Professional Documents

Culture Documents

Daily Progress Report - 120220

Uploaded by

Md Firdaus Hj MashorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Progress Report - 120220

Uploaded by

Md Firdaus Hj MashorCopyright:

Available Formats

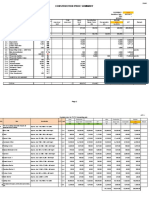

DAILY PROGRESS REPORT (124)

ONSHORE HYDROCARBON RECOVERY FROM SLUDGE AT T-7103 WINDOW : 05/09/19 TO 17/02/20

Reviewed by Progress Report as of : 12/02/2020

HSES DAILY RESULT HYDROCARBON RECOVERED WEATHER

1) HSE STATISTICS 2) MANPOWER 4) a. DAILY RESULT FOR HYDROCARBON RECOVERED 5) WEATHER FORECAST

PREVIOUS PREVIOUS DAILY (M3) ACCUMULATIVE (M3)

DESCRIPTION TODAY ACCUMULATIVE No DESCRIPTION TODAY ACCUMULATIVE

CUMULATIVE CUMULATIVE

Holding Tank 0.00 16.00

Lost Time Injury (LTI) 1 Project Manager 1723 12 1735 SLUDGE Isotank 0.00 0.00

DAY SHIFT Sunny

Restricted Work Case (RWC) 2 Operation Manager 1713 12 1725 Retention Tank 0.00 24.90

Medical Treatment Case (MTC) 3 Process Manager 1583 12 1595 HC line 0.00 1.00

IN PROCESS NIGHT SHIFT NIL

PROCESS

First Aid Case (FAC) 4 Mechanical Engineer 1743 12 1755 Water line -1.80 243.50

Near Miss 5 Planner 1453 12 1465 HC (Good oil) 0.00 0.70

Fire/Explosion Cases 6 QA/QC 1553 12 1565 HC (Wax) 0.00 347.40

Property Damages 7 Safety Site Supervisor 1928 12 1940 Water (Sche B) 0.00 0.00

RECOVERY Water (MRCSB) 123.00

Oil Spillage 8 Supervisor 2551 36 2587 0.00 HOUR LOSS DUE TO WEATHER

ZETO Rules Violation 3 0 3 9 Work Leader 3424 36 3460 SW (Sediment) 0.00 18.50

Audit 10 PTW Coordinator 1353 12 1365 SW (Froth) 6.00 8.00

YESTERDAY LOSS

Behaviour Safety (BS) 134 3 137 11 Forklift Driver 671 36 707 TOTAL 4.20 783.00

TOTAL 137 3 140 12 CSE 5894 144 6038 BALANCE TO RECOVER 285.00 36.00% Rain Hour 0

13 Semi Skill 37796 120 37916

TOTAL MANHOURS 33504 936 63853 Actual Work Hour Loss 0

b. NUMBER OF DRUMS

No. ITEMS DAILY (Drums) ACC. (Drums) REMARKS

DESCRIPTION PREVIOUS TODAY 3) HSE HIGHLIGHT ACCUMULATIVE LOSS

ACCUMULATIVE

CUMULATIVE 1 WAX 0 1838

Safe manhours 33504 936 63853 2 GOOD OIL 0.70 m3 0.70 m3 Rain Hour 33

1. All team reminded to clear and take immediate action for 3 SEDIMENTS 0 15

any spillage even spillage happened inside bund. 4 FROTH 36 48 Actual Work Hour Loss 33

2. Worker involved WAH are reminded to comply to

requirements.

3. Workers are reminded to take care of full/ half mask

respiratory hygien. TOTAL 36 1901

4. Do not included the domestic wastes to mixed wastes

drum.

