Professional Documents

Culture Documents

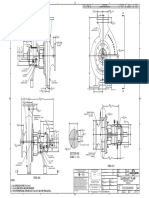

Parts and Assemblies G.A., Isometric View, Bom, Notes, 1 Cylinder Vertical Oscilating Steam Engine

Uploaded by

Orlando Rojas PintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parts and Assemblies G.A., Isometric View, Bom, Notes, 1 Cylinder Vertical Oscilating Steam Engine

Uploaded by

Orlando Rojas PintoCopyright:

Available Formats

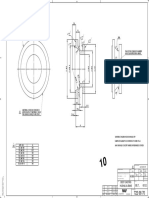

OTHER ABBREVIATIONS MATERIAL ABBREVIATIONS: M3-8PL 4 8PF 03 BRS 10 10

DP = DEEP ALU = ALUMINIUM 4

4

5°

7

PF = PRESS FIT BRS = BRASS

BRZ = BRONZE OR GUNMETAL

10

PCD = PITCH CIRCLE DIAMETER R4

2.5

15

R5

11

(BRZ/GM) 4

4-2PL

RM = REAM 4 11 11

HEX = HEXACON, 6SIDED CI = CAST IRON

2.5

CP = COMPRESSED CU = COPPER 4 22 4

3 3

50 1.97

KNL = KNURLED GRA = GRAPHITE 3-4PL 7 7

11

R4

20

MS = MILD STEEL/BRIGHT MILD STEEL

18

CSK = COUNTERSINK

PL = PLACES S/S = SILVER STEEL OR STAINLESS 13 13

R4

7

SA-n-xxx = SUB ASSEMBL-n-xxx STEEL BRS

SPS = SPRING STEEL 4 16 8 16 4 R3

7

PEEK= POLYETHER ETHER KETONE

01

6mm THICK

4 11 11 4 R3

02 ANGLE 10x10x1 2mm THICK

45

SYN = SYNTHETIC MATERIAL SUCH AS MS/ALU

VETON, NYLON, TEFLON OR RUBBER 10 10

IN GENERAL SYNTHETIC 2.2 2.2 4 5

MATERIALS SOULD BE ABLE TO 2.2 2.2 8

70 2.76 8PF

WITHSTAND THE HEAT AND

5.3

PRESSURE(S) APPLIED TO THEM. BRS

50

nnn/nnn MEANS THAT EITHER BRS BRZ

15

2.5

MATERIAL CAN BE USED

2.5

20

NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS 3 3

20

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE CSK

15

AND SHAFT TOLERANCES.

7

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE 3

APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE. 05

4RM 3 1.5 4 11 11 4

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS 06 04

TO BE METRIC FINE (MF) TUBE 4x3 OPPOSITE FACE EQUAL 6 2mm THICK

4RM

8PF

6 6

12

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BRS

BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE. M3 4 3

15 07 CU

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT 12 3

SHALL BE SILVER/HARD SOLDERED. 9 08 SOLDER 2 5

1

102 4.02

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP),

1.7

5

10

UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN COMPRESSED R2

R2

2

10

28

12

STATE.

4

12

2

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED

AND PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH MS

GLUE, EPOXY RESIN, OR SOLDER. 2

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD 1.7 0.5

10

35

BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE MATERIAL SUCH 4

M3

AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

3CF

8

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND S/S

THE MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER. 13

10

11

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MS 32

M4

14

MODEL MAKER. 15 4 10

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS BRS 10RM 4CF

ENTIRELY LEFT UP TO THE BUILDER.

