Professional Documents

Culture Documents

Storage guidelines for welding filler metals

Uploaded by

sampathkumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage guidelines for welding filler metals

Uploaded by

sampathkumarCopyright:

Available Formats

U.S. ALLOY CO.

Filler Metal dba Washington Alloy

7010-G Reames Rd.

Storage / Shelf Life Charlotte, NC 28216

www.weldingwire.com

Quality Management System

in accordance with

ISO 9001

Cert # 05-R0925

PRODUCT, PACKING AND STORAGE GUIDE

WASHINGTON ALLOY SOLDERS, WIRE, RODS shall be free of moisture & oxides, with a uniform

composition and color that is smooth and free from injurious defects. Welding, Brazing and Solder alloys

are manufactured and packaged in a manner to prevent contamination. Proper storage of these products is

essential to ensure the alloys are free of any contamination. Pallets or unopened carton should remain sealed

until they are ready for use and should be protected from rapid change in temperature & humidity, rain,

snow or water in any form. Storage of product should be in a dry well ventilated area and placed stored in

less than 60% humidity and temperatures of 50° to 90° F should be protected and have a shelf life for a

minimum of 1 year. To protect products from contaminants allow products to warm up to ambient temperate

prior to opening package and use clean gloves when handling filler metals.

In some cases alloys can be stored for many or unlimited years and may require the surface oxides removed

from the outside surface of the filler. In the case of cored alloys the ends should be sealed or crimped to

ensure safety and protection of unused core. Also it may be helpful to cut off a small amount of the filler to

make sure you have 100% of the core at the start or to remove any foreign containment.

Other Opened Filler Metals

Spooled wire or rods on welding equipment or on job sites should be coved to avoid any contamination and

if it is not is service for an extended time, should be sealed tightly, returned to its original packaging and

stored properly as stated earlier or placed in a humidity controlled cabinet with the proper identification.

6010, 6011 electrodes and all other non-coated electrodes should be returned sealed tightly to the carton or

placed in a humidity controlled cabinet with the proper identification. Other coated and cored wires may

require storage in an oven at certain temperatures.

EAST COAST GULF COAST WEST COAST

7010-G Reames Rd 4755 Alpine Drive #100A 8535 Utica Ave

Charlotte, NC 28216 Stafford, TX 77477 Rancho Cucamonga, CA 91730

Tel (888) 522-8296 Tel (877) 711-9274 Tel (800)830-9033

Fax (704)598-6673 Fax (281)313-6332 Fax (909)291-4586 2-2010 DC

Warehouse Distribution Center – Dayton, Ohio Head Office – Puyallup, Washington

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your own

evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO. assumes

no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- 6010Document1 page6010mateo zamoraNo ratings yet

- U.S. Army Improvised Munitions HandbookFrom EverandU.S. Army Improvised Munitions HandbookRating: 3 out of 5 stars3/5 (4)

- 7018 Wa - Alloy 2Document1 page7018 Wa - Alloy 2Khaled A MarashliNo ratings yet

- Family Handyman Whole House Storage & OrganizingFrom EverandFamily Handyman Whole House Storage & OrganizingFamily HandymanNo ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalFrom EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalRating: 4.5 out of 5 stars4.5/5 (3)

- 8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Document1 page8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Ehab AhmedNo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- 9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216m s sankar raoNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- Touch Up and Repair of Galvanized SteelDocument4 pagesTouch Up and Repair of Galvanized SteelGabriel HerreraNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- Alpha Aqualine 6000 WRC TB SM479-8 English 20171228Document3 pagesAlpha Aqualine 6000 WRC TB SM479-8 English 20171228Barbara AlejoNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- Are Lock Washers Available in Different Strengths and What ASTM Specification(s) Cover Them?Document3 pagesAre Lock Washers Available in Different Strengths and What ASTM Specification(s) Cover Them?Manoj SahuNo ratings yet

- Stanwade Tanks 2010Document52 pagesStanwade Tanks 2010OscarNo ratings yet

- Stratco Selection Use and MaintenanceDocument6 pagesStratco Selection Use and MaintenanceAmjad PervazNo ratings yet

- USA 316L-17 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 316L-17 Coated Electrode: Alloy Description and ApplicationKaliyaperumal DhanapalNo ratings yet

- ESPECIFICACIÓN DE E317lLT1-1Document1 pageESPECIFICACIÓN DE E317lLT1-1Nj Nelson JavierNo ratings yet