COMPLETED ACTIVITIES 12/02/20

DAY SHIFT

No Type Plan Actual

1 Cold Work 5 5

2 Hot Work

3 CSE

Total PTW 5 5

DESLUDGING (m3) IN PROCESS (m3) RECOVERY (m3)

ITEM TANK TANK NO. TOTAL VOLUME (M3) 12-Feb ITEM TANK TANK NO. TOTAL VOLUME (M3) 12-Feb COMPOSITION PRODUCT PARAMETER TOTAL VOLUME (M3) 12-Feb

T-001 A 12.00 0.00 Accumulator Tank 14.00 3.00 Schedule B COD <200 ppm 0.00 0.00

Holding Tank

T-001 B 13.00 16.00 Tricanter 0.20 0.00 WATER Treated COD < 2000 ppm 99.00 123.00

TOTAL 16.00 T-005 A 27.00 27.00 TOTAL 99.00 123.00

T-001 C1 24.00 0.00 T-005 B 27.00 17.00 Wax 179.70 347.40

Equalizing Tank

T-001 C2 20.00 0.00 T-005 C 12.00 3.00 HC Good oil BSW <0.5 % 0.00 0.70

T-001 C3 23.00 0.00 T-005 D 8.00 22.80 TOTAL 179.70 348.10

ISO tank T-001 C4 20.00 0.00 TOTAL 74.00 69.80 Sediment 2.00 18.50

T-001 C5 23.00 0.00 MPU 10.00 3.00 SW Froth 0.00 8.00

T-001 C6 23.00 0.00 T-007 A 13.50 0.00 TOTAL 2.00 26.50

SLUDGE T-001 C7 21.00 0.00 T-007 B 15.00 9.30 TOTAL RECOVERY 280.70 496.90

T-001 C8 20.00 0.00 Waste Water Holding T-007 C 3.00 21.00 BALANCE TO PROCESS 462.40 285.40

TOTAL 0.00 Tank T-007 D 19.00 11.00

T-002 A 2.00 0.00 WATER LINE T-007 E 27.00 27.00 WATER 49.40%

T-002 B 2.00 0.00 T-007 F 3.00 20.40 PROCESS & RECOVERY RATIO HC 47.00%

T-002 C 16.20 0.00 TOTAL 80.5 88.70 SW 3.60%

Retention Tank

T-002 D 15.90 0.00

T-002 E 2.00 5.00

18.00 12 ISO tanks T-007 G1 - T-007G12 0.00 76.10

T-002 F 2.00

TOTAL 23.00

Hose (est) 1.90 1.90 TOTAL 0.00 76.10

TOTAL SLUDGE 241.00 40.90 IBC- Froth 9.30 0.00

IBC & Drums - Water 1.20

TEMPORARY 3.00

STORAGE Drums - Good oil 0.20

0.00

Hose (est) 0.70 0.70

Other activities for 12/2/20 :- TOTAL 191.70 2.10

1. Waterline flushing and cleaning in progress. T-004 A 0.00

10.50

2. Water discharge volume - 2 m3.

WAX RECOVERY TANK T-004 B 15.50 0.00

3. Manual dispense of good oil from wax drums :

Total volume of good oil dispensed from drums as of 12/2/20 - 30 L from 40 drums HYDROCARBON T-004 C 0.00 0.00

6/1 16 Drums (10 L) LINE TOTAL 26.00 0.00

7/1 24 Drums (20 L) Hose 1.00 1.00

TOTAL 27.00 1.00

ACCUMULATIVE TOTAL : 651 L from 1238 drums (71 repeated drums)

TOTAL IN PROCESS 218.70 244.50

NIGHT SHIFT

No Type Plan Actual No Type Plan Actual

1 Cold Work 1 Cold Work

2 Hot Work 2 Hot Work

3 CSE 3 CSE

Total PTW Total PTW

Completed Activites Status Issue/Matter Arise Planned Activities Status Issue/Matter Arise

24 m3 water discharged

1. Extended hours for water discharge activity from Waste Water Holding Tank T-007F

S - CURVE / PROGRESS

CURRENT STATUS PREVIOUS STATUS MILESTONES

CURRENT PLANNED (%) 96.66 PREVIOUS PLANNED (%) 96.30

CURRENT ACTUAL (%) 68.25 PREVIOUS ACTUAL (%) 68.20

VARIANCE (%) -28.41 VARIANCE (%) -28.10

VARIANCE EQUIVALENT (DAY) VARIANCE EQUIVALENT (DAY)

