Professional Documents

Culture Documents

D1 - Kick Whilst Tripping

Uploaded by

David OrtegaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D1 - Kick Whilst Tripping

Uploaded by

David OrtegaCopyright:

Available Formats

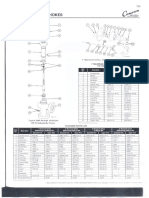

Stripping Drill - Tank Dimensions.

D1 - Kick whilst tripping.

1 - Set pipe in slips, install and close safety valve.

2 - Open HCR valve and close annular.

3 - Check well is properly closed in and valves lined up correctly.

Stripping Drill.

1 - Install single, m/u top drive, open safety valve and pressurise well to 400psi.

2 - Close safety valve, break off single, install dart sub and dart. Reconnect single

open safety valve and check that dart is holding.

3 - Ensure stripping tank is connected properly.

4 - Reduce annular closing pressure until a slight leakage occurs. This reduces wear

on the annular by lubricating element when stripping.

5 - Start stripping pipe, bleed off closed end displacement. The stripping tank has levels

indicating volume to bleed off each stand. Mud will have to be bled off slowly as the

stand is lowered, check at the end of each stand that correct volume has been bled off.

Also check and record pressure at end of each stand - the most important issue when

stripping is to ensure proper volume is bled off.

6 - After stripping 2 stands m/u top drive and fill pipe, bleed off pressure and open well

pull back to remove dart sub and safety valve.

Note: -Remove drill pipe rubbers from stands as they are stripped into well.

A stripping tank should be part of the well control equipment on every rig.

I recommend we use the tank dimensions and procedures used on rig 152 and standardise the system

across the fleet.

Following are the dimensions -

Width -35.5 inches

Length - 35.5 inches

Width - 47 inches.

Capacity - 5.7 bbls. - .1216 bbls per inch.

Level marks 4 inches apart giving .5 bbl per mark.

The tank should have an inlet which can be hooked up to kill line on standpipe manifold and an outlet

with a valve to hook up to the mud bucket return line.

Rig Up.

The stripping tank is rigged up on the rig floor. The tank is connected to the standpipe manifold. The

returns from the well are sent to the tank via the kill line. A lo-torque valve is rigged up here and the

returns controlled by a man operating lo-torque valve.

The mud bucket return line is connected to the tank and the tank drained after reading is recorded.

This system has worked very well when carrying out regular drills on Rig 152. Having the tank on the rig

floor provides good communication between the main players during a well control incident.

The ideal time for a stripping drill would be after setting 9/5/8 liner prior to drilling reservoir.

You might also like

- Tab 13-Calculations & Product ApplicationsDocument31 pagesTab 13-Calculations & Product ApplicationsDavid OrtegaNo ratings yet

- Cyber BaseDocument39 pagesCyber BaseayhamNo ratings yet

- Coiled Tubing Emergency ProceduresDocument46 pagesCoiled Tubing Emergency Proceduresazareiforoush0% (1)

- 2d Bow Truster Brunvoll Thruster Type Fu 80 LTC 2250 142Document142 pages2d Bow Truster Brunvoll Thruster Type Fu 80 LTC 2250 142Volodymyr BakotaNo ratings yet

- Shut in Procedures PDFDocument71 pagesShut in Procedures PDFRichard Reiersen100% (3)

- Burst and Pressure - Full ReportDocument18 pagesBurst and Pressure - Full ReportEspion BenNo ratings yet

- 2006 Drilling, Completion and Workover Fluids: Special Supplement ToDocument25 pages2006 Drilling, Completion and Workover Fluids: Special Supplement ToDavid OrtegaNo ratings yet

- ECU Designing and Testing Using National Instruments ProductsDocument7 pagesECU Designing and Testing Using National Instruments ProductsTYu4443No ratings yet

- 4 PumpsDocument26 pages4 PumpsdhasdjNo ratings yet

- BG2 2010 Commissioning Water SystemsDocument87 pagesBG2 2010 Commissioning Water SystemsFinlayNo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- Stuck Pipe PreventionDocument20 pagesStuck Pipe PreventionDavid Ortega100% (1)