15

```

M4

M4

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES,

8

WERE DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING. R6 70

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT 9 9

HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE SPS

RECTIFIED. 0.5 4.5 16.5

2PF BRS MS

2 12 4mm CHAMFER

QTY. PART NUMBER 16

25

4CF

1 WOBLER-01-BASE PLATE 16 COILS

=12=

4 WOBLER-02-ANGLE BRACKET MS

1 WOBLER-03-BEARING PLATE 10CF 1mm PILOT HOLES

1 WOBLER-04-CYLINDER SUPPORT PLATE 7 18 23

2 WOBLER-05-MAIN BEARING 15 40

1 WOBLER-06-PORT BLOCK 36

15

2 WOBLER-07-CONNECTOR PIPE 26 6 6

25

1 WOBLER-08-CYLINDER BASE 8 M3

1 WOBLER-09-CYLINDER A

1 WOBLER-10-CRANK PLATE BRZ

4

1 WOBLER-11-CRANK PIN

1 WOBLER-12-CRANK SHAFT 2 2 13 17

26

1 WOBLER-13-FLYWHEEL MS 18

17PCD

M3

1 WOBLER-14-FLYWHEEL SCREW

4

8

WOOD

1 WOBLER-15-CYLINDER PIVOT SHAFT

1 WOBLER-16-PIVOT SHAFT SPRING 4

3RM

4

15

4 4

1 WOBLER-17-PISTON

1 WOBLER-18-WOOD BASE

2 WOBLER-M2.5 NUT 14 8 3

45°

5

2 WOBLER-M2.5x10 C-SINK SCREW A 45° SECTION A-A 3

4 WOBLER-M3 NUT 2

12 WOBLER-M3x6 PAN HEAD SCREW

1 WOBLER-M4 NUT

2 WOBLER-M4x15-WOOD SCREW

NOTES: ORIGINAL DESIGN OBTAINED FROM THE INTERNET DESIGN WAS ALL IN FRENCH. DESIGNER AND DRAFTER UNKNOWN

TITLE DRAWING CONTENTS PROJECT No 09A-18-00 PROJECTION

MODEL SCALE: 1:1

1 CYLINDER VERTICAL OSCILATING STEAM ENGINE G.A., ISOMETRIC VIEW, BOM, NOTES, JDW DRAUGHTING SERVICES

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

MAY 2006

DATE

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

PARTS AND ASSEMBLIES

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 02 A3 No: WOBLER-01

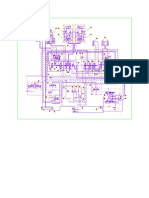

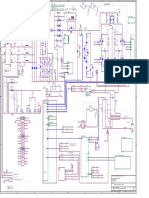

07

07

06

04

05

03

05

02

02

02

02 18

SA-101

09 08

15 13

11 12

10

SA-102 SA-103

NOTES: ORIGINAL DESIGN OBTAINED FROM THE INTERNET DESIGN WAS ALL IN FRENCH. DESIGNER AND DRAFTER UNKNOWN

TITLE DRAWING CONTENTS PROJECT No 09A-18-00 PROJECTION

MODEL SCALE: 1:1

1 CYLINDER VERTICAL OSCILATING STEAM ENGINE PARTS AND ASSEMBLIES, RENDERED JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110. MAY 2006 J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

PICTURE NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 02 OF 02 A3 No: WOBLER-02

You might also like

- ASTM A450-A450M-96aDocument10 pagesASTM A450-A450M-96aNadhiraNo ratings yet

- Ose 2 Vertical Ose Beginner 2 Svoste 00 OkDocument1 pageOse 2 Vertical Ose Beginner 2 Svoste 00 OkAnonymous MMLzZjbyNo ratings yet

- Automotive Acronyms and AbbreviationsDocument20 pagesAutomotive Acronyms and Abbreviationssampapa33% (3)

- Automotive Acronyms and AbbreviationsDocument20 pagesAutomotive Acronyms and Abbreviationssampapa33% (3)

- Automotive Acronyms and AbbreviationsDocument20 pagesAutomotive Acronyms and Abbreviationssampapa33% (3)

- 1chseaw JDW Complet PDFDocument4 pages1chseaw JDW Complet PDFOrlando Rojas PintoNo ratings yet

- Ose 12 Twin Ose Boxer OkDocument2 pagesOse 12 Twin Ose Boxer OkOrlando Rojas PintoNo ratings yet

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- Single Cylinder Oscillating Steam EngineDocument1 pageSingle Cylinder Oscillating Steam EngineNiruban Santiagu Fernando100% (1)

- Bicylindre en V PDFDocument5 pagesBicylindre en V PDFOrlando Rojas PintoNo ratings yet

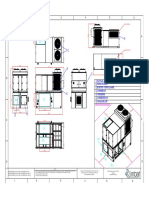