TARGET ON SCHEDULE BY

Day 2/10 of tank setup

S-curve of Hydrocarbon Recovery at T-7103

Progress percentage for the tanks setup :-

100.00% Plan % 52.58%

Actual % 25.90%

80.00% Variance -26.68

60.00%

40.00%

Cum Plan % Cum Actual %

20.00%

0.00%

19-Dec-

22-Dec-

25-Dec-

28-Dec-

31-Dec-

07-Dec-

10-Dec-

13-Dec-

16-Dec-

03-Jan-

06-Jan-

09-Jan-

12-Jan-

15-Jan-

18-Jan-

21-Jan-

24-Jan-

27-Jan-

30-Jan-

02-Feb-

05-Feb-

08-Feb-

11-Feb-

14-Feb-

17-Feb-

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

19

19

19

19

19

19

19

19

19

WEEKLY WORKING PLAN MANPOWER LOADING

Tank setup activities :

Yesterday

DATE ACTIVITIES

Day Shift Plan Actual

13/01/20 Implementing the isotanks for holding sludge strategy Manpower 51

13/01/20 To complete desludging before 18/1/20

Night Shift Plan Actual

16/01/20 Mitigation on desludging

Manpower

19/01/2020 Start demob equipment at tank bund T-7103 for handover to PBEM

20/01/2020 To start recovery of 459.6 m3 activity for 10 days

28/01/2020 To start flushing and cleaning the waterline

Today

01/02/2020 Manual dispense the good oil from wax drum

Day Shift Plan Actual

11/02/2020 To discharge water to tank dyke (untreated)

Manpower 51

19/02/2020 To start demob equipment from T-7103

Night Shift Plan Actual

Manpower

DELAY FACTOR & MITIGATION PLAN

Delay factor :

1) The readiness of the electrical from Sparco.

2) The new finding of the inside manhole (ladder).

3) Bad weather ; rain, storm until 22nd December 2019 for 33 hours accumulative.

4) The internal cameras need to take out for troubleshoot.

5) Desludging works stop due to the bottleneck at the Tricanter, MPU and Wax Processing Tank.

6) Desludging stop due to downstream bottleneck as all 4 Equalizing tank full

7) Stop work at 7pm (9/1/20) as extended and night PTW not approved due to HSE incident of staff collapsed

8) Stop work by MRCSB HSE untill all required PPE for Benzene and Mercury available

9) The preparation for fit-test for all manpowers and PMT.

10) The preparation of the additional reqiured PPE (Full mask and half mask that depends on the zoning).

11) 3 blackout days due to new PPE requirement at site due to hazard identified by IH team (benzene and mercury exceed PEL)

12) Bottleneck at Equalizing Tank as Tricanter cannot operate due to MPU down.

13) Due to the high cP value of sludge

Mitigation plan :

1) To arrange the manpower allocation in rainy and sunny time.

2) To revised the schedule and extent until the agreed time frame.

3) To complete the remaining other than the critical items yet waiting the critical one to completed.

4) To seek the MRCSB electrical team for advice on camera troubleshooting.

5) To get 240m3 additional sludge container/tank for continuous desludging to overcome the downstream bottleneck.

6) To continue on optimizing the process parameter not to compromise quality of both HC and water

7) Wax drummed at higher volume and meeting only 15%-25% water content

8) To recycle 50% or 50m³ or 2 out of 4 Equalizing Tank to T-7103 to allow space to receive untreated water from Tricanter to clear bottleneck

Prepared by,

NURUL FARHANA IZZATY BT SAKIM BADRUL HISHAM

Planner Project Manager

TiME MARINE SERVICES SDN BHD TiME MARINE SERVICES SDN BHD

You might also like

- Multihazard Risk Atlas of Maldives: Climate and Geophysical Hazards—Volume IIFrom EverandMultihazard Risk Atlas of Maldives: Climate and Geophysical Hazards—Volume IINo ratings yet