- Ficha Tecnica Adaptador Lasco SCH 80Document2 pagesFicha Tecnica Adaptador Lasco SCH 80Mafe CastilloNo ratings yet

- Company Profile Updated 2Document271 pagesCompany Profile Updated 2lerry rualloNo ratings yet

- Company Profile Updated 2Document271 pagesCompany Profile Updated 2lerry rualloNo ratings yet

- 2015-04-30 - Moneysaver - Lewis-Clark EditionDocument16 pages2015-04-30 - Moneysaver - Lewis-Clark EditionDavid ArndtNo ratings yet

- SellosDocument2 pagesSellosFreddy0523No ratings yet

- Kingpin Mounting InstructionsDocument1 pageKingpin Mounting InstructionsPablo César Suárez NogalesNo ratings yet

- Assembly SolutionsDocument14 pagesAssembly SolutionsAhmed Emad AhmedNo ratings yet

- Saw Storage HandlingDocument1 pageSaw Storage HandlingDave MulvihillNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6060 T5 T595 144Document2 pagesAalco Metals LTD Aluminium Alloy 6060 T5 T595 144Gabriel PatileaNo ratings yet

- S-Weld Clean Gel TDSDocument3 pagesS-Weld Clean Gel TDSMustafa SharadahNo ratings yet

- Company Profile Updated 2 WITH CONTACTDocument267 pagesCompany Profile Updated 2 WITH CONTACTMarc MacNo ratings yet

- Company Profile Updated 2Document271 pagesCompany Profile Updated 2christian benedict LomibaoNo ratings yet

- IPBD MANUAL-Info Catagory PDFDocument26 pagesIPBD MANUAL-Info Catagory PDFTirthankar DattaNo ratings yet

- General Product Information: Rocktech S (Slab) SeriesDocument4 pagesGeneral Product Information: Rocktech S (Slab) SeriesPhan LongNo ratings yet

- Touch Up and Repair of Galvanized SteelDocument5 pagesTouch Up and Repair of Galvanized SteelkhuzafaNo ratings yet

- Webcat Westcoast Wire Rope& RiggingDocument157 pagesWebcat Westcoast Wire Rope& RiggingAboZaidNo ratings yet

- Lead 6Document259 pagesLead 6Gene Gerona Jardeleza100% (1)

- 230 PlateDocument1 page230 Platenavin jollyNo ratings yet

- Low Melt AlloysDocument1 pageLow Melt AlloyssonytechoNo ratings yet

- Wegmanvalves Slade Catalog 2016 WebDocument76 pagesWegmanvalves Slade Catalog 2016 WebGonzalo Alonso QuintanaNo ratings yet

- S-Weld Passivator GelDocument3 pagesS-Weld Passivator Gelananth rajanNo ratings yet

- Know Your SteelDocument111 pagesKnow Your SteelJohn TsolomitisNo ratings yet

- 9 Rules For Successful Weld Repair of High Strength SteelDocument4 pages9 Rules For Successful Weld Repair of High Strength SteelRodolfoMarínNo ratings yet

- Effect of Chemical Elements in SteelDocument3 pagesEffect of Chemical Elements in SteelHossein Hosseini RadNo ratings yet

- 11 - Forged Gate Valves RPC Procedure PDFDocument52 pages11 - Forged Gate Valves RPC Procedure PDFtilakthakar1No ratings yet

- 2016-08-04 - Moneysaver - Lewis-Clark EditionDocument16 pages2016-08-04 - Moneysaver - Lewis-Clark EditionDavid ArndtNo ratings yet

- Trail/Beaver Valley/Rossland Pennywise May 14, 2013Document64 pagesTrail/Beaver Valley/Rossland Pennywise May 14, 2013Pennywise PublishingNo ratings yet

- Hansen ARS Report 2018Document84 pagesHansen ARS Report 2018Emad Ahmed KhanNo ratings yet

- Iaea Certificate of Competent Authority Special Form Radioactive MaterialsDocument7 pagesIaea Certificate of Competent Authority Special Form Radioactive MaterialsJosé Hernández BarrientosNo ratings yet

- Bucyrus DetailsDocument15 pagesBucyrus Detailscharanpalsingh95100% (2)

- SDSMetal Jacketing PolicyDocument1 pageSDSMetal Jacketing Policyabdelkader benabdallahNo ratings yet

