Industry StandardsAsim IbrahimNo ratings yet

- Propoxylated EmulsifierDocument1 pagePropoxylated EmulsifierFadhli KusumaNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Royal 876 EP GreaseDocument3 pagesRoyal 876 EP GreaseVictor ZhicayNo ratings yet

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 pagesEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Castrol Aero HF 585B Mineral Hydraulic Fluid Product DataDocument2 pagesCastrol Aero HF 585B Mineral Hydraulic Fluid Product Datanauta007No ratings yet

- Loctite 380 Black - Ficha TecnicaDocument3 pagesLoctite 380 Black - Ficha TecnicamonsepackNo ratings yet

- Pintura 7000 - System - Cold - Galvanizing - Compound - RO65 - GDH585 - 0622Document2 pagesPintura 7000 - System - Cold - Galvanizing - Compound - RO65 - GDH585 - 0622Carmen CespedesNo ratings yet

- RD108SDocument1 pageRD108SAPEX SONNo ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Keeler & Long KL65487107 Product Data SheetDocument2 pagesKeeler & Long KL65487107 Product Data SheetRussell ShacklefordNo ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- TDS 2800000925 en - USDocument2 pagesTDS 2800000925 en - USIsrael HernandezNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Technical Data Sheet for Glass Flake CoatingDocument5 pagesTechnical Data Sheet for Glass Flake CoatingsmnisNo ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- Balto FlakeDocument5 pagesBalto FlakeBiju_PottayilNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Engineering Data: GPO-3 8/11/2011 H900Document2 pagesEngineering Data: GPO-3 8/11/2011 H900Fernando OrtizNo ratings yet

- M583ch CAT D8R LGP load rating and specificationsDocument2 pagesM583ch CAT D8R LGP load rating and specificationsCarlangasPardoNo ratings yet

- Analysis and Design of Circular Prestressed Concrete Storage TanksDocument22 pagesAnalysis and Design of Circular Prestressed Concrete Storage Tankschondroc11No ratings yet

- (Report) Storage Tanks (Japan)Document179 pages(Report) Storage Tanks (Japan)RAJENDRA PRASADNo ratings yet

- Ολοκληρωμα DuhamelDocument6 pagesΟλοκληρωμα DuhamelkakarikosNo ratings yet

- Idini 2016Document28 pagesIdini 2016Luis Fernando Vergaray AstupiñaNo ratings yet

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownNo ratings yet

- PCWastewater Treatment TanksDocument12 pagesPCWastewater Treatment TanksCarlangasPardoNo ratings yet

- Lecture 18xxxxDocument9 pagesLecture 18xxxxjungzkiNo ratings yet

- 1 s2.0 S1877705817327339 MainDocument8 pages1 s2.0 S1877705817327339 MainfghfNo ratings yet

- Libro en Ingles - Chile PDFDocument192 pagesLibro en Ingles - Chile PDFPedro Ruiz MedianeroNo ratings yet

- An Efficient Algorithm For The Evaluation of Convolution IntegralsDocument22 pagesAn Efficient Algorithm For The Evaluation of Convolution IntegralsCarlangasPardoNo ratings yet

- C770573Document16 pagesC770573CarlangasPardoNo ratings yet

- 43 MaskalADocument17 pages43 MaskalACarlangasPardoNo ratings yet

- Non-Linear Structural Analysis For Seismic DesignDocument36 pagesNon-Linear Structural Analysis For Seismic DesignAsraf MuidinNo ratings yet

- Fosroc Concure WB: Water Based Concrete Curing CompoundDocument2 pagesFosroc Concure WB: Water Based Concrete Curing CompoundShaik QutubuddinNo ratings yet

- Bearing For Screw CompressorDocument8 pagesBearing For Screw Compressormk saravananNo ratings yet

- Organochloride Contamination Source IdentificationDocument5 pagesOrganochloride Contamination Source IdentificationMarwa ElsherifNo ratings yet

- Foil TrayDocument4 pagesFoil TrayLeyyNo ratings yet

- Mark Scheme Depth in ChemistryDocument19 pagesMark Scheme Depth in ChemistryAddan AddanNo ratings yet