- IGT Game King 044 Video CTRL Board Schematics (757-044-10)Document24 pagesIGT Game King 044 Video CTRL Board Schematics (757-044-10)Turko Alejandro50% (2)

- JHBDPL Project (Phase - Ii, Section - 2A) : Combined Daily Progress Report (Laying Works of Main Line & Spur Lines)Document2 pagesJHBDPL Project (Phase - Ii, Section - 2A) : Combined Daily Progress Report (Laying Works of Main Line & Spur Lines)Gururaj P KundapurNo ratings yet

- Scope Completed Scope Completed Scope Completed Scope CompletedDocument11 pagesScope Completed Scope Completed Scope Completed Scope Completedsaravan1891No ratings yet

- MTP132-Daily Report 28 June 2023Document4 pagesMTP132-Daily Report 28 June 2023Bambang ArdiansyahNo ratings yet

- Mechanical Design Calculation (Static) For HSD Storage Tanks (Tank Size: 24.0 M Dia X 13.50 M HT)Document20 pagesMechanical Design Calculation (Static) For HSD Storage Tanks (Tank Size: 24.0 M Dia X 13.50 M HT)Sangramkeshari Beja100% (1)

- Key Elements To Revive The Mature Handil FieldDocument12 pagesKey Elements To Revive The Mature Handil Fieldb mNo ratings yet

- Khu - 11 - G - Bac20 - Ea - 004 - 2Document18 pagesKhu - 11 - G - Bac20 - Ea - 004 - 2Shafiqul IslamNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- Seq Plan - MV CAPTAIN D - Barranquilla - 28000Document1 pageSeq Plan - MV CAPTAIN D - Barranquilla - 28000Roberto VillegasNo ratings yet

- MTP132-Daily Report 27 June 2023Document4 pagesMTP132-Daily Report 27 June 2023Bambang ArdiansyahNo ratings yet

- Concrete Pouring LogDocument537 pagesConcrete Pouring Logakram husseinNo ratings yet

- Industrial Water Pump 6600-P-02BDocument25 pagesIndustrial Water Pump 6600-P-02BJp RaoNo ratings yet

- ABB - Cause & Effect DiagramDocument7 pagesABB - Cause & Effect DiagramWaseem SiddiqueNo ratings yet

- 6 Monthly HSE REPORT June 2011 NEWDocument1 page6 Monthly HSE REPORT June 2011 NEWNiraNo ratings yet

- Daily Report Site Tms - 160922 Night ShiftDocument3 pagesDaily Report Site Tms - 160922 Night Shifttrisya22No ratings yet

- Supplier Document Cover Page: Greater Enfield Subsea EPCIDocument29 pagesSupplier Document Cover Page: Greater Enfield Subsea EPCIKarthikeyan GanesanNo ratings yet

- Drainage Layout (020 040) RHSDocument21 pagesDrainage Layout (020 040) RHSAnirban DeshmukhNo ratings yet

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 pagesReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriNo ratings yet

- Sur-Pid-00-009-00 - (As-Built)Document1 pageSur-Pid-00-009-00 - (As-Built)sriram sNo ratings yet

- EN-769-PL-1816 - Rev B - Journey Management PlanDocument47 pagesEN-769-PL-1816 - Rev B - Journey Management PlanSkinhead TvNo ratings yet

- Drawing List of Rockwork: Patimban Port Development Project (I) Package 1 - Terminal ConstructionDocument15 pagesDrawing List of Rockwork: Patimban Port Development Project (I) Package 1 - Terminal Constructionbim patimbanNo ratings yet

- HIHO WHEEL - FACTORY - Daily Report 220912 RESANE MUROSDocument4 pagesHIHO WHEEL - FACTORY - Daily Report 220912 RESANE MUROSManuel Jesus Cetina PachecoNo ratings yet

