Professional Documents

Culture Documents

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanCopyright:

Available Formats

Page 1 of 4

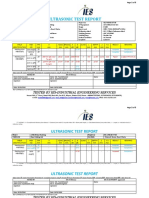

Inspection Date :16 July 2020 Report no : IES-ARBAB-UT-01

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-01 06 - - - - 73.1 - - - - - Accepted Satisfactory

Rafter Joint no -02 06 - - - - 73.1 - - - - - Accepted Satisfactory

Joint no-3 06 - - - - 73.1 - - - - - Accepted Satisfactory

Joint no-4 06 - - - - 73.1 - - - - - Accepted Satisfactory

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

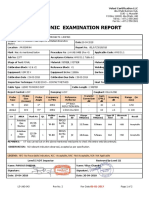

Page 2 of 4

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-05 06 60 mm left ward To left 13.24 33.19 100% 66.1 A 40.00 2.31 13.00 0.24 Repair Find the defect IP,SL

Rafter

Joint no -06 06 80 mm left ward To left 15.43 37.14 100% 66.1 A 90.00 3.41 15.43 0.00 Repair Find the defect IP,SL

Joint no-07 06 75 mm left ward To left 22.05 36.98 100% 66.1 A 40.00 2.45 22.05 0.00 Repair Find the defect IP,SL

Joint no-08 06 210 mm left ward To left 24.09 45.38 100% 66.1 A 120.00 2.67 24.09 0.00 Repair Find the defect IP,SL

Joint No-09 06 - - - - 66.1 - - - - Accepted Satisfactory

-

ULTRASONIC TEST REPORT

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 3 of 4

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-10 06 - - - - 66.1 - - - - - Accepted Satisfactory

Rafter Joint no -11 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-12 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-13 06 70 mm left ward To left 22.14 42.18 100% 66.1 A 50.00 2.30 22.10 0.04 Repair Find the defect IP,SL

Joint No-14 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no -15 06 80 mm left ward To left 12.10 45.18 100% 66.1 A Full 2.80 12.10 0.00 Repair Find the defect IP,SL

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

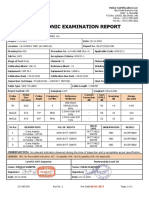

Page 4 of 4

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Rafter Joint No-16 06 60 mm left ward To left 10.14 36.18 100% 66.1 A 80.00 3.10 10.00 0.14 Repair Find the defect IP,SL

Joint no -17 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-18 06 - - - - 66.1 - - - - - Accepted Satisfactory

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

You might also like

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Inspection Release for Jacket Leg CoatingDocument2 pagesInspection Release for Jacket Leg CoatingjeswinNo ratings yet

- Real Numbers and Polynomials QuestionsDocument54 pagesReal Numbers and Polynomials QuestionsAkansha Maurya82% (22)

- AP Physics 1 Past Frqs (2018, 19,21,22.23)Document70 pagesAP Physics 1 Past Frqs (2018, 19,21,22.23)Mahmood ShanaahNo ratings yet

- Singer-201-Service-Adjusters-Manual Ocr PDFDocument72 pagesSinger-201-Service-Adjusters-Manual Ocr PDFenviroswNo ratings yet

- Intuitive Intelligence: Accessing The Wisdom of Head, Heart and HaraDocument5 pagesIntuitive Intelligence: Accessing The Wisdom of Head, Heart and HaradNo ratings yet

- Qualifying Exam Reviewer With Answers New Update 11Document96 pagesQualifying Exam Reviewer With Answers New Update 11Danica CatanduanesNo ratings yet

- Analysis of BeamsDocument14 pagesAnalysis of Beamsمحسن عبدالله البركيNo ratings yet

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNo ratings yet

- Paut 16Document4 pagesPaut 16maroof mNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Arbab Polypack UT Inspection ReportDocument4 pagesArbab Polypack UT Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ultrasonic inspection reportDocument1 pageUltrasonic inspection reportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)sumit singhNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Industrial Ultrasonic ReportDocument2 pagesIndustrial Ultrasonic ReportShifat UllahNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ultrasonic Exam Report Steam Drum JointsDocument3 pagesUltrasonic Exam Report Steam Drum JointsBalkishan DyavanapellyNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Offshore Wind Farm Jacket Inspection ReleaseDocument2 pagesOffshore Wind Farm Jacket Inspection ReleasejeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- HI-TECH NDT REPORTDocument5 pagesHI-TECH NDT REPORTMarcus AntoniusNo ratings yet

- Liquid Penetrant Testing Report for KIZAD Gas Network ConstructionDocument1 pageLiquid Penetrant Testing Report for KIZAD Gas Network ConstructionAvijit DebnathNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- ACS GW 24 001 AR029 Gose Neck ThreadDocument1 pageACS GW 24 001 AR029 Gose Neck Threadarehmanmirza1990No ratings yet

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- Report No - 038 - NFT Specialized - 20.11.2018Document1 pageReport No - 038 - NFT Specialized - 20.11.2018ADOBEENo ratings yet

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Liquid Penetrant and Ultrasonic Test ReportsDocument2 pagesLiquid Penetrant and Ultrasonic Test ReportsNiranjan KumarNo ratings yet