- Atlas Copco Desiccant Dryers: BD 100, BD 150, BD 185, BD 250, BD 300Document38 pagesAtlas Copco Desiccant Dryers: BD 100, BD 150, BD 185, BD 250, BD 300FEDOR100% (4)

- Boiler Erection PDFDocument44 pagesBoiler Erection PDFShankar Jha100% (1)

- Eurostandard PDFDocument91 pagesEurostandard PDFHAMKOBAREZNo ratings yet

- Stainless Steel Product HandbookDocument98 pagesStainless Steel Product HandbookAndry Setyawan100% (1)

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- BS3974 - 3 - Pipe SupportsDocument44 pagesBS3974 - 3 - Pipe SupportsAmrit Pal Singh100% (1)

- Simple Vertical Engine 1Document4 pagesSimple Vertical Engine 1Orlando Rojas PintoNo ratings yet

- Classification of Heat ExchangerDocument19 pagesClassification of Heat ExchangerSarayu GowdaNo ratings yet

- Ethio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringDocument11 pagesEthio Plastic Industry (Epi) : Jimma University Jimma Institute of Technology School of Chemical EngineeringHiwot Wubetu100% (1)

- Hot Tapping Calculations PDFDocument17 pagesHot Tapping Calculations PDFMSNo ratings yet

- AS2885.1 Issue Paper Nov2006 GRP PipeDocument48 pagesAS2885.1 Issue Paper Nov2006 GRP Piperjehanathan7098No ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

- Piping Vibration AssessmentDocument8 pagesPiping Vibration AssessmentMn HjhjjNo ratings yet

- Ms 1 SSCHDocument2 pagesMs 1 SSCHRobert MorrisNo ratings yet

- Oscillating V-Shaped General Arrangement & Parts Steam Engine TwinDocument1 pageOscillating V-Shaped General Arrangement & Parts Steam Engine TwinDîñ Êsh Chä ÛhâñNo ratings yet

- Minor Design FLOOR PLANS 1Document1 pageMinor Design FLOOR PLANS 1siddarth reddyNo ratings yet

- Minor Design FLOOR PLANS 2Document1 pageMinor Design FLOOR PLANS 2siddarth reddyNo ratings yet

- BombaDocument1 pageBombaBruno Gomes SoaresNo ratings yet

- Supply Air Beam Premax: Contact, Overview, Index Guideline Heating and Cooling Plexus Professor / Professor PlusDocument30 pagesSupply Air Beam Premax: Contact, Overview, Index Guideline Heating and Cooling Plexus Professor / Professor Plusportocala12No ratings yet

- DiseñoDocument1 pageDiseñosantiago carvajalNo ratings yet

- Royal Sentosa KD 3 (20221026) Alt. 3Document1 pageRoyal Sentosa KD 3 (20221026) Alt. 3Oga SuprayogaNo ratings yet

- Royal Sentosa KD 3 (20221026)Document2 pagesRoyal Sentosa KD 3 (20221026)Oga SuprayogaNo ratings yet

- Minor Design SECTIONSDocument1 pageMinor Design SECTIONSsiddarth reddyNo ratings yet

- Simple Periodic TableDocument1 pageSimple Periodic TableluxvisNo ratings yet

- Omnitronic Edp-700 Class DDocument3 pagesOmnitronic Edp-700 Class Dosman saraçNo ratings yet

- Lspic (8) - 36V 07 01 08Document1 pageLspic (8) - 36V 07 01 08luispacheNo ratings yet

- G.A. Bom, Isometric Views, Parts and Assemblies 6 Cylinder "Elbow" Steam EngineDocument1 pageG.A. Bom, Isometric Views, Parts and Assemblies 6 Cylinder "Elbow" Steam EngineErrol NietoNo ratings yet

- Analisis Instalasi Air BersihDocument8 pagesAnalisis Instalasi Air BersihHidayatullah STNo ratings yet

- Schematic - 24 Hour Clock - 2023-12-16Document1 pageSchematic - 24 Hour Clock - 2023-12-16ianguiebNo ratings yet

- So Do Nguyen Ly Mach Do DuongDocument2 pagesSo Do Nguyen Ly Mach Do DuongLhthang KtvNo ratings yet

- Eq Public PDFDocument15 pagesEq Public PDFmoisesNo ratings yet

- SOLO - Rainy November Ballad Guitar Backing Track Jam in BDocument2 pagesSOLO - Rainy November Ballad Guitar Backing Track Jam in BSam BNo ratings yet