- From (KM) To (KM) Unit Approved/ Not Approved Side Section (MCW/SR) Tcs No: Inspection Time EPC Representetive IE Representetive Location Si: No: Rfi No: Boq No: Inspection Date Description of WorkDocument1 pageFrom (KM) To (KM) Unit Approved/ Not Approved Side Section (MCW/SR) Tcs No: Inspection Time EPC Representetive IE Representetive Location Si: No: Rfi No: Boq No: Inspection Date Description of WorkAyan DuttaNo ratings yet

- Typical Details of GantryDocument1 pageTypical Details of Gantrythesprings2chsltdNo ratings yet

- TKG 002 Uha CDR Cea 002 - 3Document2 pagesTKG 002 Uha CDR Cea 002 - 3HARSHARANNo ratings yet

- Amdl - Robokon Daily: Ağa KeklikDocument2 pagesAmdl - Robokon Daily: Ağa KeklikademgsNo ratings yet

- MWPS Daily Activity Report 28 August2011Document1 pageMWPS Daily Activity Report 28 August2011Francis RayeNo ratings yet

- Cover 5W1H SheetDocument1 pageCover 5W1H Sheetpurchase.electricals2No ratings yet

- DPR Kozhikode STP N Network Zone B1 OptDocument842 pagesDPR Kozhikode STP N Network Zone B1 OptB D WNo ratings yet

- 23-Position Connector Shown, See Table Below For Alternate DimensionsDocument2 pages23-Position Connector Shown, See Table Below For Alternate DimensionsАндрей9No ratings yet

- Daily Report: Epc Isbl and Osbl For The RDMP Project RDMP Ru V - Balikpapan RDMP Balikpapan JoDocument22 pagesDaily Report: Epc Isbl and Osbl For The RDMP Project RDMP Ru V - Balikpapan RDMP Balikpapan JoMuhamad BagusNo ratings yet

- Visakhapatnam Raipur Visakhapatnam RaipurDocument2 pagesVisakhapatnam Raipur Visakhapatnam RaipurmanupriyaNo ratings yet

- QHM 2017-18Document16 pagesQHM 2017-18Ravi Kiran MNo ratings yet

- Lars Wadsr #13 NewDocument2 pagesLars Wadsr #13 NewLarsen Verlo De CastroNo ratings yet

- MTP132-Daily Report 12 July 2023Document8 pagesMTP132-Daily Report 12 July 2023Bambang ArdiansyahNo ratings yet

- HYDRAULIC Original - From TechnipDocument27 pagesHYDRAULIC Original - From TechnipGoutam GiriNo ratings yet

- Target 8 VDMR 11.11.2022 - JVCMGDocument1 pageTarget 8 VDMR 11.11.2022 - JVCMGRO PEVNo ratings yet

- (UPDATE) Repot Week I - IV GIANYAR (1 - 31 Oktober 2021)Document116 pages(UPDATE) Repot Week I - IV GIANYAR (1 - 31 Oktober 2021)Kresna SuputraNo ratings yet

- DWR 03-23Document1 pageDWR 03-23Nicon Famarin FameronagNo ratings yet

- Construction Price Summary: USD 17C0308BDocument2 pagesConstruction Price Summary: USD 17C0308BCCSNo ratings yet

- Daily Operations Report 1903 - 26-10-2014Document16 pagesDaily Operations Report 1903 - 26-10-2014macielNo ratings yet

- MTP132-Daily Report 23 July 2023Document7 pagesMTP132-Daily Report 23 July 2023Bambang ArdiansyahNo ratings yet

- P4-211-03-H-26006-00022 - 2 - A1 Cople 79006Document3 pagesP4-211-03-H-26006-00022 - 2 - A1 Cople 79006Alce CdpemexNo ratings yet

- Mitsubishi Heavy Industries, LTD.: Plan RecordDocument2 pagesMitsubishi Heavy Industries, LTD.: Plan RecordJin HernNo ratings yet