- Flowcharts and Design Equations - Eurocode 2Document7 pagesFlowcharts and Design Equations - Eurocode 2ChineseAssassinNo ratings yet

- Bloqueos Membrane Locking, Parasitic Shear and Incompressible LockingDocument18 pagesBloqueos Membrane Locking, Parasitic Shear and Incompressible LockingsirpaneteNo ratings yet

- Goodyear Black Belt Catalog 2010Document72 pagesGoodyear Black Belt Catalog 2010piero_rsNo ratings yet

- Bitoner Resin C9 BP-120 TDSDocument2 pagesBitoner Resin C9 BP-120 TDSdamiendamNo ratings yet

- Wood and Armer Slab Design Method for Twisting MomentsDocument2 pagesWood and Armer Slab Design Method for Twisting MomentsBalaji VenkateswaranNo ratings yet

- Testing Application Standard No 112-95 PDFDocument12 pagesTesting Application Standard No 112-95 PDFAlvin BadzNo ratings yet

- Grade Data Sheet for 304, 304L and 304H Stainless SteelsDocument2 pagesGrade Data Sheet for 304, 304L and 304H Stainless Steelss swamiNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- Pengembangan Deteksi Antigen Virus Sars-Cov-2 Berbasis Surface Plasmonic Resonance (SPR)Document18 pagesPengembangan Deteksi Antigen Virus Sars-Cov-2 Berbasis Surface Plasmonic Resonance (SPR)Hidayat NurNo ratings yet

- Raychem WPCT Heat Shrink SleevesDocument4 pagesRaychem WPCT Heat Shrink SleevesmngNo ratings yet

- Jianbang Coating Company ProfileDocument8 pagesJianbang Coating Company ProfileJaya IrawanNo ratings yet

- Laminar flow HEPA filterDocument2 pagesLaminar flow HEPA filterwesam allabadiNo ratings yet

- C.A.T-HSE-Hydrogen Sulphide-01Document30 pagesC.A.T-HSE-Hydrogen Sulphide-01M AbidNo ratings yet

- PDS Hempathane Topcoat 55210 en-GBDocument3 pagesPDS Hempathane Topcoat 55210 en-GBNguyễn Đặng LâmNo ratings yet

- Cox - 1975 - Overhead-Line PracticeDocument9 pagesCox - 1975 - Overhead-Line PracticePoleomanNo ratings yet

- Journal of The Taiwan Institute of Chemical Engineers Volume 45 Issue 6 2014 (Doi 10.1016/j.jtice.2014.05.012) Ameduri, Bruno - Recent Advances in The Controlled Radical (Co) Polymerization of FluoDocument10 pagesJournal of The Taiwan Institute of Chemical Engineers Volume 45 Issue 6 2014 (Doi 10.1016/j.jtice.2014.05.012) Ameduri, Bruno - Recent Advances in The Controlled Radical (Co) Polymerization of FluoRyan Eka JuniawanNo ratings yet

- Creep of MaterialsDocument67 pagesCreep of MaterialsAnilNo ratings yet

- DMA analysis of coke bottle sampleDocument32 pagesDMA analysis of coke bottle sampleDivagar SivaselvamNo ratings yet

- Chemistry A Molecular Approach Tro 2nd Edition Test BankDocument32 pagesChemistry A Molecular Approach Tro 2nd Edition Test BankAlbert Seale100% (29)

- Welding Variables WeldersDocument5 pagesWelding Variables WeldersAkhilesh KumarNo ratings yet

- Changing Markets Dirty Fashion Report Spread WebDocument35 pagesChanging Markets Dirty Fashion Report Spread WebLubabun Ni'amNo ratings yet

- Crude Oil Treatment-Libre (1) CDSCDocument55 pagesCrude Oil Treatment-Libre (1) CDSCMahmoud Abd El-Razik100% (2)

- NITESH PRASAD - 26300721021 - PE-ME802 F (1) - CompressedDocument6 pagesNITESH PRASAD - 26300721021 - PE-ME802 F (1) - CompressedBishalNo ratings yet

- Ash in Fatty Quaternary Ammonium Chlorides: Standard Test Method ForDocument1 pageAsh in Fatty Quaternary Ammonium Chlorides: Standard Test Method ForShaker QaidiNo ratings yet