- Schematic 1383834Document1 pageSchematic 1383834MarcarraroNo ratings yet

- PCM 2.0l 4 de 5Document2 pagesPCM 2.0l 4 de 5Felix VelasquezNo ratings yet

- Steel - Lack of FusionDocument6 pagesSteel - Lack of FusionJose ContrerasNo ratings yet

- Awelco Micro AWM5680-AA SCHDocument1 pageAwelco Micro AWM5680-AA SCHGrigore ManNo ratings yet

- Plot Demarcation WF 11 StampedDocument1 pagePlot Demarcation WF 11 StampedSiva PrasathNo ratings yet

- Plot Demarcation-Wf-11-StampedDocument1 pagePlot Demarcation-Wf-11-StampedSiva PrasathNo ratings yet

- STD-QD-009E RT Form Report ASME B31.3Document2 pagesSTD-QD-009E RT Form Report ASME B31.3michaelNo ratings yet

- ABRSM Innocence - Friedrich BurgmüllerDocument2 pagesABRSM Innocence - Friedrich BurgmüllertonykeysNo ratings yet

- TcvcoDocument1 pageTcvcoPedroVaNo ratings yet

- 134 Tudung SajiDocument1 page134 Tudung SajizulNo ratings yet

- Layout Workshop PBDocument1 pageLayout Workshop PBHudoyo ChannelNo ratings yet

- 320BL Hidraulico PDFDocument1 page320BL Hidraulico PDFElber Luis Chavez BarriosNo ratings yet

- Pci204h - Pci Power - Mp3000Document1 pagePci204h - Pci Power - Mp3000AdeniltonNo ratings yet

- Periodic TableDocument1 pagePeriodic TableMichael ChenNo ratings yet

- Survey LOT 8 (#14) PROWSE STREET, WEST PERTHDocument1 pageSurvey LOT 8 (#14) PROWSE STREET, WEST PERTHCarent AyuNo ratings yet

- Hidraulic SchematicDocument2 pagesHidraulic SchematicHamilton Miranda100% (1)

- 112-Pigeon Hole RFIDDocument1 page112-Pigeon Hole RFIDzul100% (1)

- B-B (1: 1.6) B C: Lks Jawa Timur 2018 Lomba Kompetensi Siswa SMKN 1 Gepol 1 / 1Document1 pageB-B (1: 1.6) B C: Lks Jawa Timur 2018 Lomba Kompetensi Siswa SMKN 1 Gepol 1 / 1Mãüç ÃfîfNo ratings yet

- Ibanez Ph99 SchematicDocument1 pageIbanez Ph99 SchematicOwen KalauNo ratings yet

- PM Gpio: Warning !!!Document8 pagesPM Gpio: Warning !!!DeathKXNo ratings yet

- Vox - AD100VTH SMDocument7 pagesVox - AD100VTH SMADAMO PATRICIO O'BYRNE RIVERANo ratings yet

- OIS J308 SD 5B LS HR 5 1502 R00 Play Area Details Sheet 02 SignedDocument1 pageOIS J308 SD 5B LS HR 5 1502 R00 Play Area Details Sheet 02 Signedmirza aliNo ratings yet

- MLT199TL: 1.5mH 750uhDocument3 pagesMLT199TL: 1.5mH 750uhAziz KamelNo ratings yet

- Falta de PenetracionDocument32 pagesFalta de PenetracionJose ContrerasNo ratings yet

- 8-Case - 06 (Hse - 302-352-402) - Sf+mixed+ng - Customer DrawingDocument1 page8-Case - 06 (Hse - 302-352-402) - Sf+mixed+ng - Customer DrawinggeorgianconstantinNo ratings yet

- Body Casting Hushalva Ämne: Linköping SwedenDocument1 pageBody Casting Hushalva Ämne: Linköping SwedenKishan SolankeNo ratings yet

- POSTER HolsetHX35Document1 pagePOSTER HolsetHX35Juan Carlos Constanzo PincheiraNo ratings yet

- JP 1 2 3 4 5 A1 A2 A3 A4Document18 pagesJP 1 2 3 4 5 A1 A2 A3 A4Juan carlos hernandez rubioNo ratings yet

- Phong Nha Resort - 180628Document14 pagesPhong Nha Resort - 180628Nam BuiNo ratings yet

- MonkDocument1 pageMonkAnthonny FelipeNo ratings yet

- PP.28 PP.340: JOB Desindo JOB DesindoDocument1 pagePP.28 PP.340: JOB Desindo JOB DesindoadearifiantoNo ratings yet

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemREMZONANo ratings yet

- Dedicated Most Humbly To The Right-Hand Little Finger: 120 Handstücke Für Angehende Klavierspieler, Book 2, No 46Document1 pageDedicated Most Humbly To The Right-Hand Little Finger: 120 Handstücke Für Angehende Klavierspieler, Book 2, No 46Constantin Aurel-HermanNo ratings yet