- Stuck Pipe PreventionDocument20 pagesStuck Pipe PreventionDavid Ortega100% (1)

- Instructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeDocument38 pagesInstructions On Installation, Operation and Maintenanace For Sam Turbo Pump Typevikash kumarNo ratings yet

- Swabbing Equipments Mod 2Document5 pagesSwabbing Equipments Mod 2Anonymous Vb1Tsv106No ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- Drilling With Casing 04Document15 pagesDrilling With Casing 04Dian Sikumbang100% (2)

- Workover Operations ManualDocument17 pagesWorkover Operations ManualAbdelhak Hadji100% (1)

- Tab 04-Packer Milling ToolsDocument29 pagesTab 04-Packer Milling ToolsDavid Ortega100% (1)

- Pumps 06 - MaintenanceDocument13 pagesPumps 06 - MaintenancePyae Sone KyawNo ratings yet

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- Method Statement of Chiller Preventive MaintenanceDocument5 pagesMethod Statement of Chiller Preventive MaintenanceBalajiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- BRC Installation Manual PDFDocument32 pagesBRC Installation Manual PDFZoltán Gyulai0% (1)

- Pump Room SystemsDocument8 pagesPump Room SystemsArdyas Wisnu Baskoro100% (1)

- The Tripping ProcessDocument3 pagesThe Tripping ProcessFabrizioLaVitaNo ratings yet

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageDavid OrtegaNo ratings yet

- SOP (Mud Pump)Document3 pagesSOP (Mud Pump)Kunal GautamNo ratings yet

- Higgins 78ft Operating Manual PT71-94Document19 pagesHiggins 78ft Operating Manual PT71-94Sean CampbellNo ratings yet

- Trip TankDocument23 pagesTrip TankNaser KhanNo ratings yet

- Well Control Drills and Exercises WIPER TRIPDocument3 pagesWell Control Drills and Exercises WIPER TRIPmanuelperdomotNo ratings yet

- Dosing PumpDocument10 pagesDosing PumpniceseshaNo ratings yet

- Workover Programme - Tubing Change OutDocument11 pagesWorkover Programme - Tubing Change OutE_Amr_SorourNo ratings yet

- Tripping Operations - Best PracticesDocument3 pagesTripping Operations - Best PracticesYougchu Luan100% (2)

- Deulin e A Et Al Mechanics and Physics of Precise Vacuum MecDocument244 pagesDeulin e A Et Al Mechanics and Physics of Precise Vacuum MecHien TranNo ratings yet

- Re Entry WorkDocument3 pagesRe Entry WorkAnilNo ratings yet

- 89 Sub Surface Safety Valves SSSV InstallationDocument16 pages89 Sub Surface Safety Valves SSSV InstallationManuel Coxe100% (1)

- Reference Guide: Elevator Selection Guide For All Varco BJ Air Operated and Manual ElevatorsDocument16 pagesReference Guide: Elevator Selection Guide For All Varco BJ Air Operated and Manual ElevatorsDavid OrtegaNo ratings yet

- Kick Drill While Drilling - Pit Drills ProcedureDocument3 pagesKick Drill While Drilling - Pit Drills Proceduremontacer badreddine100% (1)

- Valves Gate DamperDocument54 pagesValves Gate DamperLalit MeenaNo ratings yet

- Well Control - Combined Stripping and Volumetric MethodDocument3 pagesWell Control - Combined Stripping and Volumetric MethodAbdul Hameed Omar100% (1)

- Hydrojetting Daily InspectionDocument6 pagesHydrojetting Daily InspectionUnknownNo ratings yet

- Ram Pump DTU S1Document12 pagesRam Pump DTU S1Andri Betmanto100% (1)

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsDocument51 pagesW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanNo ratings yet

- KTM512 Extended Guide ENDocument12 pagesKTM512 Extended Guide ENFilip SerafimovNo ratings yet