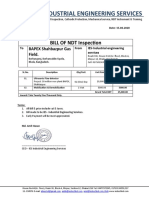

- BILL OF NDT Inspection: To From IES-Industrial Engineering ServicesDocument2 pagesBILL OF NDT Inspection: To From IES-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

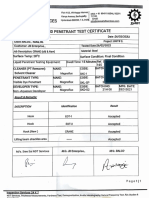

- MD - Akibur Sheikh PT Test ReportDocument2 pagesMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Sujan Das PT Test ReportDocument2 pagesSujan Das PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsDocument3 pagesUltrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsMD Shadikul Huq ShezanNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- IES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesDocument1 pageIES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNo ratings yet

- IES-Hydraulic Test ReportDocument4 pagesIES-Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- IES-Hydraulic Test ReportDocument4 pagesIES-Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportDocument1 pageIes-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Boiler UTG Seperation Wall Burner SideDocument2 pagesBoiler UTG Seperation Wall Burner SideMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Date Description Serial No Quantity Weight/ PecessDocument12 pagesDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanNo ratings yet

- Help For Report ShezanDocument5 pagesHelp For Report ShezanMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- MailDocument1 pageMailMD Shadikul Huq ShezanNo ratings yet

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDocument7 pagesTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: BILL OF NDT InspectionDocument1 pageIes-Industrial Engineering Services: BILL OF NDT InspectionMD Shadikul Huq ShezanNo ratings yet

- Lecture Notes in Mechanical Engineering: For Further VolumesDocument765 pagesLecture Notes in Mechanical Engineering: For Further VolumesKarim SalesNo ratings yet

- Astm F1446Document11 pagesAstm F1446AlbertoNo ratings yet

- Soal B InggrisDocument6 pagesSoal B Inggrishari fajarNo ratings yet

- UHPFRC-Gaps in Design & Construction Guidelines by Shri Aditya SharmaDocument15 pagesUHPFRC-Gaps in Design & Construction Guidelines by Shri Aditya SharmaSreekanth SattirajuNo ratings yet

- Thermal Properties of Matter - 3Document16 pagesThermal Properties of Matter - 3Nik AshrafNo ratings yet

- Discussion: Ferrous Alloys Specimen 1 (X17)Document6 pagesDiscussion: Ferrous Alloys Specimen 1 (X17)Starscream Aisyah100% (1)

- 19 SolutionsDocument8 pages19 SolutionsRainierGo0% (1)

- What Is Mathematics GoedelDocument238 pagesWhat Is Mathematics Goedeledgartepe4324No ratings yet

- How Tall A Column in Block Caving 2014-May-2Document11 pagesHow Tall A Column in Block Caving 2014-May-2carlo cerruttiNo ratings yet

- Color Theory SpanishDocument2 pagesColor Theory Spanishapi-311422349No ratings yet

- Gabriel Eugenio CHAO, Dispersive Surface Acoustic Waves in Poroelastic MediaDocument143 pagesGabriel Eugenio CHAO, Dispersive Surface Acoustic Waves in Poroelastic MediaOlegNo ratings yet

- MTH108 Courseoutline F2023Document7 pagesMTH108 Courseoutline F2023ahmeddhillon1No ratings yet

- Zhang 2017Document12 pagesZhang 2017Maki SrbijaNo ratings yet

- June 2019 QP - Unit 4 WJEC Further Maths A-LevelDocument7 pagesJune 2019 QP - Unit 4 WJEC Further Maths A-LevelDarren DowlingNo ratings yet

- Specific Heat of An Unknown MetalDocument17 pagesSpecific Heat of An Unknown MetalUtku AğcaNo ratings yet

- Development of A High-Performance Magnetic GearDocument7 pagesDevelopment of A High-Performance Magnetic GearAigounNo ratings yet

- Raouf Khosravi: M.Sc. in Mechanical Engineering, Energy ConversionDocument3 pagesRaouf Khosravi: M.Sc. in Mechanical Engineering, Energy ConversionParisa AziziNo ratings yet

- EEE 213 Electronics Devices & Circuits 3 EEE 214 Electronics Devices & Circuits Laboratory 1.5Document4 pagesEEE 213 Electronics Devices & Circuits 3 EEE 214 Electronics Devices & Circuits Laboratory 1.5Khaled faisalNo ratings yet

- A Modified Hodgkin-Huxley Model To Show The Effect PDFDocument23 pagesA Modified Hodgkin-Huxley Model To Show The Effect PDFjeforand123No ratings yet

- Tech Rep 4-2011 Copper Zirkonium AlloysDocument14 pagesTech Rep 4-2011 Copper Zirkonium AlloysBahadır UysalNo ratings yet

- Identification of Principal Factors Causing UnbalancedDocument6 pagesIdentification of Principal Factors Causing UnbalancedEng Bagaragaza RomualdNo ratings yet

- BASIC 2 EF QR NuevoDocument60 pagesBASIC 2 EF QR NuevoKarolina Uc santanaNo ratings yet

- IADC Vol-1 09 Downhole ToolsDocument36 pagesIADC Vol-1 09 Downhole Toolsballa bammouneNo ratings yet

- Mathematics Question Paper Set CDocument3 pagesMathematics Question Paper Set CADITHYA SUJINo ratings yet