- WORKSHOPSDocument1 pageWORKSHOPSApurva MahadikNo ratings yet

- Minuet Bach ViolinDocument1 pageMinuet Bach ViolinQueijoNo ratings yet

- Steel - Worm Holes (Pipes)Document32 pagesSteel - Worm Holes (Pipes)Jose ContrerasNo ratings yet

- Super Famicom Development WikiDocument1 pageSuper Famicom Development WikiJohn CentenoNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- A3 Tcose Sheet 01 PDFDocument1 pageA3 Tcose Sheet 01 PDFसचिन पटेलNo ratings yet

- A3 Tcose Sheet 01 PDFDocument1 pageA3 Tcose Sheet 01 PDFसचिन पटेलNo ratings yet

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocument2 pages4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoNo ratings yet

- Vertical Twin Compound Bob Middleton 09 03 10 PDFDocument12 pagesVertical Twin Compound Bob Middleton 09 03 10 PDFOrlando Rojas PintoNo ratings yet

- Ose 53cyl Etoile Ose 3 Sisters OkDocument2 pagesOse 53cyl Etoile Ose 3 Sisters OkJulio Almanza100% (1)

- General Arrangement, Bom, Isometric View, Part and Ass'S 4-Cylinder Boxer Type Single Acting Oscillating Steam EngineDocument2 pagesGeneral Arrangement, Bom, Isometric View, Part and Ass'S 4-Cylinder Boxer Type Single Acting Oscillating Steam EngineOrlando Rojas PintoNo ratings yet

- 2cwse PDFDocument2 pages2cwse PDFOrlando Rojas PintoNo ratings yet

- 1 Manual A-CDocument68 pages1 Manual A-COrlando Rojas PintoNo ratings yet

- CPVC SpecificationDocument2 pagesCPVC Specificationviralnanobio_4150420No ratings yet

- SEC 15490 Swimming PoolsDocument8 pagesSEC 15490 Swimming Poolsjaianit89No ratings yet

- Astm D2918-99 (2012)Document4 pagesAstm D2918-99 (2012)Alex LeungNo ratings yet

- DB60/DB60L Control Valve Assemblies Parts Catalog: Rev. D (1/22/10) - enDocument37 pagesDB60/DB60L Control Valve Assemblies Parts Catalog: Rev. D (1/22/10) - enJosé Júnior Dias EleutérioNo ratings yet

- Is 10611 1983Document16 pagesIs 10611 1983Rakesh RanjanNo ratings yet

- Rotomolding Manholes - 2333Document20 pagesRotomolding Manholes - 2333mujeebscribdNo ratings yet

- PC01040301 0318-0219 en Viking ProductCatalogue Gas CO2HPDocument228 pagesPC01040301 0318-0219 en Viking ProductCatalogue Gas CO2HPgobilgobilNo ratings yet

- Annex 3..3 - Electrical WorksDocument24 pagesAnnex 3..3 - Electrical WorksEdgardo ZipaganNo ratings yet

- 2016CompositeList Web 20Document1 page2016CompositeList Web 20AnuranjanNo ratings yet

- Heavy Duty Post Shore:: Increase The Load, Decrease The CostDocument2 pagesHeavy Duty Post Shore:: Increase The Load, Decrease The CostJonathan ThomasNo ratings yet

- Pipe (Fluid Conveyance)Document10 pagesPipe (Fluid Conveyance)siswoutNo ratings yet

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument19 pagesBritish Standard: A Single Copy of This British Standard Is Licensed ToRonnie1478100% (1)

- Front Attachment: Section 4Document40 pagesFront Attachment: Section 4suriantoNo ratings yet

- Identifying and Recording Piping Locations: 6.1.10.6 Localized RepairsDocument10 pagesIdentifying and Recording Piping Locations: 6.1.10.6 Localized RepairsEphrem GizachewNo ratings yet

- Nautic Steels Catalogue 2014b PDFDocument79 pagesNautic Steels Catalogue 2014b PDFmeet_sachin-1No ratings yet

- 80 Series Mda Installation ManualDocument31 pages80 Series Mda Installation ManualAnonymous qNM765ILNo ratings yet

- HSS Column Load TablesDocument127 pagesHSS Column Load Tablesclam2014No ratings yet