- Sorel Summer Boots: Jgi'eDocument48 pagesSorel Summer Boots: Jgi'ePennywise PublishingNo ratings yet

- Battery Warranty CertificateDocument2 pagesBattery Warranty Certificatefaisal_yb100% (2)

- 4340 Chrome-Moly Welding Wire and Rod Spec SheetDocument1 page4340 Chrome-Moly Welding Wire and Rod Spec SheetPankaj KumbhareNo ratings yet

- Technical Data Sheet: Baysilone Fluid of Oh 702EDocument3 pagesTechnical Data Sheet: Baysilone Fluid of Oh 702E조주열No ratings yet

- Minimum Space Requirements PDFDocument4 pagesMinimum Space Requirements PDFAbey VettoorNo ratings yet

- Resume of Prram64Document2 pagesResume of Prram64api-25351400No ratings yet

- RTR (Reinforced Thermosetting Resin Pipe) Work PresentationDocument15 pagesRTR (Reinforced Thermosetting Resin Pipe) Work Presentationqamar qateebNo ratings yet

- 01.4TB.041 Plating of Contact Surfaces in Switchgear and Circuit BreakersDocument1 page01.4TB.041 Plating of Contact Surfaces in Switchgear and Circuit Breakerschandraippa2No ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- PIpe To Pipe Joint DetailsDocument1 pagePIpe To Pipe Joint DetailssampathkumarNo ratings yet

- Painter Qualification StandardDocument3 pagesPainter Qualification StandardsampathkumarNo ratings yet

- TCB Greenkote FlyerDocument2 pagesTCB Greenkote FlyersampathkumarNo ratings yet

- Super Durable Finish Coating System: AdvantagesDocument2 pagesSuper Durable Finish Coating System: AdvantagessampathkumarNo ratings yet

- Procedure For Liquid Penetrant Examination-II-YY1AST7-v 2 0Document11 pagesProcedure For Liquid Penetrant Examination-II-YY1AST7-v 2 0sampathkumarNo ratings yet

- ASME B16.5 Flanges PDFDocument50 pagesASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNo ratings yet

- Aws Qc5-91 - Standard For Certification of Welding EducatorsDocument12 pagesAws Qc5-91 - Standard For Certification of Welding Educatorscamelod555No ratings yet

- BS 970 EN8 EN9, EN19, EN24, EN36 Etc. and The Most Equivalent Is Grade 080M40 Steel in BS 970-1991.Document4 pagesBS 970 EN8 EN9, EN19, EN24, EN36 Etc. and The Most Equivalent Is Grade 080M40 Steel in BS 970-1991.ashwiniNo ratings yet

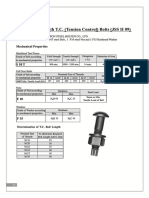

- Catelogue S10T High Strength TCBolt (JSS II 09)Document1 pageCatelogue S10T High Strength TCBolt (JSS II 09)sampathkumarNo ratings yet

- WFH Log Sheet 23.03 To 28.03Document6 pagesWFH Log Sheet 23.03 To 28.03sampathkumarNo ratings yet

- Mobile Services: Your Account Summary This Month'S ChargesDocument3 pagesMobile Services: Your Account Summary This Month'S ChargessampathkumarNo ratings yet

- Macalloy Corporate Brochure September 2018 LR PDFDocument12 pagesMacalloy Corporate Brochure September 2018 LR PDFsampathkumarNo ratings yet

- 100 KG - 400 Degc Front-Loading-Flux-Drying-Oven-ModelDocument1 page100 KG - 400 Degc Front-Loading-Flux-Drying-Oven-ModelsampathkumarNo ratings yet

- Coryel AWS CWI ExamDocument46 pagesCoryel AWS CWI Examjoehodoh100% (2)

- TCR Engineering Profile-NEW 2020Document38 pagesTCR Engineering Profile-NEW 2020sampathkumarNo ratings yet

- Kobelco 7150 PDFDocument11 pagesKobelco 7150 PDFSaktiawan Arief ChandraDwi Panusantara100% (2)

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationRatnakumarChittoorNo ratings yet

- WFH-LOGDocument6 pagesWFH-LOGsampathkumarNo ratings yet

- Conformances: Type: NeutralDocument2 pagesConformances: Type: NeutralsampathkumarNo ratings yet

- Material Handling Storage PDFDocument25 pagesMaterial Handling Storage PDFAshis Das0% (1)