- Dgs 1510-002 Rev 1 Scada Operating PhilosophyDocument12 pagesDgs 1510-002 Rev 1 Scada Operating PhilosophysiddharthangandhiNo ratings yet

- Proyek Pembangunan Instalasi Perpipaan Air Limbah Zona UtaraDocument1 pageProyek Pembangunan Instalasi Perpipaan Air Limbah Zona Utararahmat nuryadiNo ratings yet

- TKG 002 Uha CDR Cea 003 - 3Document2 pagesTKG 002 Uha CDR Cea 003 - 3HARSHARANNo ratings yet

- Supplier Document Cover Page: Greater Enfield Subsea EPCIDocument16 pagesSupplier Document Cover Page: Greater Enfield Subsea EPCIKarthikeyan GanesanNo ratings yet

- Khu - 11 - G - Bac20 - DS - 001 - 2Document2 pagesKhu - 11 - G - Bac20 - DS - 001 - 2Shafiqul IslamNo ratings yet

- Anchor Base Plate and Bolt Sizing Calculation Narmada Rev. 4-chkDocument7 pagesAnchor Base Plate and Bolt Sizing Calculation Narmada Rev. 4-chkSamwailNo ratings yet

- Drawings of Switchyard Bay Marshalling KioskDocument74 pagesDrawings of Switchyard Bay Marshalling KioskNihar SenapatiNo ratings yet

- Boiler Room - HVAC LayoutDocument11 pagesBoiler Room - HVAC LayoutZameer BashqNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- ABL-KRDCL-WCP1-MISC-JN-01 - 3of3 Rev ADocument1 pageABL-KRDCL-WCP1-MISC-JN-01 - 3of3 Rev AJayavardhanNo ratings yet

- Herunefer W 13Document3 pagesHerunefer W 13Islam AtifNo ratings yet

- No. Despription Amount (USD) Remarks Architechture: Total #REF!Document63 pagesNo. Despription Amount (USD) Remarks Architechture: Total #REF!tianhe zhaoNo ratings yet

- Eps EkDocument22 pagesEps EkvienergresourcesNo ratings yet

- Dashboard DPR BBP 07 Desember 2023Document1 pageDashboard DPR BBP 07 Desember 2023vorda buaymadangNo ratings yet

- Hac Schedule: Contract No.: PGB/HO/19/2016/0009Document4 pagesHac Schedule: Contract No.: PGB/HO/19/2016/0009Naveen RaoNo ratings yet

- r2 BERSINAR Cafe Ledger Book OCT 2018Document8 pagesr2 BERSINAR Cafe Ledger Book OCT 2018Md Firdaus Hj MashorNo ratings yet

- Front End Loader Specification For PDDocument2 pagesFront End Loader Specification For PDMd Firdaus Hj MashorNo ratings yet

- Tik Tok - Case StudyDocument5 pagesTik Tok - Case StudyMd Firdaus Hj MashorNo ratings yet

- Cake Yard Area For PDDocument1 pageCake Yard Area For PDMd Firdaus Hj MashorNo ratings yet

- Screenshot 2020-01-24 at 7.17.47 PM PDFDocument3 pagesScreenshot 2020-01-24 at 7.17.47 PM PDFMd Firdaus Hj MashorNo ratings yet

- Western Food MenuDocument1 pageWestern Food MenuMd Firdaus Hj MashorNo ratings yet

- Results - FinalDocument13 pagesResults - FinalMd Firdaus Hj MashorNo ratings yet

- Job Method Statement For (To Renovate Sinar Haemodialysis Jasin Melaka)Document17 pagesJob Method Statement For (To Renovate Sinar Haemodialysis Jasin Melaka)Md Firdaus Hj MashorNo ratings yet

- Ferro TechDocument4 pagesFerro TechMd Firdaus Hj MashorNo ratings yet

- Pencemaran Dan RemediasiDocument68 pagesPencemaran Dan RemediasiaquintizaNo ratings yet

- Mike 11 RefDocument536 pagesMike 11 RefBình PiNo ratings yet

- Geothermal Application Experiences in TurkeyDocument8 pagesGeothermal Application Experiences in TurkeyJessica IvanaNo ratings yet

- MVJ20ENV59 - MODULE 2 (FinalDocument120 pagesMVJ20ENV59 - MODULE 2 (FinalHamsaNo ratings yet

- Benzerra 2012Document11 pagesBenzerra 2012MiftakhaeriahNo ratings yet

- Brick and Block CatalogueDocument7 pagesBrick and Block CatalogueDe Vedant SharmaNo ratings yet

- Top Mcqs On: Indian ClimateDocument67 pagesTop Mcqs On: Indian ClimateBhat AakeebNo ratings yet

- Sustainable Urban Drainage-Green RoofDocument36 pagesSustainable Urban Drainage-Green RoofGabriel WongNo ratings yet

- RESOLUTIONDocument4 pagesRESOLUTIONOCLEO T. ORPIO100% (2)

- Intro To Water Management and IrrigationDocument22 pagesIntro To Water Management and IrrigationJulius Jimenez100% (2)

- CHAPTER 8 - WATER AND FLARE SYSTEM Edit MOSH 211220Document27 pagesCHAPTER 8 - WATER AND FLARE SYSTEM Edit MOSH 211220subash1111111No ratings yet

- The Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Document6 pagesThe Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Kasim ButkovicNo ratings yet

- ANDRITZ Separation - Your Separation SpecialistDocument24 pagesANDRITZ Separation - Your Separation SpecialistMostafaNo ratings yet

- Case Study (Mula-Mutha) Pune RiverfrontDocument15 pagesCase Study (Mula-Mutha) Pune RiverfrontVishnu KasturiNo ratings yet

- 5 Social Studied SA-2 Q.P 20-21Document1 page5 Social Studied SA-2 Q.P 20-21Creative StreamNo ratings yet

- Is 10262-2019Document44 pagesIs 10262-2019ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ96% (141)

- By Date RRLDocument4 pagesBy Date RRLRei GiananNo ratings yet

- Aquamarine Water Treatment SW PlantsDocument5 pagesAquamarine Water Treatment SW PlantsZainalNo ratings yet

- Agron 609Document14 pagesAgron 609Chandrakanth KhatravathNo ratings yet

- Name Location Sample Physcial CHEMICAL (MG/L) : Water Quality Testing Physical, Chemical and MicrobacterialogicalDocument4 pagesName Location Sample Physcial CHEMICAL (MG/L) : Water Quality Testing Physical, Chemical and MicrobacterialogicalmawaaggreyNo ratings yet

- Read & Writing BDocument13 pagesRead & Writing BPenang Home TuitionNo ratings yet

- Cat - Selecao - Linha B - 50 HZ CT 656-11-17 PDFDocument101 pagesCat - Selecao - Linha B - 50 HZ CT 656-11-17 PDFAmandaNo ratings yet

- Saarrthi Sovereign Pune - 0Document1 pageSaarrthi Sovereign Pune - 0rajat charayaNo ratings yet

- Flood Disaster Management in Assam: December 2020Document6 pagesFlood Disaster Management in Assam: December 2020Krishnaa BoraNo ratings yet

- Common Property RightsDocument13 pagesCommon Property Rightsbliss luNo ratings yet

- Tehnology-B: by Gamini Rajakaruna Senior Lecturer International College of Business and Technology Sri LankaDocument142 pagesTehnology-B: by Gamini Rajakaruna Senior Lecturer International College of Business and Technology Sri LankaSachindra Kaushalya PremasiriNo ratings yet

- 3-Liquid Retaining StructuresDocument3 pages3-Liquid Retaining StructuresTabish IslamNo ratings yet

- About Organica Biotech Private LimitedDocument2 pagesAbout Organica Biotech Private Limitedacc walaNo ratings yet

- PR Reaearch WorkDocument3 pagesPR Reaearch WorkGreen ArcNo ratings yet

- Saes A 012Document36 pagesSaes A 012Michael RobinsonNo ratings yet