0% found this document useful (0 votes)

64 views4 pagesPROJECT PROGRESS Sample

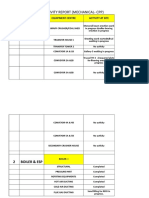

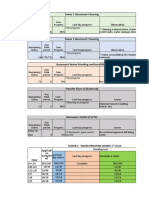

The document provides a progress update on various repair and construction projects related to damaged piping. It details the status of projects to repair flow lines for wells Ezz#1, Ezz#2, Ezz#10, Ezz#11, Ezz#17, and Ezz#18, as well as construction of new flow and injection lines. The progress ranges from 80% to 100% complete across the various sub-projects as of January 2020.

Uploaded by

Majdi JerbiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

64 views4 pagesPROJECT PROGRESS Sample

The document provides a progress update on various repair and construction projects related to damaged piping. It details the status of projects to repair flow lines for wells Ezz#1, Ezz#2, Ezz#10, Ezz#11, Ezz#17, and Ezz#18, as well as construction of new flow and injection lines. The progress ranges from 80% to 100% complete across the various sub-projects as of January 2020.

Uploaded by

Majdi JerbiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd