Professional Documents

Culture Documents

Aeration Time For ETO in Plastics PDF

Aeration Time For ETO in Plastics PDF

Uploaded by

instrumed_globalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeration Time For ETO in Plastics PDF

Aeration Time For ETO in Plastics PDF

Uploaded by

instrumed_globalCopyright:

Available Formats

(28) G . A. Misraky, A. V. Beran, and E. J.

Prescott, Anesthesi- ACKNOWLEDGMENTS AND ADDRESSES

198(1963).

O ~ J X V24.

.

(29) A. Goldstein. L. Aronow. and M. Kalman. in “Principles of Received March 3, 1972, from the Departmen/ of Plrarmocology,

Drug Action.” Harper and Row, New York, N. Y., 1969. p. 726. Scliool of Plrurmary, Temple Unirersiiy, Pliiludelphia, PA 19140

Accepted for publication June 6. 1973.

(30) T. H. lngalls and F. J. Curley. N. OrgI. J. Mrd., 257, 1121 Presented to the Pharmacology and Toxicology Section, APHA

(1957). Academy of Pharmaceutical Sciences, Houston meeting, April

(31) C. T. Grabowski. Sciewe, 134, 1359(1961). 1972.

(32) Z. K . S t e m h a and J. Hodr, Biol. Neoiiot.. 10, 303(1966). Abstracted in part from a thesis submitted by P. A. Arcuri to

(33) D. A. Hutchins and K. J. Rogers, Brir. J. Plltrrmncol., 39, 9 Temple University in partial fulfillment of the Doctor of Philosophy

(1970). degree requirements.

(34) M. J. Ettinger and A. Gero, Arch. / u / . Plmrmncodyn. ‘flier., The authors thank Dr. Robert S. Thompson for his advice and

164,96( 1966). assistance in the radio-sodium transfer aspect of this study.

(35) A. Huggett. F. L. Warren, and N. V. Warren, J. Physiol., * Temple University Summer Fellowship Recipient 1968--1970.

113, 258(1951). A To whom inquiries should be directed.

Residual Ethylene Oxide in

Gas-Sterilized Medical-Grade Silicones

J. D. WHITE*. and T. J. BRADLEYt

ethanol) which is formed in the presence of chloride ions

Abstract [_I Re<idual gas was extracted from ethylene oxide-treated (1 2).

1

silicone sheets by high vacuum distillation, and the residue sub- Medical-grade silicones are widely used in tissue

sequently was analyxd hy GLC. To indicate the necessary aera-

tion time of the materials before they can be considered safe implants and can be successfully sterilized both by

to use, the desorption characteristics of ethylene oxide in three types conventional methods and by ethylene oxide. With the

of the silicone polymer were studied. Very rapid desorption of the latter method, there is uncertainty concerning the reten-

gas to low residual levels was observcd i n the two nonreinforced tion time of the gas, together with the possibility of

silicone rubbers examined: medical-grade silicone sheeting and a

medical-grade elastomer. The third material, Dacron-reinforced cytotoxic reaction products. Thcse considerations

silicone sheeting, lost the gas at a considerably slower rate, after an prompted this study.

initial rapid drop. due to retention by the Dacron reinforcement.

Keyphrases u Silicone sheets. medical grade -absorption and TIIEORY

diffusion of ethylene oxide after gas sterilization 0 Ethylene oxide

gas sterilization--absorption and ditfusion from medical-grade If there is a uniform distribution of a dissolved gas in a thin slab

silicone sheets n Sterilization with ethylenc oxide -absorption and of material and the surfaces are suddenly exposed to i e r o

ditrusion from medical-grade silicone sheets partial pressure of the gas and maintained at that. the gas

begins to clear from the material. I t can he shown ( 3 ) that. after

an initial period during which the mean gas concentration in the

medium decreases by 10 207::. the concentration at all points

During the last couple of decades, there has been an decreases exponentially with the same half-time:

ever incrcasing trend to utilize synthetic rubber and

plastics in medical instruments and equipment as well

as i n permanent or semipermanent implants and

prostheses. Because many synthetic materials are heat

labile, conventional dry heat or autoclaving processes where:

have becn substituted by low temperature sterilization Ti I = half-time (sec.)

methods, L = thickness of material (cm.)

One such method is ethylene oxide gaseous steriliza- D = diffusion coefficient (cm.*sec-l) xonstant for a given gas,

temperature, and material

tion, and its relative merits have already been well

documented. However, one serious disadvantage of Thus, if the total amount of dissolved gas can be calculated as a

sterilization with this gas is that ethylene oxide remains function of time, the diffusion coefficient can be deduced from the

slope of the exponential (which indicates the time taken for the

in the material, and its presencc in a polymeric device concentration of dissolved gas to decrease by half) and the thickness

can prcsent potential toxicological problems if the gas is of the medium; repeating the experiment with a different thickness

rclcased to tissue. Only in recent years, with the increas- of the material provides a check on the value.

ing use of GLC. has it been discovered that various The TI;? of Eq. 1 is also a measure of the rate of diffusion iiiro

the material.

types of polymeric materials may contain reaction Tahle I shows the diffusion coefficient of ethylene oxide i n several

products of ethylene oxide other than ethylene glycol, plastics at 23”. Knowledge of the diffusion coefficient of ethylene

such as the highly toxic ethylene chlorohydrin (2-chloro- oxide in a particular material a t room temperature should permit

1634 0Journnl of Plmrmuceuiicul Sciprires

Table I-Diffusion Coefficient of Ethylene Oxide in Polyethylene,

Polypropylene, and Polybutylene at 23

s i l i c o n e membrane

Density, Diffusion Coefficient,

Polymer g. cm.-8 cm.* sec.-I

Polyethylene 0.913 6.17 x Teflon 0 rings

Polyethylene 0.917 3.52 x

Polyethylene 0.930 1.83 X 10-

Polyethylene 0.963 1.30 x 10-8 s t a i n l e s s s t e e l body

Polypropylene 0.904 0.44 x

1.09 x

-

Polypropylene 0.906 10"

Polybu tylene 0.914 1.09 x 10-8

0 From data shown in Table X of ReJerence 4.

1 cm.

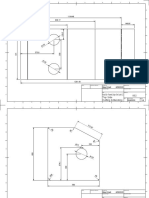

some predictions to be made concerning the minimum aeration time Figure I--Diffitsion cell (25-mm.ditrnieter niicrosyrittgefilter holder).

necessary to achieve sterile, nontoxic medical devices manufactured

from that material.

EXPERIMENTAL RESULTS AND DISCUSSION

Materials-Medical-grade silicone sheetingl, reinforced and The results obtained for the uptake of ethylene oxide by the

nonreinforced, and a room temperature vulcanizing medical-grade heat vulcanized silicone using the IR spectroscopy method and

silicone elastomer (Mastic 382)l were used. measuring the decrease in absorbance at 11.5 p are displayed in

GLC-A dual flame-ionization gas chromatograph* was used. Fig. 2. It can be seen that equilibration cccurs within a short time.

The columns were of glass tubing, 4 mm. i.d. and 1.5 m. ( 5 ft.) in By plotting the logarithm of residual ethylene oxide rersus de-

length. The packing consisted of 80 100-mesh Porapak Q J for the sorption time, the predicted straight-line graphs of Fig. 3 are

estimation of ethylene oxide and of polyethylene glycol 20,000, 107; obtained; these plots permit ready calculation of the diffusion co-

w/w, on 100-120-mesh Diatomite C 3 for the estimation of ethylene efficient of ethylene oxide in the elastomer, a room temperature

chlorohydrin. Nitrogen was used as the carrier gas at a flow rate of vulcanized silicone rubber.

35 ml. min.-l with a column oven temperature of 125", an injection The desorption curves of ethylene oxide from heat vulcanized

temperature of 175", and a detector oven temperature of 200". The silicone sheeting, nonreinforced and Dacron reinforced (Figs. 4 and

injection solvent was distilled water. Peak areas were obtained from 5 , respectively), suggest a two-stage desorption mechanism and

the product of the peak height and the width at half the peak height. require further investigation. An examination of Fig. 1 showed that

IR Determinatiorro---A double-beam grating IR spectrophotom- it was possible that a compressed film of ethylene oxide had built

eter' was employed. Standard gas cells ( I 50-ml. capacity) were used up on the surface of the heat vulcanized silicone without gas pene-

to follow the uptake of ethylene oxide by the silicone, pith measure- tration into its interior. Removal from the sterilizer would produce

ments being made at 11.5 p. Internal reflection spectroscopy was rapid loss of this surface film until only a relatively strongly held

carried out using a KRS-5 crystal (thallous-bromide-iodide com- monolayer of adsorbed ethylene oxide remained. (This would

plex)l and a beam incidence angle of 60". correspond to the almost horizontal part of the curves and the

Exposure to Ethylene Oxide-Uniformly thin sheets of the three amount agrees closely with calculation of monolayer capacity.)

types of silicone were cut into strips (each measuring approximately This possibility was investigated in two ways:

20 X 76 mm.), which were freely suspended from a glass rod by

metal clips. The strips of the different materials were then exposed

in turn to purc ethylene oxide (1200 mg. I.-') at 23" and 60%

relative humidity in the gas sterilizerKfor a sufficient time to ensure

equilibration (24 hr.). Three manual evacuation cycles were then 400

carried out to empty the sterilizer chamber of the toxic ethylene w

m

oxide, and the strips were removed from the sterilizer. This pro- a

cedure was followed by aeration a t 23' under a gentle stream of air. 2 350

m

the samples being taken at accurately timed intervals for extraction 4

and analysis. W

Extraction of Residual Ethylene Oxide-Vacuum extraction -0 300

X

techniques for residual ethylene oxide and its reaction products have 0

already been used successfully (5-7). The method employed here W

was based on distillation under high vacuum, with a distillate trap

3 250

J

cooled in liquid nitrogen. The extracted sterilant residues were t

I

then dissolved in a small volume of distilled water for quantitative t; 200

determination by GLC. LL

Dflusion Cell-A small, stainless steel diffusion cell was set up 0

using a filter', with the silicone as a membrane to form the two c

z 150

compartments of the cell (Fig. 1). A 50-ml. gar syringe full of pure

ethylene oxide was attached to one side while an empty syringe,

equipped with a sampling device, was fitted to the other compart-

ment; the pistons of the syringes allowed the contained gases to

remain a t atmospheric pressure at all times. The system was tested

underwater for leaks and found to be gas tight. Samples were with-

drawn at timed intervals from the receiver compartment and esti-

mated on the gas chromatograph.

L?--

10

---,-

20

- -

30

-,--*-----

40 50

1Dow Corning Center for Aid to Medical Research, Midland, Mich. EXPOSURE TIME, min.

* Pye Series 104.

2 Pyc Unicam, Cambridge. England. Figure 2- -Plot of amount of ethylene oxide absorbedin 1.0-mm. thick,

4 Perkin-Elmer 237. heat culcanized silicone rubber versus time exposed to the gas. The

6 "Victoria Steriliscr." The Medical Supply Association Ltd., London,

England. uolume of ethylene oxide admitted to the gas cell is shown in paren-

6 M illipore, Millipore Corp., Bedford. Mass. theses beside each curce.

Vol. 62, No. 10, October 1973 01635

10' -

10'

E :

p

E

ci

d 10'

W

d

e 5

W

z

W

-1 10'

>

I

Li

-I

c

3

e3 10

a

I T I -LT--

20

i 40 60 80

7

100

---

DESORPTION TIME, rnin.

Figure 3 Plor of log residuul efliylerie oxide irt room remperatitrr reinforced materials was calculated using Eq. 1 ; the results are

cirlcarrizrd silirorie elustomer versus ~lesorptioiirime. Key: 0, 2.0- shown in Table I I .

mm. tilick sheer; utidA, 1.0-niin. rliick sheer. Since Fig. 5 indicates that it is the Dacron reinforcement and not

the silicone that governs the desorption of ethylene oxide, it was

not possible to obtain a value for the diffusion coefficient of the gas

I . By internal reflection spectroscopy, ail IR technique used essen- in the reinforced material. However, it was noted that during the

tially to study surface phcnomena. This technique was employed in first 45 min. after removal from the sterilizer the ethylene oxide

an effort to detect the existence of a thin film of adsorbed ethylene level dropped to approximately 10% of its equilibrium value;

oxide on the silicone immediately after renioval from the sterilizer. thereafter, the half-time (i.e., the time for the concentration of dis-

No ethylene oxide was detected; however, this does not exclude the solved ethylene oxide to decrease by half) was observed to k about

possibility of a monomolecular surface layer because the sensitivity I 0 0 rnin., which would seem to imply that reinforced silicone sheeting

of the method is low. is completely safe to use after 24 hr. aeration.

2. By determining the diffusion of ethylene oxide through a mem- Although the vacuum process i s known to extract reaction prod-

brane of the siliconc in the diffusion cell. The results (Fig. 6) indicate ucts of ethylene oxide when these are present (and has been success-

that ethylene oxide is, in fact, absorhcd by heat vulcanized silicone fully used for this purpose by the authors), none was detected in any

and diffuses very rapidly through it. With this knowledge, the silicone sheeting.

shape of the desorption curves of Fig. 5 can he explained hy the An incontinence implant was used as the test piece in the final

relatively slow release of absorbed ethylene oxide from the Dacron

tricot weave reinforcement in the middle of the sheet of heat

vulcanired silicone.

Since it had been confirmed that absorption and diffusion do

occur, the diffusion coeficient of ethylene oxide in the two non- 350 i

-1

2 250 1

I

W

I

Li 200

k 1

I - I

I

.d

I

1 I----, -, -I-- I r - v r 7- 1 - r--

I-

4W

a 504 i Atwrp:lo; of ethyla-s oxidn b' rilieo rs d r m

80 160 240 320 400 480 560 40 80 120 160 ZOO 240

DESORPTION TIME, rnin. MINUTES

Figure 4-Plof of log residicul erhylerie o.tide in heat cirlruiiized Figure &Plor of amount of erliyliwe oxide wliicli has diflitsed through

silicone rithber versus clesorprioii rime. Key: 0, 1.6-ri1iti. fliick direr; u J .O-mm.thick ntembranr of Itrut rulcnriized silirone rubber versus

aiid A. 1.0-mm. thick sheet. time.

1636 Journal of Pharmaceutical Sciences

Table 11-Diffusion Coefficient of Ethylene Oxide in Silicone perature (23") was for 24 hr., after which the analysis was carried

Sheeting at 23" out; 4 p.p.m. ethylene oxide was detected.

Diffusion

Mean Coefficient, CONCLUSIOYS

Material Thickness, mm. cm.2 sec.-l

This study shows that the diffusion of ethylene oxide in non-

Room temperature 1 .o 7 . 7 x 10-6 reinforced medical-grade silicone (heat or room temperature vulcan-

vulcanized silicone 2.0 8 . 0 x 10-6 ized) is extremely rapid and that in the case of relatively simple

Heat vulcanized 1 .o 4 . 3 x lo-' shapes the minimum aeration timc required to eliminate ethylene

silicone sheeting 1.6 4.2 X oxide can be obtained from Cy. 1.

Dacron-reinforced silicone sheeting loses the gas at a considerably

slower rate due to retention by the Dacron reinforcement, and it is

study to predict minimum aeration time using the diffusion co- recommended that a minimum aeration of 24 hr. be adopted for

efficient. The body of the device, comprising the electronic com- this material.

ponents enclosed in room temperature vulcanized silicone, mea-

sured 38 mm. in diameter and was 10.8 mm. deep. Attached to it

were two 23 mm. long wire leads, surrounded by heat vulcanized REFERENCES

silicone approximately 0.7 mm. thick.

Two assumptions were made in working out the theoretical ( I ) F. Wesley, B. Rourke, and 0. Darbishire, J. Food Sci., 30,

aeration time for the level of residual ethylene oxide to fall to a low lO37( 1965).

value: (u) the body of the device could be considered as being (2) A. C. Cunliffe and F. Wesley, Brir. Med. J . . 2, 5 7 3 1967).

composed entirely of room temperature vulcanired silicone, and ( h ) (3) J. Crank, "Mathematics of DifTusion." Clarendon Press,

the silicone would contain a maximum of 13,000 p.p.m. ethylene Oxford, England, 1967, chap. 1V.

oxide after sterilization. (This value comes from the previous experi- (4) R. K. O'Leary, P1i.D. dissertation, University of Texas,

ments on this material.) Austin, Tex., 1969.

The first assumption i R not entirely unjustified since any void ( 5 ) J. E. Whitbourne, J. A. Mogenhan, and R. R. Ernst, J.

areas in the center of the electronics compartment will have attained Pharm. Sci., 58, 1024(1969).

the equilibrium concentration of ethylene oxide throughout the (6) J. A. Mogenhan, J. E. Whitbourne, and R. R. Ernst, ihid., 60,

surrounding silicone. Since the half-time for this thickness of silicone 222( 1971).

is approximately 170 min. at 23". after sterilization at 50' for 1 hr. (7) B. Warren, J . Pharni. Pliurmacol., 23, 170S( 1971).

a uniform equilibrium concentration of absorbed ethylene oxide

(1 3.000 p.p.m.) will probably not have been achieved.

Ignoring losses from the sides of the body, the time necessary to ACKNOWLEDGMENTS AND ADDRESSES

fall to 10 p.p.m. ethylene oxide was calculated using Eq. 1 and the

experimental value of the diffusion coefficient of ethylene oxide in Received February 12,1973, from the * Deparfineiir of Biochc~niistry,

room temperature vulcanized silicone at 23"; the time was found Vicroriu Ir?/iriiiary. Glasgow, G42 9 T Y , Scorluiid, and the t D r -

to be about 27 hr. parrmenr of Pharniacerrfical Techiiology, Unirersify of S!raflrclyde,

This value was tested using the implant device described. The Glasgow, GI I X W , Scorluiid.

article, wrapped in the routine paper-polypropylene pack which Accepted for publication May 24, 1973.

presents no barrier to the passage of ethylene oxide gas, was sub- The authors thank Dr. C. Weymes. Victoria Infirmary, and F. C.

jected to the normal sterilizing procedure, i.e., exposure to I200 Gillespie and D. Rowan, Department of Clinical Physics and Bio-

mg. ethylene oxide/l. for 1 hr. at 50", followed by seven automatic engineering, for their cooperation in this work.

evacuation cycles of the chamber. Aeration at the ambient tem- A To whom inquiries should be directed.

Vol. 62, No. 10, October 1973 01637

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Earth and Life Science: Quarter 1 - Module 2Document24 pagesEarth and Life Science: Quarter 1 - Module 2JT SaguinNo ratings yet

- Philips NMR and MRIDocument98 pagesPhilips NMR and MRItsram90No ratings yet

- Grade 9 Science (K To 12)Document6 pagesGrade 9 Science (K To 12)Christine DinglasanNo ratings yet

- Chapter 6 Thermodynamic Properties of FluidsDocument31 pagesChapter 6 Thermodynamic Properties of FluidsMuhammad Fawwaz100% (1)

- ENG - Electrodes - LQDocument6 pagesENG - Electrodes - LQinstrumed_globalNo ratings yet

- Form Publisher Template 24.645Document4 pagesForm Publisher Template 24.645instrumed_globalNo ratings yet

- Chehab Industrial and Medical Gases S.A.L: Beirut, Lebanon Saifi, Nahib Houbika St. Chehab BLDGDocument15 pagesChehab Industrial and Medical Gases S.A.L: Beirut, Lebanon Saifi, Nahib Houbika St. Chehab BLDGinstrumed_globalNo ratings yet

- MIT Covid 19 Face Shield Folding InstructionsDocument2 pagesMIT Covid 19 Face Shield Folding Instructionsinstrumed_globalNo ratings yet

- MOH Needs For COVID 19Document32 pagesMOH Needs For COVID 19instrumed_globalNo ratings yet

- Open Source Medical Supply Local Response Guide V1.1Document17 pagesOpen Source Medical Supply Local Response Guide V1.1instrumed_globalNo ratings yet

- Top Side 002 Aerosol Box - Parametric Design - Bent 3 Parts V2.2Document4 pagesTop Side 002 Aerosol Box - Parametric Design - Bent 3 Parts V2.2instrumed_globalNo ratings yet

- Aesculap Surgical Instruments: Cardiovascular and Thoracic Surgery Main CatalogDocument31 pagesAesculap Surgical Instruments: Cardiovascular and Thoracic Surgery Main Cataloginstrumed_globalNo ratings yet

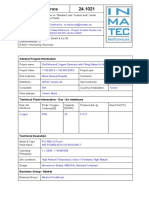

- Project Reference - 24.1021Document2 pagesProject Reference - 24.1021instrumed_globalNo ratings yet

- Beirut Explosion Impact Assessment: Status Update #1Document41 pagesBeirut Explosion Impact Assessment: Status Update #1instrumed_globalNo ratings yet

- Important Safety Notice!!!: To The Customers and Users of Heated Dräger Breathing CircuitsDocument2 pagesImportant Safety Notice!!!: To The Customers and Users of Heated Dräger Breathing Circuitsinstrumed_globalNo ratings yet

- Supercut Scissors: Aesculap Surgical InstrumentsDocument12 pagesSupercut Scissors: Aesculap Surgical Instrumentsinstrumed_globalNo ratings yet

- Permagna-Set: Aesculap Surgical InstrumentsDocument40 pagesPermagna-Set: Aesculap Surgical Instrumentsinstrumed_globalNo ratings yet

- Universal PPE Cap TopDocument1 pageUniversal PPE Cap Topinstrumed_global100% (1)

- User's Manual: GSM FAX Terminal-8848Document13 pagesUser's Manual: GSM FAX Terminal-8848instrumed_globalNo ratings yet

- Tosoh AIA Test Menu: Unit Dose Test Cup Reagent SystemDocument2 pagesTosoh AIA Test Menu: Unit Dose Test Cup Reagent Systeminstrumed_globalNo ratings yet

- Breif Report v1.1Document4 pagesBreif Report v1.1instrumed_globalNo ratings yet

- Asco Minature PSOL ValvesDocument1 pageAsco Minature PSOL Valvesinstrumed_globalNo ratings yet

- Aalco Aluminium Alloy SpecificationsDocument5 pagesAalco Aluminium Alloy SpecificationsmatthewpincottNo ratings yet

- Tamaya NC 77Document20 pagesTamaya NC 77edtatel73No ratings yet

- MEE 212 Pre - CH 3Document16 pagesMEE 212 Pre - CH 3alhassan Abdul MaleeqNo ratings yet

- 10 Physics Guess by MNA Ghumman Smart SyllabusDocument5 pages10 Physics Guess by MNA Ghumman Smart Syllabusabdullah95% (19)

- Nfpa - 286Document19 pagesNfpa - 286Yakdhan YaseenNo ratings yet

- Photoelectric Effect3Document2 pagesPhotoelectric Effect3miltonNo ratings yet

- Seminar ReportDocument35 pagesSeminar Reportnilufar100% (1)

- 29-12-19 - SR - Icon All - GTM-6 - Key & Sol's NOPASSDocument16 pages29-12-19 - SR - Icon All - GTM-6 - Key & Sol's NOPASSZomatoswiggy0% (1)

- A Computer Program Incorporating Pitzers EquationsDocument208 pagesA Computer Program Incorporating Pitzers EquationsRodrigo Alarcón VásquezNo ratings yet

- Doppler LogDocument6 pagesDoppler LogAhmed Wagdy MohmedNo ratings yet

- Renganathan Perumal CVDocument6 pagesRenganathan Perumal CVAl GHANMINo ratings yet

- Isolation and Characterization of Degradation Products of Moxidectin PDFDocument20 pagesIsolation and Characterization of Degradation Products of Moxidectin PDFAnonymous 7aE6O6No ratings yet

- A Universal Wear Law For Abrasion: Matthew T. Siniawski, Stephen J. Harris, Qian WangDocument6 pagesA Universal Wear Law For Abrasion: Matthew T. Siniawski, Stephen J. Harris, Qian WangTamara Maria Ortiz MendezNo ratings yet

- Dehydol LS 6 TI en 2013Document4 pagesDehydol LS 6 TI en 2013Erhan KüçükNo ratings yet

- Phonon Wave FunctionDocument11 pagesPhonon Wave FunctionSaeed AzarNo ratings yet

- Experiment 1 - Compression MoldingDocument16 pagesExperiment 1 - Compression MoldingJasmine NguNo ratings yet

- Meaning of The Water CycleDocument3 pagesMeaning of The Water CycleCARLOS CIFUENTESNo ratings yet

- Coomassie Blue (R-250, G-250) : Products DescriptionDocument4 pagesCoomassie Blue (R-250, G-250) : Products DescriptionCyberSquare IndiaNo ratings yet

- Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsDocument1 pageSpecification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsAbraham Garcia Maldonado100% (1)

- 1D Kinematics ReviewDocument10 pages1D Kinematics ReviewBeverly RamosNo ratings yet

- Nutrient Cycles: The Water CycleDocument8 pagesNutrient Cycles: The Water CycleWalt MahovlichNo ratings yet

- Kristoffersen 2006Document7 pagesKristoffersen 2006ScheNo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentinNo ratings yet

- VDM® Alloy 625 - Nickel Iron Alloy - MatmatchDocument4 pagesVDM® Alloy 625 - Nickel Iron Alloy - MatmatchRaznovrsni KutakNo ratings yet

- Benzoic Acid in CheeseDocument20 pagesBenzoic Acid in CheeseyarahluNo ratings yet

- Comparison of Microwave-Assisted Hydro Distillation Withthe Traditional Hydro Distillation Method in The Extraction of Essential Oils From Thymus Vulgaris L.Document6 pagesComparison of Microwave-Assisted Hydro Distillation Withthe Traditional Hydro Distillation Method in The Extraction of Essential Oils From Thymus Vulgaris L.myrtarom100% (4)