- Hydro CyclonesDocument7 pagesHydro CyclonesMohamed Ali HorrigueNo ratings yet

- Well Control SystemDocument7 pagesWell Control SystemKulodipNo ratings yet

- Jones Hydrant OM 8-21-09Document6 pagesJones Hydrant OM 8-21-09RktBatamNo ratings yet

- Well Control EquipmentDocument12 pagesWell Control EquipmentSamad Ali SiddiquiNo ratings yet

- Enerpac P-392 Service InstructionsDocument8 pagesEnerpac P-392 Service InstructionsSergio ReyesNo ratings yet

- Circulation Pump A27-A30angDocument11 pagesCirculation Pump A27-A30angpavan3229100% (1)

- Eo Reactor Work Instruction RevDocument4 pagesEo Reactor Work Instruction Revvishal bailurNo ratings yet

- 605JMIOMDocument4 pages605JMIOMEduardo SolisNo ratings yet

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- Trip TankDocument23 pagesTrip TankSwakshar Jyoti HazarikaNo ratings yet

- Daily Report Trainee EngineerDocument4 pagesDaily Report Trainee Engineerhurry yashwantNo ratings yet

- IOM Manual For Air Cylinder Operated ValvesDocument21 pagesIOM Manual For Air Cylinder Operated Valvesjhon riosNo ratings yet

- Coc Oral Exam Preparation (Part - 12) : Stern TubeDocument3 pagesCoc Oral Exam Preparation (Part - 12) : Stern Tubeaadarsh kumarNo ratings yet

- BR5100 Installation and TroubleshootingDocument2 pagesBR5100 Installation and TroubleshootingRégis OngolloNo ratings yet

- 810586Document11 pages810586John MaldonadoNo ratings yet

- Preventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)Document25 pagesPreventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)mukesh ojhaNo ratings yet

- Pump Manual Update June 2018Document8 pagesPump Manual Update June 2018Abdallah AbdelrehimNo ratings yet

- Liquid EndsDocument4 pagesLiquid EndsShesharam ChouhanNo ratings yet

- Pump Le400 Roy LmiDocument4 pagesPump Le400 Roy LmiShesharam ChouhanNo ratings yet

- Trip TankDocument23 pagesTrip TankNaser Khan100% (1)

- IWCF EquipmentDocument50 pagesIWCF Equipmentsalem123gmaalNo ratings yet

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 pagesBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Boiler Mountings PDFDocument47 pagesBoiler Mountings PDFZohaib Alam100% (1)

- Owner'S Manual: Artmolds' Pressure PotDocument4 pagesOwner'S Manual: Artmolds' Pressure PotAnonymous Wyb8Y1No ratings yet

- Manual A ArgonautDocument14 pagesManual A ArgonautalexmancillaNo ratings yet

- Condeser Tubing and Removal, DocDocument6 pagesCondeser Tubing and Removal, Docdebu1985No ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- BOILERDocument2 pagesBOILERLagon AinNo ratings yet

- 34.27Ft Catwalk Reach: Customer ApprovalDocument1 page34.27Ft Catwalk Reach: Customer ApprovalDavid OrtegaNo ratings yet

- Oil & Gas Drilling User's GuideDocument16 pagesOil & Gas Drilling User's GuideDavid OrtegaNo ratings yet

- Union Drill Line Service Guidelines Product BulletinDocument2 pagesUnion Drill Line Service Guidelines Product BulletinDavid OrtegaNo ratings yet

- Wireline Stripping OperationsDocument5 pagesWireline Stripping OperationsDavid OrtegaNo ratings yet

- Subject: Ba-Ba 41 14-3/4" Stuck Pipe Incident July 12 2,001Document2 pagesSubject: Ba-Ba 41 14-3/4" Stuck Pipe Incident July 12 2,001David OrtegaNo ratings yet

- Stuck Pipe/Tight Pipe Incident Reporting Form: Page 1 of 2Document2 pagesStuck Pipe/Tight Pipe Incident Reporting Form: Page 1 of 2David OrtegaNo ratings yet