- Ceramic Weld Backing TapesDocument4 pagesCeramic Weld Backing TapessampathkumarNo ratings yet

- UT ProcedureDocument12 pagesUT Proceduresampathkumar100% (1)

- Jis G 3106 PDFDocument38 pagesJis G 3106 PDFTùng Lê Đinh50% (2)

- Dezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bDocument12 pagesDezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bOleg ShkolnikNo ratings yet

- Catalogue Indium CorporationDocument5 pagesCatalogue Indium CorporationPhilippe GuillemetNo ratings yet

- Harga Satuan Dasar Upah dan MaterialDocument576 pagesHarga Satuan Dasar Upah dan MaterialKHOIRUSNo ratings yet

- Valve: From Wikipedia, The Free EncyclopediaDocument12 pagesValve: From Wikipedia, The Free EncyclopediaAVINASHRAJNo ratings yet

- Sand and Aggregate Royalty SheetDocument3 pagesSand and Aggregate Royalty Sheetsohail3007No ratings yet

- Doors Windows Glazing GlossaryDocument64 pagesDoors Windows Glazing GlossaryacetopposNo ratings yet

- Typical Textures, Part 2: Thermomechanical Processing (TMP) of BCC MetalsDocument32 pagesTypical Textures, Part 2: Thermomechanical Processing (TMP) of BCC MetalsSally Sedano AmayaNo ratings yet

- Carbonation of Flyash ConcretDocument6 pagesCarbonation of Flyash ConcretAnshul SoniNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Annexure-10 Dropper SpecificationDocument1 pageAnnexure-10 Dropper SpecificationAnkit AgarwalNo ratings yet

- TuflineLinedBallValve 332148 2-07Document12 pagesTuflineLinedBallValve 332148 2-07Marcio NegraoNo ratings yet

- International Thermocouple Color CodesDocument2 pagesInternational Thermocouple Color CodesNAYEEMNo ratings yet

- Practical Application of Intensive Quenching Process for Steel PartsDocument8 pagesPractical Application of Intensive Quenching Process for Steel PartsDouglas RodriguesNo ratings yet

- Recovery Recrystallization Grain GrowthDocument13 pagesRecovery Recrystallization Grain GrowthsivaenotesNo ratings yet

- AER Chem Compat ChartDocument10 pagesAER Chem Compat ChartJosh WhiteNo ratings yet

- Gate HouseDocument1 pageGate HouseJoseph Mwangi WambuguNo ratings yet

- Hiarc Products EngDocument16 pagesHiarc Products EngnbjshaaNo ratings yet

- Civil Fiber Reinforced Concrete ReportDocument12 pagesCivil Fiber Reinforced Concrete ReportPANKAJ KUMAR BTechNo ratings yet

- Heresite Trifold Brochure WebDocument6 pagesHeresite Trifold Brochure Webray griffitNo ratings yet

- Visiomer - Hema P Products - Flyer - December 2020 - v2Document3 pagesVisiomer - Hema P Products - Flyer - December 2020 - v2sasidharkanthetiNo ratings yet

- NDT Defects RecordsDocument1 pageNDT Defects RecordsAnonymous OEUUoKHYRNo ratings yet

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Document38 pagesNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoNo ratings yet

- Full-Size Wood Toy: Kenworth Dump TruckDocument36 pagesFull-Size Wood Toy: Kenworth Dump Truckhulusi67100% (4)

- Chapter 1 - What Is SteelDocument22 pagesChapter 1 - What Is SteelH C DunejaNo ratings yet

- Available DTD Documents in PDFDocument11 pagesAvailable DTD Documents in PDFdsgaviation100% (2)

- An17822a PDFDocument18 pagesAn17822a PDFhectorsevillaNo ratings yet

- How To Make Electrum Magicum For A Magic MirrorDocument5 pagesHow To Make Electrum Magicum For A Magic Mirrorqbl777No ratings yet

- Kingston Model 115: Kingston Safety & Relief ValvesDocument2 pagesKingston Model 115: Kingston Safety & Relief ValvesAntonio SerranoNo ratings yet

- PETA SEBARAN REKOMENDASI PENGANGKUTAN LIMBAH B3Document118 pagesPETA SEBARAN REKOMENDASI PENGANGKUTAN LIMBAH B3Dimas Dwi Ivandri 2No ratings yet

- AWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFDocument30 pagesAWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFahmedabdelaziz851647No ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)