- Acid Pill Contigency NSE1Document7 pagesAcid Pill Contigency NSE1David OrtegaNo ratings yet

- SS09302015NOV101 (15 BBL Land)Document5 pagesSS09302015NOV101 (15 BBL Land)David OrtegaNo ratings yet

- Catalog For Clamps For Clamp Hub ConnectionsDocument17 pagesCatalog For Clamps For Clamp Hub ConnectionsDavid OrtegaNo ratings yet

- All-Track Service: AT-80HD Operator ManualDocument28 pagesAll-Track Service: AT-80HD Operator ManualDavid OrtegaNo ratings yet

- Cameron H2 Part NumbersDocument1 pageCameron H2 Part NumbersDavid OrtegaNo ratings yet

- SONDIR Peternakan BogorDocument5 pagesSONDIR Peternakan BogoralfiNo ratings yet

- HiltiDocument10 pagesHiltiAnonymous YDwBCtsNo ratings yet

- STEEL2Document524 pagesSTEEL2Abdul HadhiNo ratings yet

- Evaporator and Condensers TypesDocument4 pagesEvaporator and Condensers TypesOwais SiddiquiNo ratings yet

- Ma - MaintenanceDocument36 pagesMa - MaintenanceBRILLIANCE AUTO LIFENo ratings yet

- Es1003 Lathe Drawtube SpecificationsDocument7 pagesEs1003 Lathe Drawtube SpecificationsEMS Metalworking MachineryNo ratings yet

- Actiflow: Using Openfoam Technology For Aeroconsulting: Delft, November 4 2010Document25 pagesActiflow: Using Openfoam Technology For Aeroconsulting: Delft, November 4 2010Sattar Al-JabairNo ratings yet

- Annex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyDocument3 pagesAnnex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyAndré MartinsNo ratings yet

- OperationManual For Horizontal PumpDocument20 pagesOperationManual For Horizontal PumpSergio PonceNo ratings yet

- Scedule Maintenance KBN Mill 2020Document9 pagesScedule Maintenance KBN Mill 2020slamet supriyadiNo ratings yet

- Automatic Tyre Pressure Inflation SystemDocument3 pagesAutomatic Tyre Pressure Inflation SystemKarthick MNo ratings yet

- Class: CC (Advanced) Waves Test No. 27 (Single Correct Choice Type)Document4 pagesClass: CC (Advanced) Waves Test No. 27 (Single Correct Choice Type)umang dhandhaniaNo ratings yet

- Variable Valve Timing For A Camless Stepping Valve Engine Variable Valve Timing For A Camless Stepping Valve EngineDocument8 pagesVariable Valve Timing For A Camless Stepping Valve Engine Variable Valve Timing For A Camless Stepping Valve EngineLéo CardozoNo ratings yet

- Canter 3 5 FE84DDocument4 pagesCanter 3 5 FE84DShahul Hameed Jawahar100% (2)

- p1k Pde2577tcuk 052009 PDFDocument20 pagesp1k Pde2577tcuk 052009 PDFwalid8311No ratings yet

- Noise and Vibration From Railway Vehicles: David Thompson and Chris JonesDocument47 pagesNoise and Vibration From Railway Vehicles: David Thompson and Chris JonesVICTOR HUGO ORTIZ MOSCOSONo ratings yet

- Further Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionDocument7 pagesFurther Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionMark SternNo ratings yet

- CDS23061 GPA M1 PackageDocument10 pagesCDS23061 GPA M1 PackageDavid SvídaNo ratings yet

- Structural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionDocument20 pagesStructural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionTJPRC PublicationsNo ratings yet

- Specification Part 2 Specs - 5 Pipe WorksDocument37 pagesSpecification Part 2 Specs - 5 Pipe WorksMaulidNo ratings yet

- Linatex Premium Rubber Spec SheetDocument1 pageLinatex Premium Rubber Spec Sheet_Asylum_No ratings yet

- Exhaust Gas Piping Specification-5ADocument2 pagesExhaust Gas Piping Specification-5AbhaskarNo ratings yet